Patents

Literature

40results about How to "Thorough atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

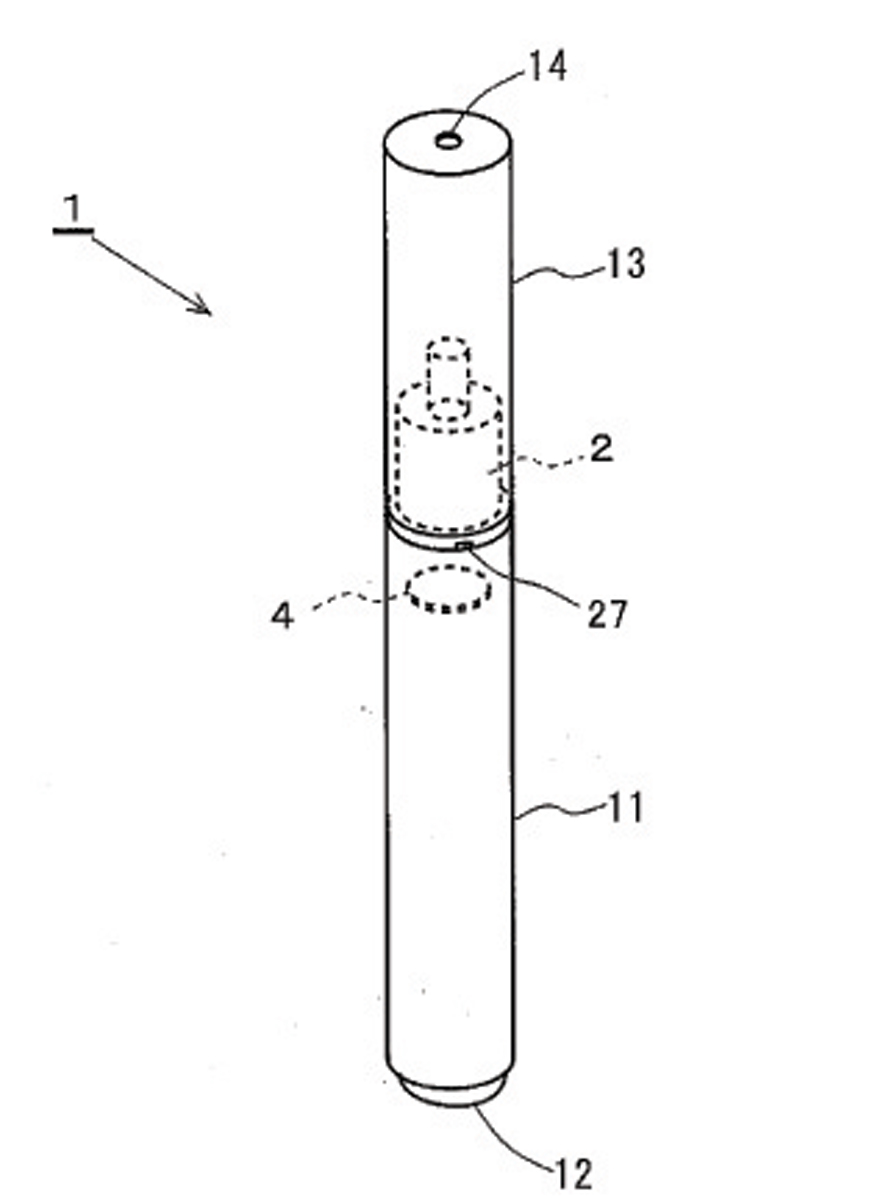

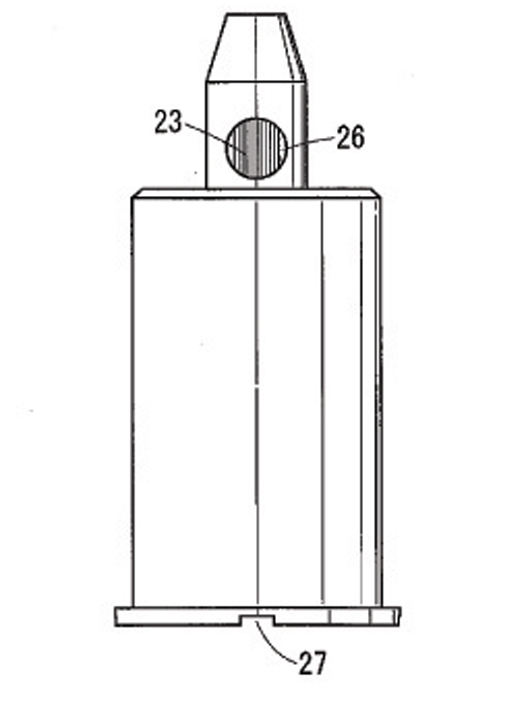

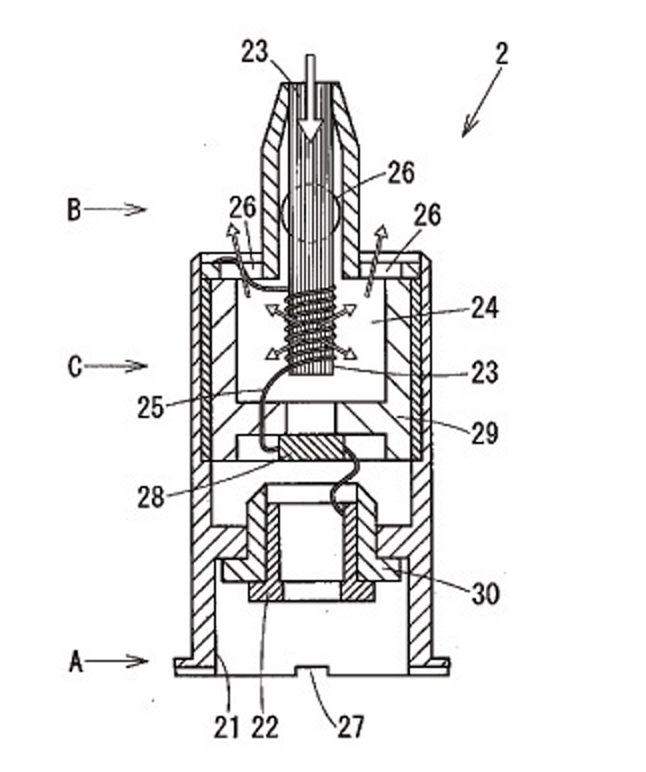

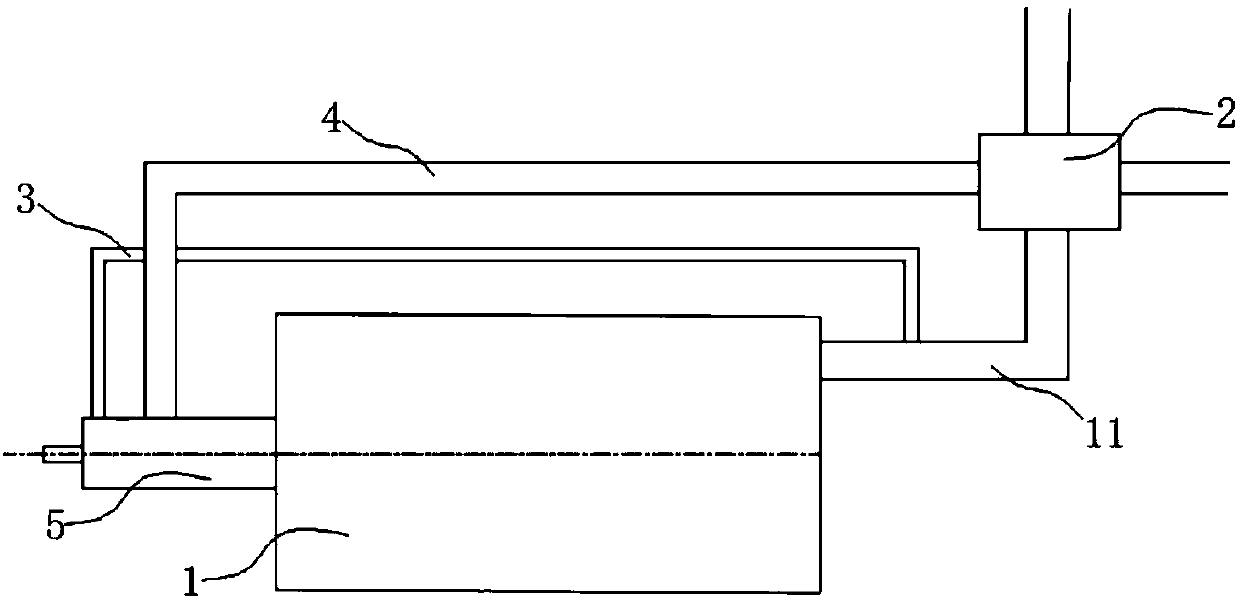

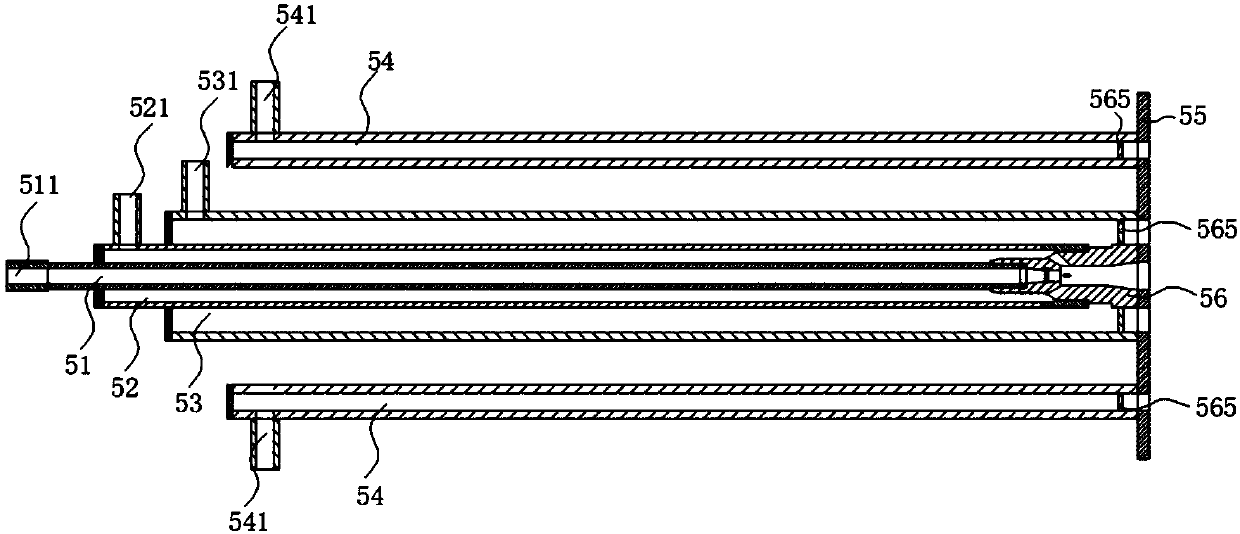

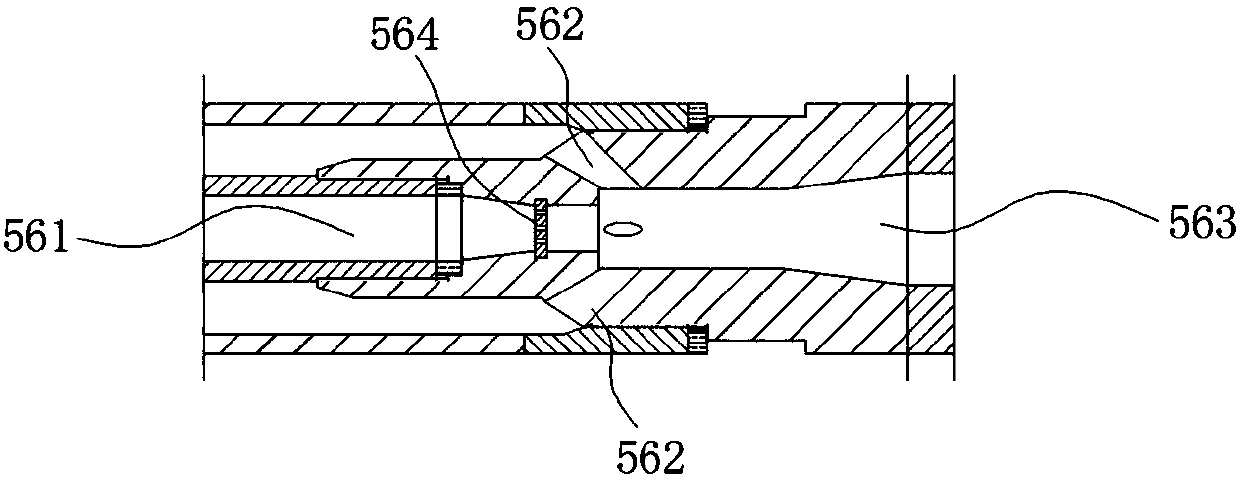

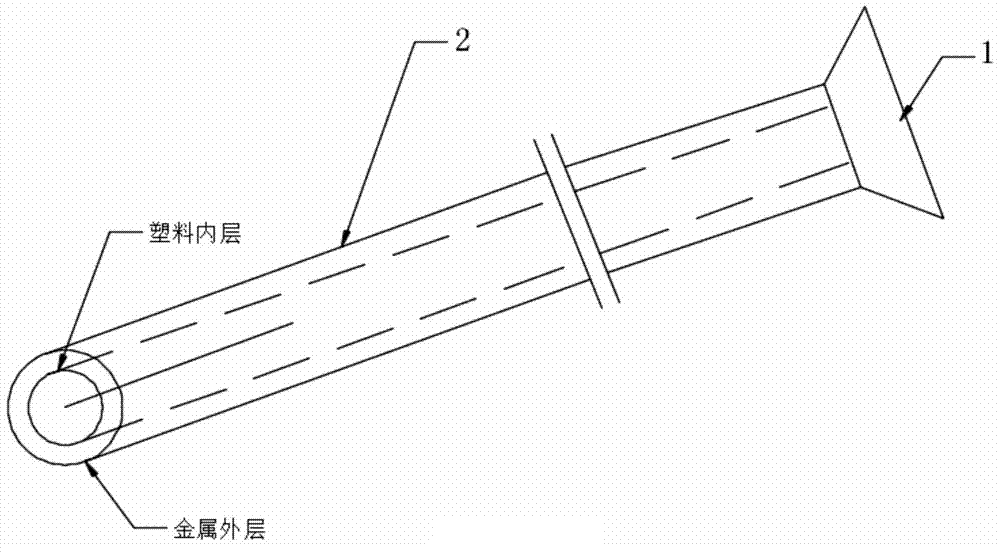

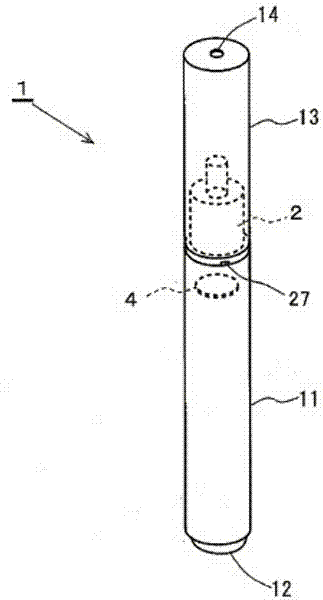

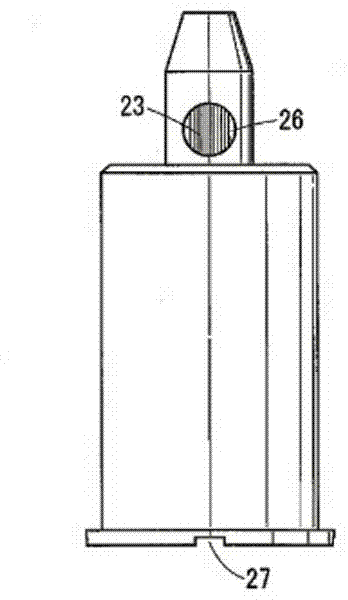

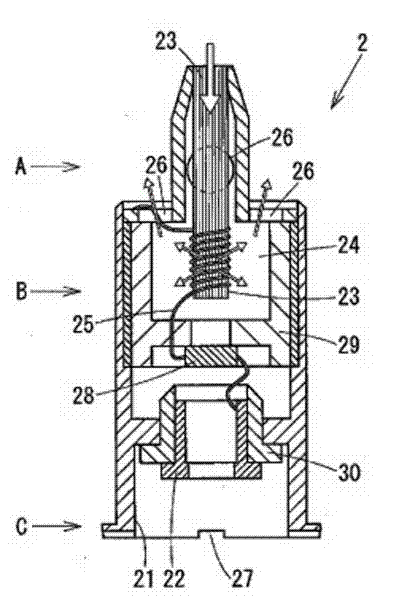

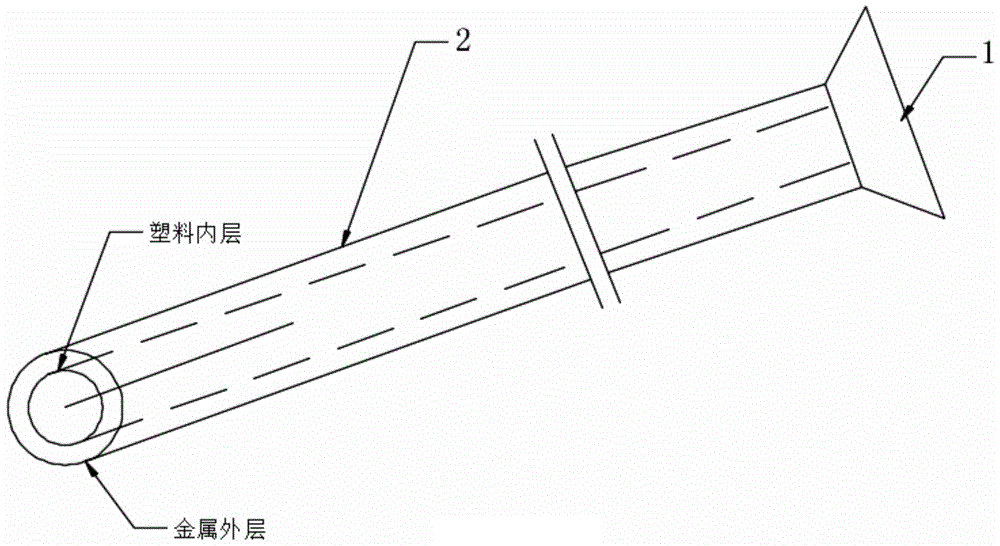

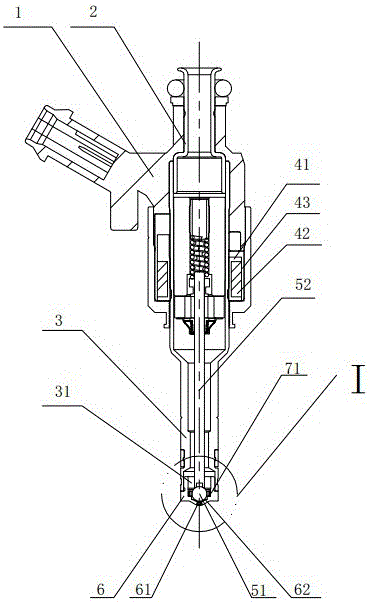

Atomizer for electronic smoking set

InactiveCN101986906AThorough atomizationAdd thermal safety deviceTobacco devicesGlass fiberEngineering

The invention discloses an atomizer for an electronic smoking set, which comprises an atomizer, wherein an oil suction device, a gasification device and a power supply device are arranged on the atomizer, through holes are arranged on a cover body and a pipe body of the oil suction device, glass fiber beams are arranged in the pipe body, the gasification device comprises a pipe type ceramic seat, a sealing cover for separating an inner cavity is arranged in the ceramic seat, through holes are arranged on the sealing cover, a heating chamber is formed between one side of the sealing cover and the cover body of the oil suction device, the glass fiber beams extending out of the cover body are accommodated in the heating chamber, heating wires are wound and arranged on the glass fiber beams at the place, a protecting device is arranged on the other side of the sealing cover positioned at outlets of the through holes, one end of the protecting device is connected with the heating wires, and the other end is connected with the power supply device. The traditional mode from nickel screen oil suction to glass fiber wire heating is changed, and the direct oil suction by the glass fiber wires is adopted, so that the atomization is more thorough. A temperature protecting device is added, when the temperature of the atomizer per se reaches 85 DEG C, a circuit can be automatically shut off, thus various safety accidents caused by high temperature can be prevented.

Owner:日本JBS株式会社

Power plant coal conveying system environment-friendly type composite dust depositing agent

The invention discloses a power plant coal conveying system environment-friendly type composite dust depositing agent, which comprises the following components by weight: 20-40% of surfactant, 1-20% of coagulation agent, 30-40% of moisture absorbent, 0.1-1% of antifoaming agent and the balance of water. The dilution proportion of the dust depositing agent can be freely adjusted between 1: 200 and 1: 2000, dust depositing can be rapidly realized, and reentrainment of dust can be avoided in a long time.

