Centralized pressure supplying method of hydraulic stations

A technology of hydraulic station and pressure oil pipe, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motor components, etc., which can solve the problems of low effective utilization rate of hydraulic station and waste of electric energy, etc., and improve the effective utilization rate , reduce the waste of electric energy, and meet the needs of machine tool work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

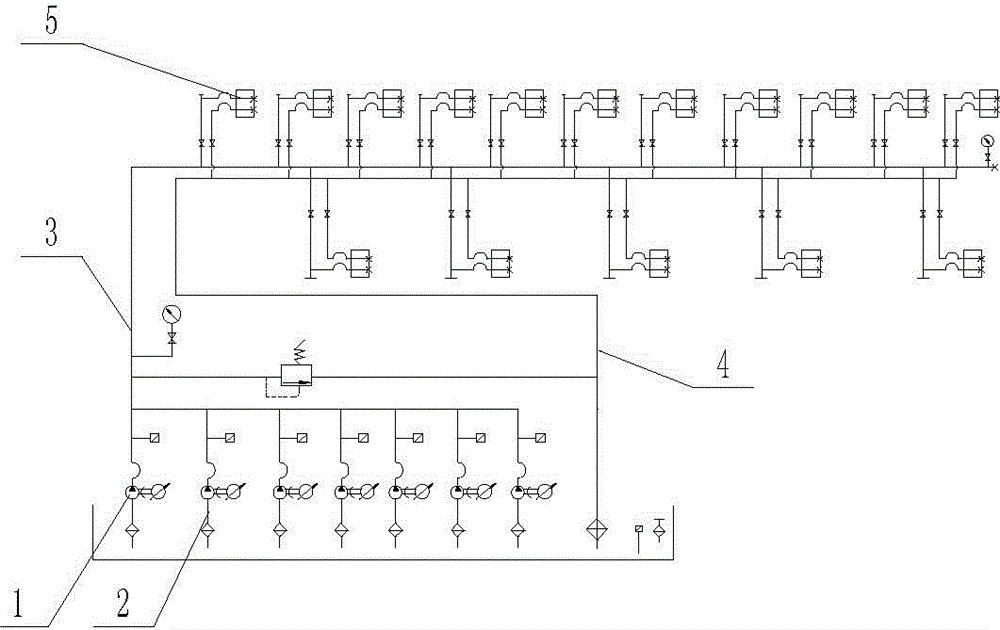

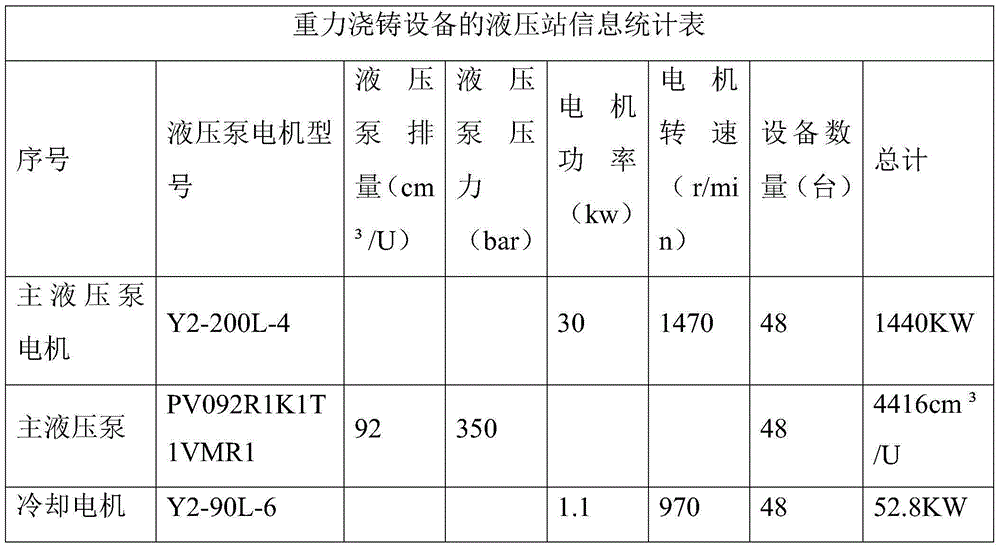

[0027] A machinery processing factory has 3 gravity casting equipment lines arranged side by side, each production line has 16 gravity casting equipment, and each gravity casting equipment has an independent hydraulic station. The hydraulic station parameters of the gravity casting equipment in this factory are as follows :

[0028]

[0029] Among the 3 gravity casting equipment lines arranged side by side in this factory, the power consumption of No. 1 casting line is as shown in Table 1:

[0030]

[0031] Table 1

[0032] According to the data analysis in Table 1, the current power consumption of the hydraulic system of this equipment is about 11.66 degrees per hour.

[0033] The annual power consumption of the hydraulic systems of the 48 equipment of the 3 gravity casting equipment lines arranged side by side in this factory is shown in Table 2:

[0034]

[0035] Table 2

[0036] The solution of the present invention: the centralized pressure supply method of th...

Embodiment 2

[0070] The difference between embodiment two and embodiment one is: take 30% of the maximum flow accumulation value, that is, 1325cm 3 / U and 30% of the accumulated maximum pressure, namely 5040bar, are the rated flow and rated pressure of the new hydraulic station respectively.

Embodiment 3

[0072] The difference between embodiment three and embodiment two is: take 25% of the maximum flow accumulation value, that is, 1104cm 3 / U and 25% of the accumulated value of the maximum pressure, namely 4200bar, are the rated flow and rated pressure of the new hydraulic station respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com