Air purge spray nozzle for rolling production

An air purging and nozzle technology, which is applied in metal rolling, metal rolling, spraying devices, etc., can solve the problems of large air consumption, inconvenient adjustment and high noise of nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

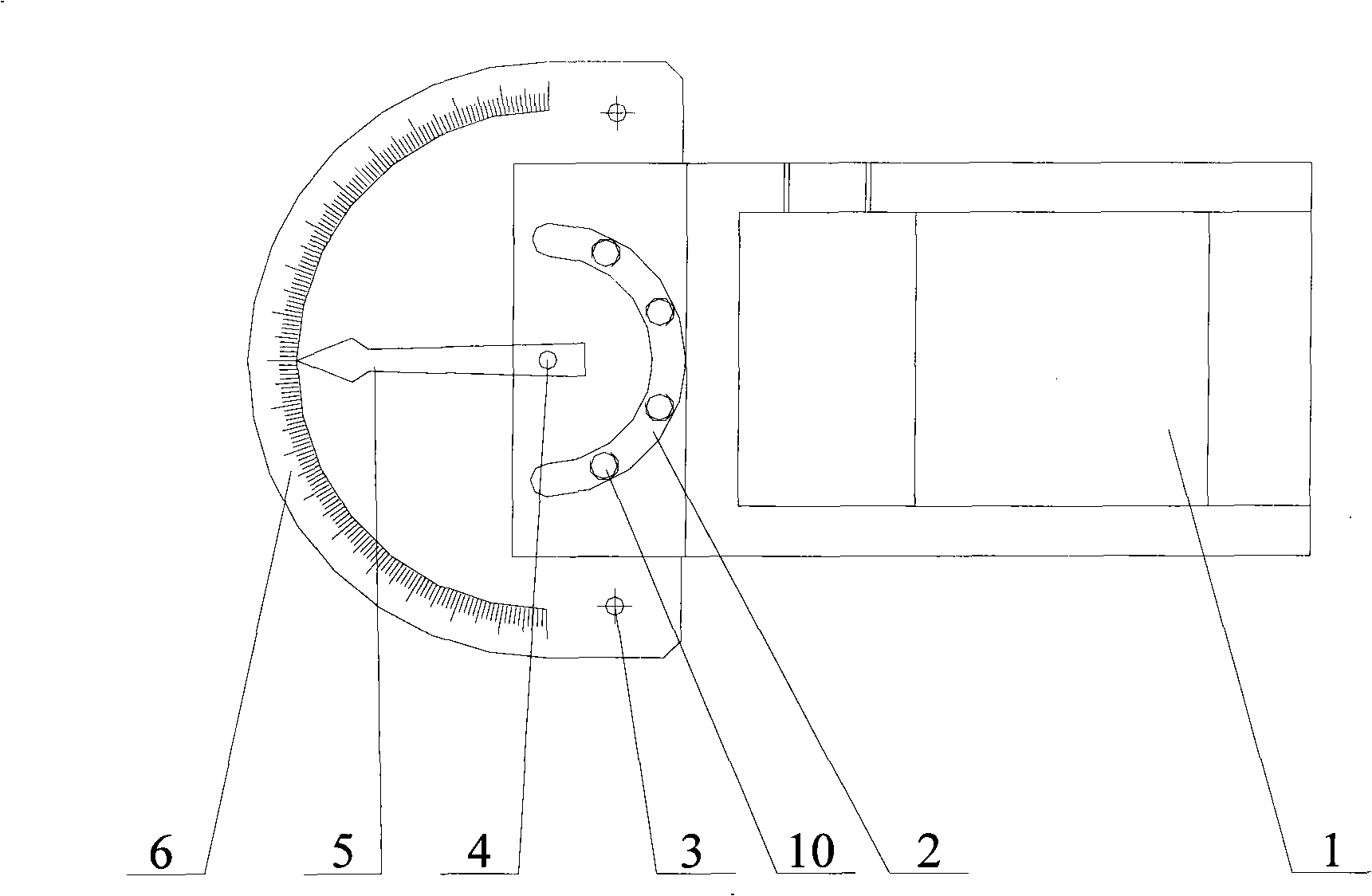

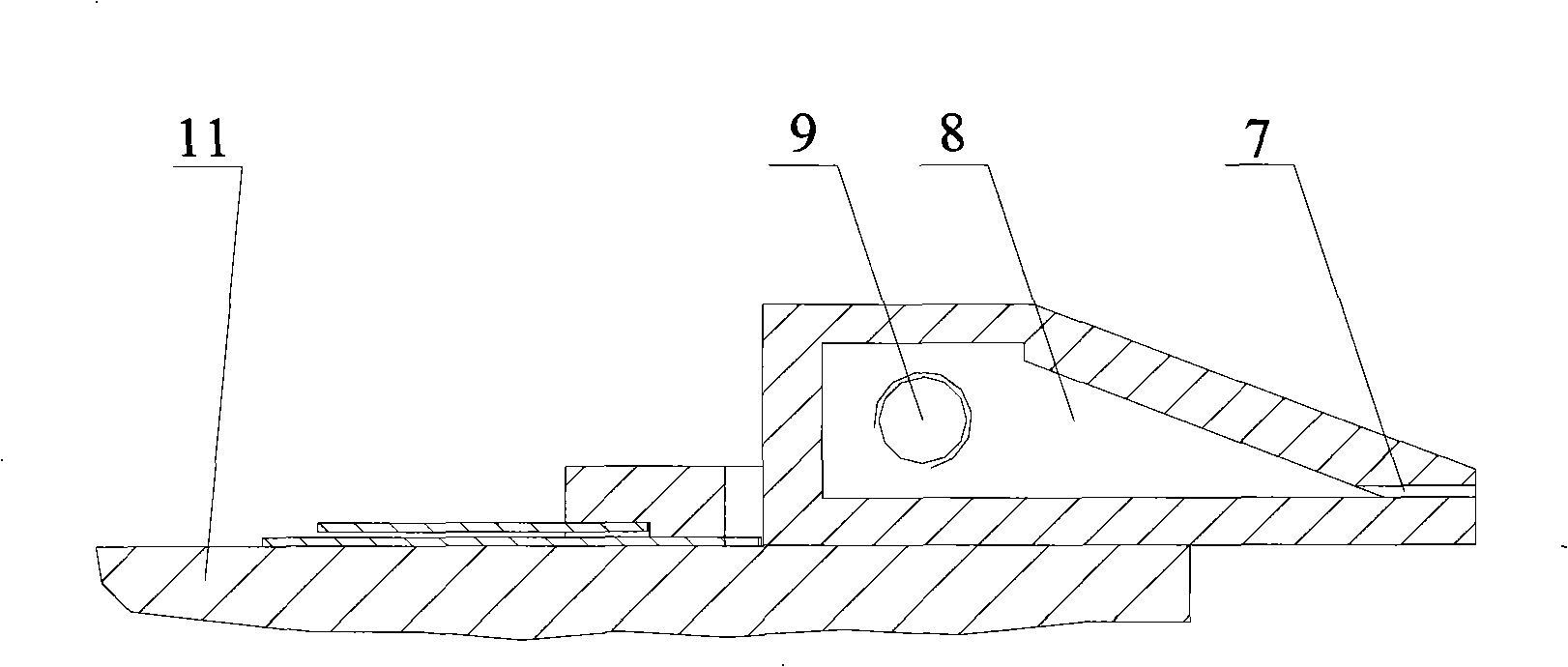

[0019] Such as figure 1 , figure 2 The air blowing nozzle shown in the rolling production includes a flat nozzle 1, a position pointer 5, and an indicator plate 6. The fixing bolt passes through the hole 3 to fix the indicator plate 6 on the installation base 11, and the position pointer 5 is fixed on the flat nozzle 1. On the top, the position pointer 5 and the flat nozzle 1 are hinged with the indicator plate 6 through the hinge point 4; the flat nozzle 1 includes the air inlet 9, the air outlet 7 and the nozzle body, and the side of the nozzle body has an annular groove 2, and the adjustment screw 10 Pass through the annular groove 2 and connect with the indicating plate 6, lock or loosen the adjusting screw 10 to realize the locking or separation of the flat nozzle 1 and the indicating plate 6, that is, screw in the adjusting screw 10 to fix the flat nozzle 1 and the indicating plate 6, Loosen the adjusting screw 10 to separate the flat nozzle 1 from the indicator plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com