Plate type evaporating apparatus with steam heat pump

A plate type evaporation, heat pump technology, applied in evaporation, multi-effect evaporation, chemical instruments and methods, etc., can solve problems such as heat waste, and achieve the effect of reducing noise, compact structure and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

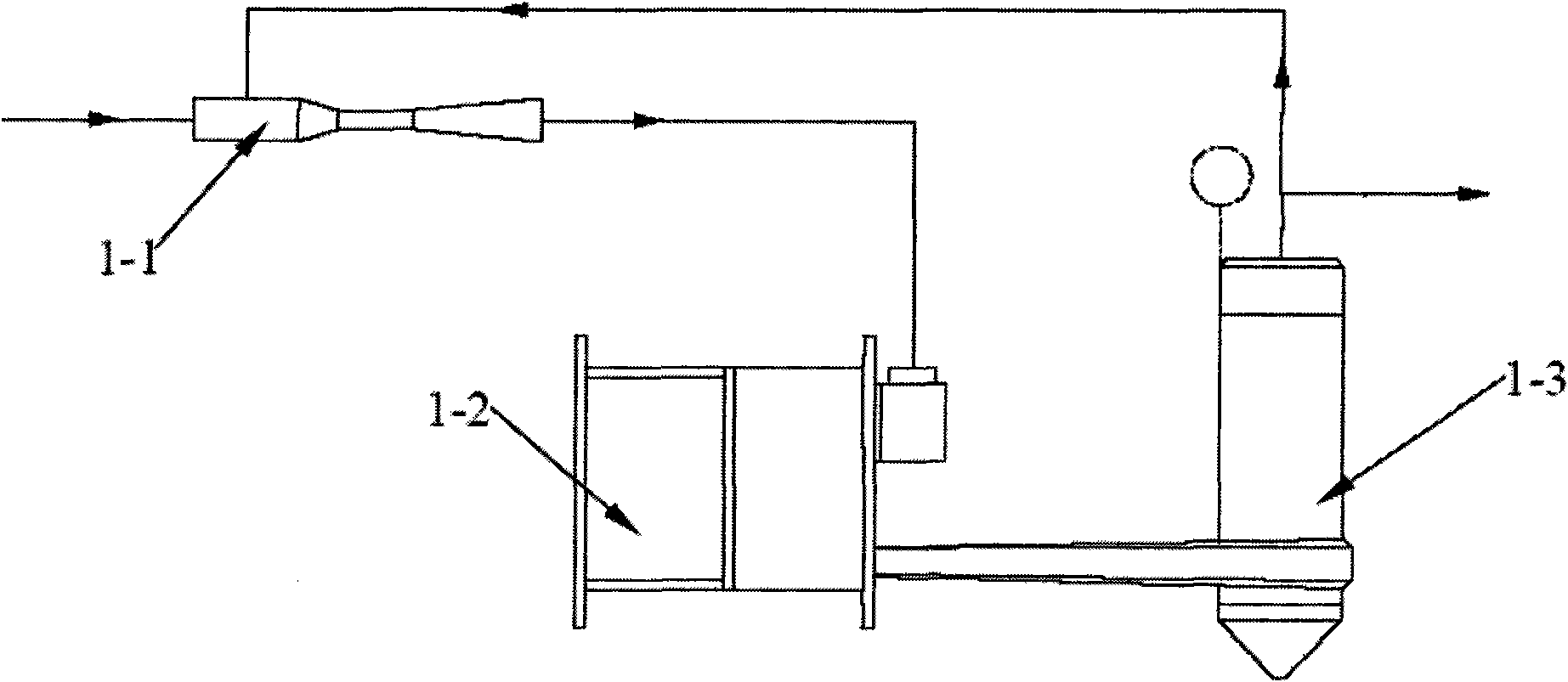

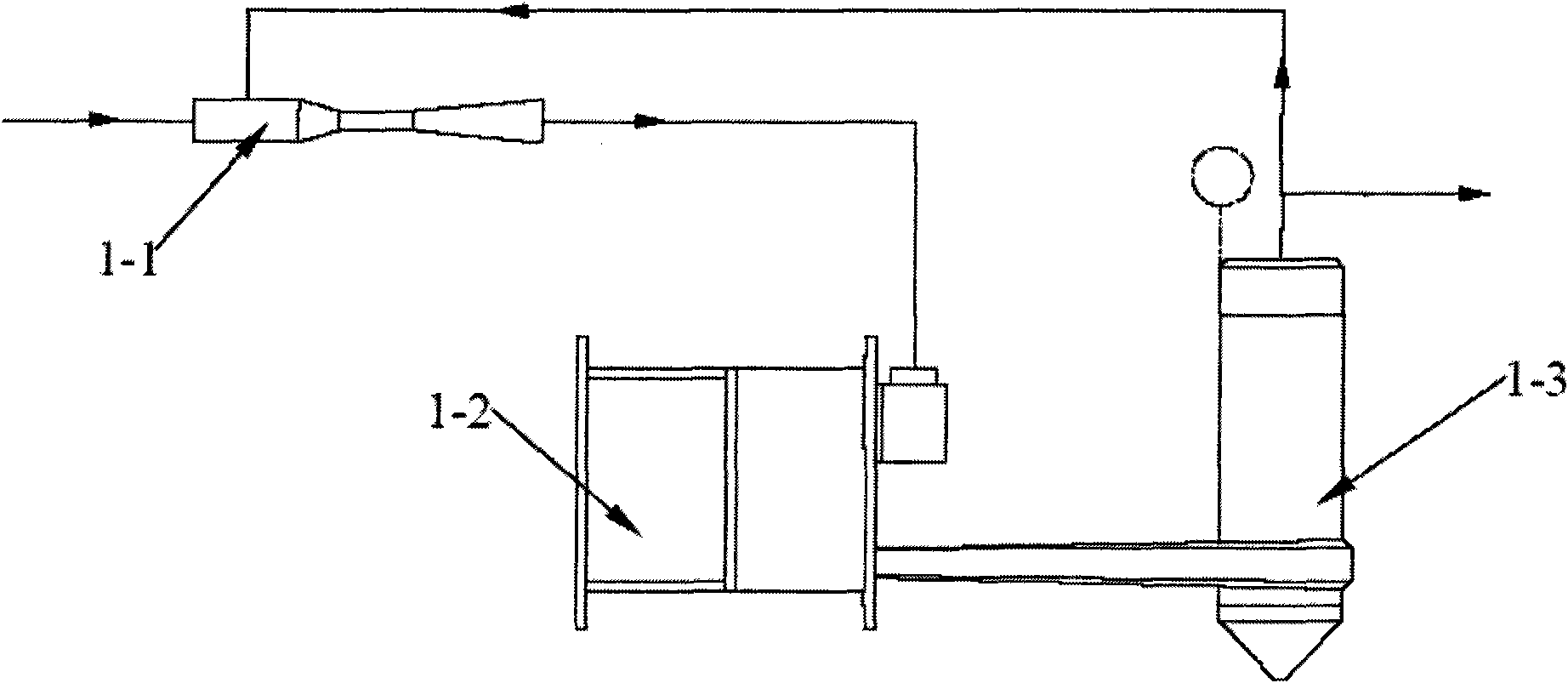

[0015] The specific description of the present invention is given below in conjunction with the accompanying drawings, such as figure 1 It is a structural diagram of the plate evaporator with steam heat pump according to the present invention when used as a one-effect evaporation system. As shown in the figure, the two input ports of the steam heat pump 1-1 are respectively connected to the high-pressure driving steam inlet and the one-effect separator The output of 1-3, the output of the steam heat pump is connected to the first-effect evaporator 1-2, and the output of the first-effect separator passes through the 3-pass and outputs the low-pressure steam as the next-effect evaporated steam.