Owner:SHANGHAI YICHEN AUTOMATION TECH

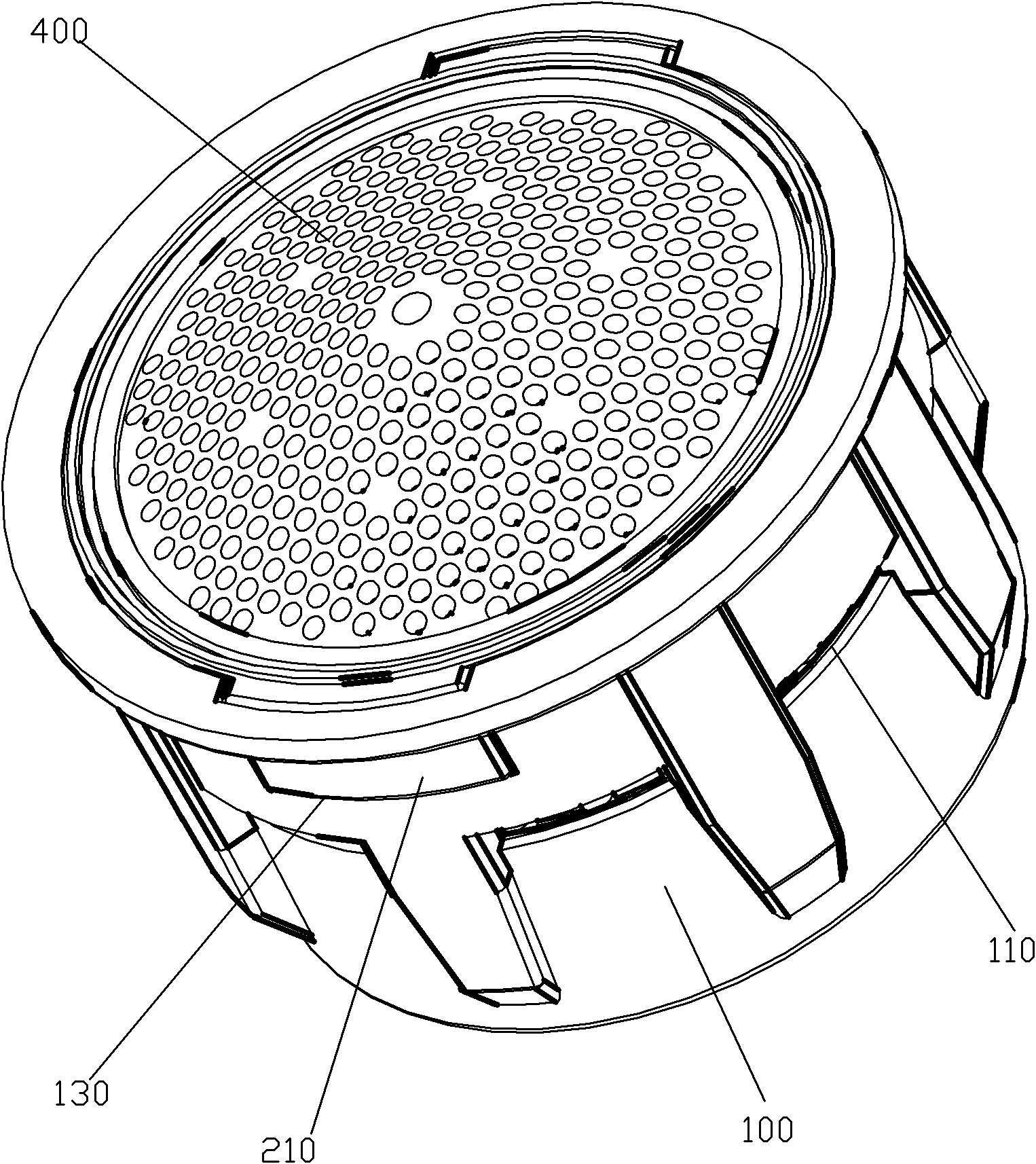

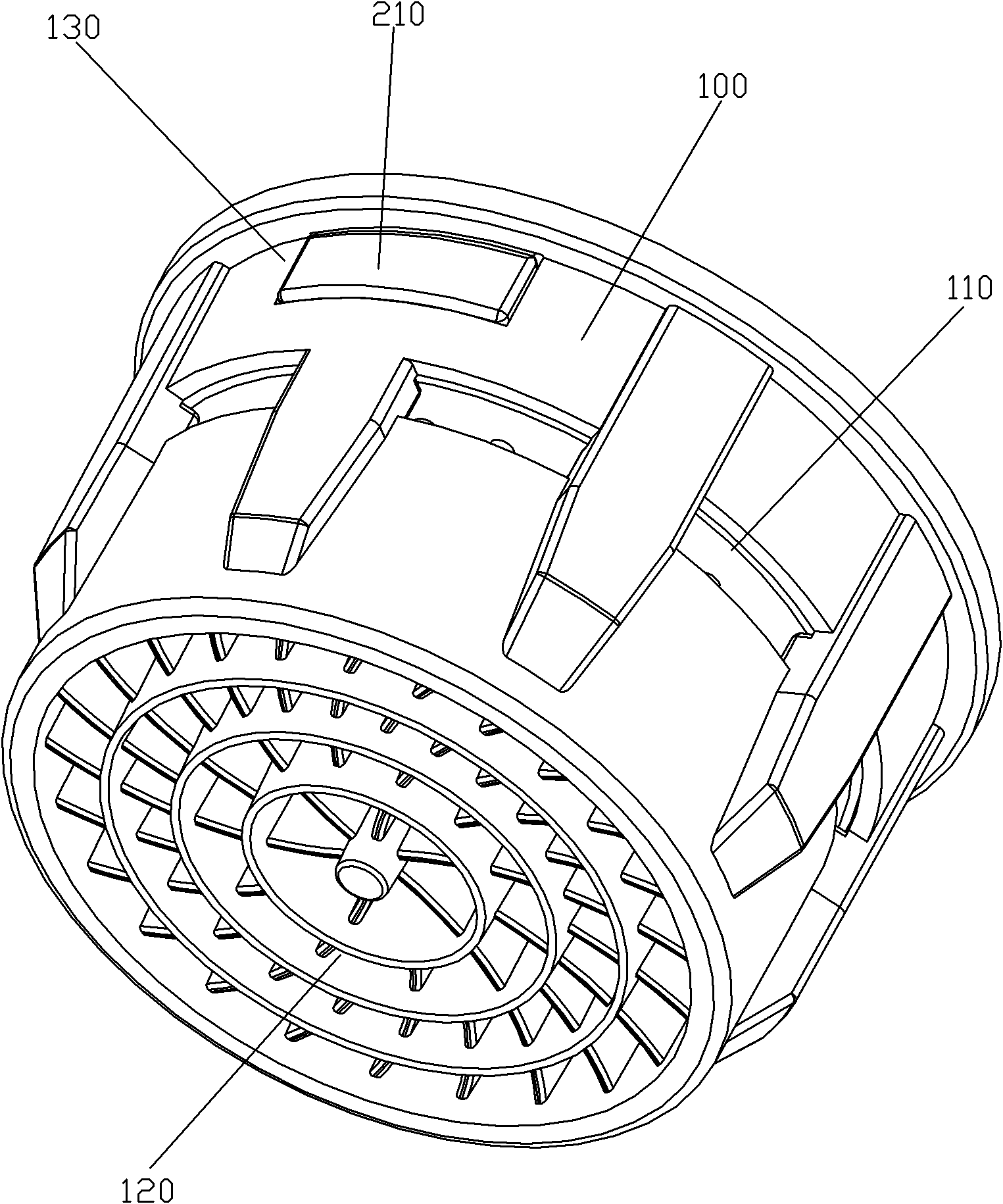

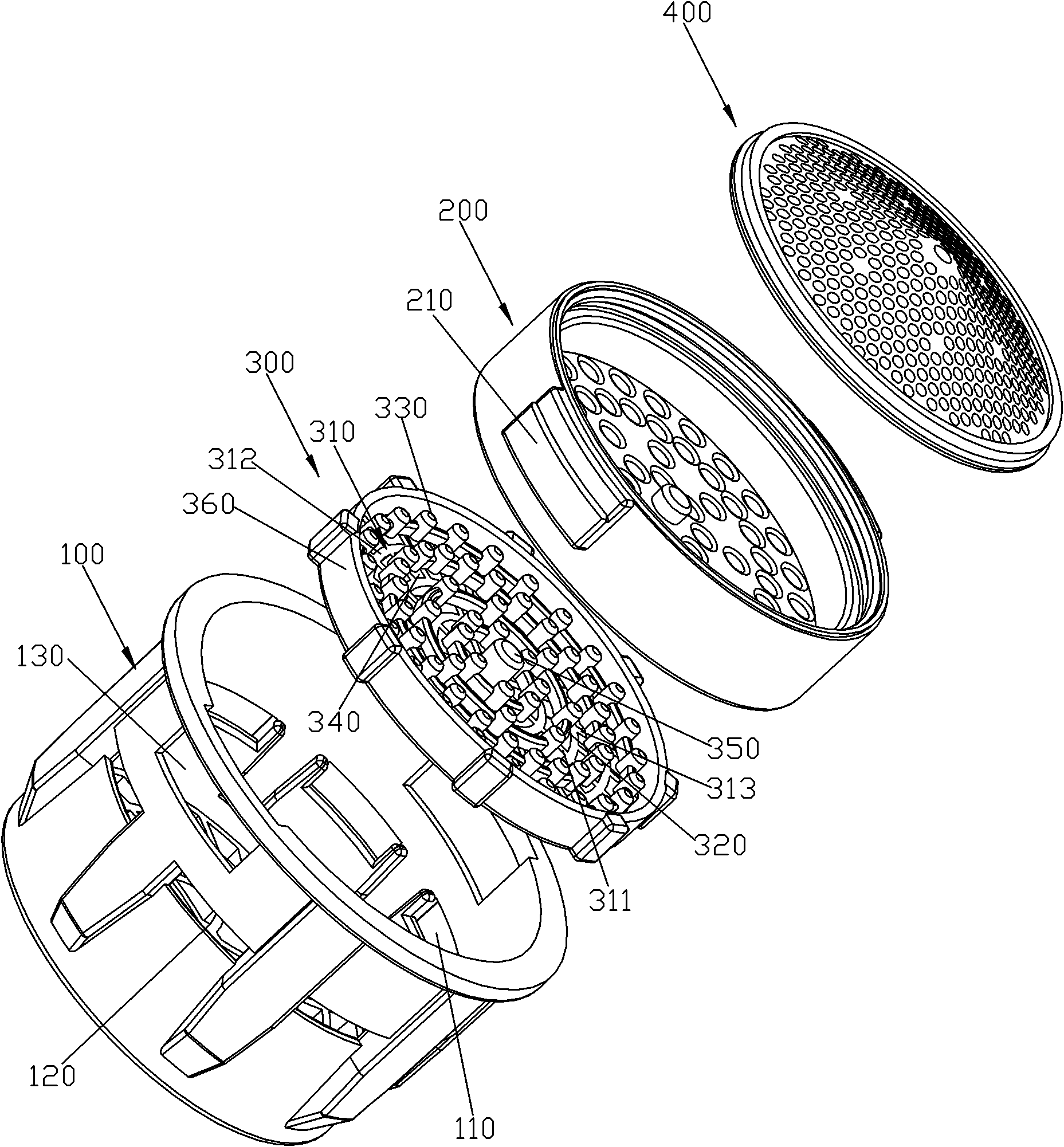

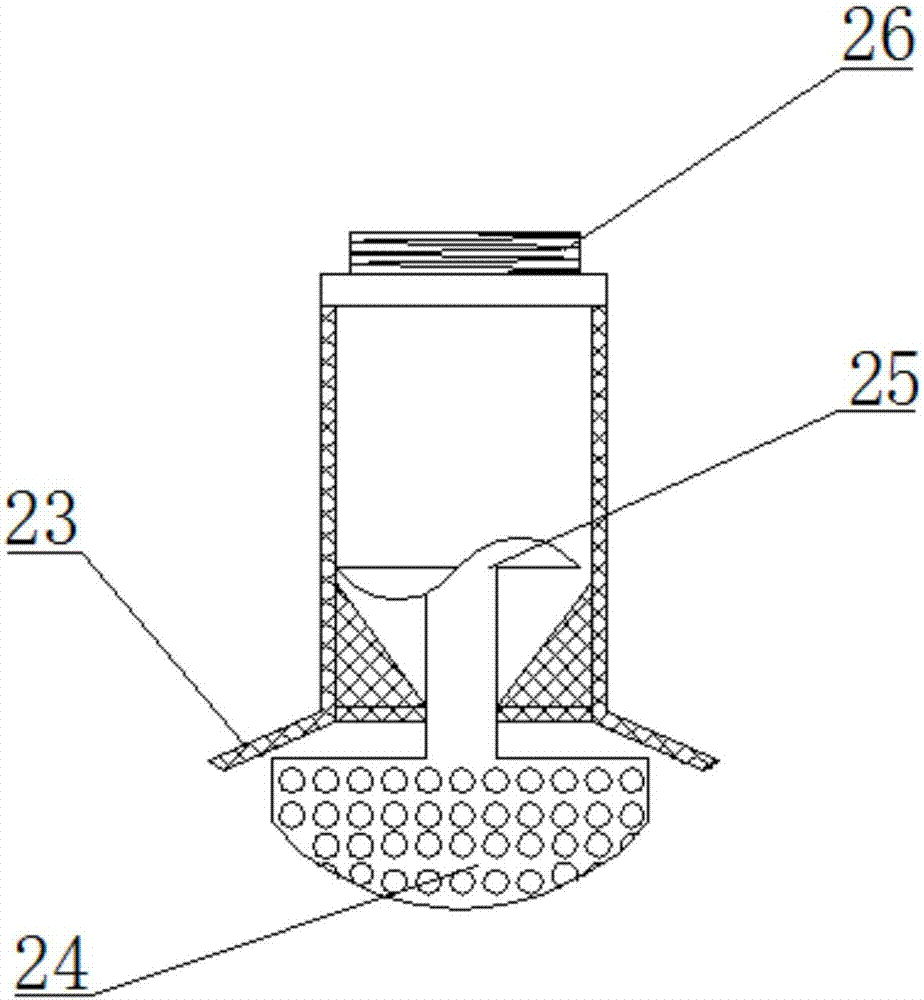

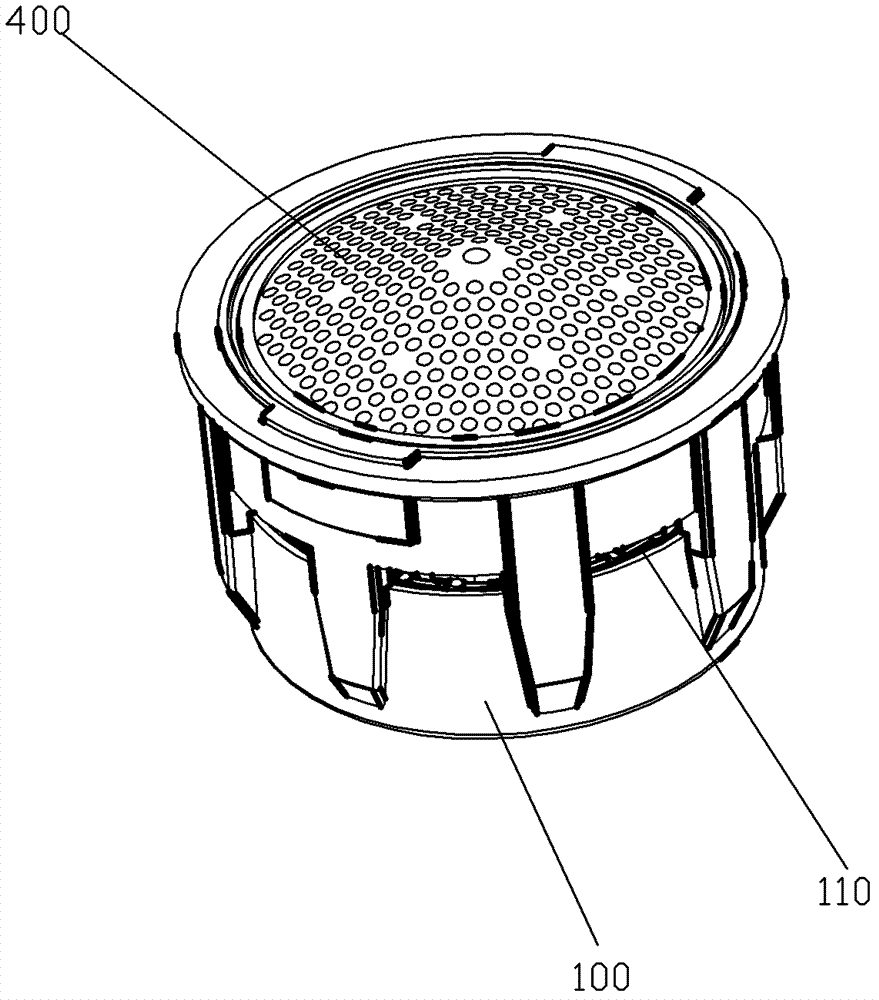

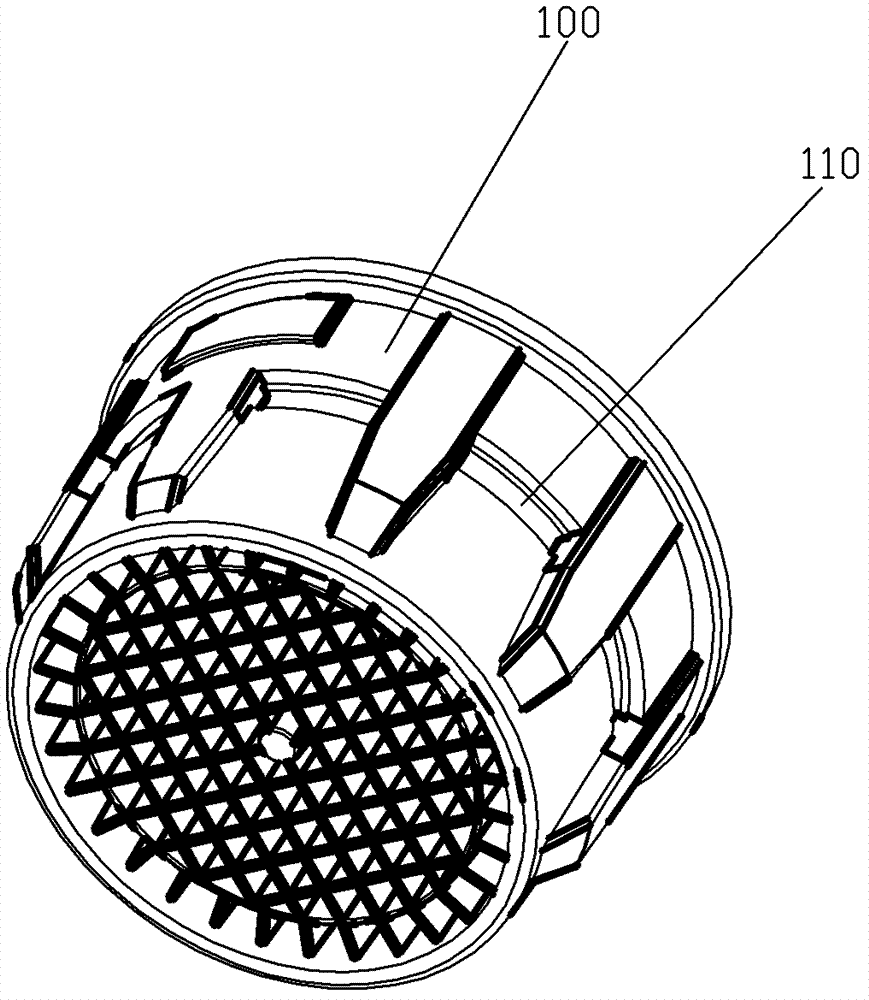

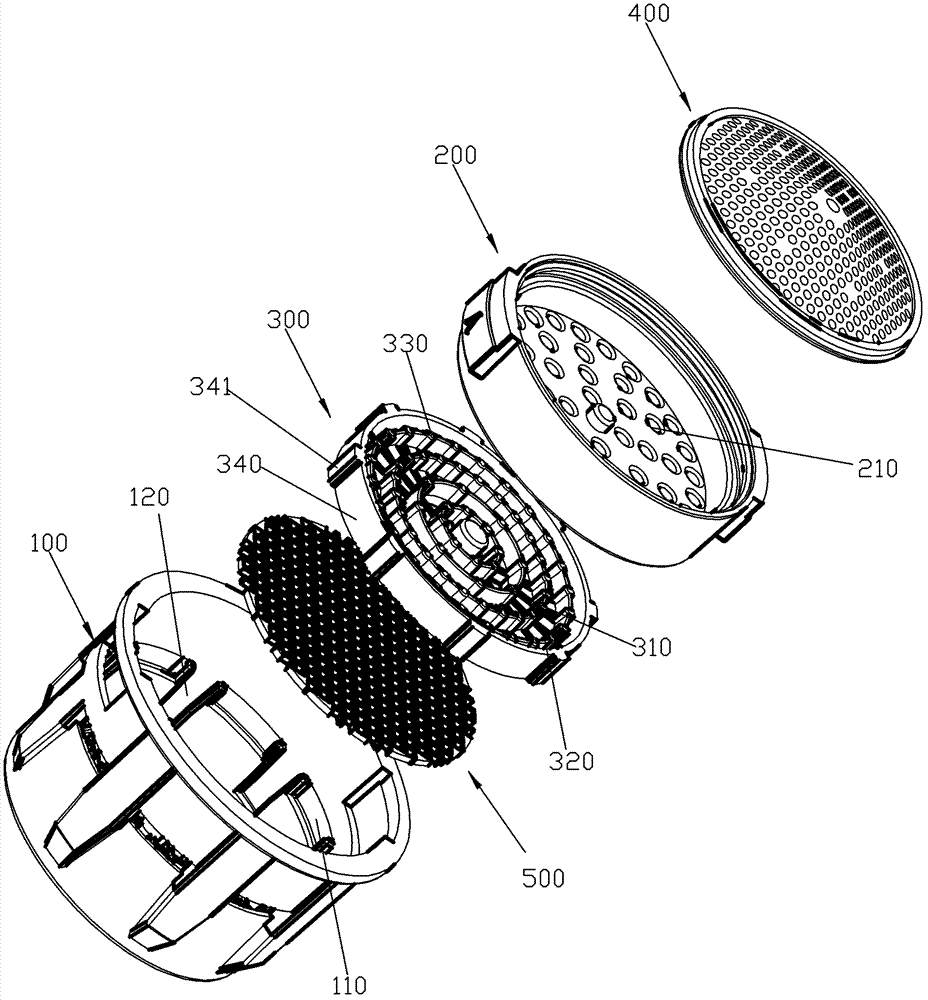

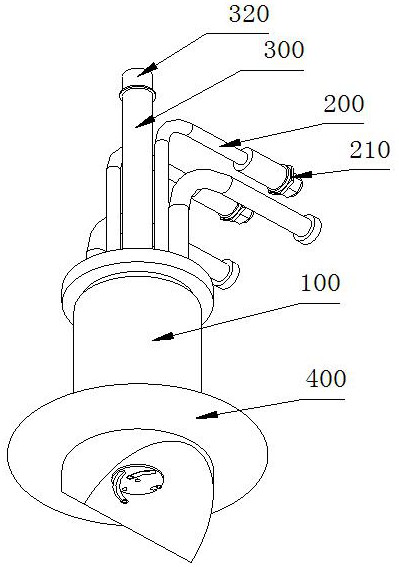

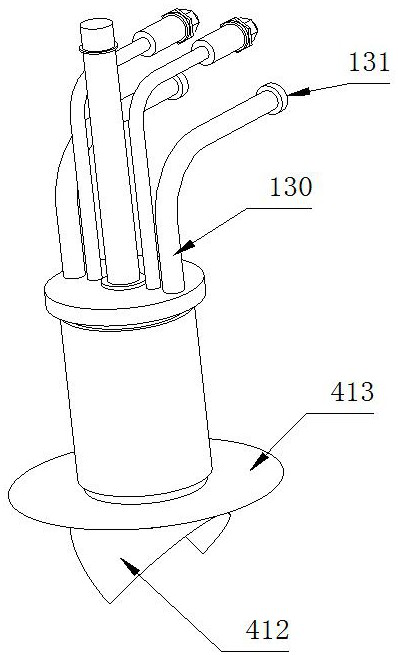

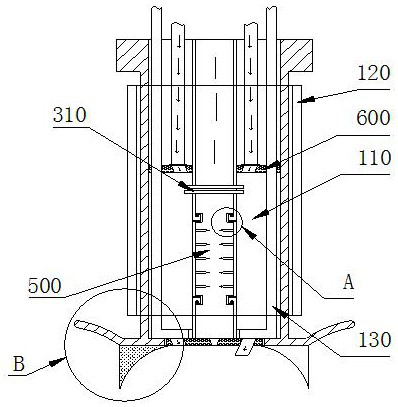

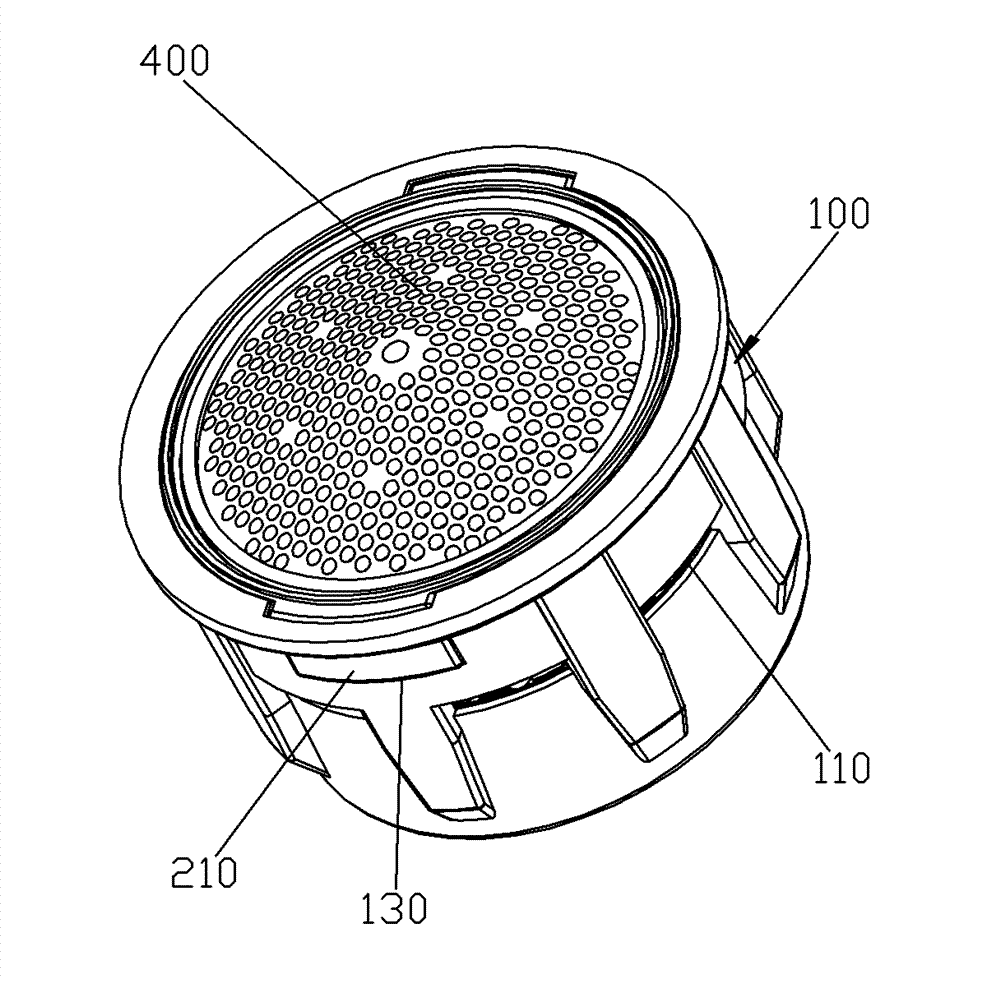

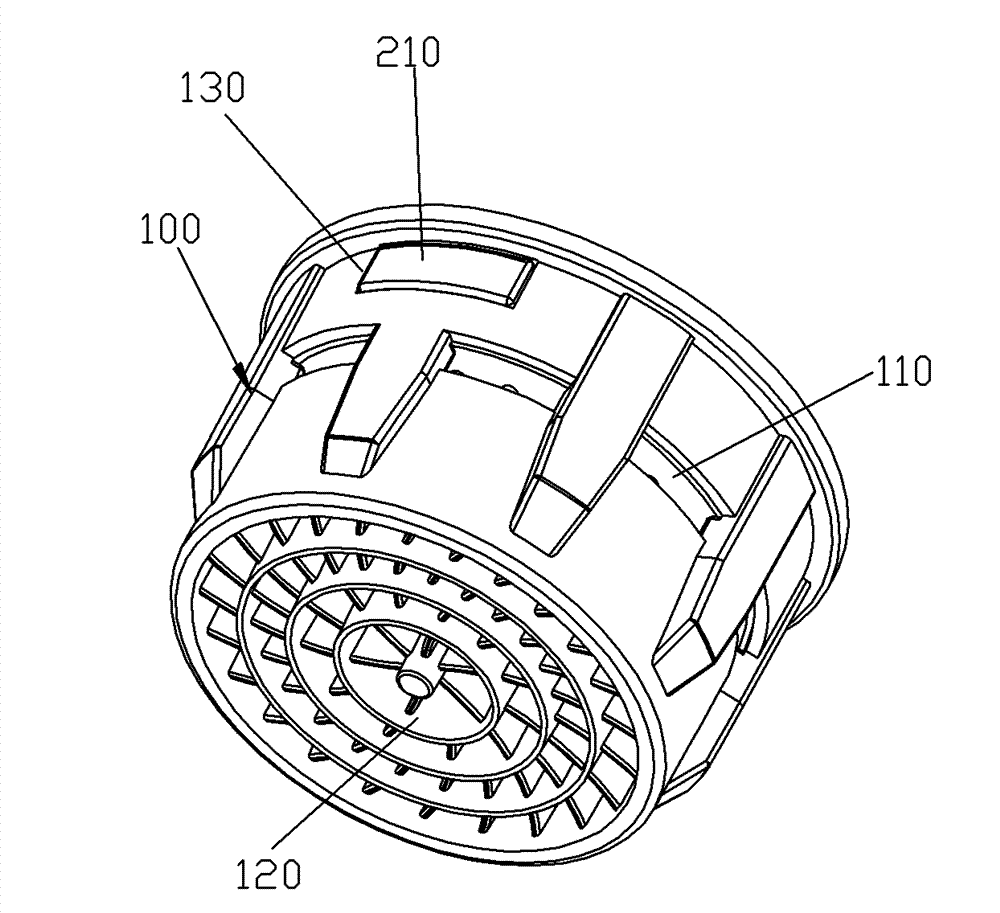

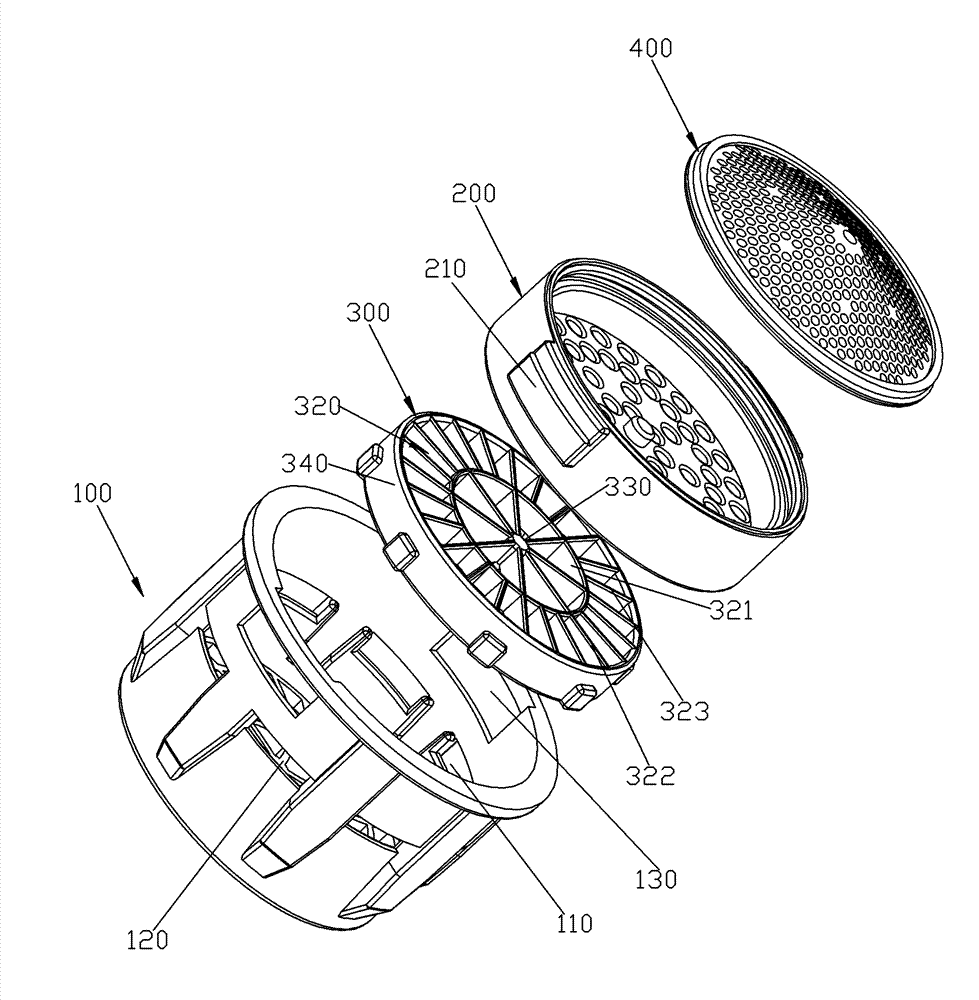

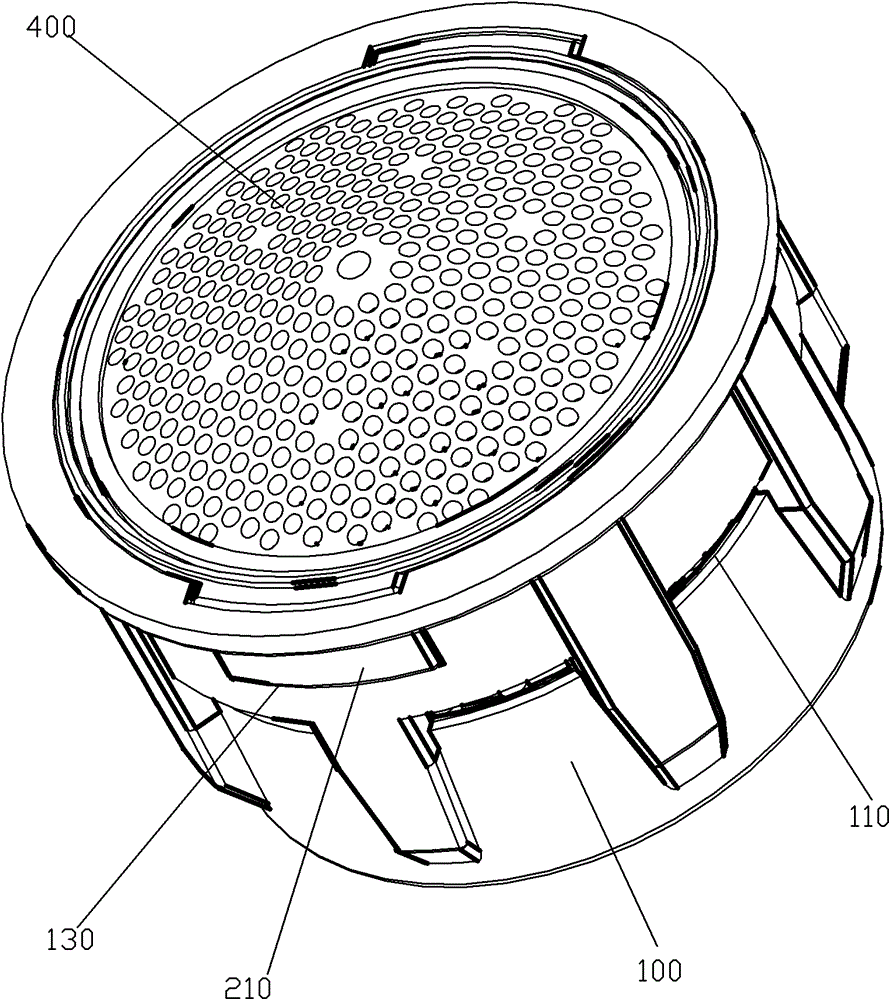

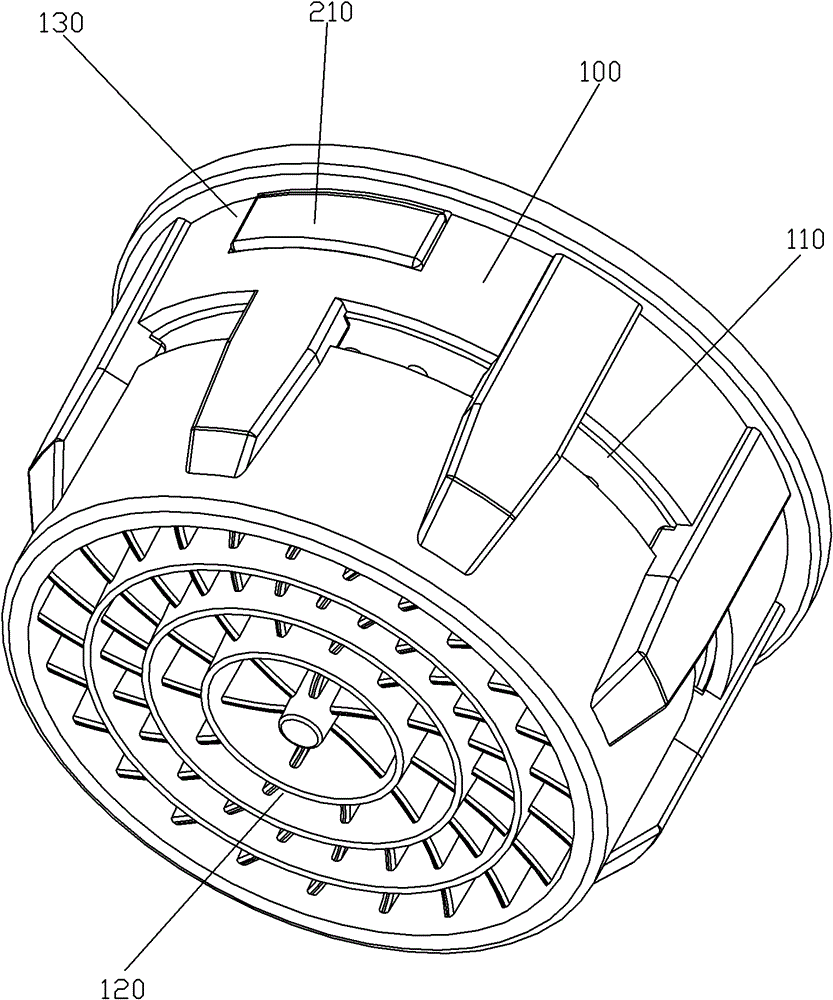

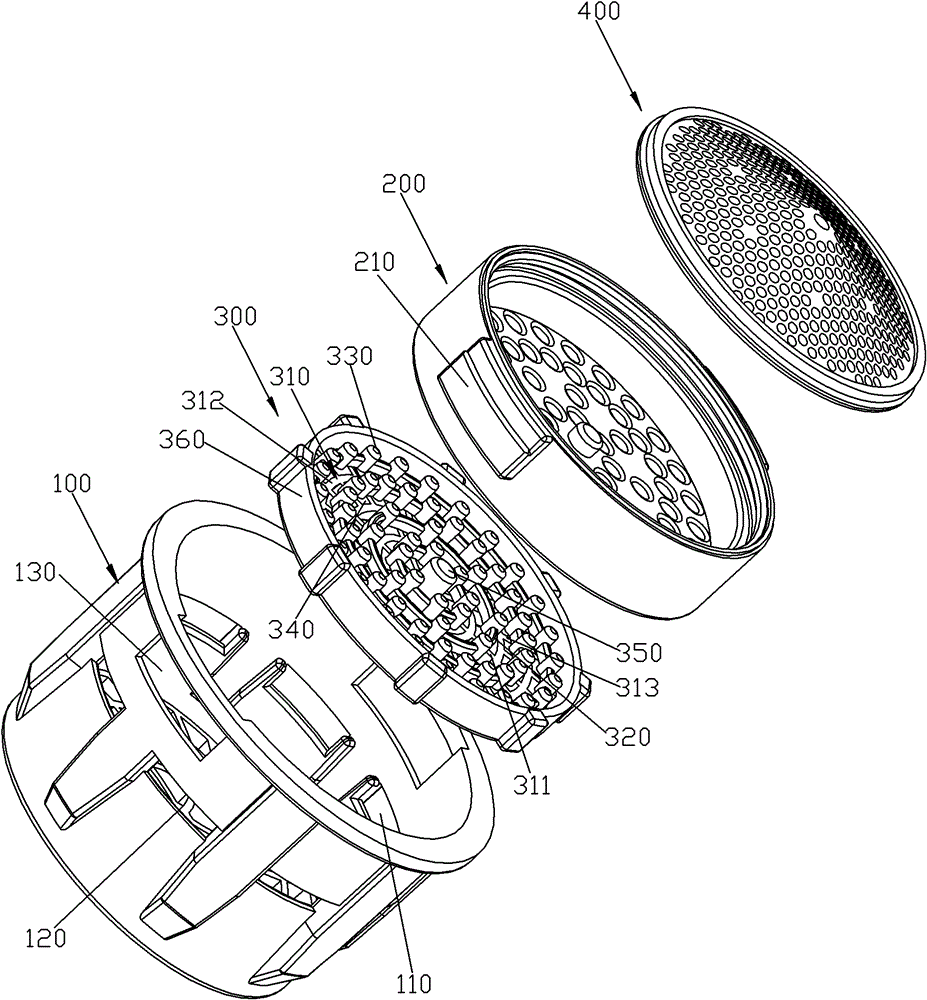

Bubbler

ActiveCN102210988AIncreased jet collision chanceIncreased jet multiple collision chanceWater resource protectionFlow mixersWater savingWater flow

The invention discloses a bubbler, comprising a body (100), a flow divider (200) and an inserting member (300), wherein the flow divider (200) and the inserting member (300) are installed in the body (100), the body (100) is provided with an air suction hole (110) penetrating through the inside and the outside, a jet flow is formed by a water flow under the action of the flow divider (200) and collides the inserting member (300) to generate an atomization effect and is mixed with air sucked by the air suction hole (110), the inserting member (300) comprises a plurality of bottom-layer clapboards (310), a plurality of middle-layer clapboards (320) and a plurality of upper-layer convex columns (330) which are fixedly connected together, channels (340) are formed between adjacent bottom-layer clapboards (310) and between adjacent middle-layer clapboards (320), and collision surfaces of the upper-layer convex columns (330), the middle-layer clapboards (320) and the bottom-layer clapboards(310) form three layers at intervals along the direction (X). The bubbler has the advantages of increasing a plurality of jet flow collision chances, has excellent water saving effect and full water granules.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

