Patents

Literature

32results about How to "Enhanced spray atomization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

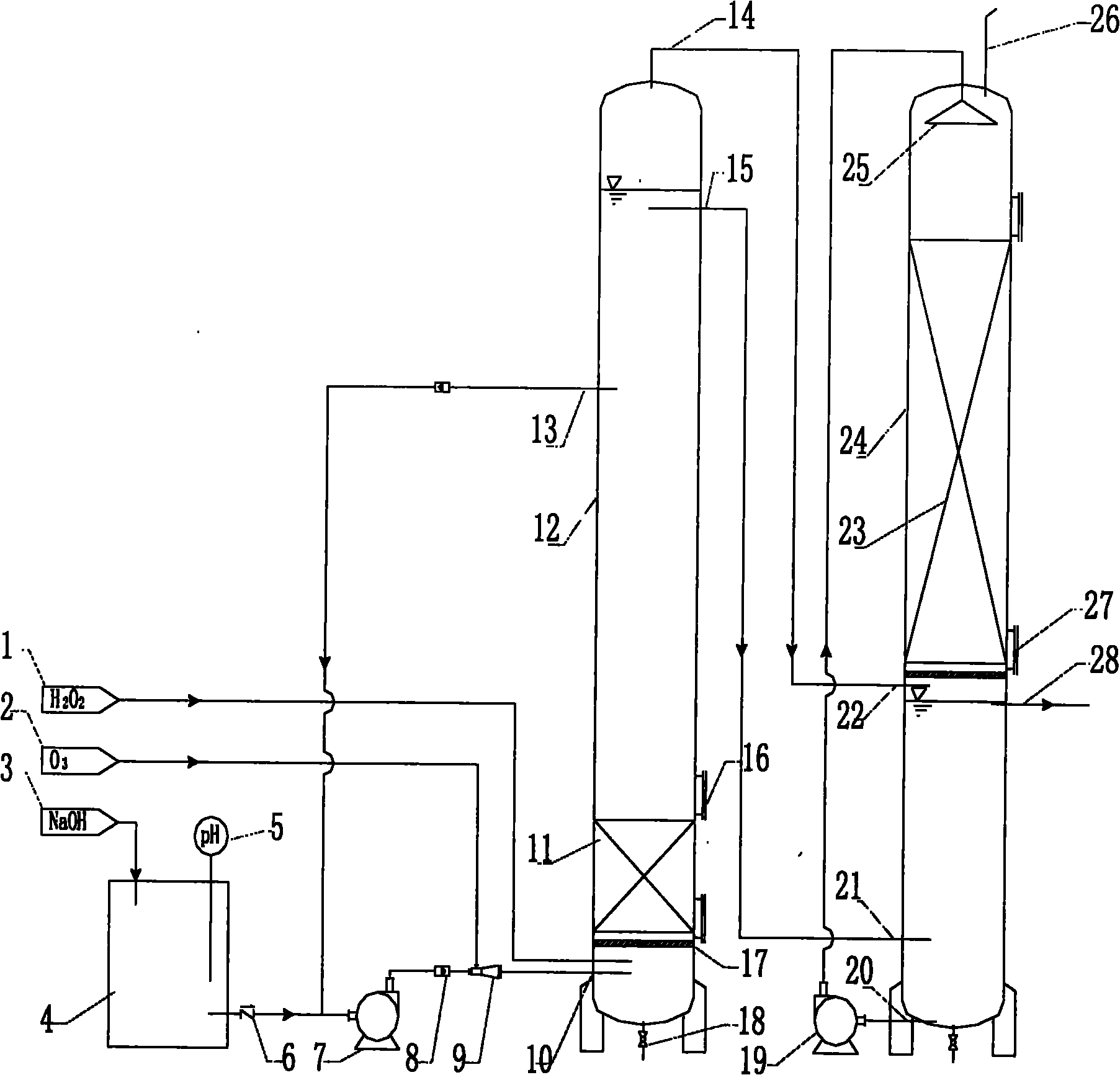

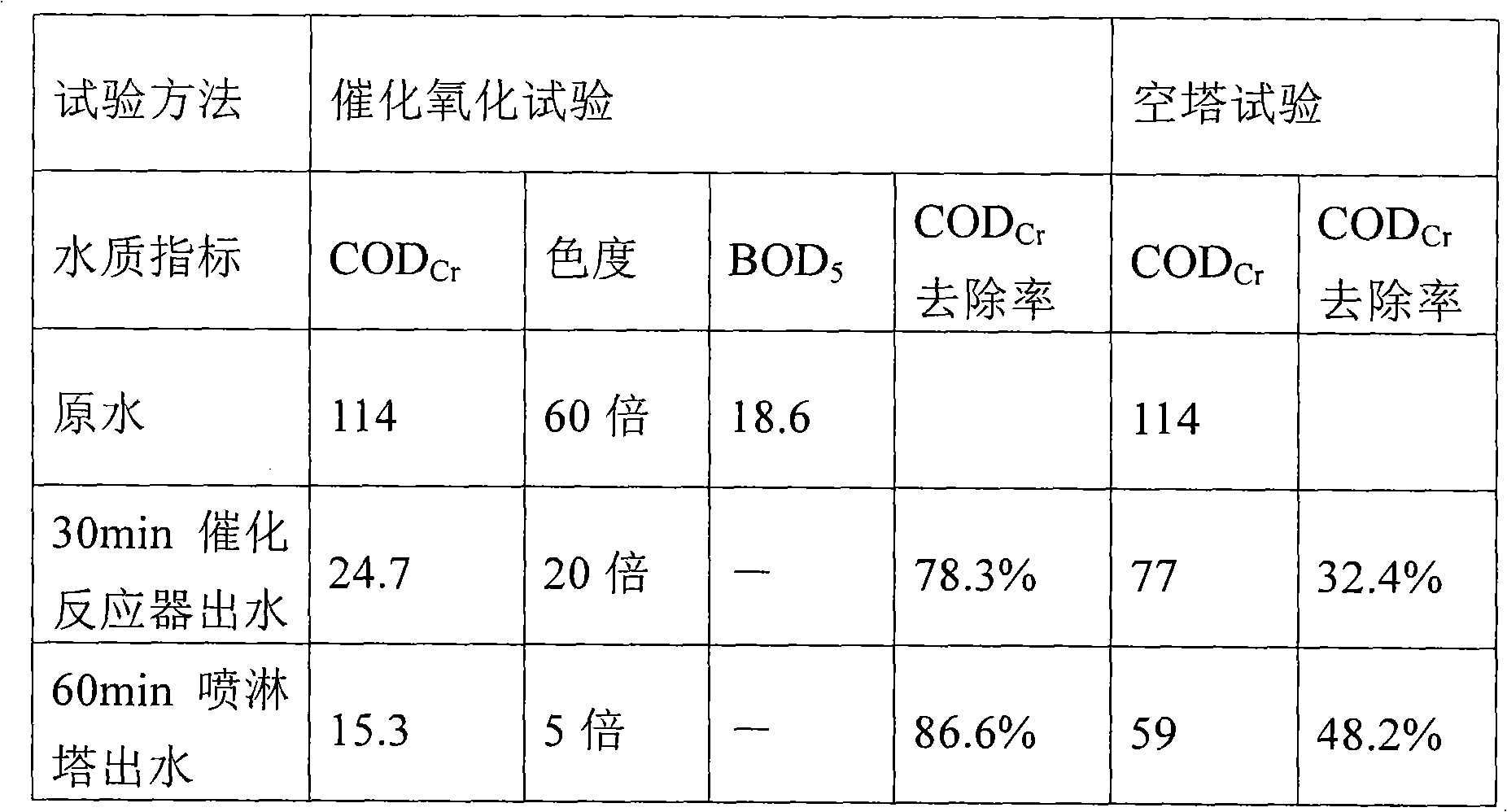

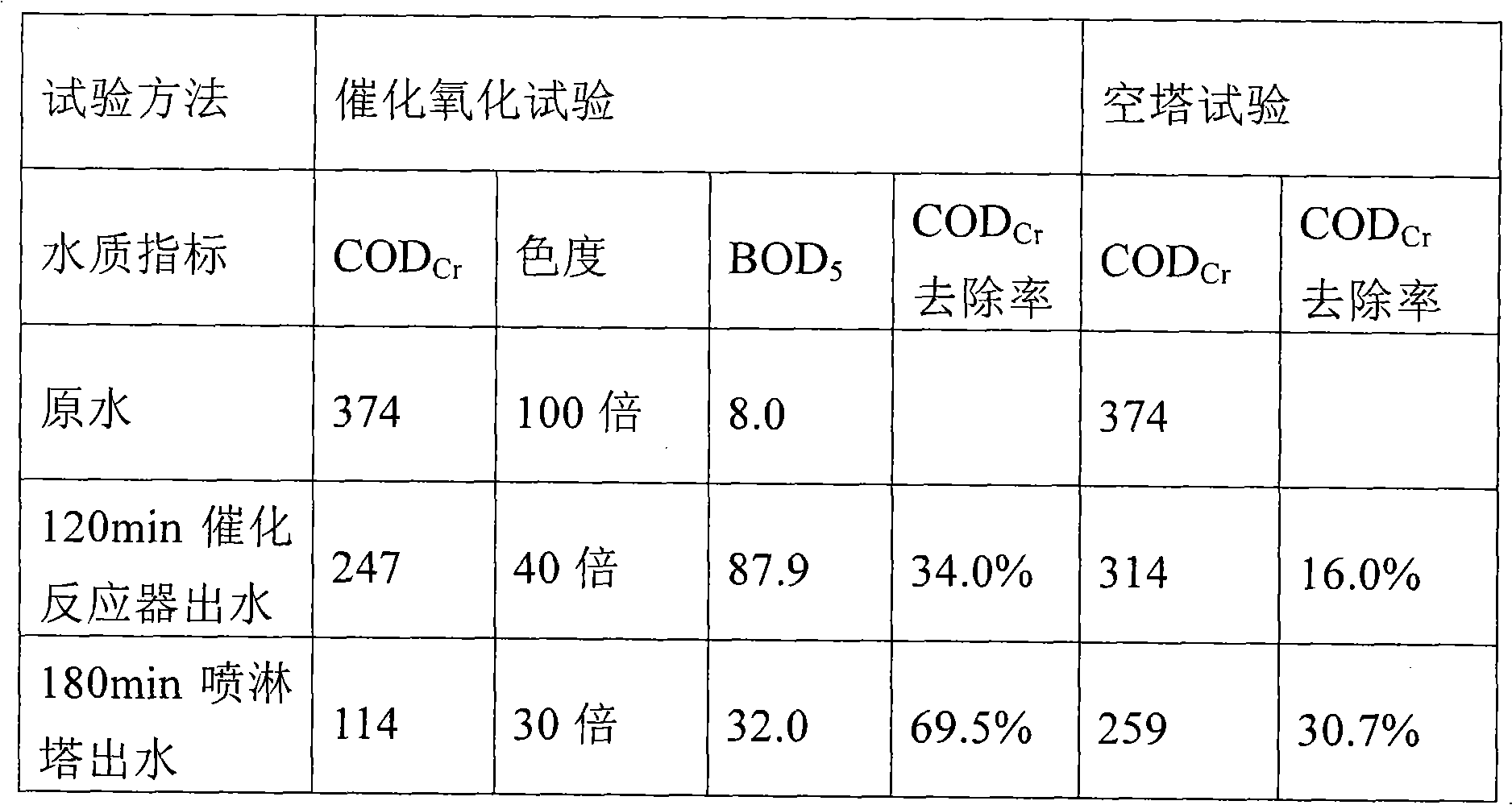

Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

ActiveCN101781036AIncrease contact areaImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentWastewaterPh regulation

The invention provides equipment and a method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone. The equipment comprises a feeding system, an ozone catalytic reaction tower and a spray absorbing tower; the feeding system comprises a wastewater pH regulation device, a wastewater feeding pipeline, a hydrogen peroxide aqueous solution feeding pipeline, an ozone feeding pipeline and a pH regulator feeding pipeline; the wastewater pH regulation device is communicated with the wastewater feeding pipeline and the pH regulator feeding pipeline respectively; the ozone feeding pipeline is communicated with the wastewater feeding pipeline; the ozone catalytic reaction tower is communicated with the wastewater feeding pipeline and the hydrogen peroxide aqueous solution feeding pipeline respectively so that wastewater undergoes once catalytic reaction in the presence of a first catalyst to generate a liquid flow and an ozone tail gas flow which are subjected to initial treatment; and the spray absorbing tower is communicated with a catalytic reaction system, is used for spraying at least one part of the liquid flow which is subjected to the initial treatment, and is contacted with the ozone tail gas flow in the presence of a second catalyst to undergo second catalytic reaction.

Owner:ENN ENVIROTECH CO LTD

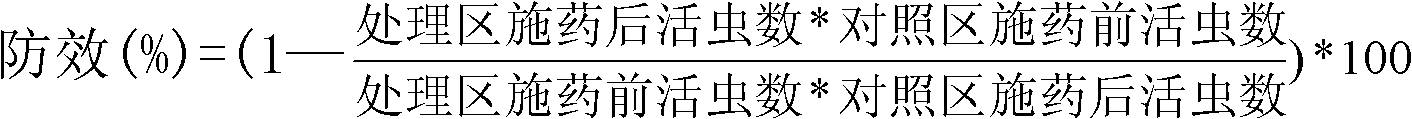

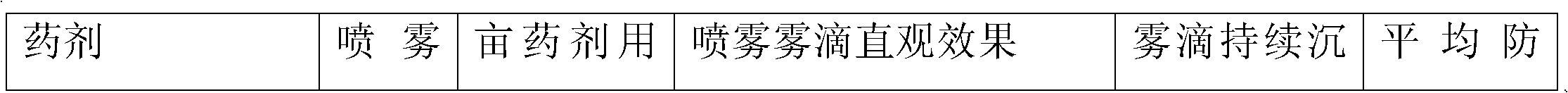

A kind of pesticide adjuvant and preparation method thereof

