Automatic variable-displacement walking motor assembly, hydraulic driving walking control system and application thereof

A travel motor, automatic variable technology, applied in transmission control, fluid pressure actuation system components, servo motors, etc., can solve problems such as poor operating comfort, sudden braking, and non-compliance with driving operation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, this case is described in further detail.

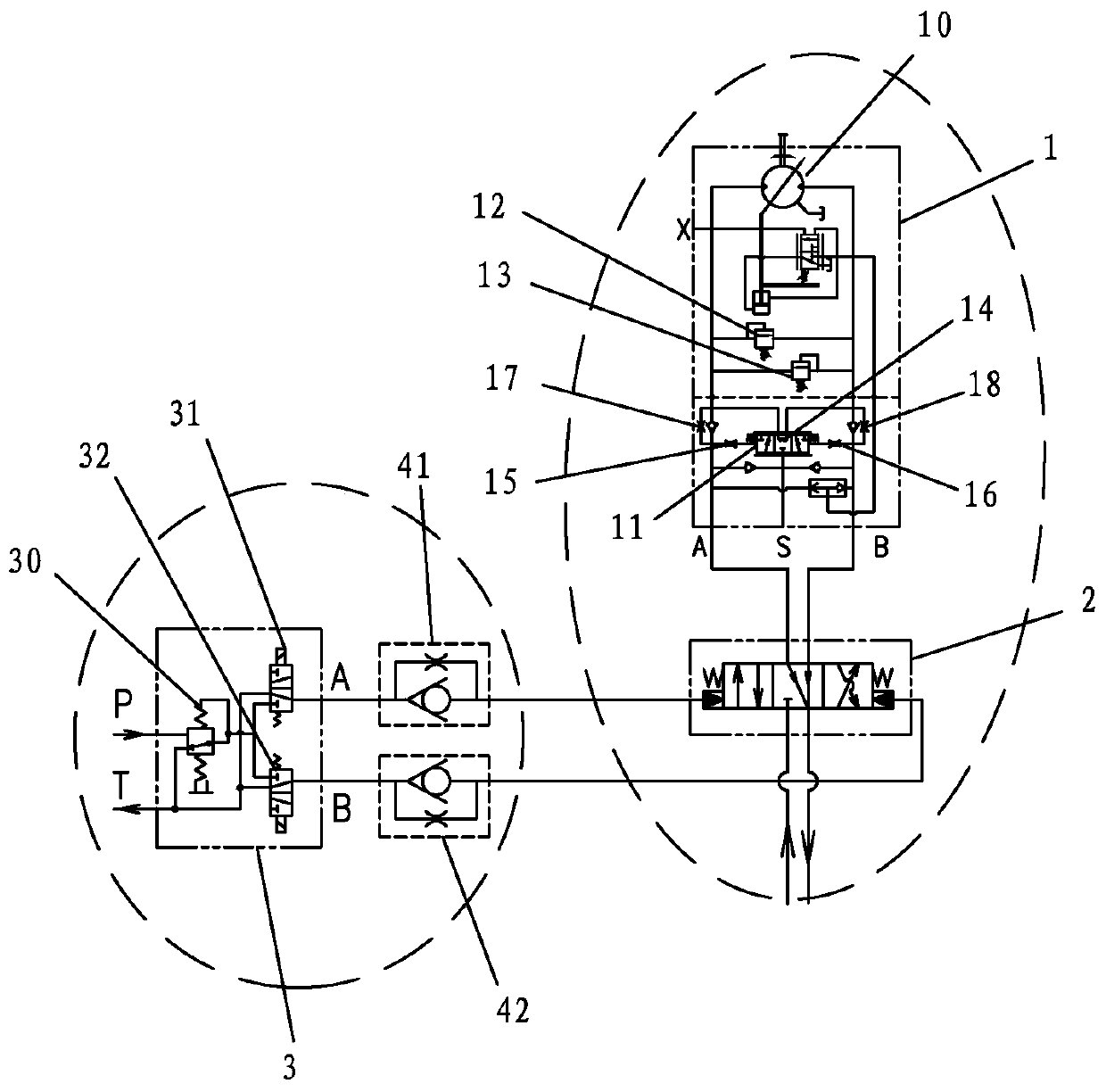

