Clash pulse-jet filter cartridge ash removal system with automatic synergistic change of jet pressure

A technology of injection pressure and filter cartridge, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc. degree reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

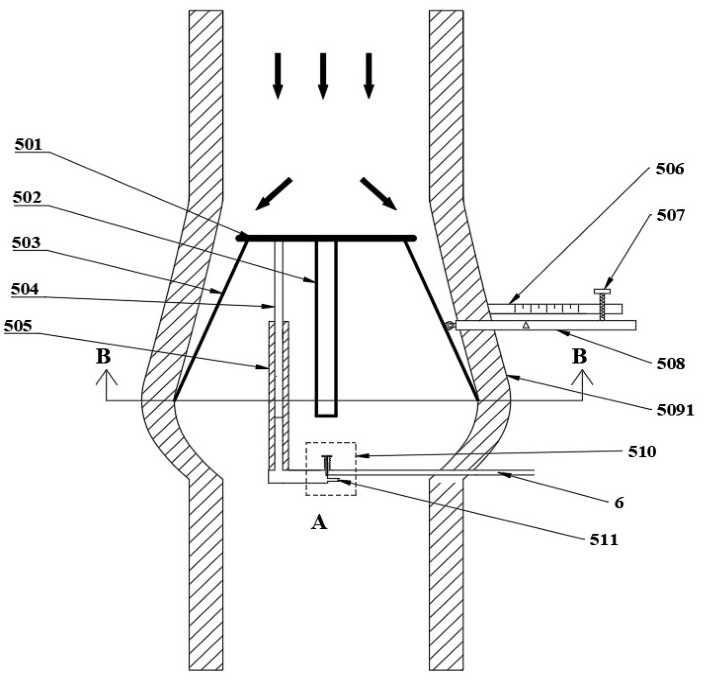

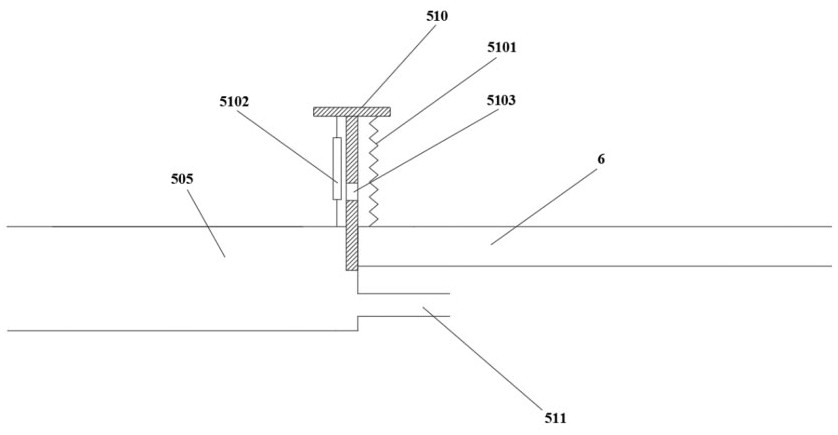

[0041] Taking the slide rails 5011 of the gradually opening circulation valve 5 and the gradually closing circulation valve 12 as an example, there are five pairs of locking protrusions 50111, and the corresponding baffle 501 has five stop positions so that the baffle 501 and the first valve housing Between 5091 and the second valve housing 5092, there are five gears of air flow passage area, that is, there are five gears of opening degree between the gradually opening circulation valve 5 and the gradually closing circulation valve 12 . The gear positions are defined by the opening degrees of the gradually opening circulation valve 5 and the gradually closing circulation valve 12, and the opening degrees are defined as first to fifth gears from small to large.

[0042] In this embodiment, it is set that the gradually opening circulation valve 5 is in the first gear, and the gradually closing circulation valve 12 is in the fifth gear.

[0043] When cleaning the filter cartridge...

Embodiment 2

[0058] When the part of the filter cartridge 14 needs continuous energy-concentrated colliding airflow to clean the dust, the position of the positioning rod 508 can be manually adjusted and the positioning screw 507 can be tightened so that the position of the positioning rod 508 is fixed. At this time, the sliding rod 503 is fixed by the positioning rod 508 , so that the baffle plate 501 cannot move, even if it is impacted by the pulse air flow, the gears of the gradually opening circulation valve 5 and the gradually closing circulation valve 12 will not change, and then keep the opening constant to maintain a stable outlet pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com