A pesticide additive of the present invention, by selecting a suitable solvent, cosolvent, viscosity reducer, penetrant type and ratio, the additive system has reasonable volatility, density, flash point, viscosity, and adhesion, and can A certain amount of pesticide active ingredients are fully dissolved, and the preparations of insecticides, fungicides, and plant growth regulators formulated with this adjuvant can be directly used in ultra-low volume without any change or addition of additives. Spraying or spraying with a hot fog machine is used for preventing and controlling pests and diseases on crops or promoting effective tillering of crops; meanwhile, a preparation method of the pesticide adjuvant is also disclosed.

Owner:GAUNGXI TIANYUAN BIOCHEM

Steel plate minimum spangle galvanizing spray art

InactiveCN101545085ALow viscosityImprove atomization effectHot-dipping/immersion processesSheet steelAir knife

The invention discloses a steel plate minimum spangle galvanizing spray art, comprising that: the steel plate is heated by a heating stove and reduced to enter a zinc kettle for galvanizing and an air knife scrapes the excessive zinc liquor; the steel plate is sprayed and cooled by a minimum spangle machine on the surface to form a minimum spangle; the surface of the minimum spangle steel plate obtained in the step 2 is finished, wherein the diameter of the nozzle of the minimum spangle is 1.5-3 mm, water pressure is 1.5-4 bars, compressed-air pressure is 1.4-6 bars, the distance between the nozzle of the minimum spangle machine and the air knife is regulated to 400-600 mm, preferred 500 mm and the cooling water in the minimum spangle machine intake pipe is preheated to 30-50 DEG C. By checking-out, the plated surface spangle of the minimum spangle galvanizing steel plate removes the grain boundary and is suitable for subsequent coating. The subsequent coating plated surface is smooth and the oil paint quantity can be saved by 8% when the film thickness is 15 mum.