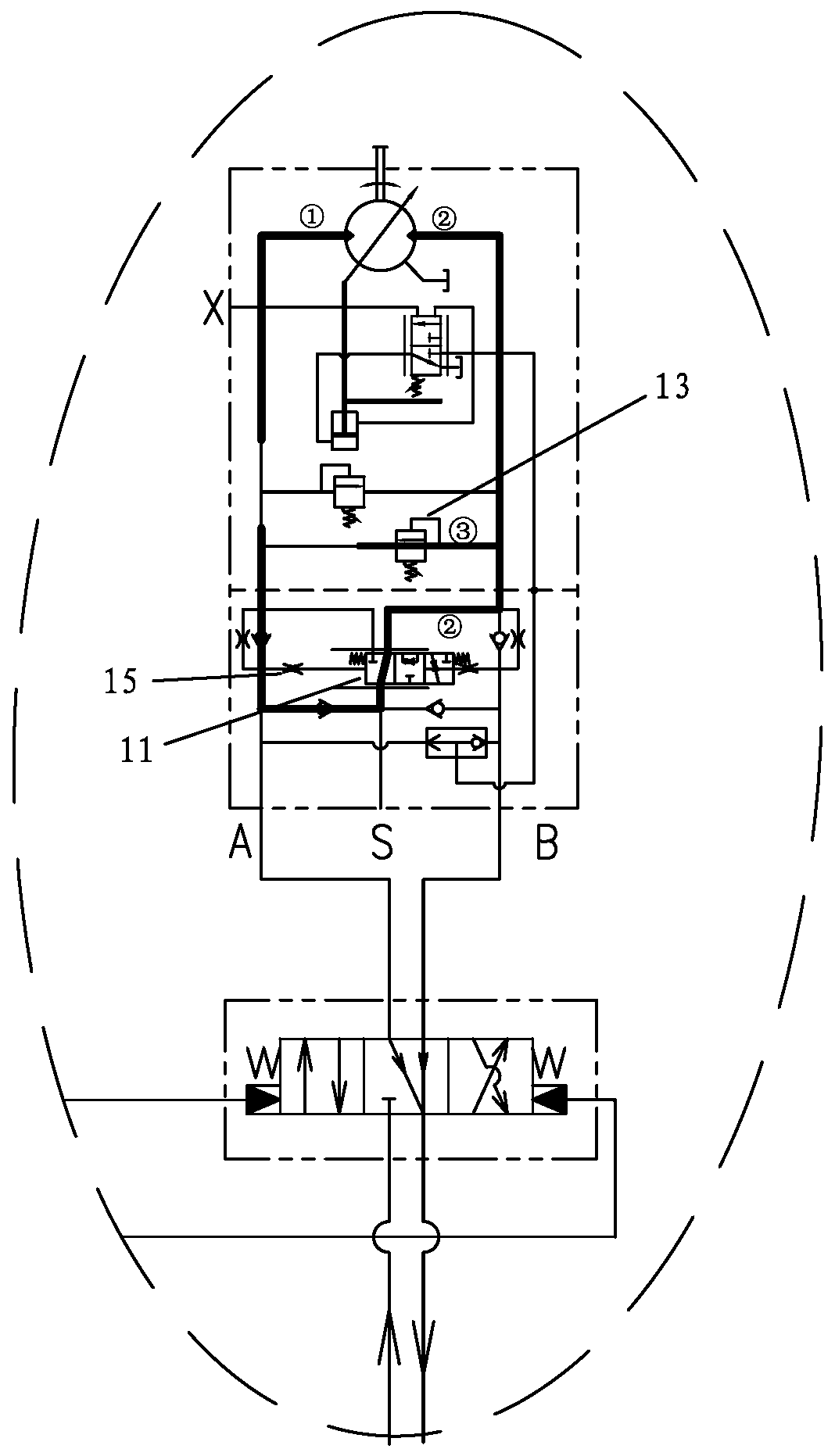

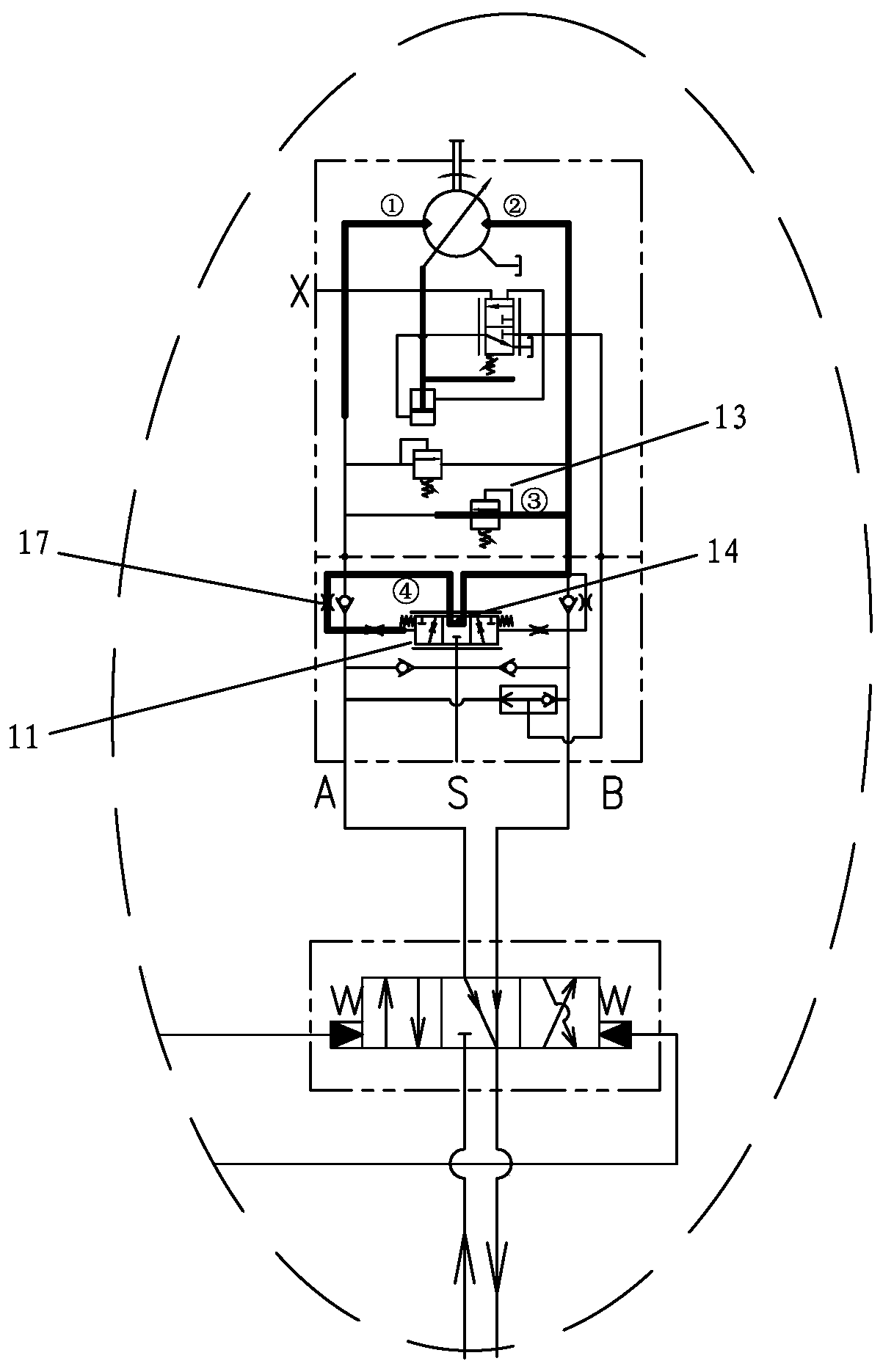

[0024] This case involves a hydraulic drive travel control system, such as Figure 1-3 As shown, the high-voltage automatic variable travel motor assembly 1 is adopted. The walking control system preferably also has a hydraulically controlled reversing valve 2 and a walking foot pilot valve 3, which are sequentially adapted and connected with the high-pressure automatic variable-variable walking motor assembly 1 to realize effective walking control. figure 1 , the left dotted circle corresponds to the pilot oil circuit, and the right dotted circle corresponds to the working oil circuit. The walking foot pilot valve 3 is provided with a pilot valve pedal 30, a forward switch 31 and a rear leg switch 32, and the working ports include an oil source port P and a fuel tank port T. The forward switch 31 and the rear leg switch 32 correspond to port A and port B respectively, and are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com