Air compressor system control method based on data driving

A control method and data-driven technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of numerous input and output parameters and complex control, and achieve the effects of reducing human intervention, improving overall energy efficiency, and stabilizing the outlet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

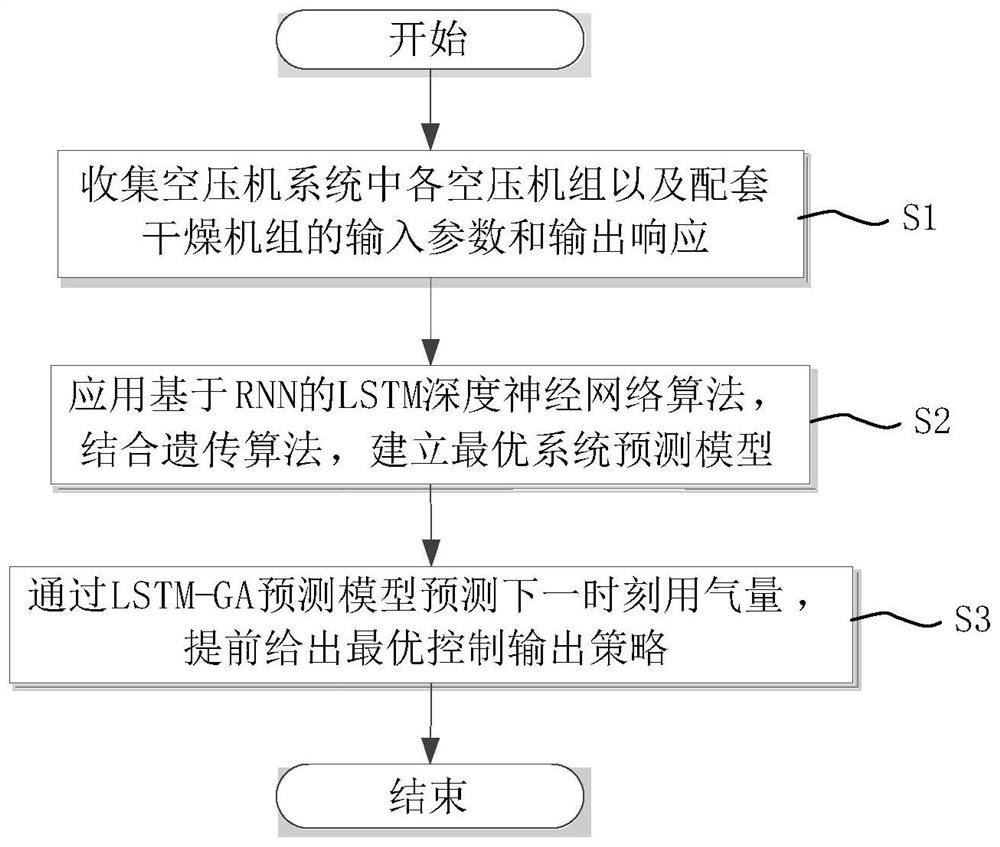

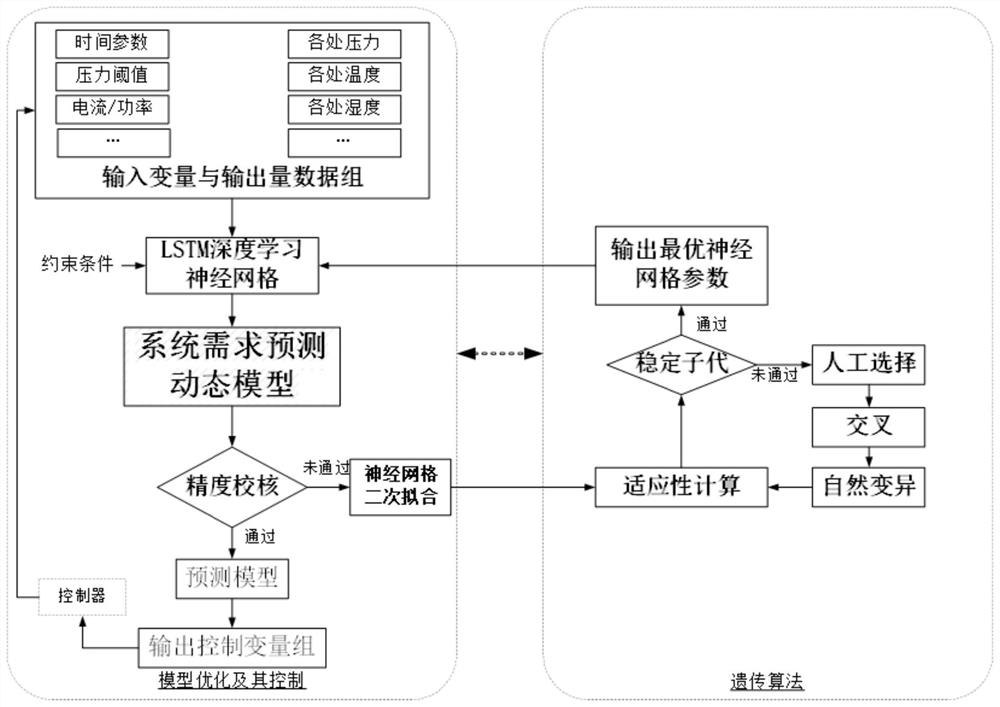

[0018] figure 1 It is a schematic diagram of the control flow of the data-driven air compressor system of the present invention; figure 2 It is a schematic diagram of data-driven air compressor system control parameters and interaction in the present invention.

[0019] See figure 1 and figure 2 , the data-driven air compressor system control method provided by the present invention includes the following steps:

[0020] Step S1: Through input parameters such as each equipment of the existing air compressor unit and the entire system running time, loading time, and drying unit running time, as well as the output response of the air compressor system, output pressure and flow of the main pipe, etc. Data, remove the unreasonable data caused by the replacement of equipment.

[0021] Step S2: Apply the LSTM (Long Short-Term Memory, long-short-term me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com