Owner:福建凯景新型科技材料有限公司

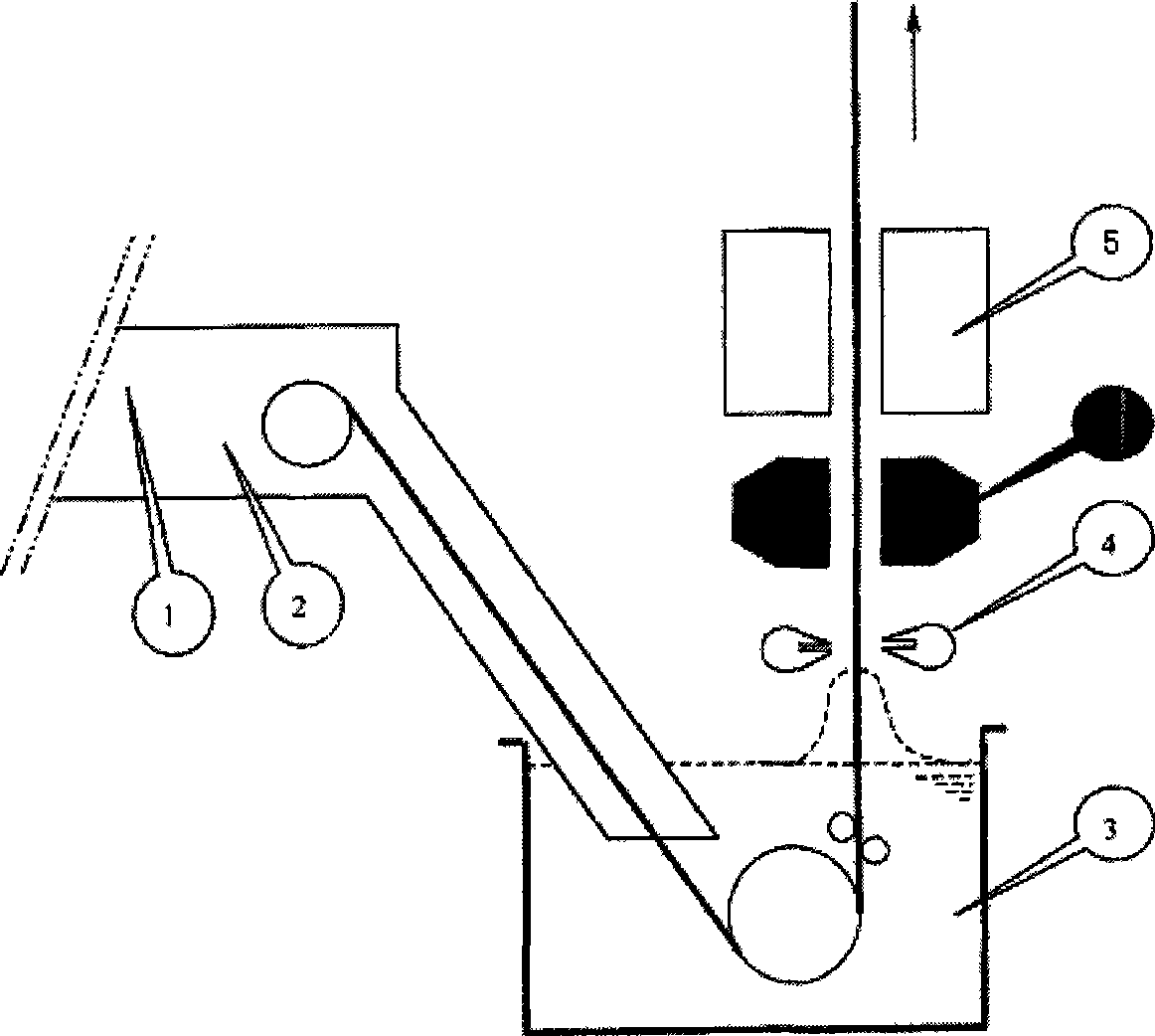

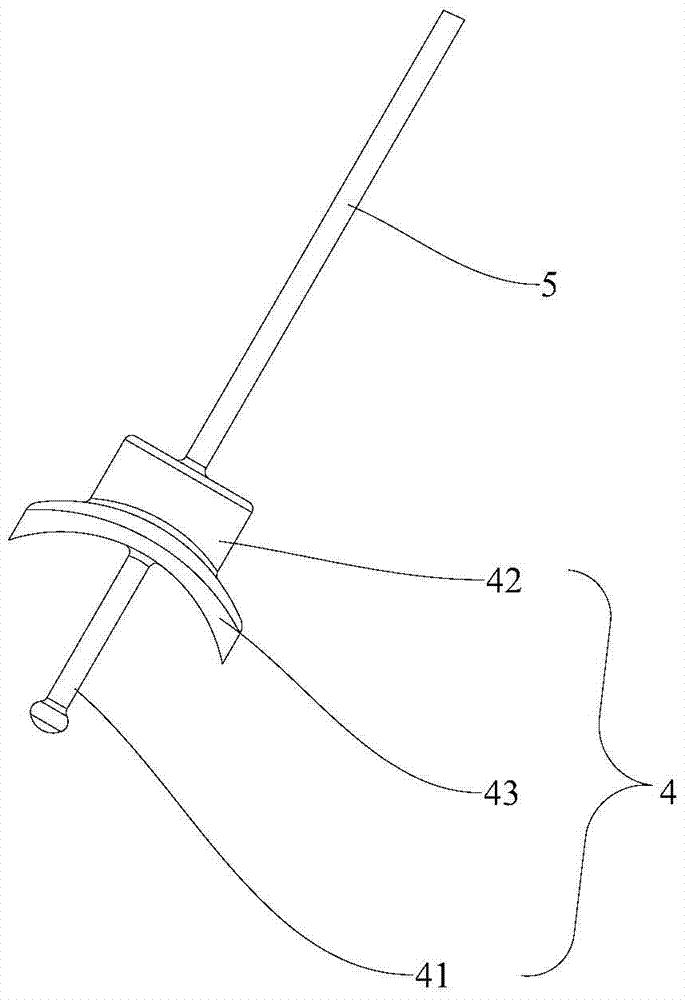

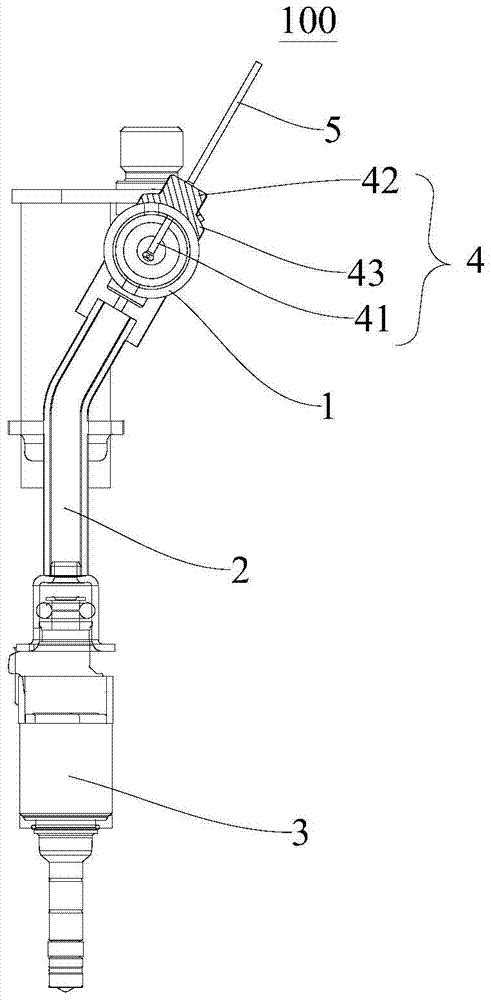

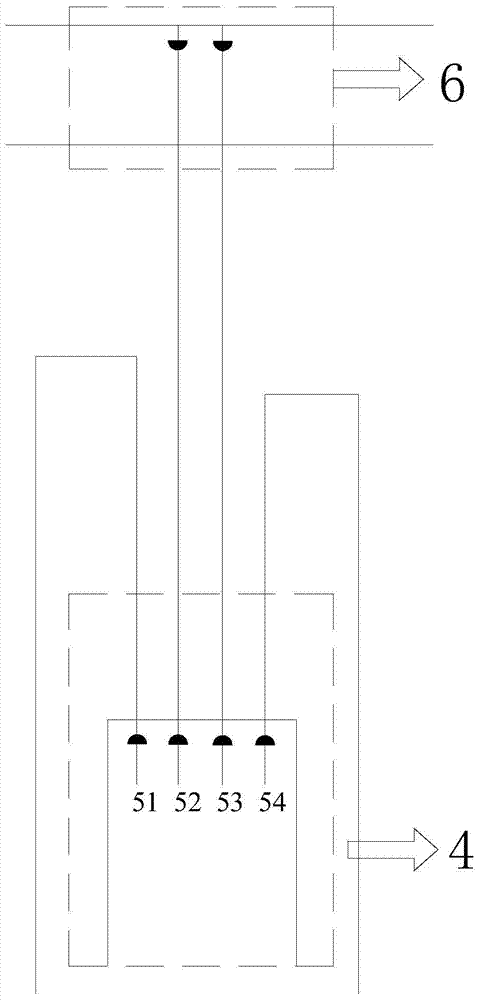

Gasoline engine spark plug, ignition method thereof and detection method

InactiveCN108512036AGuaranteed successful startupPrevent tank floodingSparking plugsElectric ignition installationGasolineEngineering

The invention provides a gasoline engine spark plug, which comprises a center electrode part and a grounding electrode part arranged around the center electrode part, wherein the center electrode partis provided with a wiring screw, an insulator arranged around the wiring screw and a center electrode which is arranged at the tail end of the wiring screw in a mode of being integrated with the wiring screw and protrudes from the insulator, the grounding electrode part comprises a metal shell and a grounding electrode which extends out from the metal shell at the tail end of the metal shell, andthe grounding electrode and the center electrode are arranged opposite to each other at an interval so as to form an air gap. The gasoline engine spark plug is further provided with an electromagnetic induction heating coil, wherein the electromagnetic induction heating coil is close to the tail end of the grounding electrode part and the tail end of the center electrode part and located betweenthe center electrode part and the grounding electrode part. The invention further provides an ignition method of the spark plug, which comprises a step of heating the spark plug before the ignition. The gasoline engine spark plug enables an automobile to normally start at a low temperature, enables the engine temperature to quickly rise to the normal operating temperature, and is small in pollution and capable of removing carbon deposition and prolonging the service life of the engine.

