Industrial heat energy recycling system

A thermal energy and industrial technology, applied in the field of thermal energy reuse system, can solve the problems of inability to maintain stable indoor temperature, stable hot spot temperature, unstable outlet pressure fluctuation, large power consumption, etc., to achieve reduced flow, stable outlet pressure, The effect of saving heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

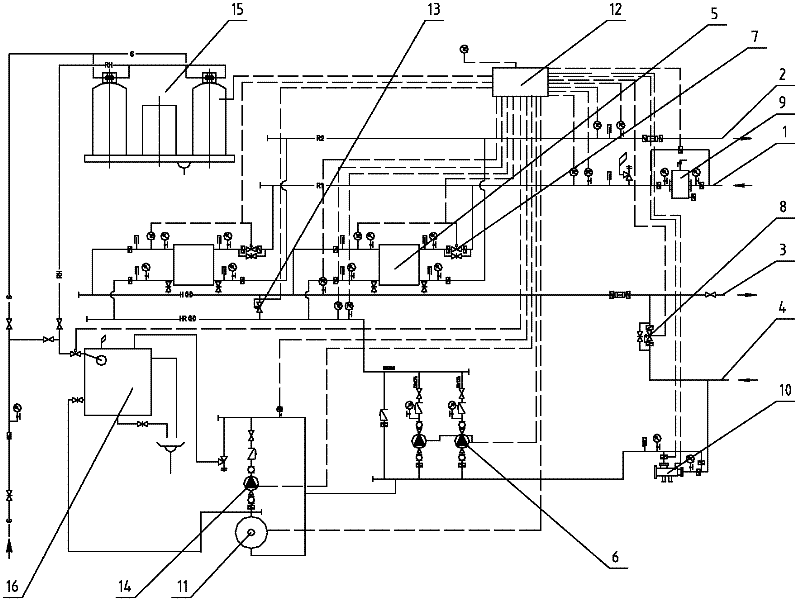

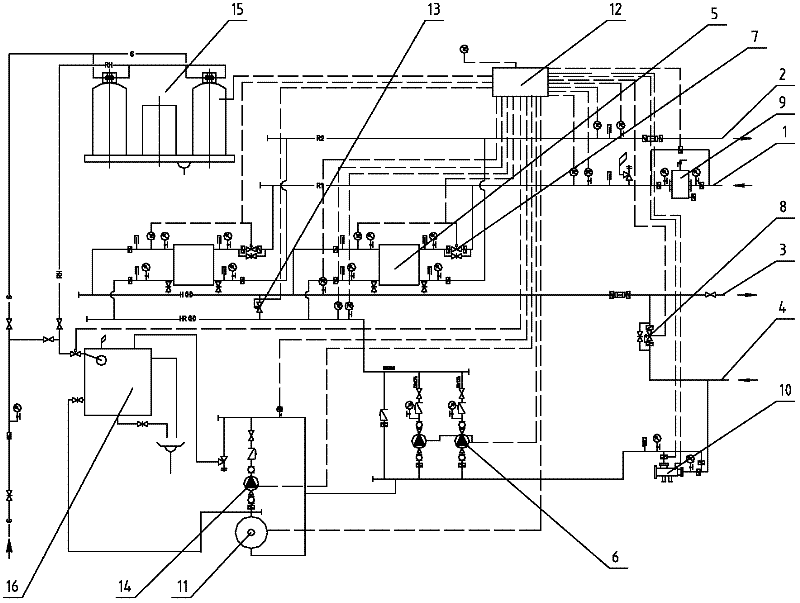

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] As shown in the figure, an industrial heat energy reuse system, the heat energy generated in the industrial production process uses water as a carrier to enter the hot side water inlet pipeline 1, and then the circulating water enters the hot side return water pipeline through the filter 9 with automatic backwash function 2 to form an inner loop. Before entering the return water pipeline 2 on the hot side, the hot water will undergo heat exchange through the heat exchanger 5 and transfer the heat energy to another water circulation system that provides heat energy for customers. A temperature regulating valve 7 is installed in front of the heat exchanger 5 to adjust the heat energy of the customer. The flow of hot water in the hot side water inlet pipeline 1 is adjusted according to the demand condition, and the temperature regulating valve 7 is controlled by the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com