Impact-resistant reverse unloading distribution type high-precision gas pressure reduction device

A decompression device and shock-resistant technology, which is applied to the valve's device for absorbing fluid energy, valve device, functional valve type, etc., to achieve the effects of improving sensitivity and stability, improving adjustment response speed, and reducing outlet pressure deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

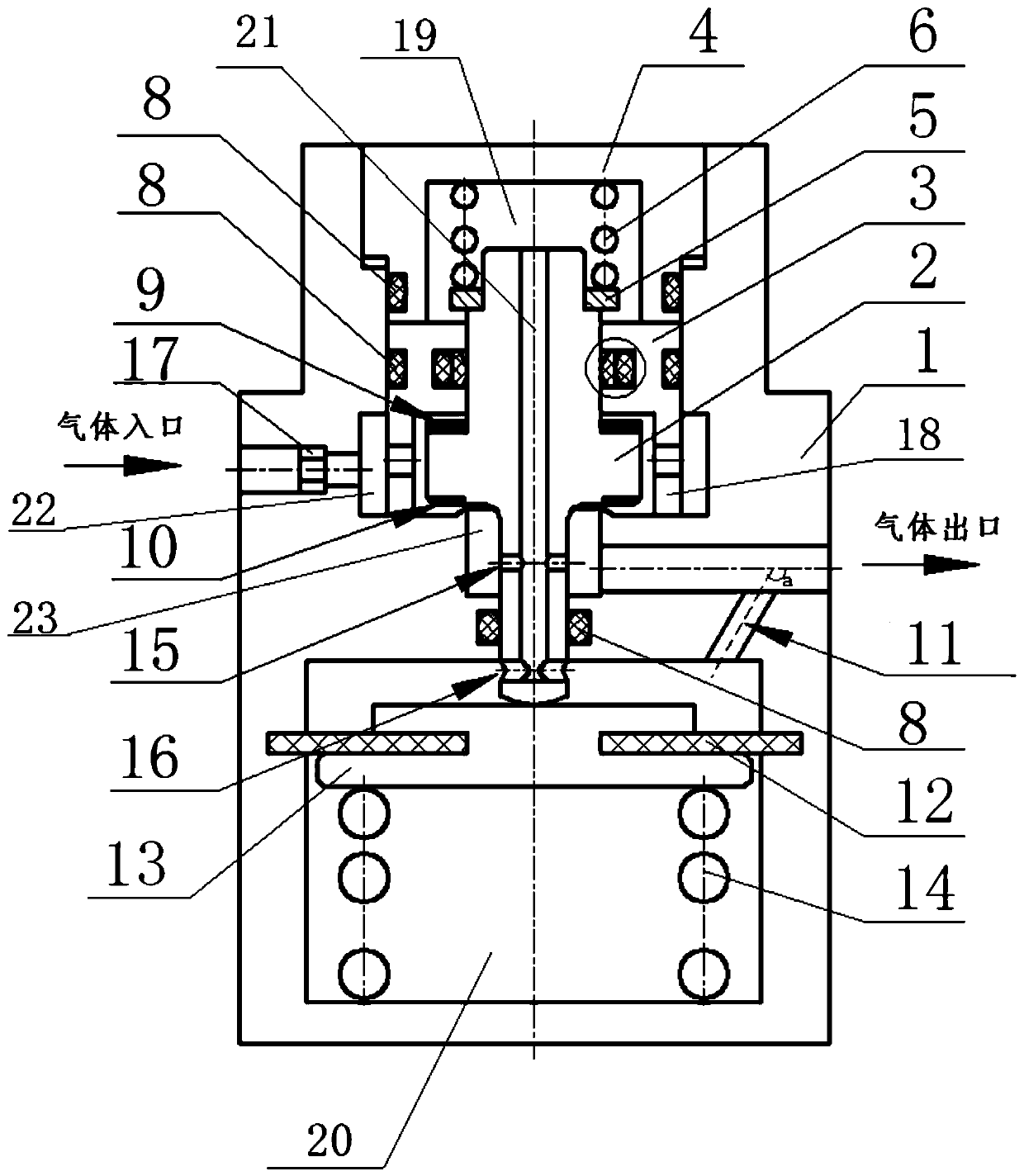

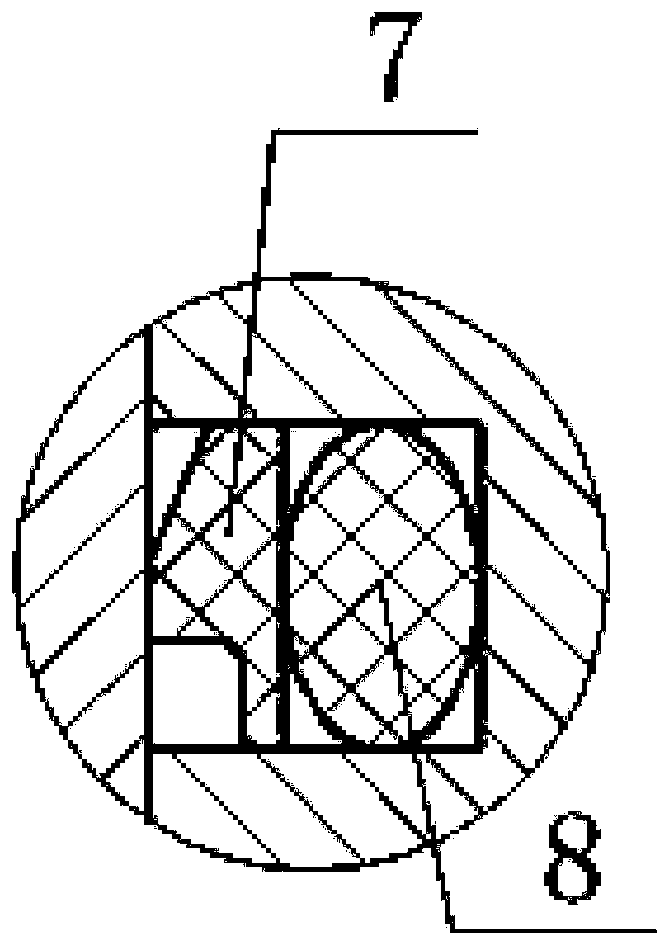

[0039] Such as figure 1 and figure 2 As shown, the impact-resistant reverse unloading distributed pressure-induced high-precision gas decompression device includes a valve body 1 , a valve core 2 and an unloading ring 3 .

[0040]The valve body 1 is integrated with a valve seat function, its lower end is sealed, and the upper end is provided with a blocking cover 4; The lower end of the chamber is a pressure sensitive chamber 20 ; a reset component is arranged in the pressure introduction chamber 19 , and a pressure sensitive component is arranged in the pressure sensitive chamber 20 . The upper end is designed with a blocking cover to facilitate the disassembly and assembly of the valve core and unloading ring in the inner cavity of the valve.

[0041] The spool 2 integrates the functions of the unloading rod and the ejector rod,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com