Owner:HITACHI AUTOMOTIVE SYST SUZHOU

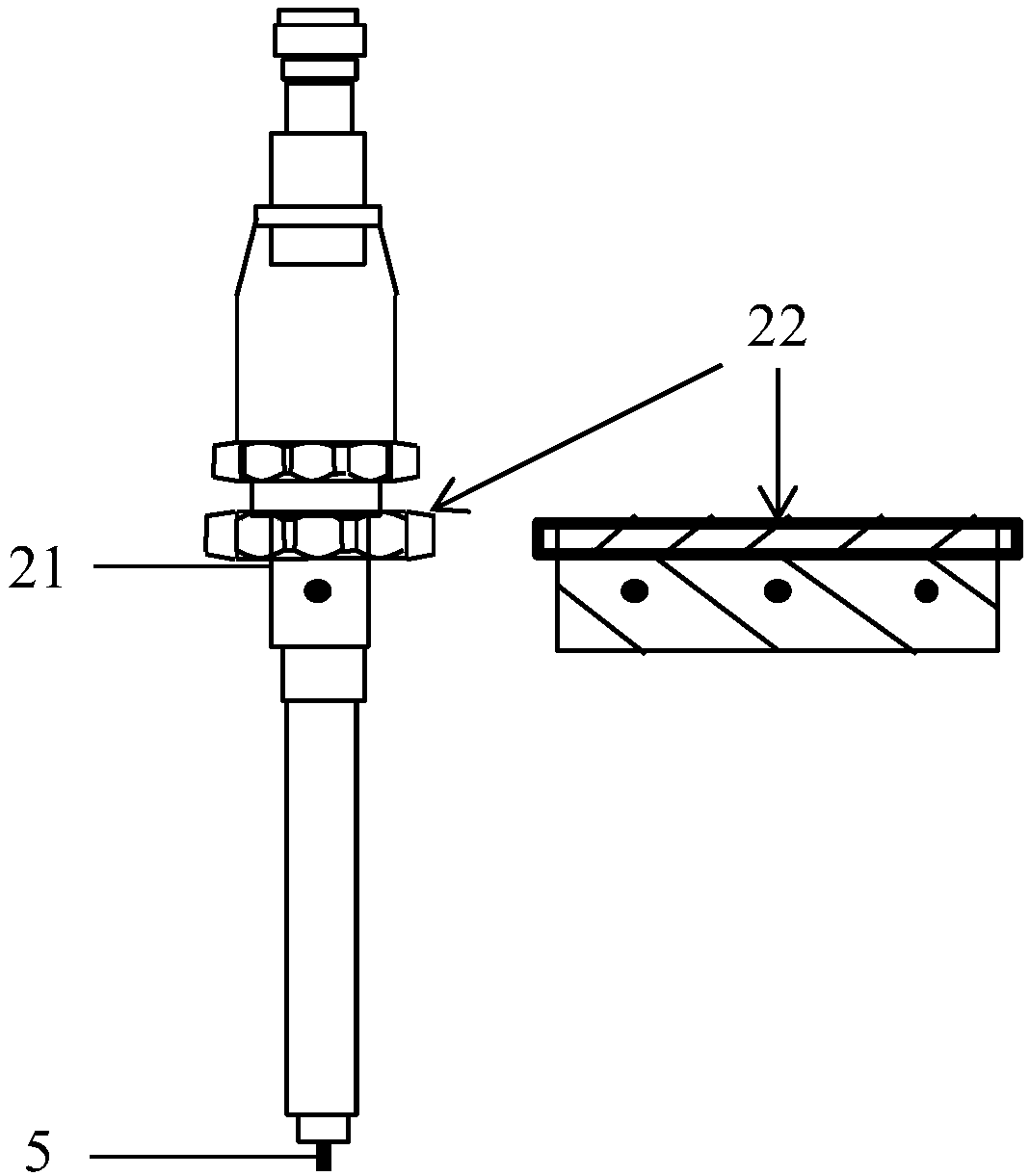

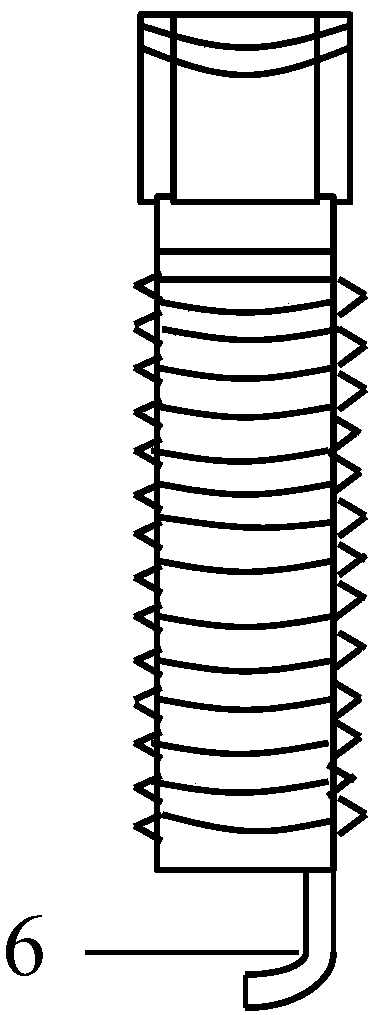

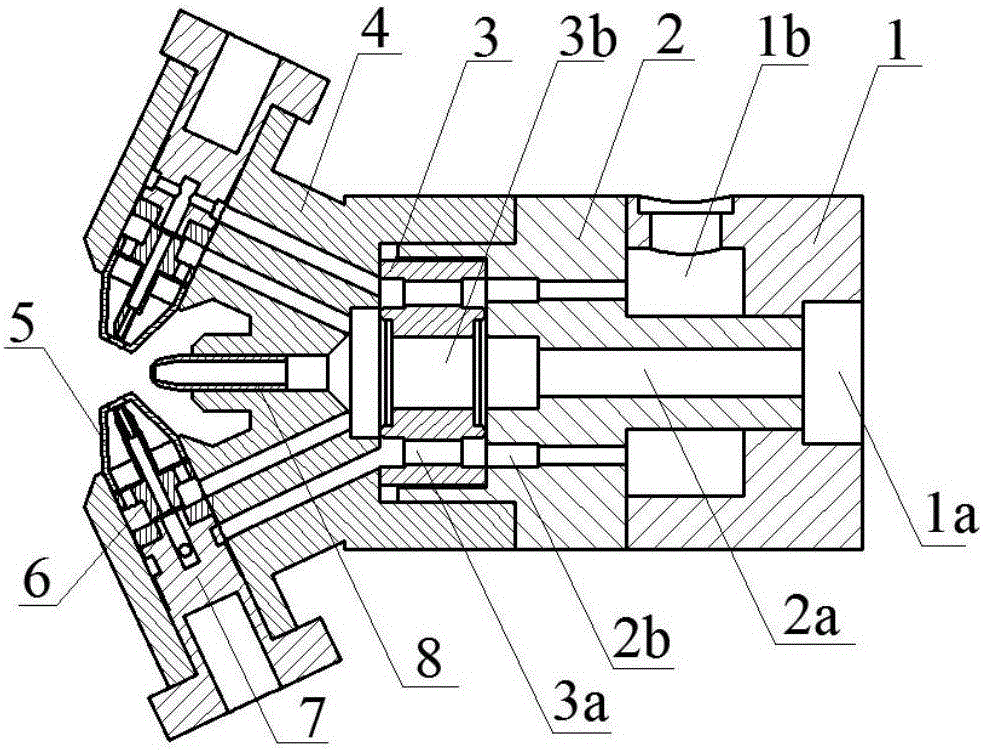

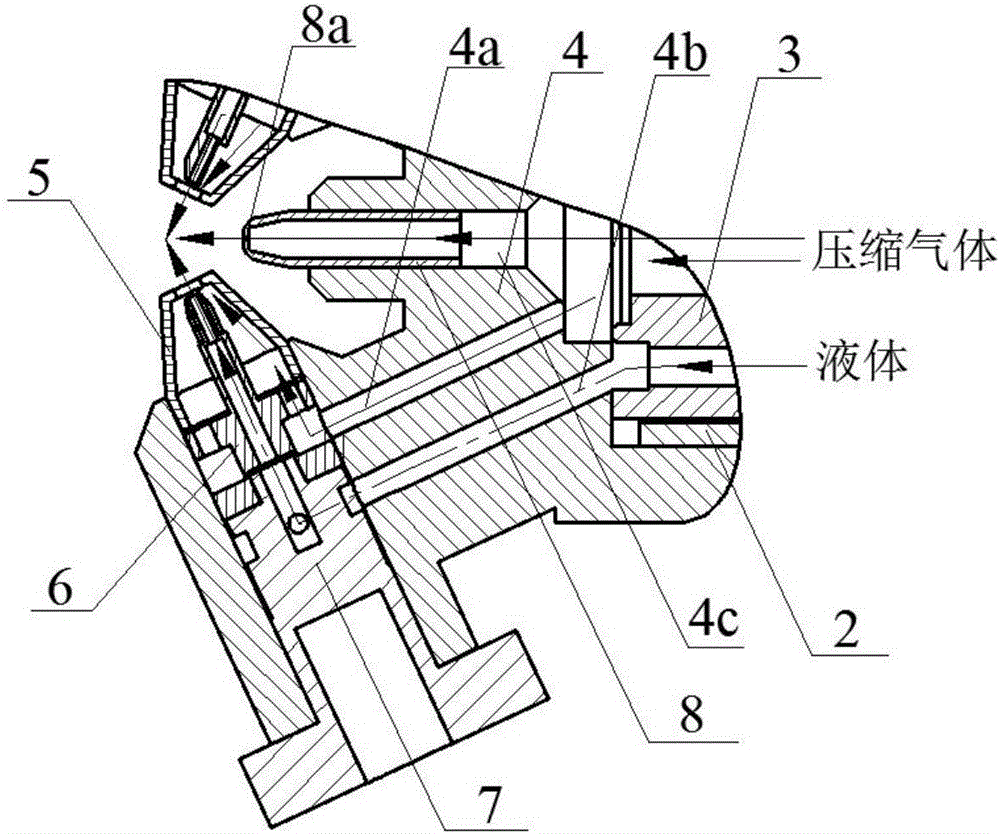

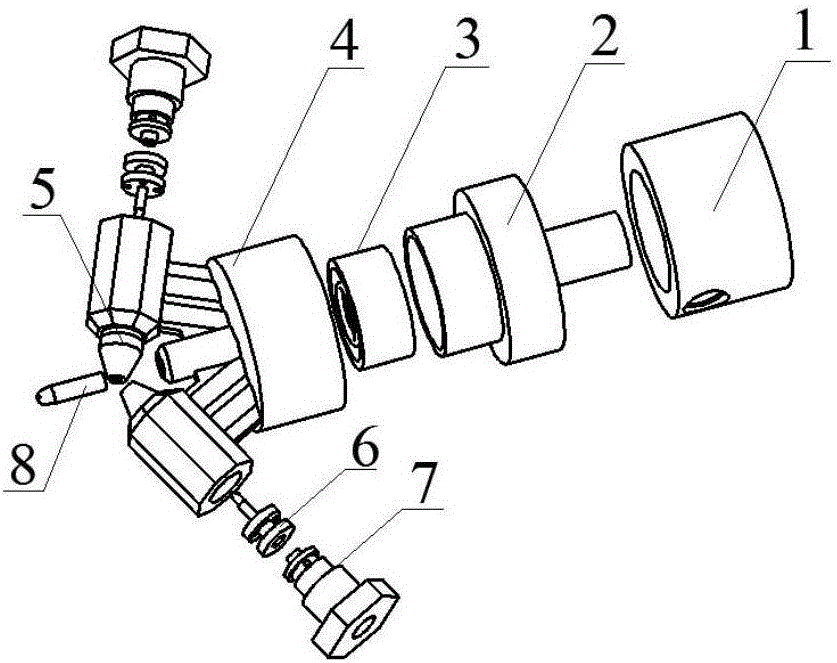

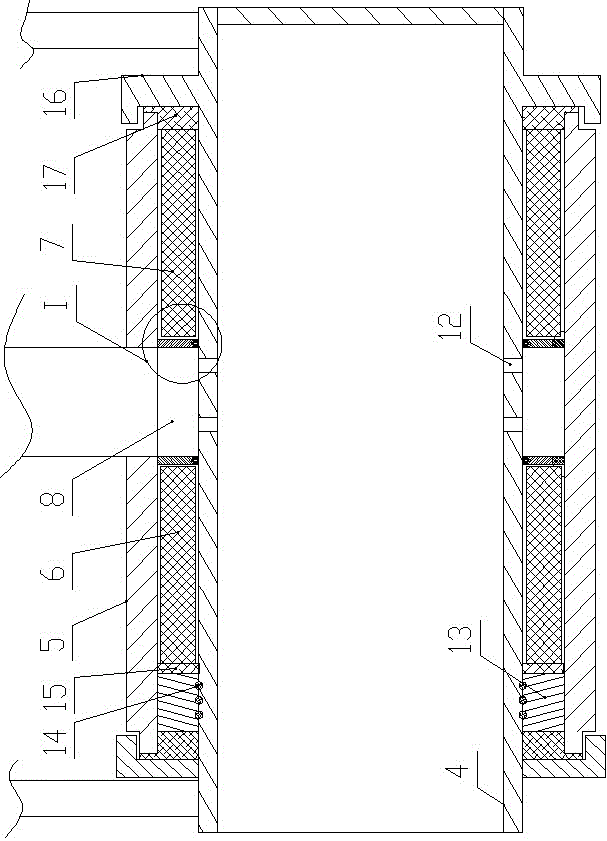

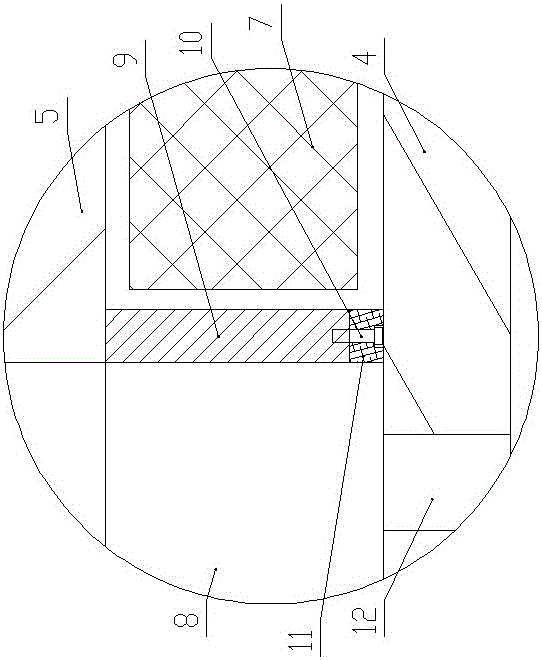

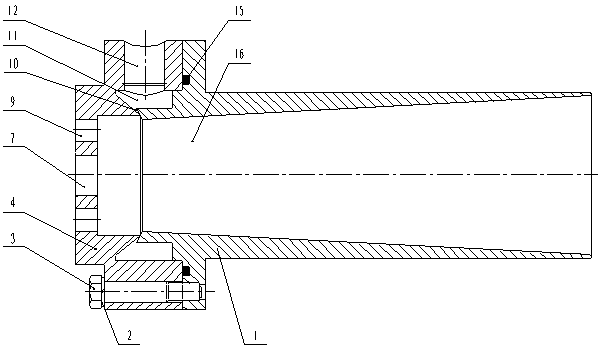

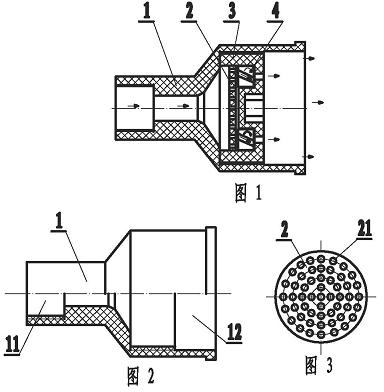

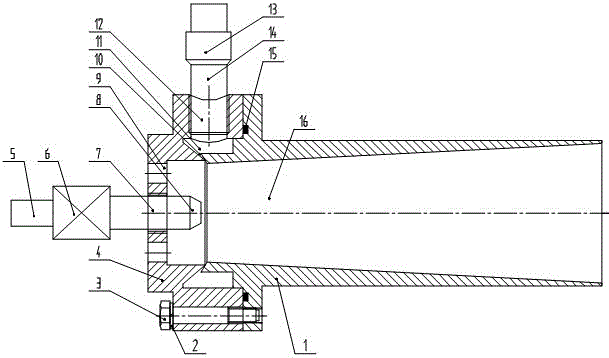

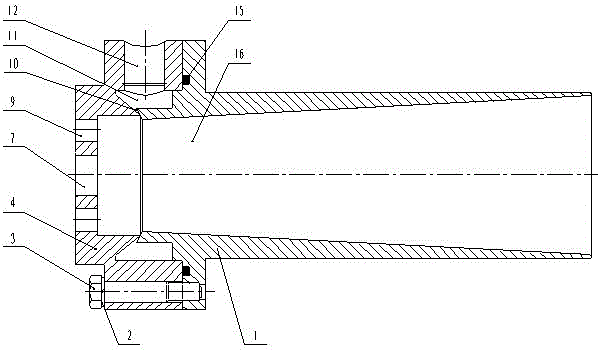

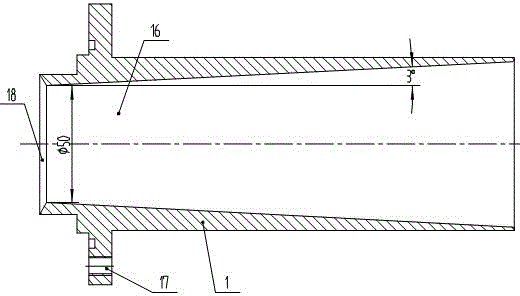

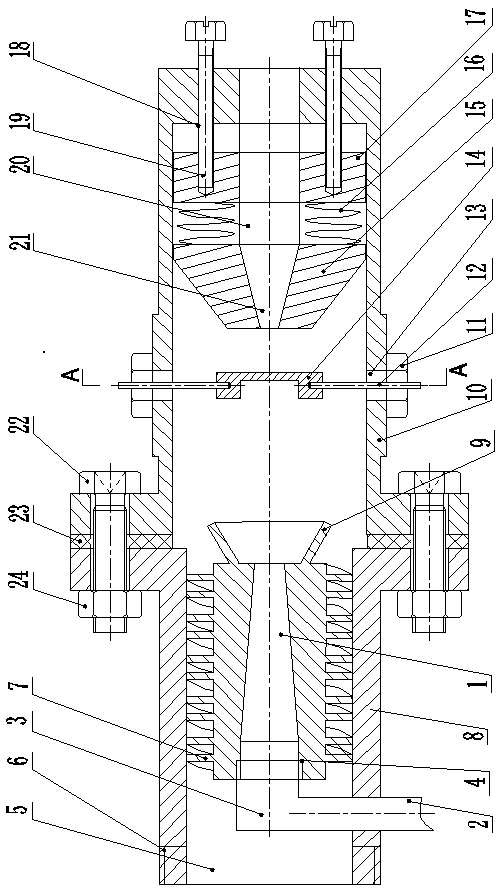

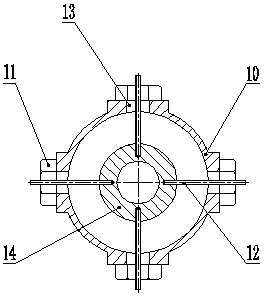

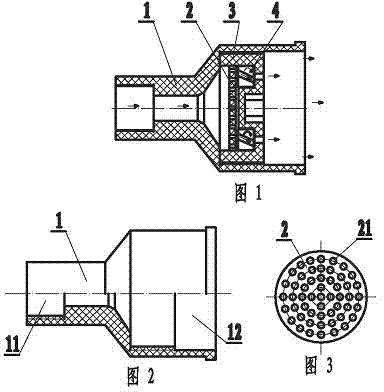

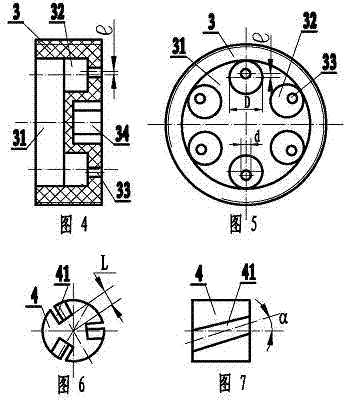

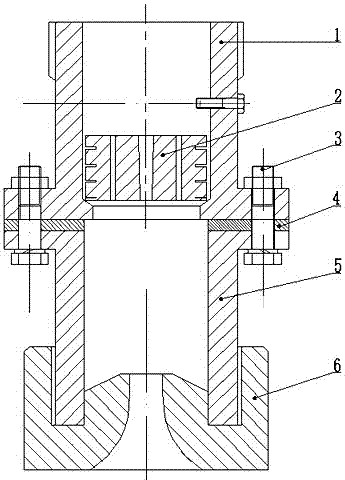

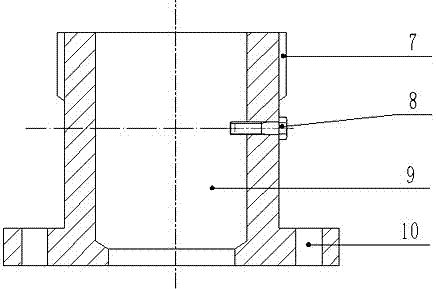

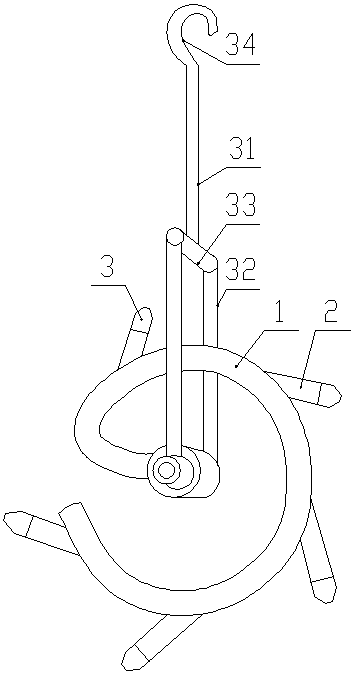

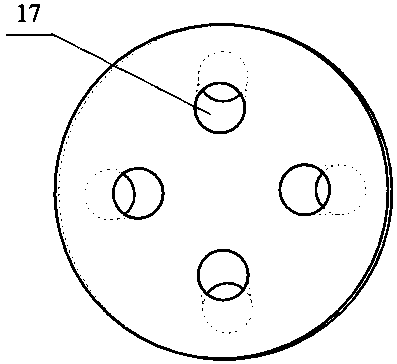

Secondary atomization two-phase flow nozzle

ActiveCN106540825AEnhanced spray atomization effectReduce wasteLiquid spraying apparatusRubber ringEngineering

The invention discloses a secondary atomization two-phase flow nozzle. The secondary atomization two-phase flow nozzle comprises a feeding sleeve, a flow guide pipe, a flow guide rubber ring, a flow distribution pipe, an ejection needle and two atomization nozzles, wherein the flow distribution pipe, the flow guide pipe and the feeding sleeve are connected in sequence from front to back; the flow guide rubber ring is arranged between the flow distribution pipe and the flow guide pipe; a first atomization nozzle and a second atomization nozzle are fixedly connected with two sides of the center of a front end of the flow distribution pipe; the