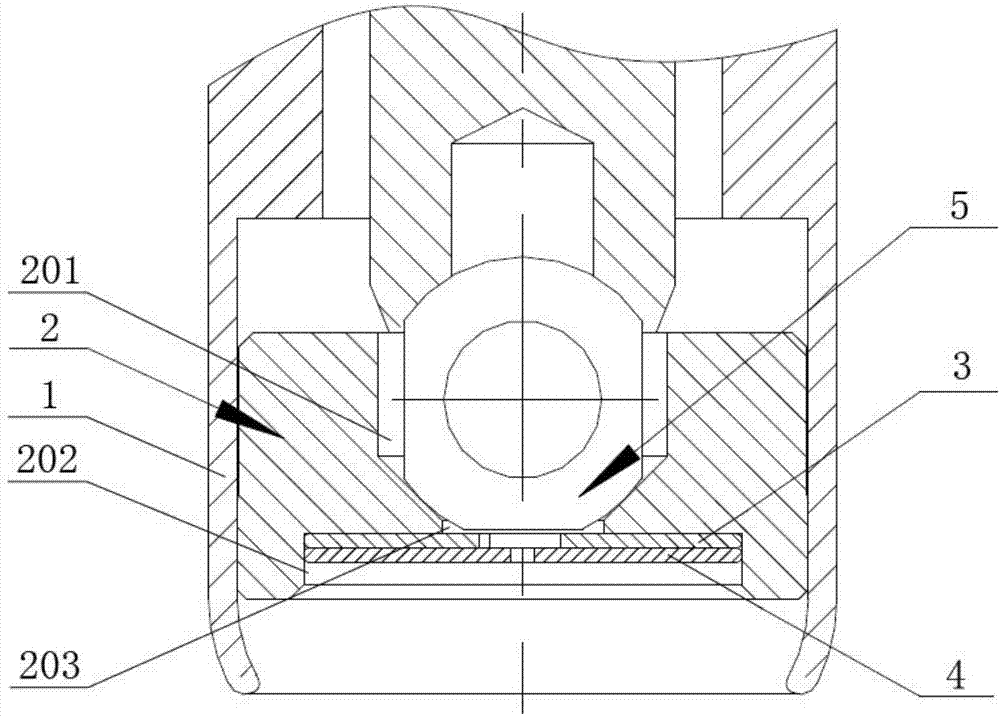

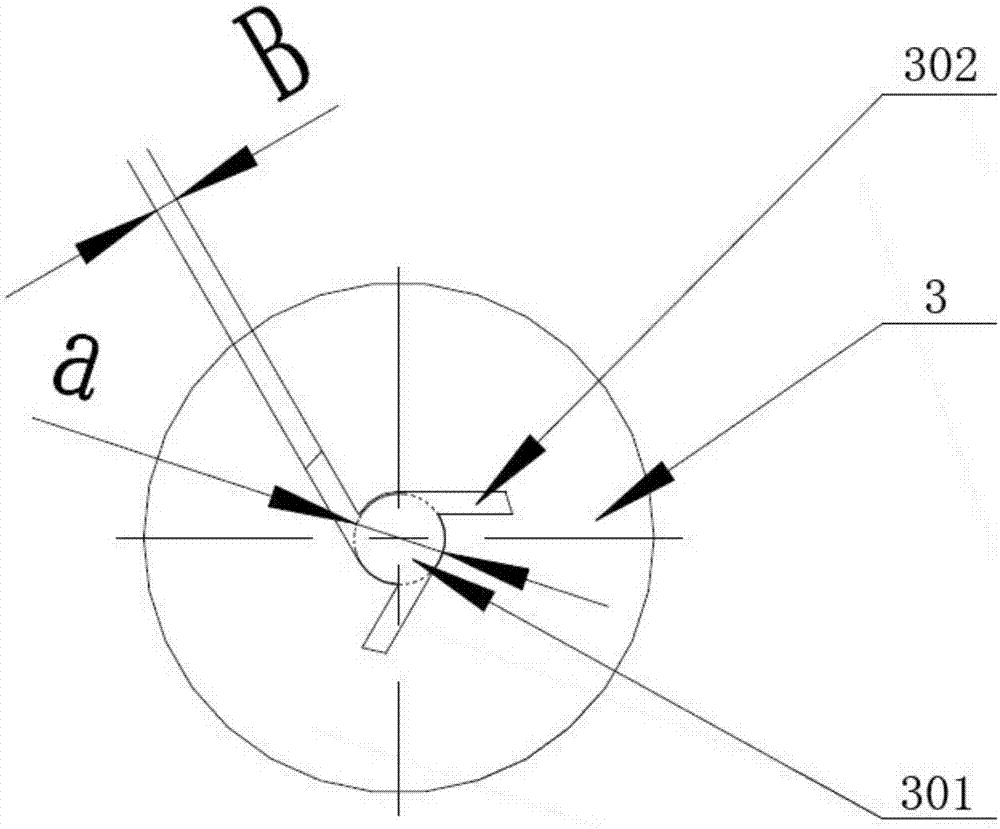

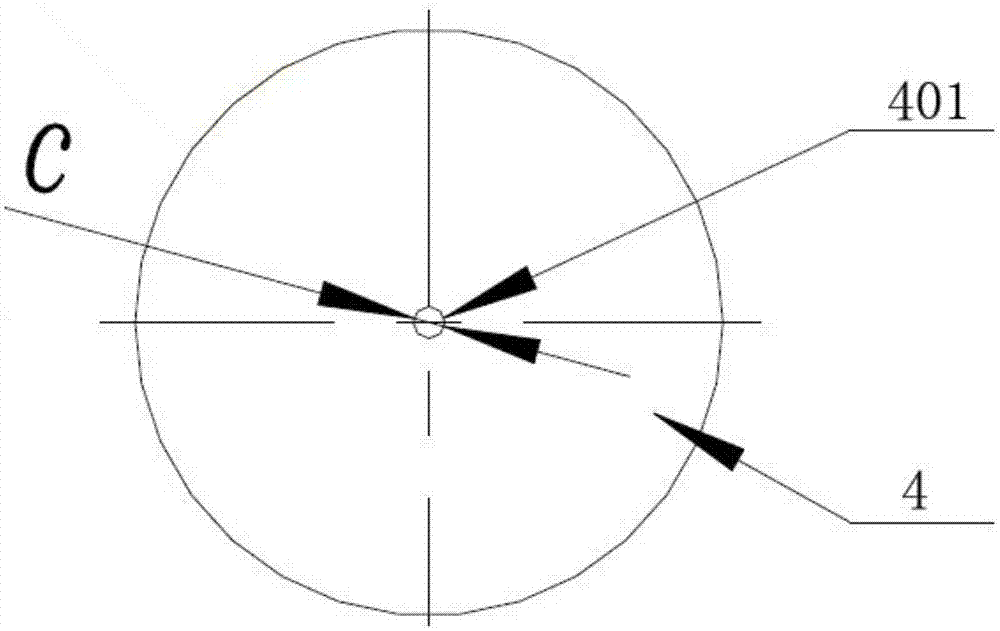

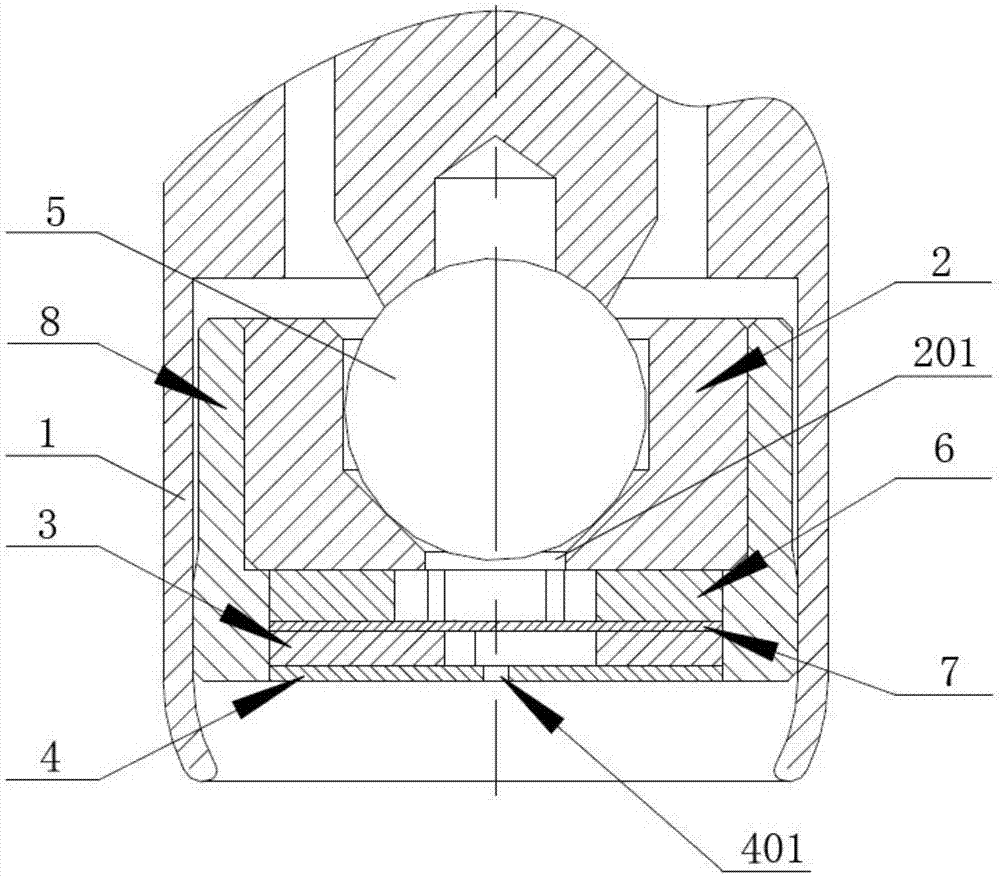

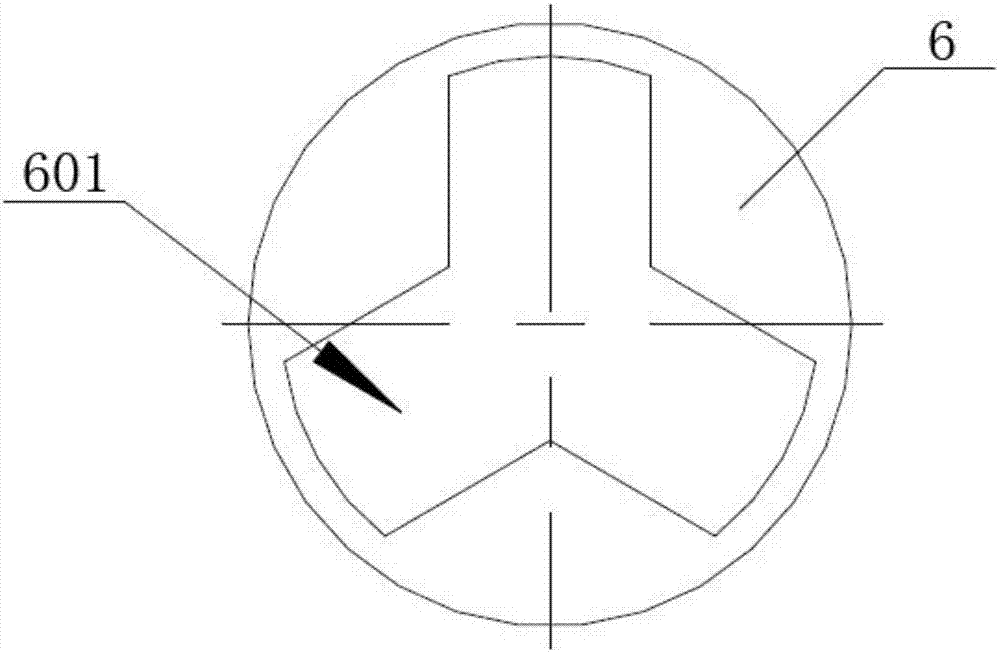

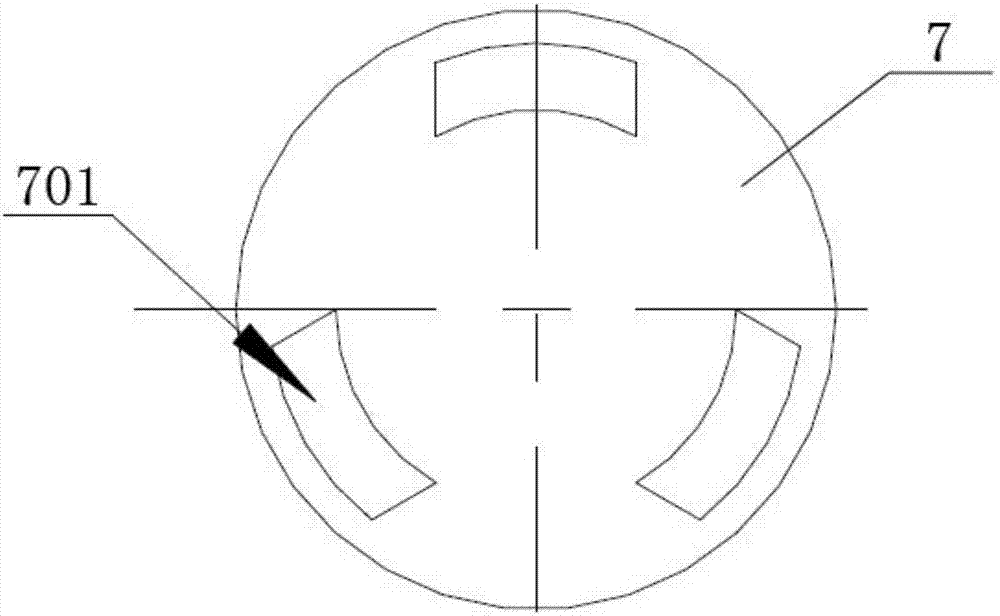

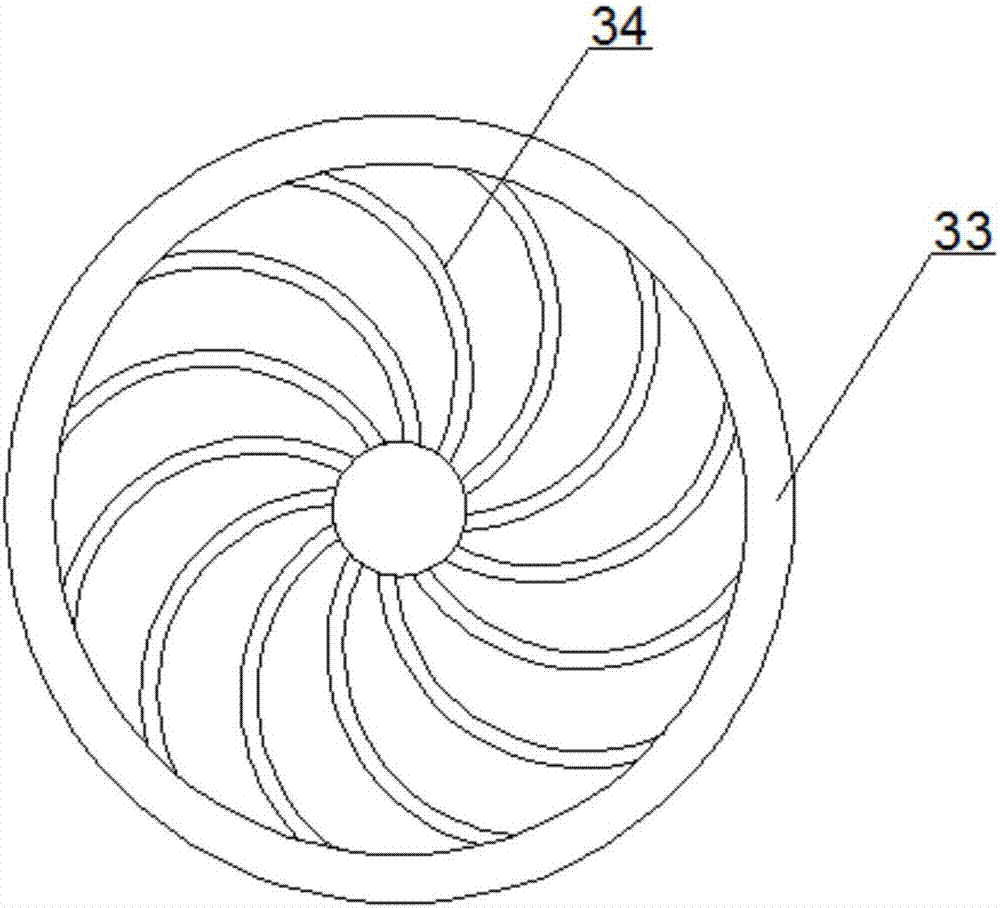

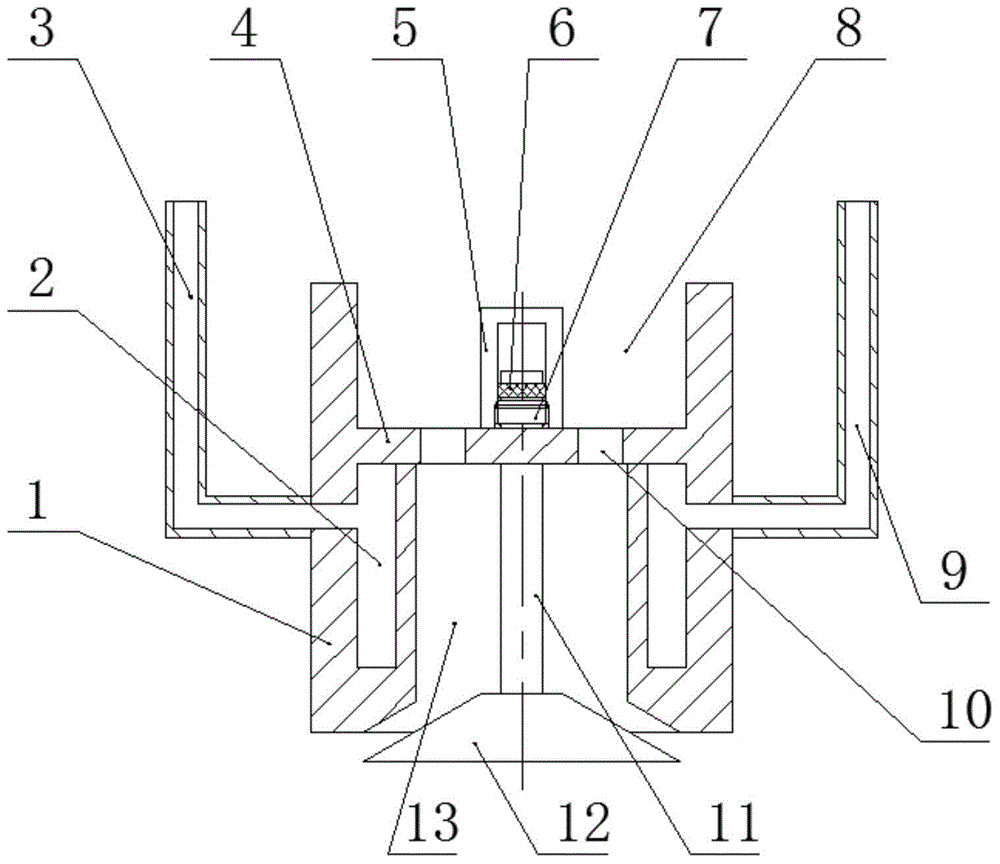

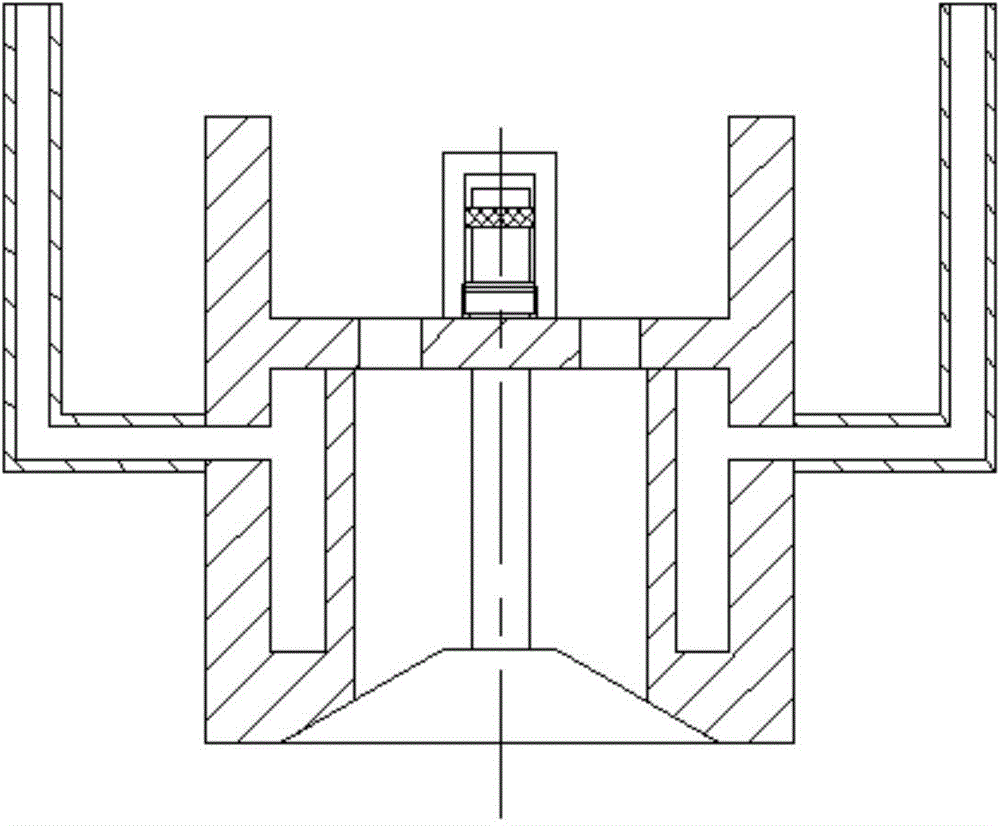

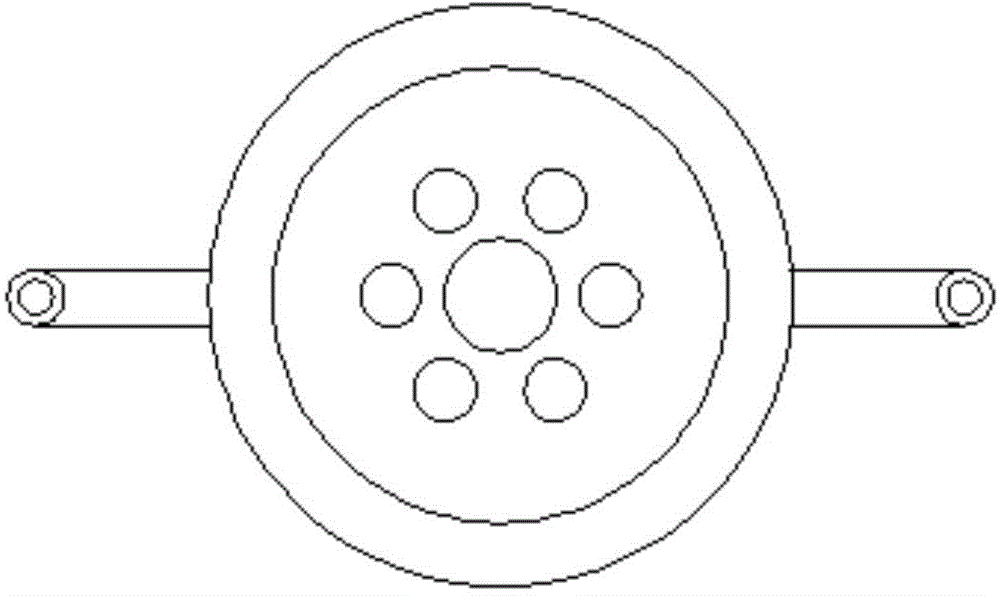

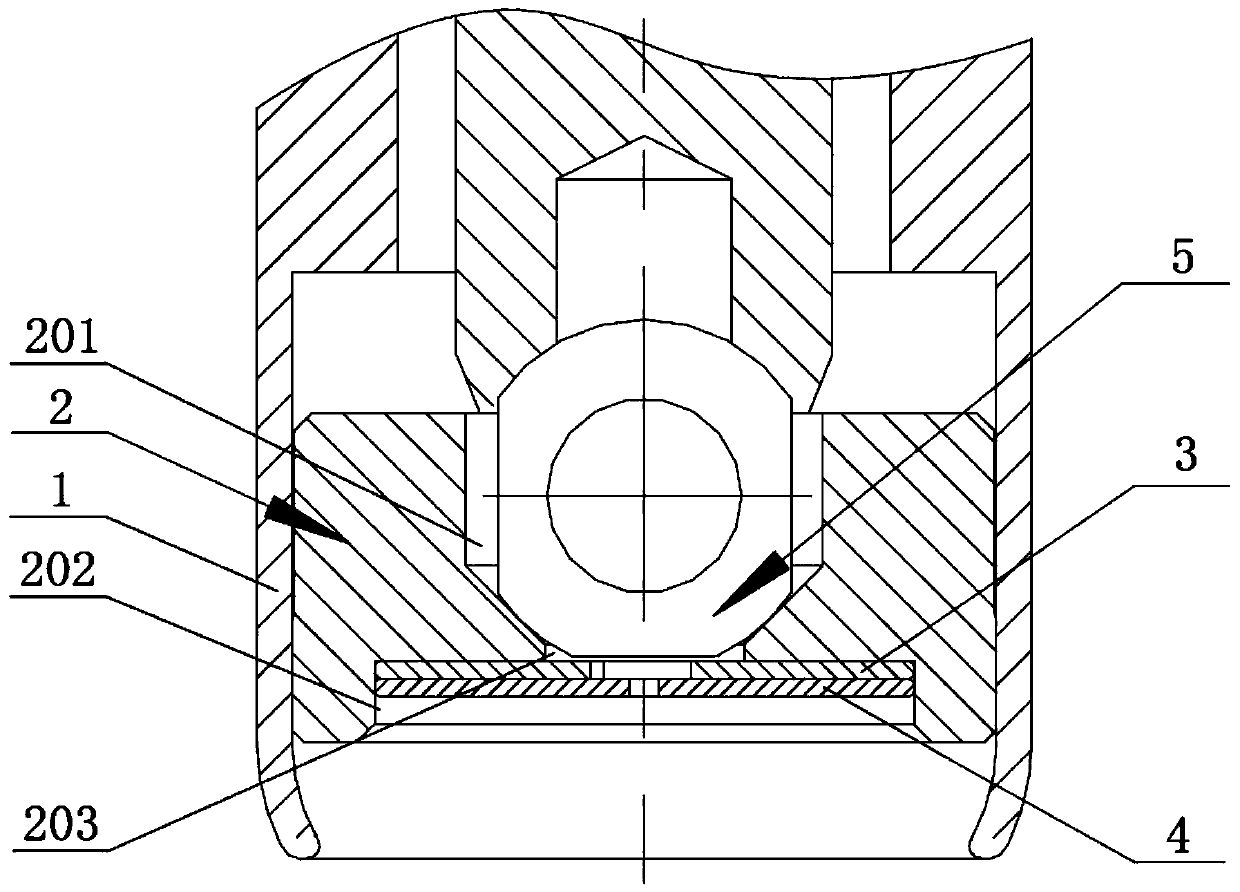

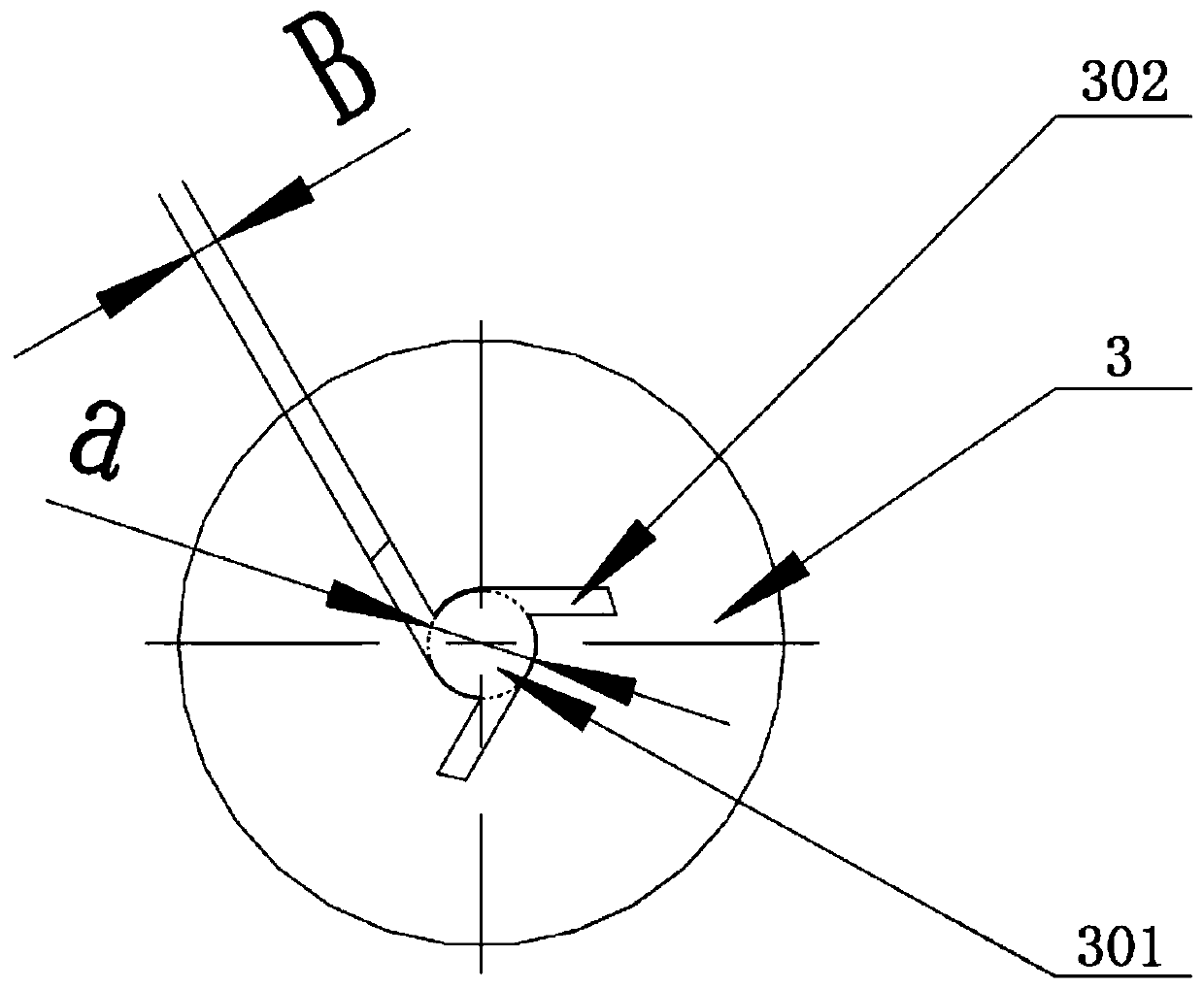

Single-hole atomizing oil sprayer and swirl atomizing structure thereof

ActiveCN107956619AThorough atomizationFine granularityFuel injection apparatusMachines/enginesCombustionSprayer

The invention discloses a swirl atomizing structure of a single-hole atomizing oil sprayer and further discloses the single-hole atomizing oil sprayer. The swirl atomizing structure comprises a pipe body, a valve seat, a swirl piece and a metering piece, a first mounting groove is formed in the top end of the valve seat, a second mounting groove is formed in the bottom end of the valve seat, and the first mounting groove and the second mounting groove communicate with each other through a valve hole. The swirl piece is tightly attached to the bottom face of the second mounting groove, and themetering piece is tightly attached to the bottom face of the swirl piece. A swirl hole is formed in the swirl piece, and a metering hole is formed in the metering piece. A plurality of swirl grooves are formed in the swirl piece. After a fluid passes through the valve hole, under the effect of the swirl grooves, a fluid beam is impacted to form a turbulent flow or a swirl flow distributed in the swirl groove direction, then when the fluid passes through the metering hole, the atomizing effect is obviously improved, the fluid is more thoroughly atomized, the particle size of atomized particlesis more fine, the fuel oil atomizing effect is improved, mixing and sufficient combustion of fuel oil and air are facilitated, carbon is prevented from being accumulated in a cylinder, and the vehicleemission cleanness is improved. The single-hole atomizing oil sprayer has the beneficial effects.

Owner:GUANGXI CARTIER TECH CO LTD

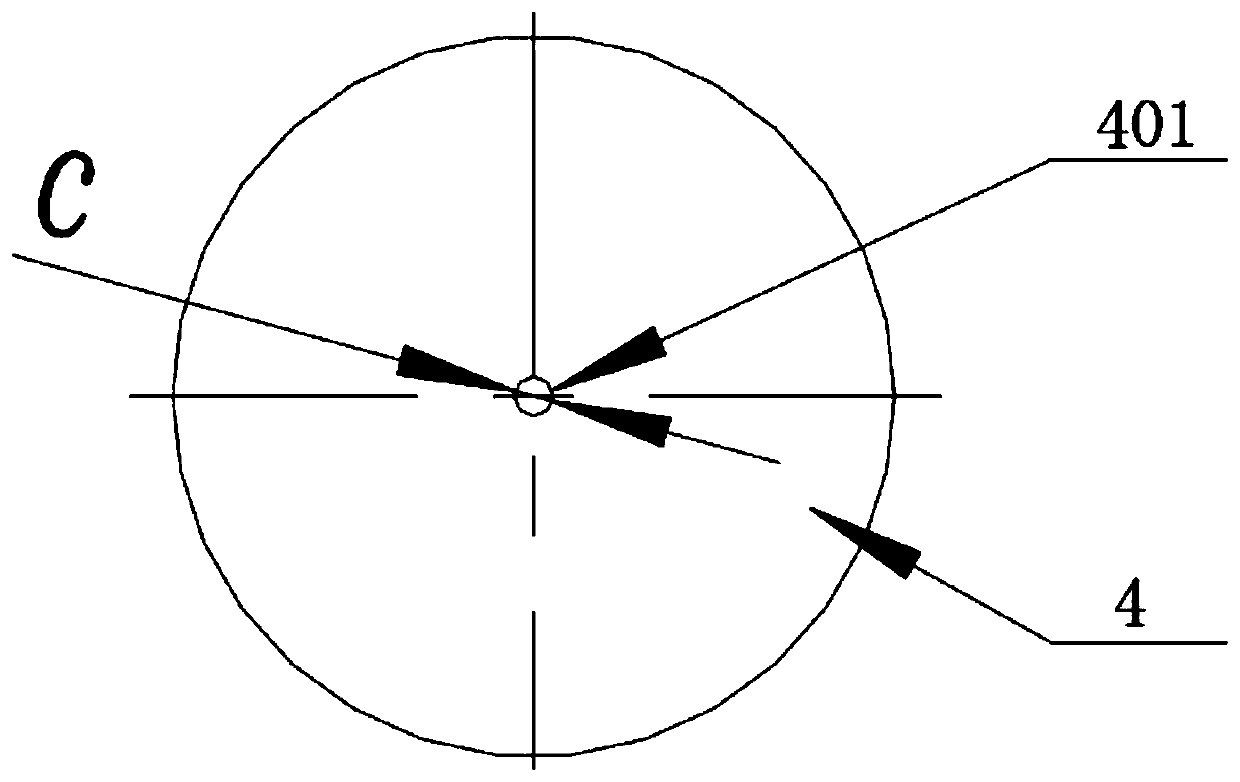

Single-hole atomization oil sprayer and front atomization structure thereof

ActiveCN107989731AThorough atomizationFine granularityFuel injection apparatusMachines/enginesCycloneCombustion

The invention discloses a front atomization structure of a single-hole atomization oil sprayer. The front atomization structure of the single-hole atomization oil sprayer comprises a pipe body, a mounting sleeve, a valve base, a flow separation piece, a flow passing piece, a cyclone piece and a metering piece. A flow separation groove is formed in the flow separation piece for dividing a fluid beam into multiple parts. A flow passing hole is formed in the flow passing piece for further performing the flow separation limiting on the divided fluid. The cyclone piece is provided with a cyclone hole and a cyclone groove; after the divided fluid passes through the cyclone groove, the bottom of the cyclone groove is shielded by the metering piece to generate acute impact and to form turbulent flows; and the turbulent flows are gathered in the cyclone hole. When the fluid beam forming the turbulent flows passes through a metering hole after passing through the cyclone hole, the atomization effect is obviously improved, the liquid atomization is more thorough, the particle size of atomization particles is finer, and the fuel atomization effect is improved; and when the structure is appliedto an engine cylinder, mixing with air and full combustion are facilitated, accumulation of carbons in the cylinder is prevented, and the vehicle discharge cleanness is improved. The invention further discloses the single-hole atomization oil sprayer; and the beneficial effects are as above.