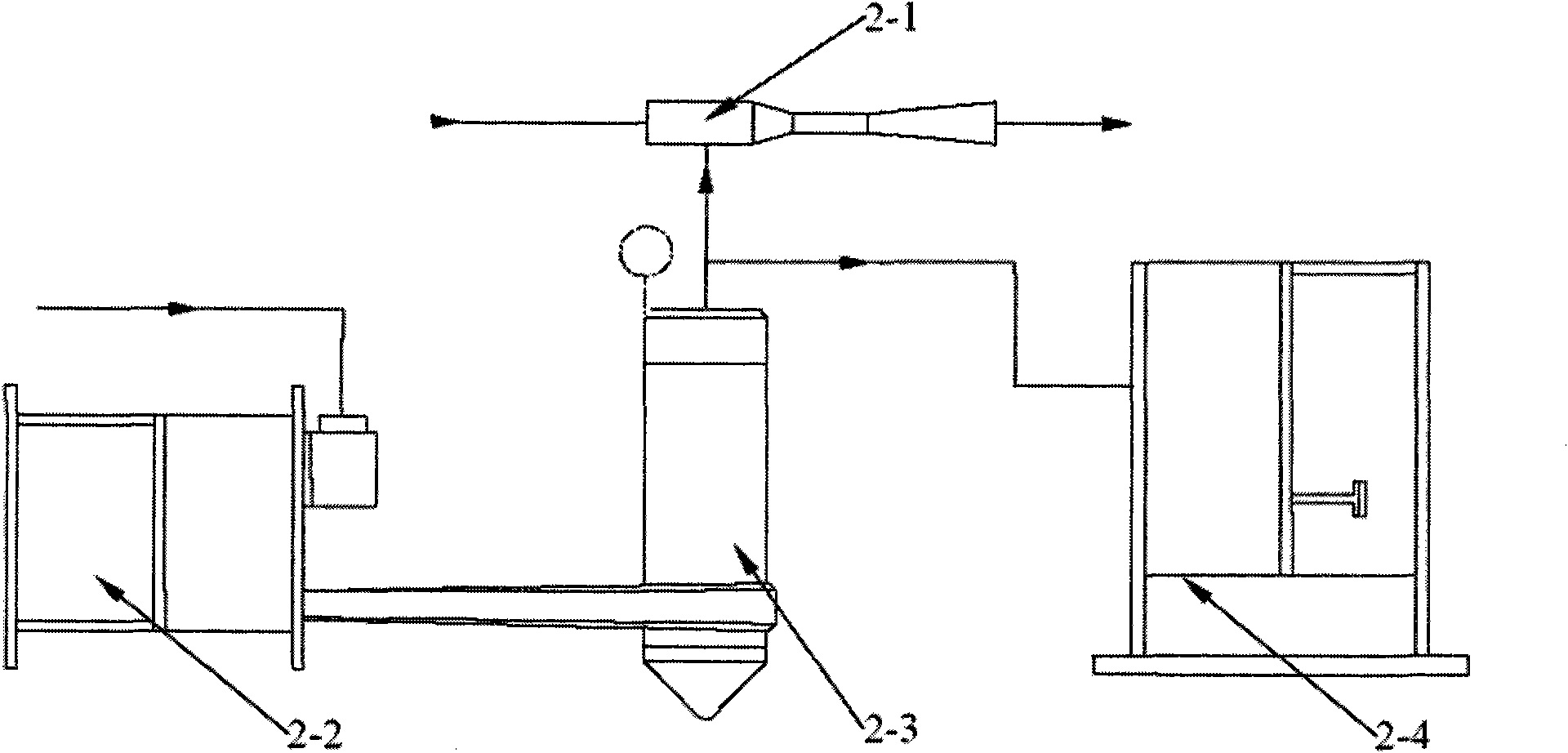

[0016] figure 2 It is a structural diagram of the plate evaporator with steam heat pump according to the present invention when used as a final effect evaporation system. In the figure, the input of the steam heat pump 2-1 is the high pressure steam and the output of the final effect separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com