first atomization nozzle and the second atomization nozzle are mounted at the front end of the flow distribution pipe in a manner of being obliquely and symmetrically arranged; the feeding sleeve is provided with a gas inlet for introducing compressed gas and a liquid inlet for introducing liquid; a central gas inlet flow guide hole is formed in the front end of the center of the flow distribution pipe along the axis direction; the ejection needle is arranged in the central gas inlet flow guide hole. According to the secondary atomization two-phase flow nozzle, a manner of combining gas-liquid two-phase flow primary atomization with secondary collision is adopted, and a lot of ultrafine fog drops can be generated; the disadvantages that a traditional technology cannot combine large atomization amount, fine grain diameter, long emission range and directed spraying are overcome.

Owner:JIANGSU ACAD OF AGRI SCI

Engine

ActiveCN104405549AReduced precision requirementsSave R&D costsFuel injection apparatusMachines/enginesFuel oilCarbon deposition

The invention discloses an engine. The engine comprises a fuel oil guide rail, a plurality of connecting pipes, a plurality of fuel oil sprayers, a plurality of fuel oil spraying detection devices, a plurality of fuel oil heating devices, and a controller; the fuel oil sprayers are connected to the fuel oil guide rail respectively through the connecting pipes; the fuel oil spraying detection devices are used for detecting working states of the fuel oil sprayers; the fuel oil heating devices are arranged corresponding to the connecting pipes respectively; each fuel oil heating device comprises a heater component