Owner:GUANGXI CARTIER TECH CO LTD

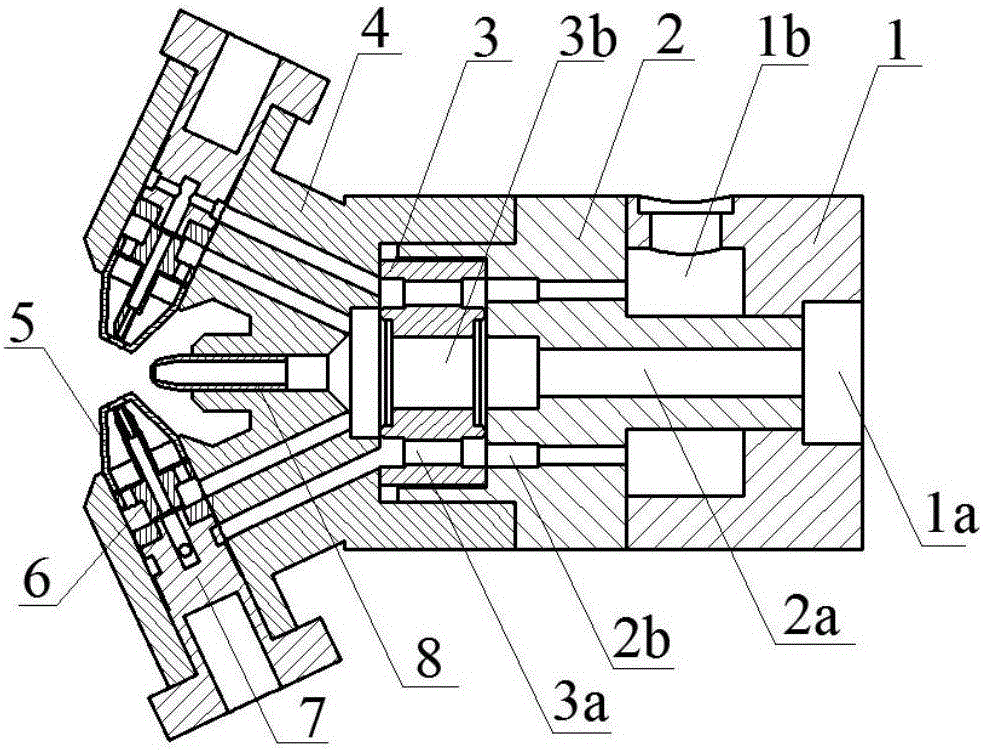

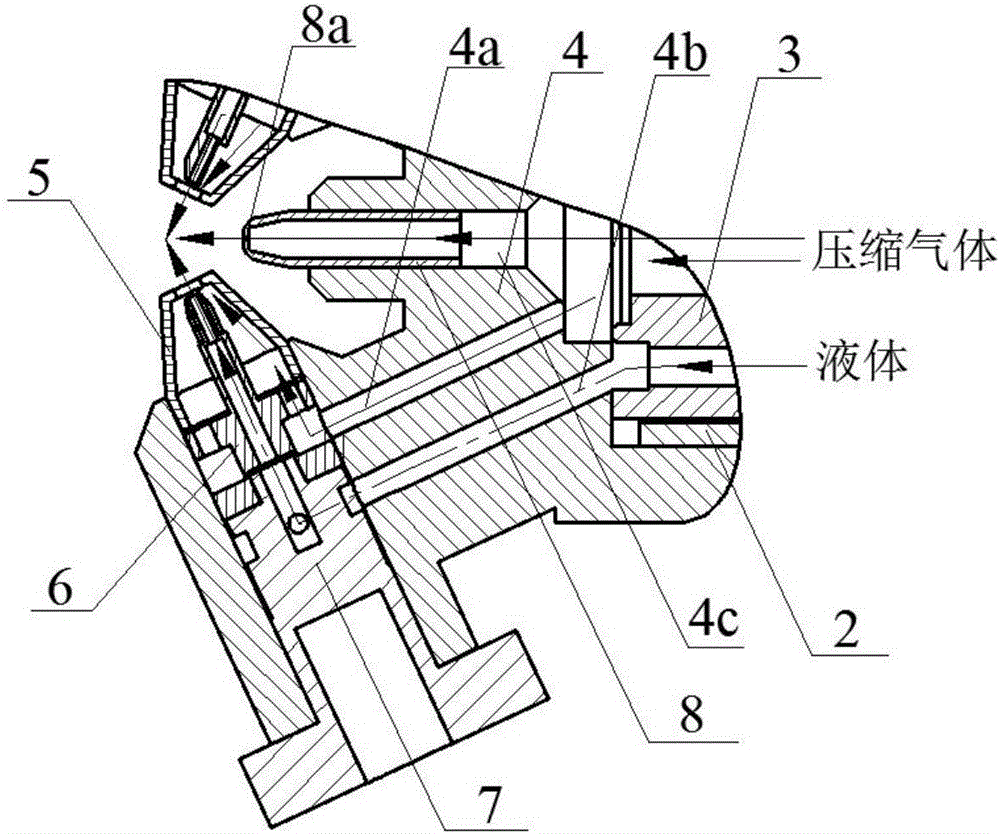

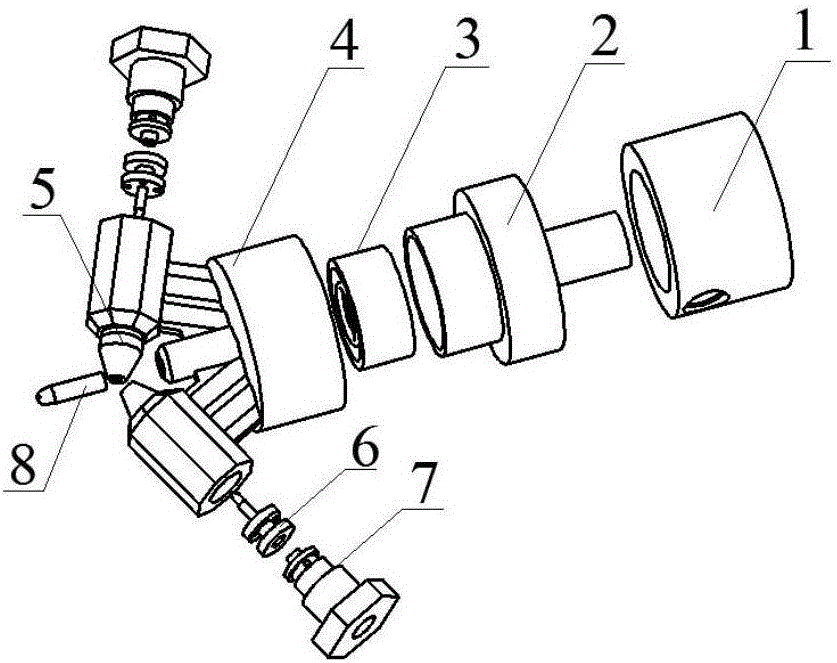

Secondary atomization two-phase flow nozzle

ActiveCN106540825AEnhanced spray atomization effectReduce wasteLiquid spraying apparatusRubber ringEngineering

The invention discloses a secondary atomization two-phase flow nozzle. The secondary atomization two-phase flow nozzle comprises a feeding sleeve, a flow guide pipe, a flow guide rubber ring, a flow distribution pipe, an ejection needle and two atomization nozzles, wherein the flow distribution pipe, the flow guide pipe and the feeding sleeve are connected in sequence from front to back; the flow guide rubber ring is arranged between the flow distribution pipe and the flow guide pipe; a first atomization nozzle and a second atomization nozzle are fixedly connected with two sides of the center of a front end of the flow distribution pipe; the first atomization nozzle and the second atomization nozzle are mounted at the front end of the flow distribution pipe in a manner of being obliquely and symmetrically arranged; the feeding sleeve is provided with a gas inlet for introducing compressed gas and a liquid inlet for introducing liquid; a central gas inlet flow guide hole is formed in the front end of the center of the flow distribution pipe along the axis direction; the ejection needle is arranged in the central gas inlet flow guide hole. According to the secondary atomization two-phase flow nozzle, a manner of combining gas-liquid two-phase flow primary atomization with secondary collision is adopted, and a lot of ultrafine fog drops can be generated; the disadvantages that a traditional technology cannot combine large atomization amount, fine grain diameter, long emission range and directed spraying are overcome.

Owner:JIANGSU ACAD OF AGRI SCI

Water-proof and methanol-proof treatment process for wood floor

ActiveCN103216077ANo deformationImprove waterproof performanceStarch coatingsFlooring insulationsToxic gasPulp and paper industry

The invention discloses a water-proof and methanol-proof treatment process for a wood floor. The process comprises the following steps of cleaning the edges of the wood floor, and removing dust pollution; pouring a water-proof agent into a container, and pumping into a nozzle by using a high-pressure pump for spraying; forming a negative-pressure area by using a recovering pump at the mouth of the nozzle, atomizing liquid, and pumping the residual water-proof agent into the container; and making the edges of the wood floor pass through the nozzle at a uniform speed, spraying the atomized water-proof agent onto the edges of the wood floor at a constant speed, sealing edges and curing to form a water-proof methanol-proof protection layer. The water-proof and methanol-proof treatment process disclosed by the invention has the advantages of extremely high water-proofing performance and toxic gas emission resistance, and the problems of wood floor deformation and methanol emission existing in the conventional wood floor can be solved effectively.

Owner:李寻

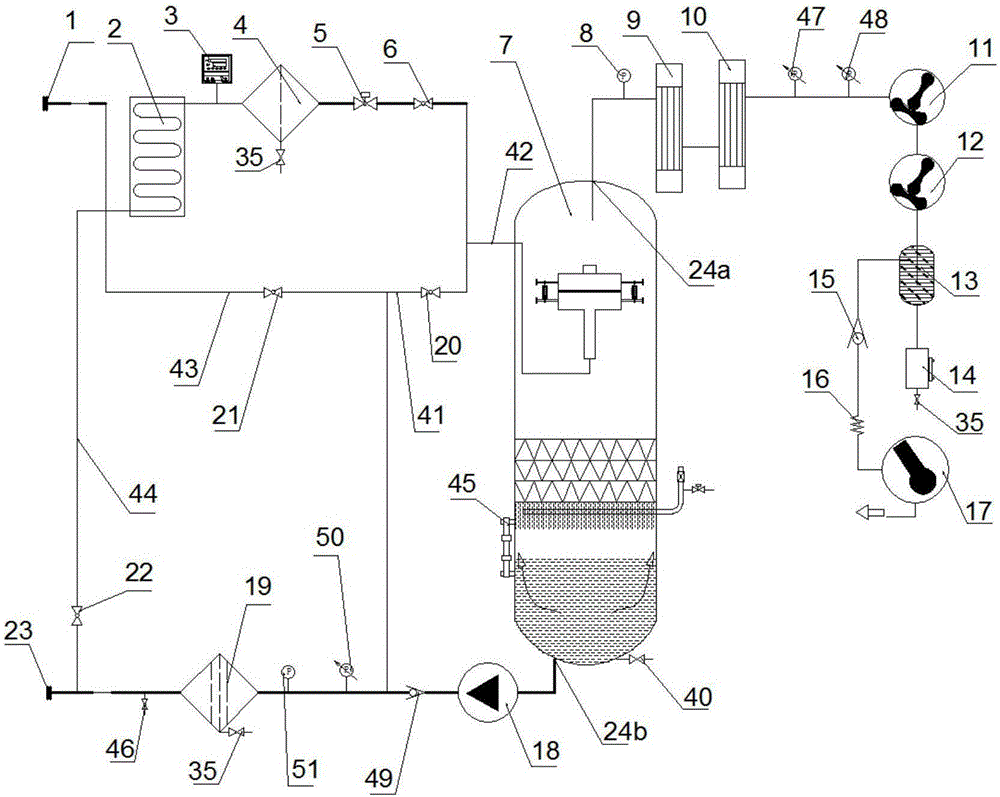

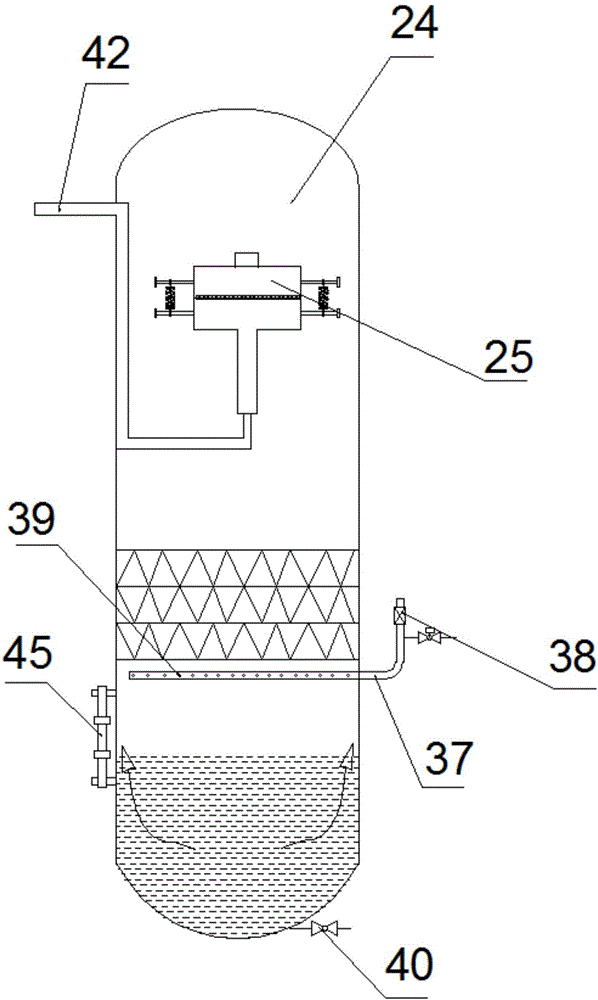

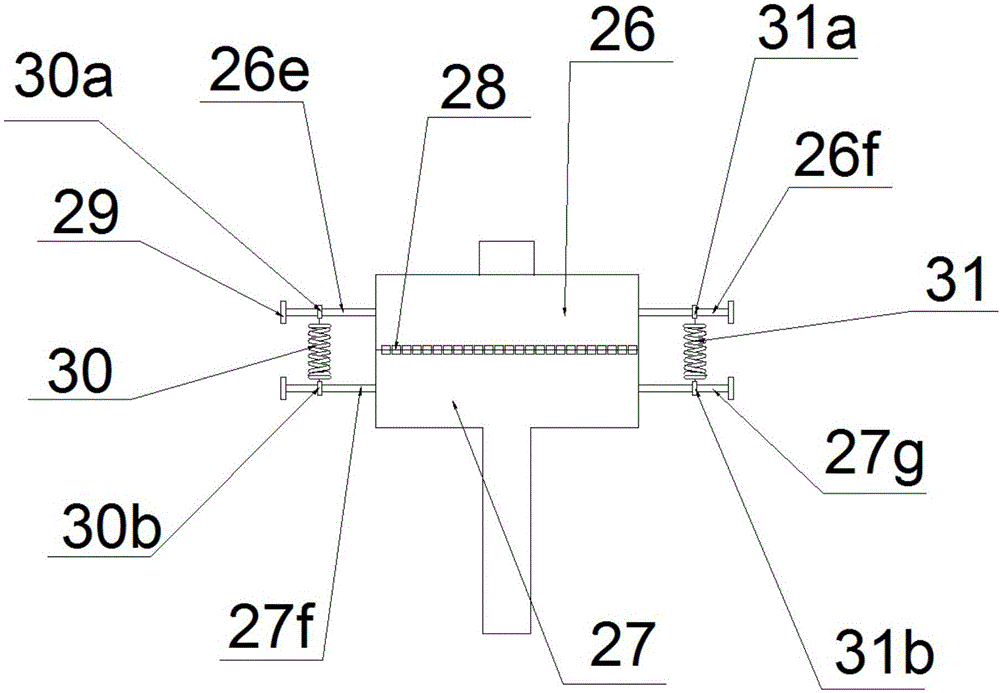

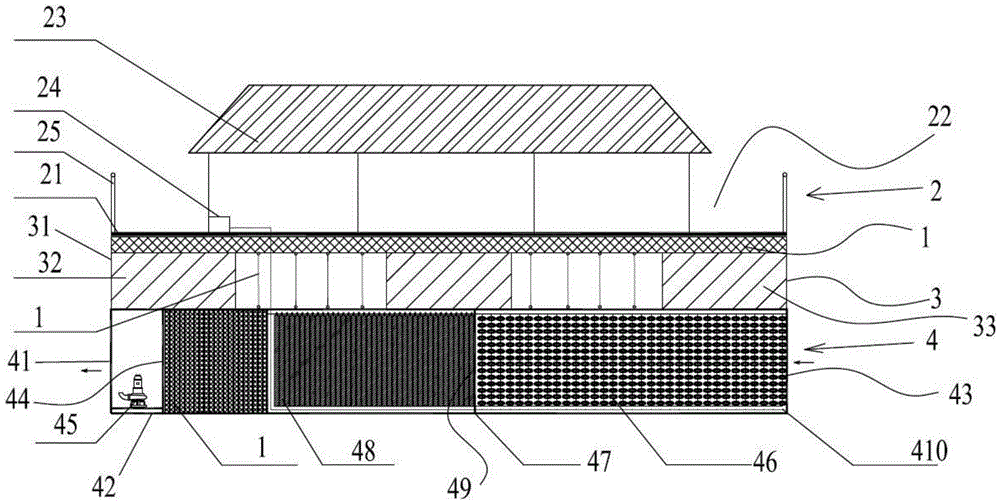

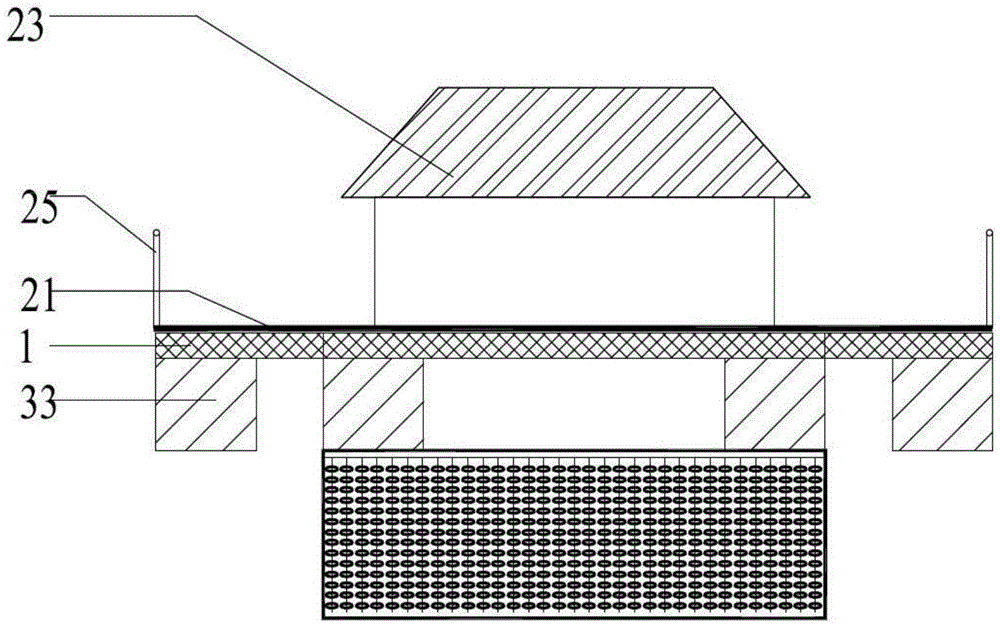

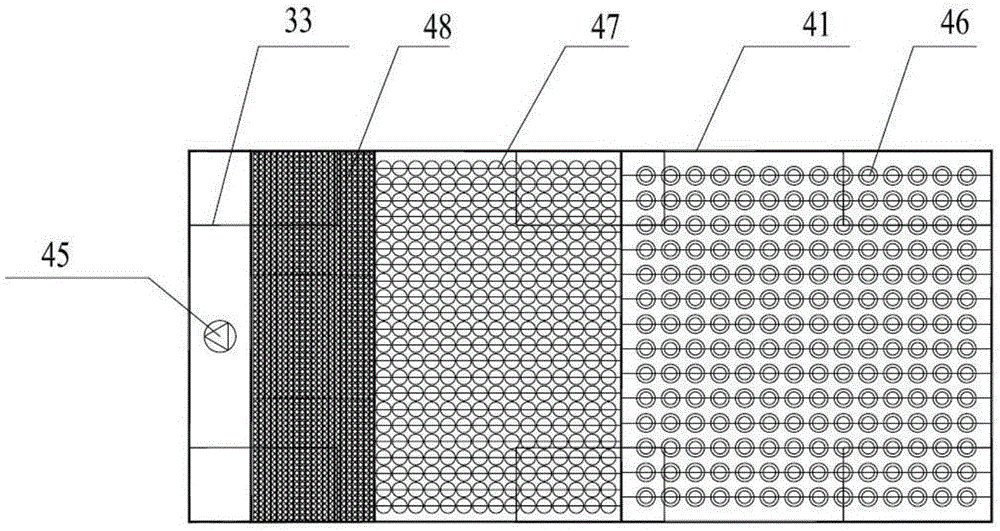

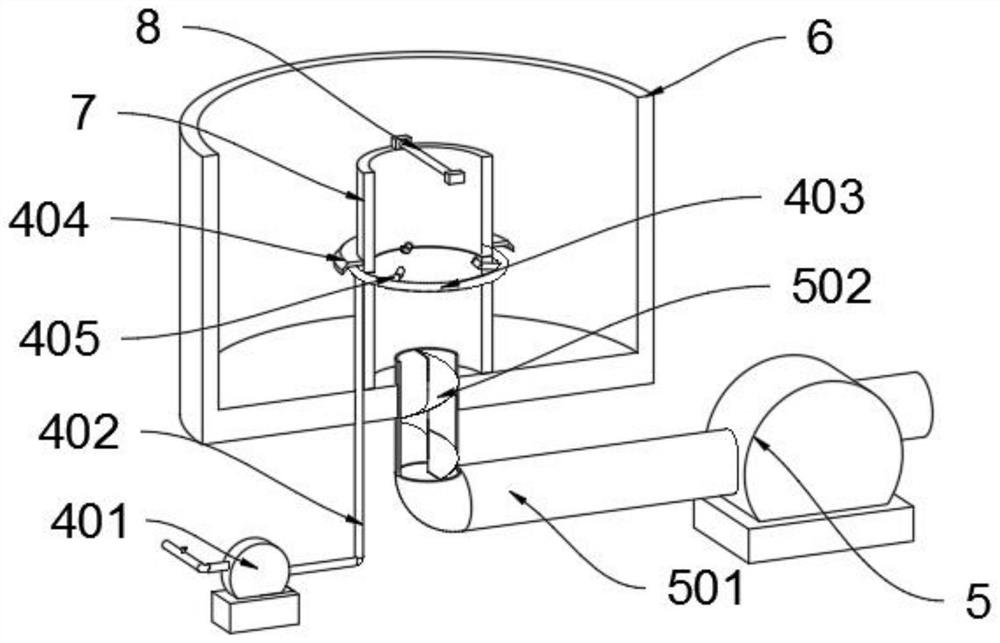

Three-stage high-vacuum oil filter system

ActiveCN106479660AEasy to separateHeating oil filter effect is goodLubricant compositionThree stagePressure reduction

The invention provides a three-stage high-vacuum oil filter system, comprising a vacuum separation system, comprising a vacuum tank and an atomizer arranged in the upper space in the vacuum tank. The three-stage high-vacuum oil filter system has the advantages that as an oil circuit outlet is added, oil can be turned into oil droplets more thoroughly and can be atomized better; as an oil circuit is divided into two paths by a Y-shaped oil spout, which is equivalent to a sudden pressure reduction, oil and water gain a wider diffusion range at the oil circuit outlet, atomizing is more thorough, and it is easier to make separation.

Owner:山东沃特润滑科技有限公司

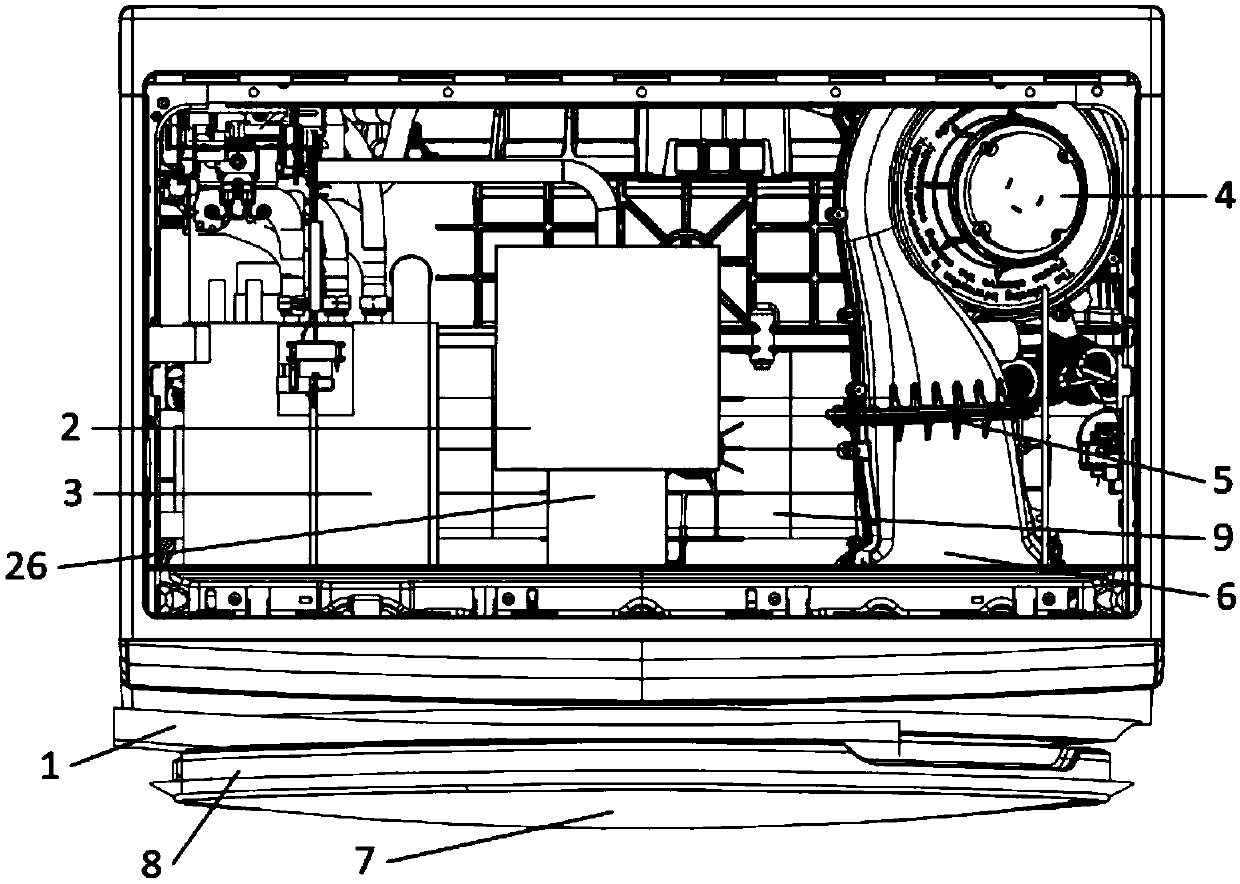

Ultrasonic vapor generating device for clothes processing device

InactiveCN110409134APlay a bactericidal effectReduce residual stressOther washing machinesWashing machine with receptaclesWater storage tankVapor generator

The invention belongs to the technical field of clothes processing, and provides an ultrasonic vapor generating device for a clothes processing device in order to solve the problem that a vapor generating device in an existing washing and drying integrated machine is high in energy consumption and poor in safety. The clothes processing device comprises an outer tub and an inner tub rotationally arranged in the outer tub. The ultrasonic vapor generating device comprises a water storage tank, a water inlet part communicated with the water storage tank and used for pouring water into the water storage tank, an ultrasonic vapor generator arranged in the water storage tank and used for generating vapor, a vapor conveying channel communicated with the water storage tank and used for conveying vapor into the inner tub, and a controller for controlling the operations of the water inlet part and the ultrasonic vapor generator. The ultrasonic vapor generating device is simple in structure and low in manufacturing cost, is low in energy consumption, low in water consumption and high in safety coefficient in the vapor generating process, and is quite good in user experience.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

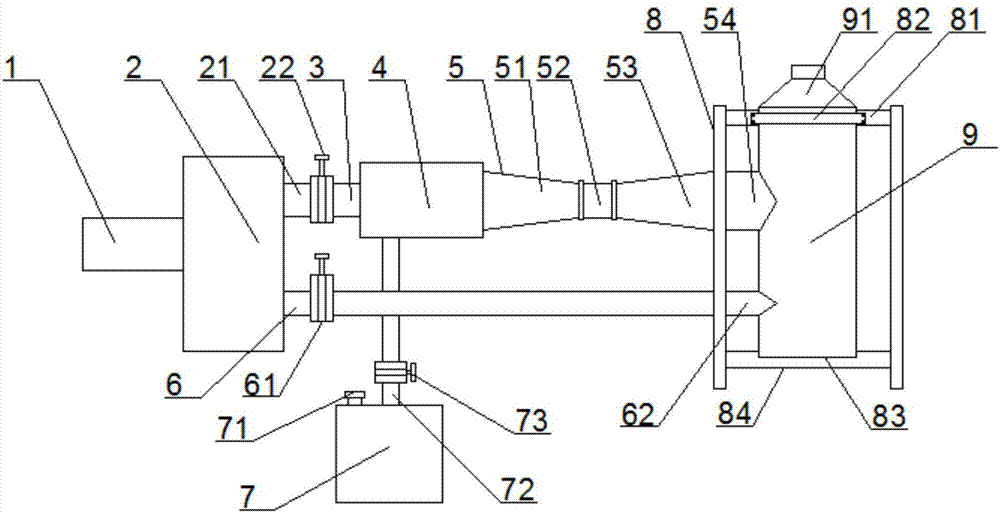

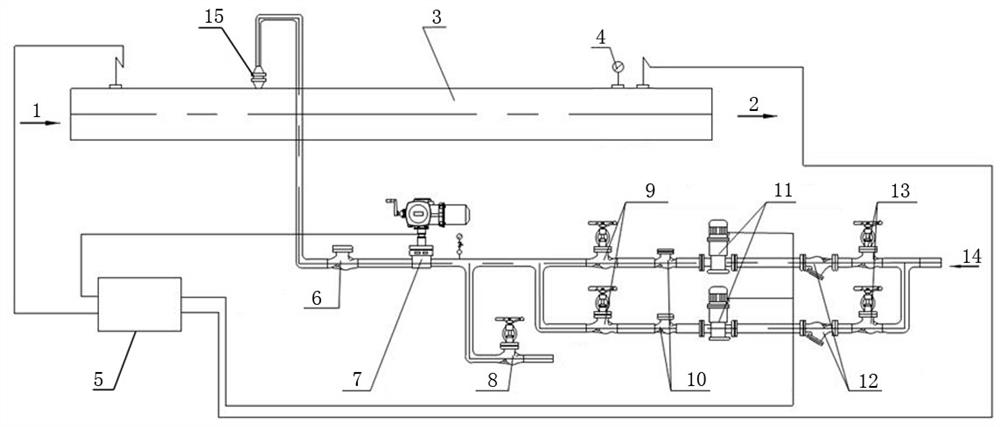

Fuel oil dilute oxygen combustion system

InactiveCN109915821AWell mixedMix thoroughlyCombustion using gaseous and pulverulent fuelBurnersCombustion systemFuel oil

The invention discloses a fuel oil dilute oxygen combustion system comprising a furnace body, a heat exchanger, a smoke backflow pipe, a combustion supporting gas pipe and a combustor body. The combustor body is installed on the furnace body. The two ends of the smoke backflow pipe communicate with the combustor body and a smoke discharge pipe correspondingly. The two ends of the combustion supporting gas pipe communicate with the combustor body and the heat exchanger. The heat exchanger is further connected with the smoke discharge pipe. The combustor body is provided with a fuel oil pipe, acompressed gas pipe, a smoke pipe and multiple combustion supporting pipes. The fuel oil pipe, the compressed gas pipe, the smoke pipe and the combustion supporting pipes are all fixed to an installation plate. A fuel oil atomization mixer is arranged at the end, close to the installation plate, of the fuel oil pipe. The fuel oil atomization mixer is provided with a fuel oil hole and multiple compressed gas holes. The fuel oil hole and the compressed gas holes all communicate with a mixing cavity. The fuel oil hole communicates with the fuel oil pipe, the section of the fuel oil hole firstly shrinks and then keeps unchanged in the fuel oil flowing direction, and a flow distributor is arranged at the narrowest position of the section. The compressed gas holes communicate with the compressedgas pipe, and the section of each compressed gas hole shrinks in the compressed gas direction. Spinning disks are arranged at the positions, close to the installation plate, of the smoke pipe and thecombustion supporting pipes. The fuel oil dilute oxygen combustion system is good in atomized fuel oil, smoke and combustion supporting gas mixing, stable in flameless combustion and capable of saving energy.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