and a driver; each heater component comprises a temperature detection module and a heater; and the controller is connected with the fuel oil spraying detection devices and the fuel oil heating devices of the engine. The engine can reduce the phenomena that fuel oil wets a wall, and engine oil is diluted; the combustion process of the engine is more sufficient, and the generation of carbon deposition and hydrocarbon emissions are reduced; and the heat efficiency of the engine is improved, and meanwhile oil consumption is reduced.

Owner:GREAT WALL MOTOR CO LTD

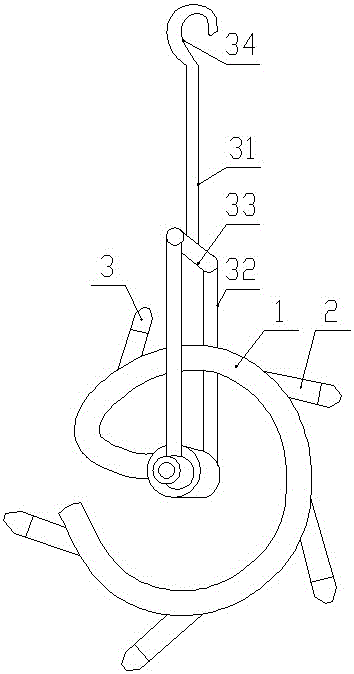

Full-automatic rotary spraying device

InactiveCN105971659AAchieve the purpose of automatic rotationGood spray atomization effectDust removalFire preventionSprayerWater flow

A full-automatic rotary spraying device comprises a supporting frame, a rotary water pipe and a water feeding rotating mechanism. The rotary water pipe is rotatably connected to the supporting frame through the water feeding rotating mechanism. The rotary water pipe is in the shape of the Achimedean spiral, the inner end of the rotary water pipe is connected with the water feeding rotating mechanism, and the outer end of the rotary water pipe is sealed. At least two water outlet pipe heads are evenly arranged on the rotary water pipe in the tangential direction of the water flowing direction, and atomizing sprayers are arranged at the outer ends of the water outlet pipe heads. The full-automatic rotary spraying device is reasonable in structure design, good in sealing effect, uniform in water spraying, good in atomizing effect and capable of reducing dust in a coal mining roadway .