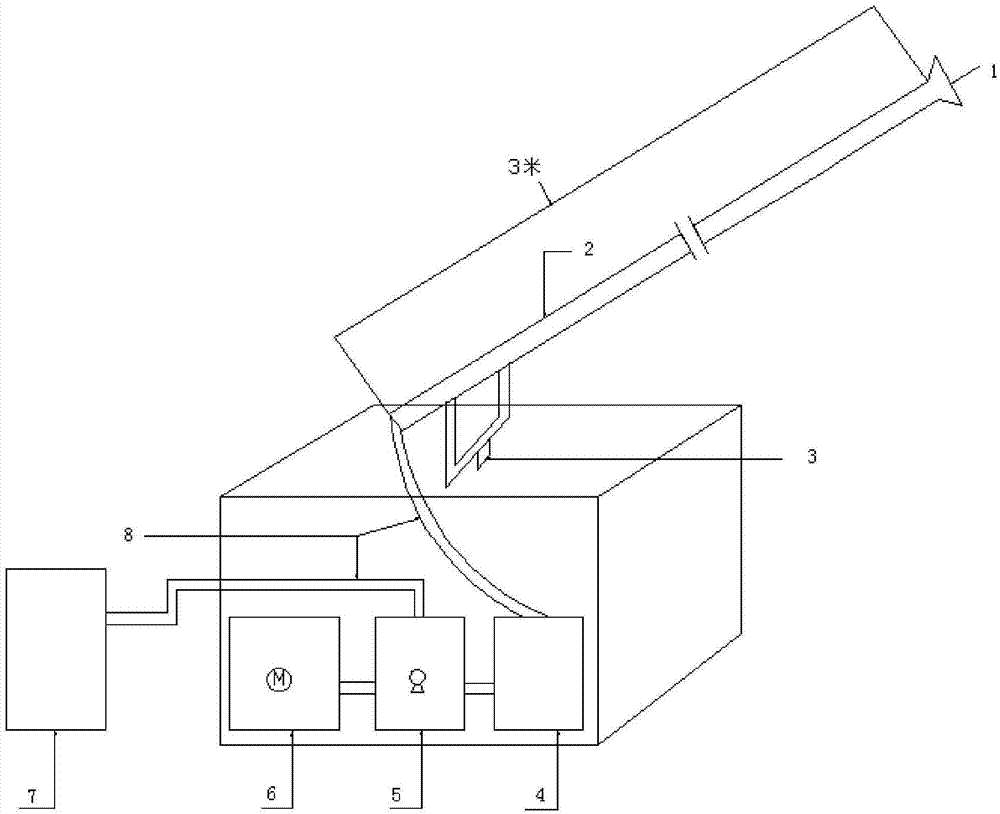

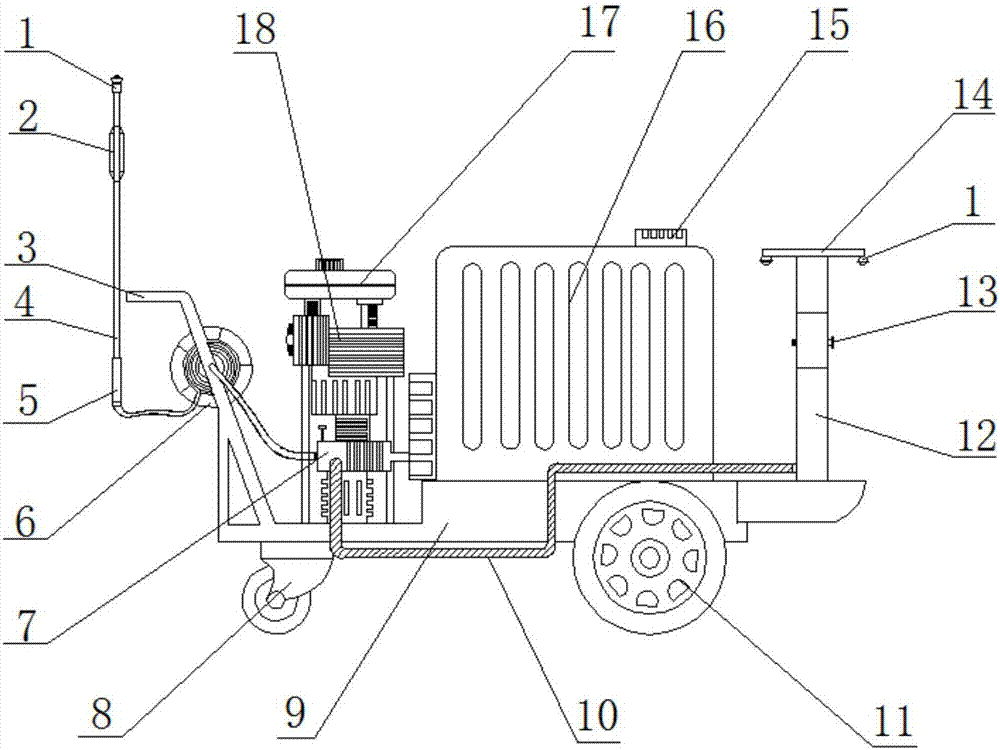

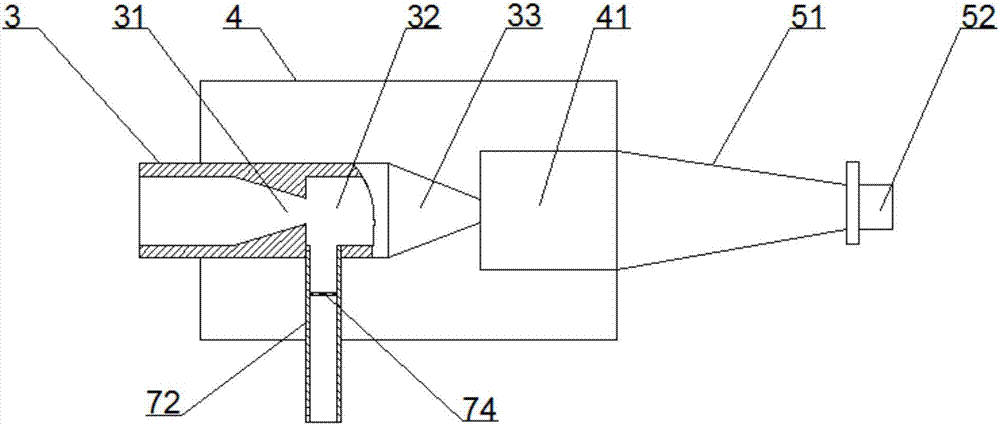

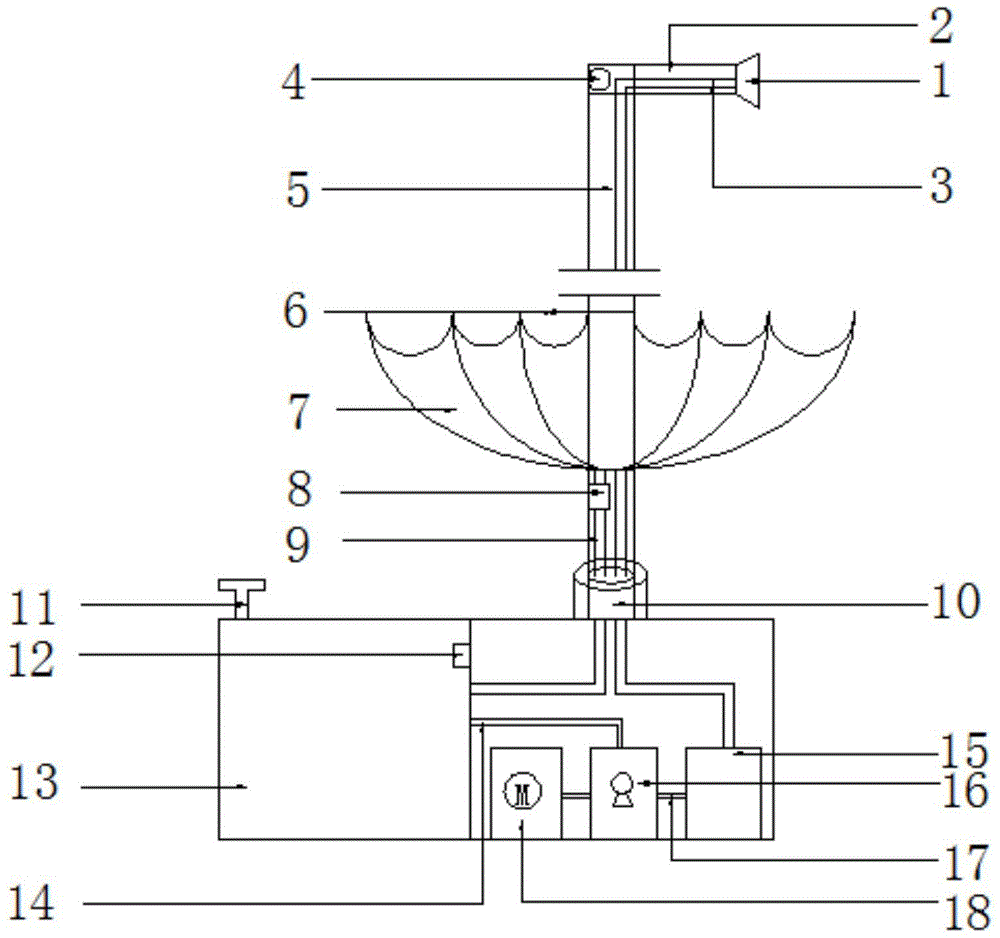

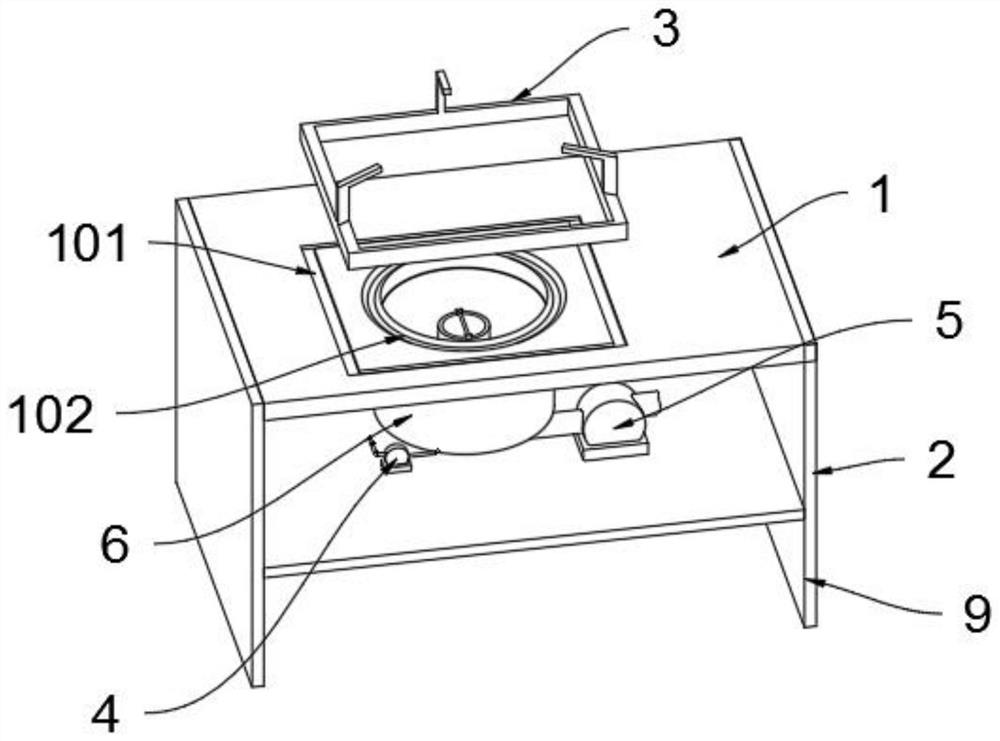

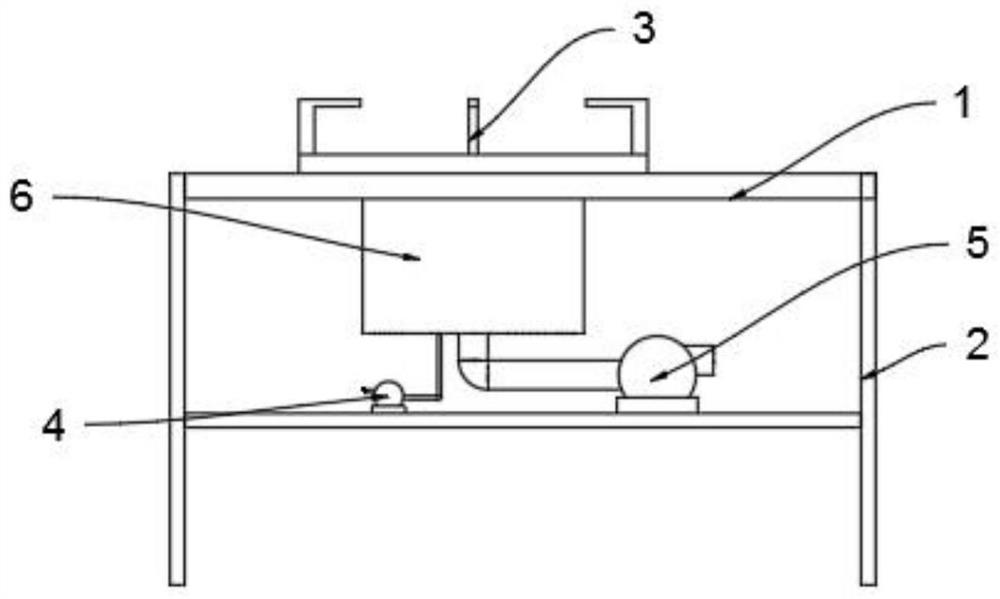

Multifunctional electrostatic water mist spraying machine for controlling atmospheric pollution

ActiveCN104772240ASpray evenlyThorough atomizationSpray discharge apparatusAutomatic controlSpray nozzle

The invention relates to the field of a spraying device, and aims at providing a multifunctional electrostatic water mist spraying machine for controlling atmospheric pollution. The multifunctional electrostatic water mist spraying machine for controlling the atmospheric pollution comprises a spray rod, a spray nozzle, an electrostatic generator, a liquid pump, a motor, an automatic control device and a water pipe, wherein the motor is connected with the liquid pump, the liquid pump is used for pumping and conveying external liquid to the electrostatic generator through the water pipe, the electrostatic generator is used for charging the liquid, the spraying rod is connected with the electrostatic generator through the water pipe, and the spray nozzle is arranged on the spray rod. The multifunctional electrostatic water mist spraying machine for controlling the atmospheric pollution has the advantages that the water mist charges can be better combined with contaminants in the air, so that the atmospheric pollution in the ambient environment is eliminated; in addition, the spraying device can automatically rotate, meanwhile, the spraying at any angle around the axis can be realized through regulating the transverse and longitudinal directions, the high-space spraying operation can be completed, in addition, the spraying is uniform, the atomization is thorough, small water drops are prevented from being formed around the spray nozzle, the spraying dust removal from top to bottom is realized, and greater space is influenced in once spraying.

Owner:ZHEJIANG UNIV

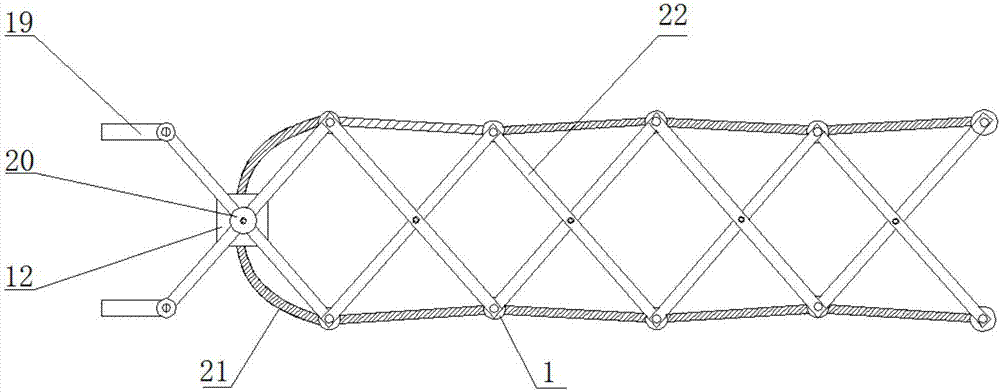

Vegetable planting pesticide spraying machine

InactiveCN107873685AEffective and convenient sprayingThorough atomizationInsect catchers and killersAgricultural engineeringFuel tank

The invention discloses a vegetable planting pesticide spraying machine, comprising a diesel engine, a base, and a water tank. The diesel engine is connected with a water pump in a transmission manner. The water pump is below the diesel engine. The diesel engine is fixedly connected with a fuel tank. The fuel tank is above the diesel engine. The water pump is fixedly connected with the base. The base is under the water pump. A telescopic pesticide spraying rod is used in the novel pesticide spraying machine, and a pesticide spraying range can be adjusted as needed, so as to effectively and conveniently spray pesticides for plants, and manpower is saved. For the novel first pesticide spraying rod, just through adjusting space of a telescopic handle, length of the first pesticide spraying rod can be adjusted through a telescopic support, and the first pesticide spraying rod can be folded and opened conveniently. A novel nozzle is provided with blades, and the blades and pesticide spraying holes are connected through a shaft with holes. When a pesticide passes through the pesticide spraying holes, the pesticide spraying holes can rotate, so atomization of the pesticide is more thorough.

Owner:藤县杰丰生态农业有限公司

Atomizer for electronic smoking set

InactiveCN101986906BThorough atomizationAdd thermal safety deviceTobacco devicesGlass fiberEngineering

The invention discloses an atomizer for an electronic smoking set, which comprises an atomizer, wherein an oil suction device, a gasification device and a power supply device are arranged on the atomizer, through holes are arranged on a cover body and a pipe body of the oil suction device, glass fiber beams are arranged in the pipe body, the gasification device comprises a pipe type ceramic seat,a sealing cover for separating an inner cavity is arranged in the ceramic seat, through holes are arranged on the sealing cover, a heating chamber is formed between one side of the sealing cover and the cover body of the oil suction device, the glass fiber beams extending out of the cover body are accommodated in the heating chamber, heating wires are wound and arranged on the glass fiber beams at the place, a protecting device is arranged on the other side of the sealing cover positioned at outlets of the through holes, one end of the protecting device is connected with the heating wires, and the other end is connected with the power supply device. The traditional mode from nickel screen oil suction to glass fiber wire heating is changed, and the direct oil suction by the glass fiber wires is adopted, so that the atomization is more thorough. A temperature protecting device is added, when the temperature of the atomizer per se reaches 85 DEG C, a circuit can be automatically shut off, thus various safety accidents caused by high temperature can be prevented.

Owner:日本JBS株式会社

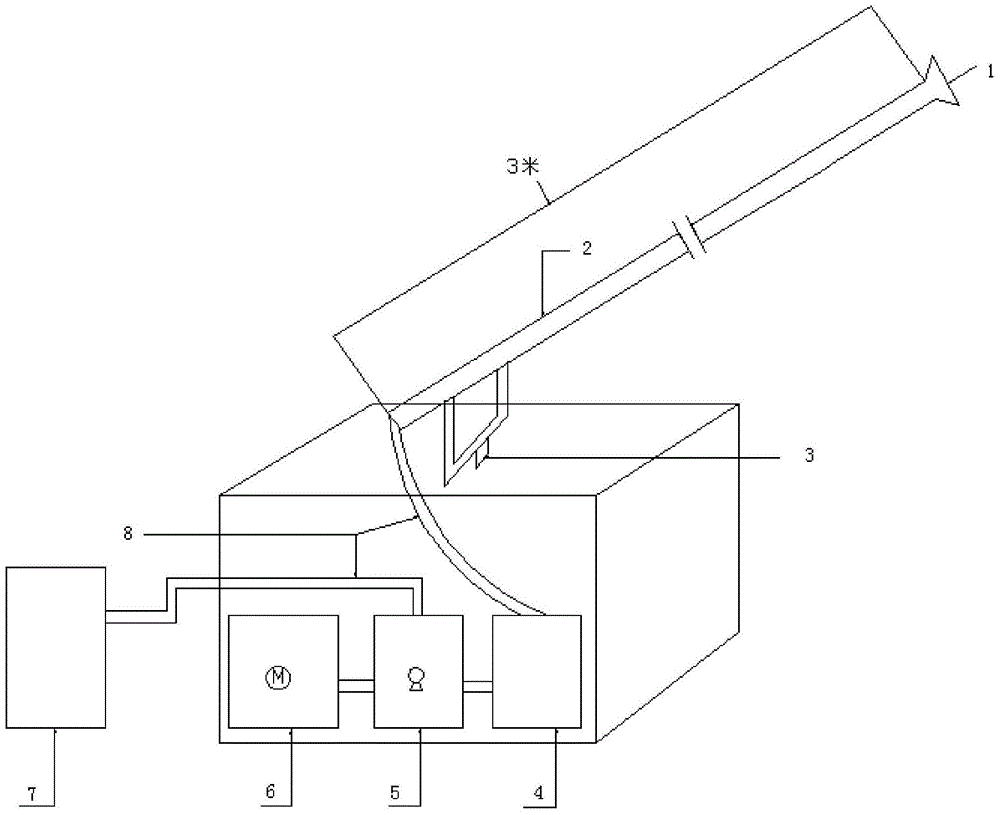

Energy saving and environmental protection vaporizing-type fuel oil burner

The invention discloses an energy saving and environmental protection vaporizing-type fuel oil burner which comprises a high-pressure air inlet and a flame cup. The high-pressure air inlet is connected to the inlet end at the left side of a gas distributor, and a first high-pressure gas pipe and a second high-pressure gas pipe are arranged at the right side of the gas distributor. The first high-pressure gas pipe communicates with a first Venturi tube, and the first Venturi tube penetrates through an atomizer and further communicates with a second atomizing cavity in the atomizer. A first Venturi tube throat part is arranged inside the first Venturi tube, and the lower end of the first Venturi tube throat part is connected with a fuel oil pipe. A first atomizing cavity is formed in the right side of the first Venturi tube throat part and further communicates with the second atomizing cavity through an atomizing nozzle. The second atomizing cavity communicates with a second Venturi tube. The energy saving and environmental protection vaporizing-type fuel oil burner is reasonable in structural design, fuel oil can be atomized more thoroughly through two times of atomization, the fuel oil can be fully burnt, waste gas exhausted after burning is reduced, heat power is more fierce, the heating speed is higher, and the flame temperature of a burning sprayer is raised while energy losses are reduced; and moreover, no liquid pump is required and cost is reduced.