Owner:焦作煤业(集团)新乡能源有限公司

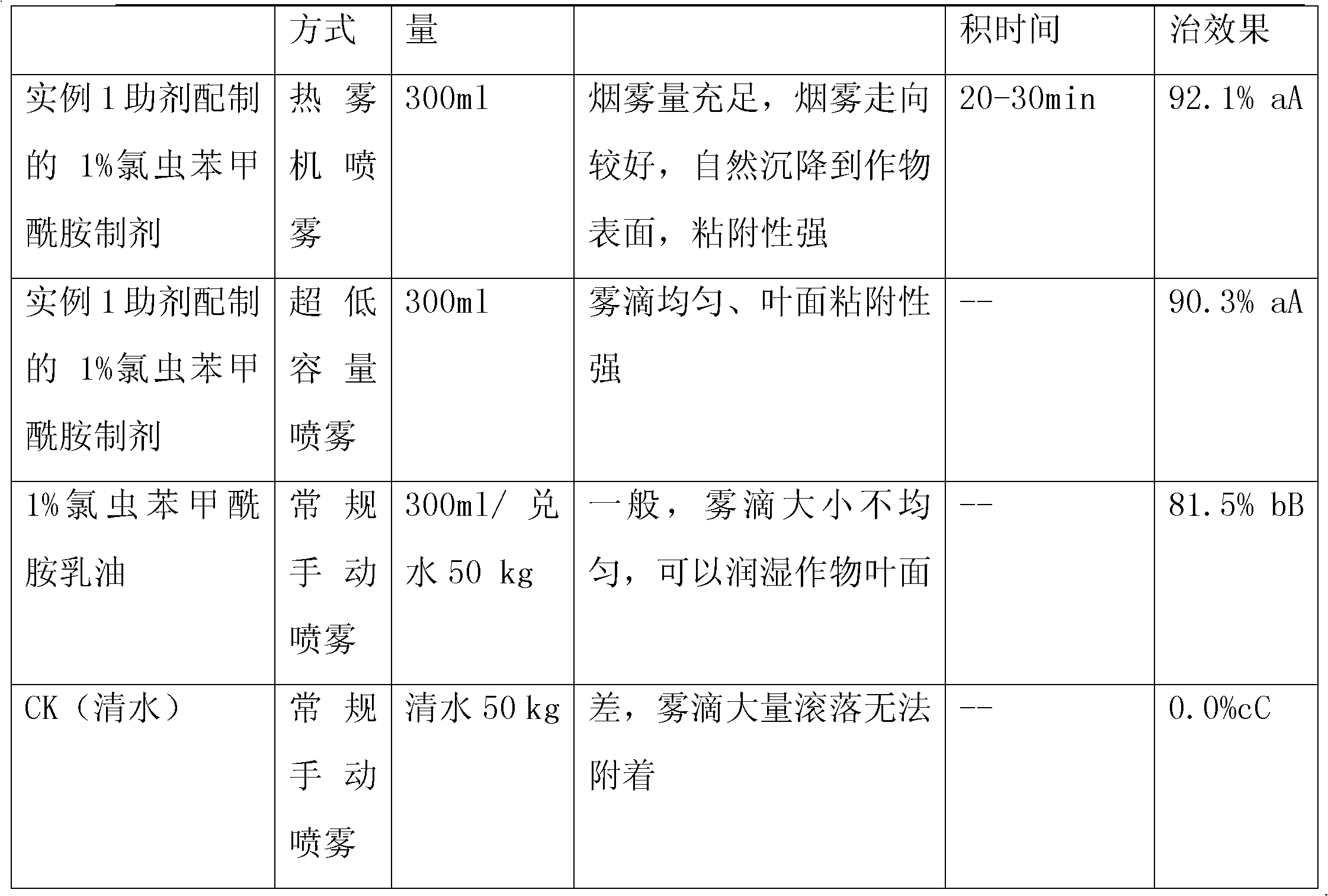

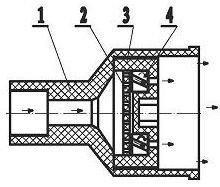

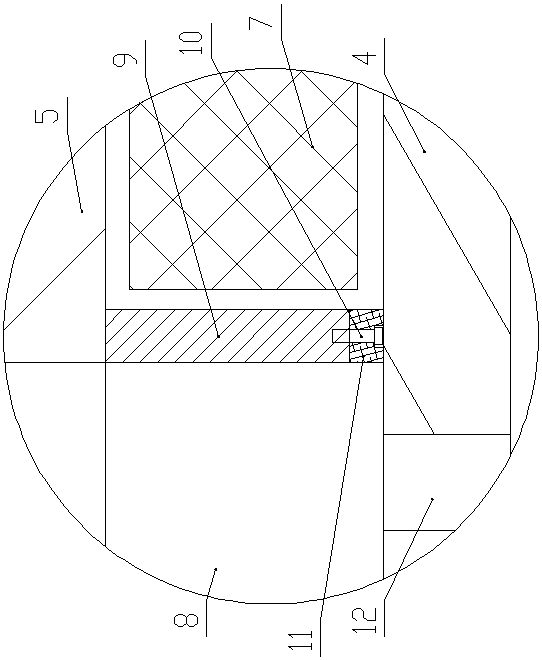

Atomizing and spraying device of conical air flow field

InactiveCN103362533ALarge water mist coverageEnhanced spray atomization effectDust removalFire preventionEngineeringCoal

The invention relates to an atomizing and spraying device of a conical air flow field. The device is characterized in that a dustproof end cap is fixedly arranged on a casing to form a conical annular seam, a generating line of the conical annular seam and an axis form an included angle, the conical annular seam forms a spraying angle of the conical air flow field, the center of the dustproof end cap is provided with a water pipe inlet, the periphery of the center of the dustproof end cap is uniformly provided with eight ventilation holes in the circumferential direction, the connecting part of the dustproof end cap and the casing is provided with a compressed air inlet which is communicated with compressed air, and the pipe diameter of the casing is gradually increased from interior to exterior to form a horn-shaped passage structure. The atomizing and spraying device has the advantages that a mechanical rotary part and a power source are not arranged, so the safe production of coal mines is favorable, the spraying and atomizing effects are good, and the coverage range of water mist is large; the structure is simple, and the convenience in use is realized; and the noise is less, and the working is safe and reliable.

Owner:TAIYUAN UNIV OF TECH

Composition of urea reducing agent capable of improving atomization effect

InactiveCN102397749AHigh purity requirementsImprove removal reaction efficiencyExhaust apparatusDispersed particle separationAlcoholMicrobiology