Owner:刘操

Fuel nozzle

InactiveCN104214029AThorough atomizationGuaranteed to workFuel injection apparatusMachines/enginesCombustionHeat losses

The invention relates to a fuel nozzle. The fuel nozzle is characterized by comprising a shell, a fuel preheating device, an oil filter and an oil spray device, wherein the fuel preheating device, the oil filter and the oil spray device are sequentially installed on the shell, an oil circuit is arranged inside the fuel preheating device and communicated with the inside of the shell, a resistance wire is arranged inside the shell, the oil spray device is arranged on the end part of the shell, and fuel directly enters the oil spray device after passing by the oil filter. The fuel nozzle is simple and compact in structure, has characteristics of small size and light weight and is small in heat loss and also capable of effectively improving the combustion efficiency of the fuel.

Owner:HARBIN DONGAN ENGINE GRP

Multifunctional electrostatic water spray machine for air pollution control

ActiveCN104772240BImprove bindingSmooth rotationSpray discharge apparatusAutomatic controlAtmospheric air

The invention relates to the field of a spraying device, and aims at providing a multifunctional electrostatic water mist spraying machine for controlling atmospheric pollution. The multifunctional electrostatic water mist spraying machine for controlling the atmospheric pollution comprises a spray rod, a spray nozzle, an electrostatic generator, a liquid pump, a motor, an automatic control device and a water pipe, wherein the motor is connected with the liquid pump, the liquid pump is used for pumping and conveying external liquid to the electrostatic generator through the water pipe, the electrostatic generator is used for charging the liquid, the spraying rod is connected with the electrostatic generator through the water pipe, and the spray nozzle is arranged on the spray rod. The multifunctional electrostatic water mist spraying machine for controlling the atmospheric pollution has the advantages that the water mist charges can be better combined with contaminants in the air, so that the atmospheric pollution in the ambient environment is eliminated; in addition, the spraying device can automatically rotate, meanwhile, the spraying at any angle around the axis can be realized through regulating the transverse and longitudinal directions, the high-space spraying operation can be completed, in addition, the spraying is uniform, the atomization is thorough, small water drops are prevented from being formed around the spray nozzle, the spraying dust removal from top to bottom is realized, and greater space is influenced in once spraying.

Owner:ZHEJIANG UNIV

Fog eliminating and dust reducing device

InactiveCN105617806AImprove bindingImprove universalityCombination devicesUsing liquid separation agentThermodynamicsElectric control

The invention relates to the technical field of air pollution treatment, in particular to a fog eliminating and dust reducing device which comprises a pneumatic flow ejector, a nitrogen adding system, a powder adding system, a spraying system and an electric control box connected with components and controlling the same. The nitrogen adding system, the powder adding system and the spraying system are all connected with the pneumatic flow ejector, and a rotary supporting system matched with the pneumatic flow ejector is arranged at the bottom of the pneumatic flow ejector. The fog eliminating and dust reducing device is compact in structure, convenient to operate and suitable for various working condition environments.

Owner:叶伟武

A device for controlling air pollution and smog in public open spaces

ActiveCN104815496BImprove bindingAvoid formingUsing liquid separation agentElectrostatic spraying apparatusAutomatic controlAtmospheric air

The invention relates to the field of spraying device and aims at providing a device for treating atmospheric pollution ad haze in a public open space. The device for treating the atmospheric pollution ad haze in the public open space comprises a water supply device, an execution device and a collection device. The water supply device adopts a liquid reservoir and is used for storing liquid. The execution device comprises a spray nozzle, a combined spray rod, an automatic control system, a motor, a liquid pump and an electrostatic generator. The collection device comprises a collector, a sensor and a filter and is used for recovering rainwater or spraying mist drips sprayed by the spray nozzle. Water mist can be well combined with pollutants in atmosphere, and accordingly surrounding atmospheric pollution is removed. The device can complete higher space spraying operation, is even in mist spraying and thorough in atomization, prevents small water drops from being formed around the spray nozzle, achieves mist spraying from top to bottom and removes the atmospheric pollution ad haze, and the space influenced by one-time spraying is larger.

Owner:ZHEJIANG UNIV

Environment-friendly composite dust-reducing agent for power plant coal handling system

InactiveCN104017543BQuick dustAvoid secondary dustOther chemical processesEngineeringHandling system

The invention discloses a power plant coal conveying system environment-friendly type composite dust depositing agent, which comprises the following components by weight: 20-40% of surfactant, 1-20% of coagulation agent, 30-40% of moisture absorbent, 0.1-1% of antifoaming agent and the balance of water. The dilution proportion of the dust depositing agent can be freely adjusted between 1: 200 and 1: 2000, dust depositing can be rapidly realized, and reentrainment of dust can be avoided in a long time.

Owner:SHANGHAI YICHEN AUTOMATION TECH

Fog dissipation and dust falling device

InactiveCN105944474AImprove bindingImprove universalityCombination devicesUsing liquid separation agentSupporting systemEngineering

The invention relates to the technical field of air pollution treatment and particularly relates to a fog dissipation and dust falling device. The fog dissipation and dust falling device comprises a wind force ejector, a nitrogen adding system, a powder adding system, an atomization system and an electric control cabinet for connecting and controlling all the components, wherein the nitrogen adding system, the nitrogen adding system and the atomization system are connected with the wind force ejector; and a rotary supporting system adaptive to the wind force ejector is arranged at the bottom of the wind force ejector. The device is the fog dissipation and dust falling device which is compact in structure and convenient to operate and can be suitable for a plurality of types of working condition environments.

Owner:叶伟武

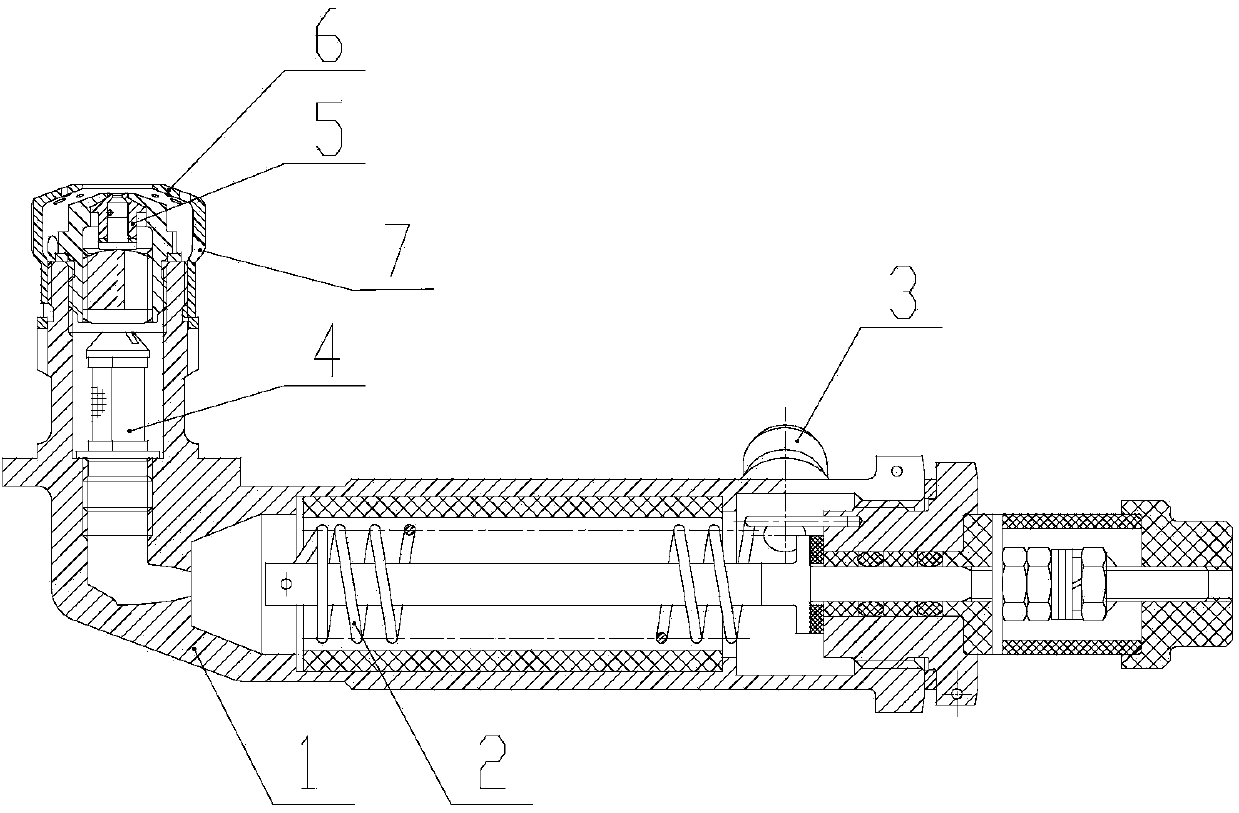

Air heating type fuel economizer

InactiveCN103603752AThorough atomizationExacerbated thermal movementMachines/enginesThermal treatment of fuelEngine powerVacuum chamber

An air heating type fuel economizer comprises a casing, a partition plate, a water inlet pipe, a water outlet pipe, a valve, a vacuum chamber, a mandril and a sealing piece. The casing is a hollow pipe with openings at two ends, and a water cavity is arranged in the lateral wall of the casing. The partition plate is arranged in the cavity of the casing and divides the cavity of the casing into an air inlet cavity and an air outlet cavity along the axial direction. Air holes are formed in the partition plate so as to enable the air inlet cavity to be communicated with the air outlet cavity. The water inlet pipe is fixedly arranged on the casing outer wall, and an inner cavity of the water inlet pipe is communicated with the water cavity. The water outlet pipe is fixedly arranged on the casing outer wall, and an inner cavity of the water outlet pipe is communicated with the water cavity. The valve is arranged at the air outlet cavity port position so as to control opening or closing of an air outlet cavity port. The vacuum chamber is arranged on the partition plate. One end of the mandril is fixedly connected with the valve, and the other end of the mandril extends into the vacuum chamber. The sealing piece is arranged at one end of the mandril extending into the vacuum chamber. By heating the air, fuel atomization is thorough, engine power is increased, oil consumption is reduced, energy is saved, and the environment is protected.

Owner:南宁明航节能科技有限公司

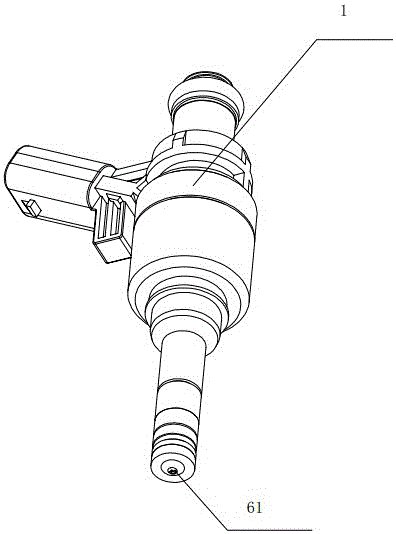

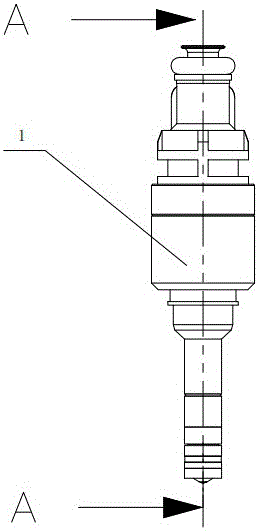

an engine fuel injector

ActiveCN103410647BReduce volumeQuick liftFuel injection apparatusMachines/enginesFuel oilPetroleum engineering

Owner:WENZHOU BATON ELECTRONICS TECH

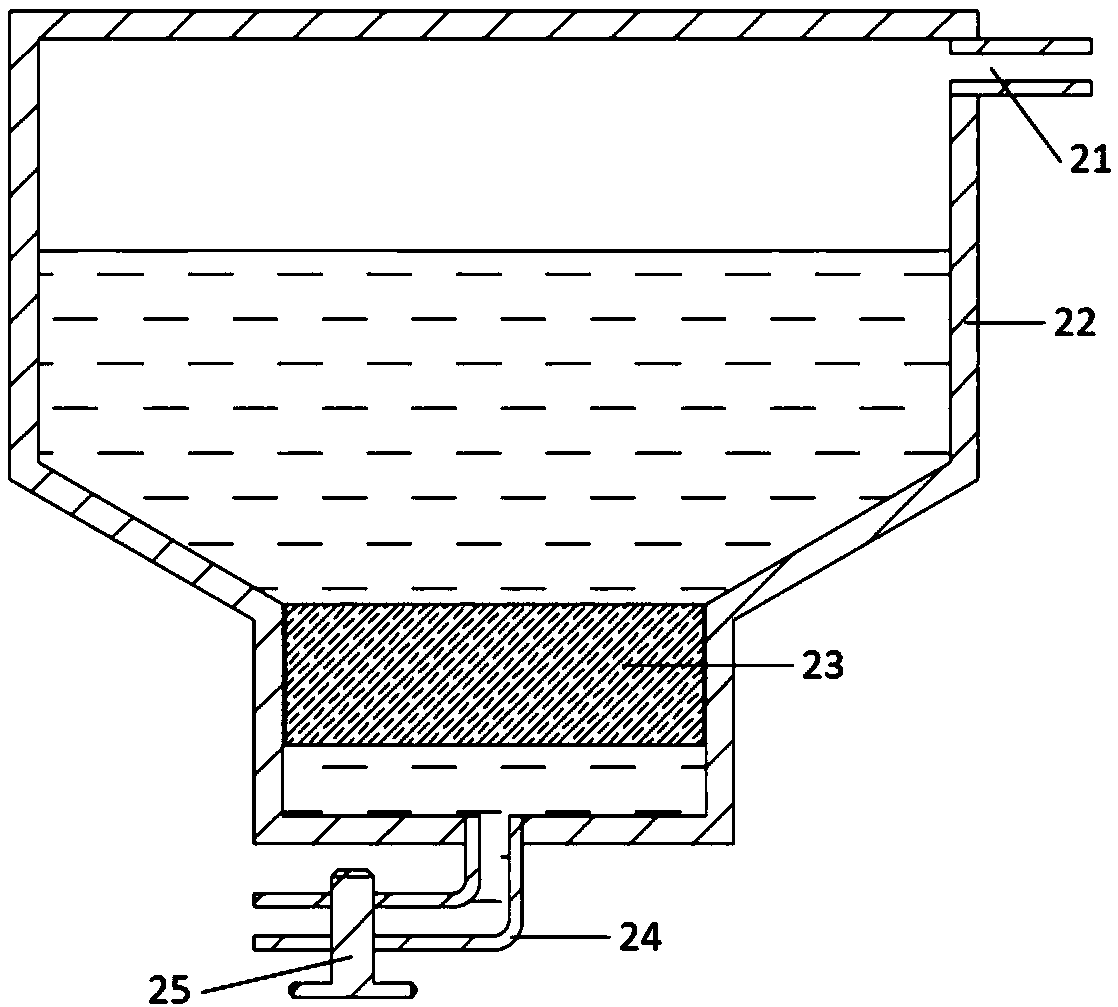

Device for improving titanium tetrachloride refining heat exchange efficiency and method thereof

PendingCN113353975AReduce demandHigh trafficChemical industryTitanium tetrachlorideSteam pressureSteam line

The invention relates to a device for improving titanium tetrachloride refining heat exchange efficiency and a method thereof, the device comprises a water atomization device and a vaporization unit, a spray head in the water atomization device is installed on a steam pipeline at the inlet end of a heat exchanger and is used for spraying water mist into the steam pipeline, and the spray head is arranged at the position, close to the superheated steam inlet end, of the steam pipeline; the vaporization unit is a venturi tube, and the venturi tube is arranged in the steam pipeline at the downstream of the spray head and used for vaporizing the water mist and mixing the vaporized water mist with the superheated steam to obtain saturated steam; according to the method for improving the titanium tetrachloride refining heat exchange efficiency, the superheated steam is converted into saturated steam, and the steam temperature is reduced. On one hand, the problem that the refining yield is influenced by outsourcing steam flow fluctuation in winter can be solved, and production is met under low steam pressure; on the other hand, steam can be directly saved by 3-4 t / h, and cost reduction and efficiency improvement are achieved.

Owner:洛阳双瑞万基钛业有限公司

Gas-water mixing bubbler

InactiveCN102359154BFull grainEnlarged jet impact surfaceWater resource protectionDomestic plumbingWater savingWater flow

The present invention discloses a gas-water mixing bubbler. The gas-water mixing bubbler comprises a body, a splitter and an insertion part. The body is hollow, and forms an assembly hole. The insertion part and the splitter are arranged and connected inside the assembly hole. The body is provided with a suction hole, wherein the internal of the suction hole and the external of the suction hole are penetrated. The splitter is provided with jet flow holes. The insertion part comprises a lower-layer grid portion and an upper-layer grid portion. The lower-layer grid portion comprises a plurality of spokes. The upper-layer grid portion comprises a plurality of round rods, wherein the round rods are arranged concentrically. The round rods form fixed connections with the spokes. The round rods are provided with plural pairs of projections, wherein the projections form annular arrays. Each pair of the projection is respectively convexly arranged on the inner rod surface and the outer rod surface of the round rod, and is matched to form a cylinder. The positions of the cylinders are relative to the fixed connection positions of the round rods and the spokes. The position of the upper end surface of the cylinder is at the same level as the position of the upper end surface of the round rod. The jet flow holes of the splitter are corresponding to the cylinders of the insertion part, such that the water flow passes through the jet flow holes, and directly impacts on the cylinders of the insertion part. The gas-water mixing bubbler has the following advantages that: the jet flow impacting opportunity is increased, the multiple impacting opportunities of the jet flow are increased, the water-saving effect is excellent, and the water particles are full.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Anti-crystallization freeze-crack urea nozzle

ActiveCN113565605BReduce vibrationExtended service lifeInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

Owner:YANTAI YINGDE PRECISION MASCH CO LTD

Bubble former

InactiveCN102205212BReduce volumeLess materialFlow mixersTransportation and packagingWater flowEngineering

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Bubbler

ActiveCN102210988BIncreased jet collision chanceIncreased jet multiple collision chanceWater resource protectionFlow mixersWater savingInhalation

The invention discloses a bubbler, which comprises a body (100), a diverter (200) and an insert (300), the diverter (200) and the insert (300) are assembled into the body (100), and the body (100) is provided with an air suction hole (110) penetrating inside and outside. The water flow is affected by the flow divider (200) to form a jet. Mixing, the insert (300) includes a plurality of bottom partitions (310), a plurality of middle partitions (320) and a plurality of upper bosses (330) fixed together, and the adjacent bottom partitions (310) A channel (340) is formed between the adjacent middle partition (320), and the collision surface of the upper convex column (330), the collision surface of the middle partition (320) and the collision surface of the bottom partition (310) form a spaced along the direction (X). three floors. It has the following advantages: increase the chance of jet collision, increase the chance of multiple collisions of jet, good water saving effect, and full water particles.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Method for producing biomass oil from straws

PendingCN111849534AMild production conditionsLow equipment requirementsLiquid hydrocarbon mixture productionHydrocarbon oils treatmentOrganic acidDepolymerization

The invention discloses a method for producing biomass oil from straws. The method is characterized by comprising the following steps: (1) washing and drying a straw material; (2) crushing the straw material; (3) preparing a straw depolymerization solvent, wherein the volume ratio of organic acid to hydrogen peroxide is 24: 1-22: 3; (4) depolymerizing the straw powder in a solvent under the conditions that the pressure is normal, the temperature is 30-70 DEG C, the solid-to-liquid ratio of the straw powder to the depolymerizing solvent is 1: 12-1: 60, the mechanically stirring rotating speed of 90-150rpm, and the depolymerizing time is 12-48h; (5) filtering a depolymerizing product at normal temperature and normal pressure, and carrying out solid-liquid separation; and (6) rectifying the separated liquid to remove the organic acid solvent, and adding ethanol to prepare the biomass oil.

Owner:GUIZHOU INST OF TECH

A single-hole atomizing fuel injector and its swirl atomizing structure

ActiveCN107956619BThorough atomizationFine granularityFuel injection apparatusMachines/enginesSprayerEngineering

The invention discloses a swirl atomizing structure of a single-hole atomizing oil sprayer and further discloses the single-hole atomizing oil sprayer. The swirl atomizing structure comprises a pipe body, a valve seat, a swirl piece and a metering piece, a first mounting groove is formed in the top end of the valve seat, a second mounting groove is formed in the bottom end of the valve seat, and the first mounting groove and the second mounting groove communicate with each other through a valve hole. The swirl piece is tightly attached to the bottom face of the second mounting groove, and themetering piece is tightly attached to the bottom face of the swirl piece. A swirl hole is formed in the swirl piece, and a metering hole is formed in the metering piece. A plurality of swirl grooves are formed in the swirl piece. After a fluid passes through the valve hole, under the effect of the swirl grooves, a fluid beam is impacted to form a turbulent flow or a swirl flow distributed in the swirl groove direction, then when the fluid passes through the metering hole, the atomizing effect is obviously improved, the fluid is more thoroughly atomized, the particle size of atomized particlesis more fine, the fuel oil atomizing effect is improved, mixing and sufficient combustion of fuel oil and air are facilitated, carbon is prevented from being accumulated in a cylinder, and the vehicleemission cleanness is improved. The single-hole atomizing oil sprayer has the beneficial effects.

Owner:GUANGXI CARTIER TECH CO LTD

Acetanilide and high-efficiency synthesis method thereof

ActiveCN108440326AIncrease profitReduce generationOrganic compound preparationCarboxylic acid amides preparationChemical industrySodium acetate

The invention discloses acetanilide and a high-efficiency synthesis method thereof, and belongs to the field of chemical industry. The high-efficiency synthesis method comprises the following steps: atomizing aniline to obtain a first raw material, mixing concentrated hydrochloric acid and water, then atomizing to obtain a second raw material, sending the first raw material and the second raw material into a mixing chamber, and mixing to obtain a mixed material; stirring a sodium acetate solution, and introducing acetic anhydride into the sodium acetate solution while an inert gas obtained bypreheating the mixed material to 180-200 DEG C is brown into the sodium acetate solution. By the high-efficiency synthesis method, the reaction efficiency is high, the continuity is good, the reactioncan start and stop at any time, and the flexibility is good. The acetanilide is prepared according to the high-efficiency synthesis method, and is high in purity, low in cost and convenient to prepare.

Owner:新乡市锦源化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com