Owner:FAW GROUP

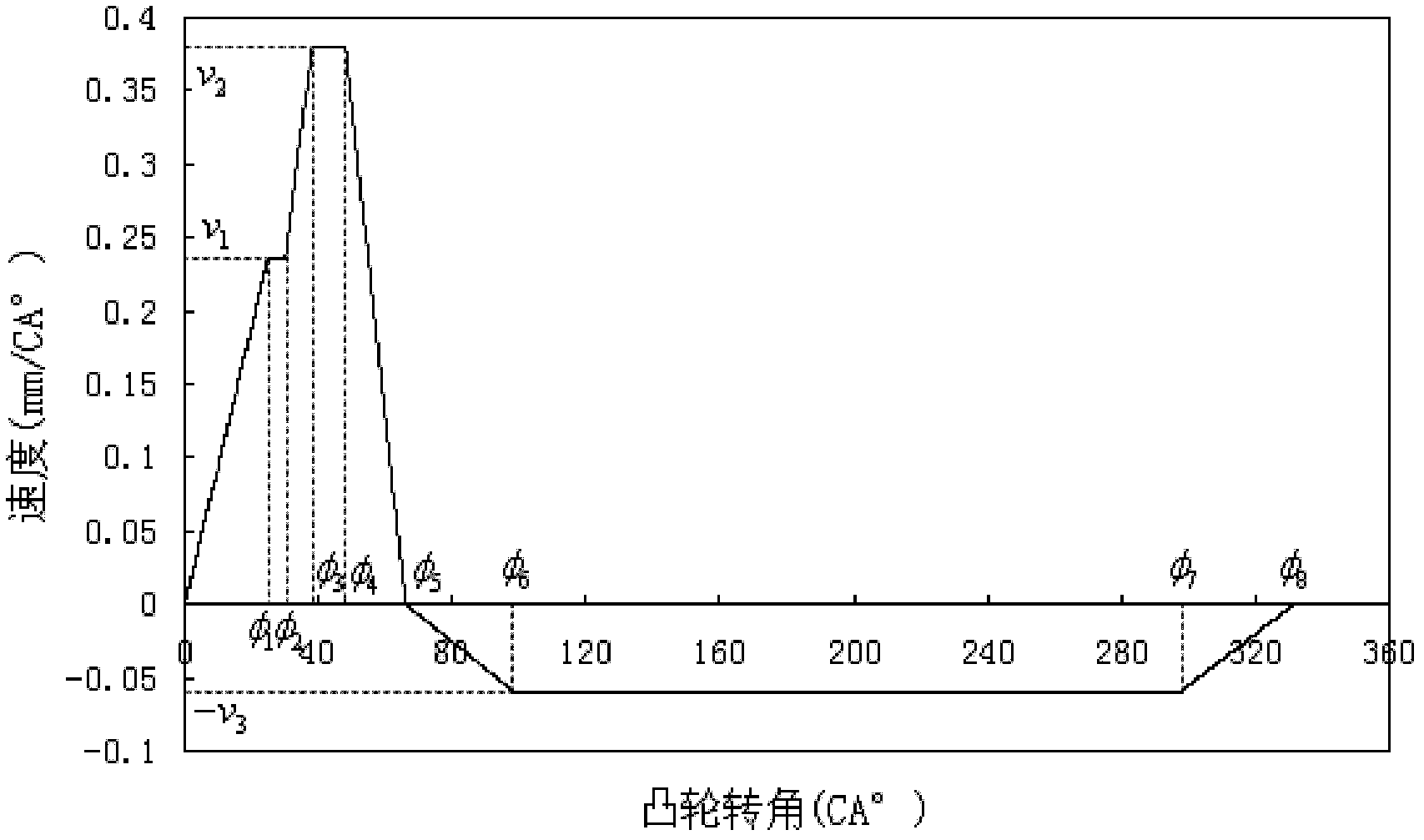

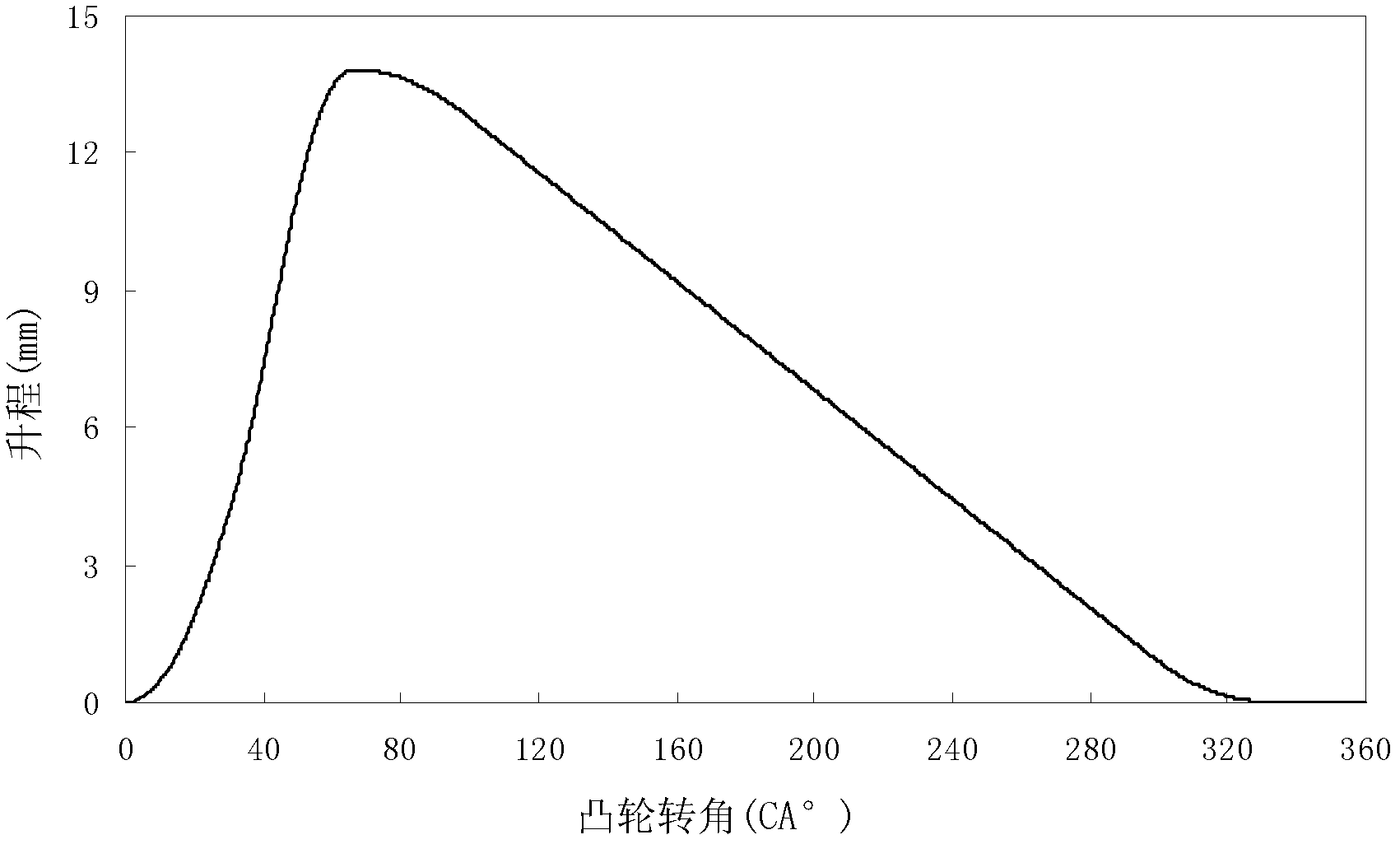

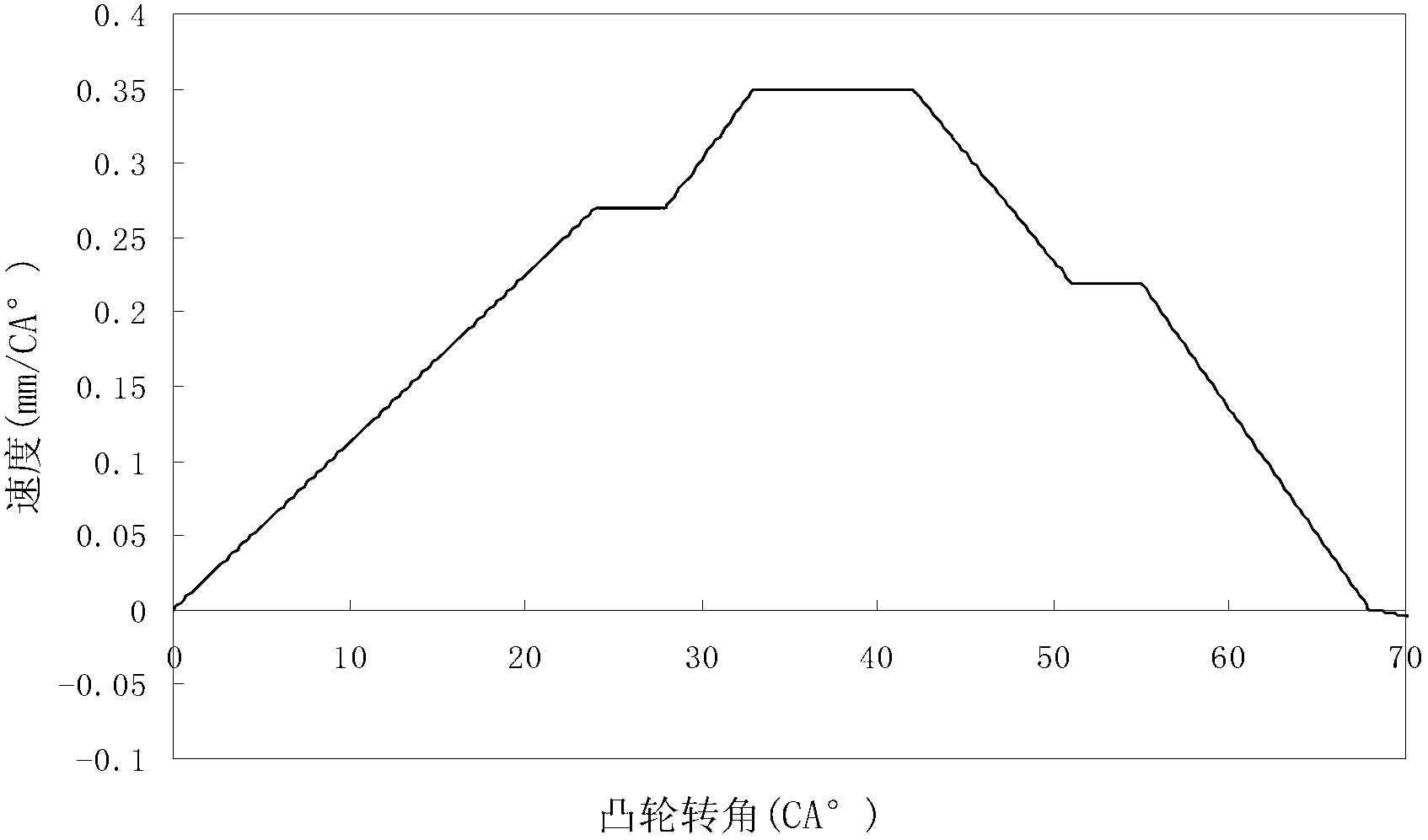

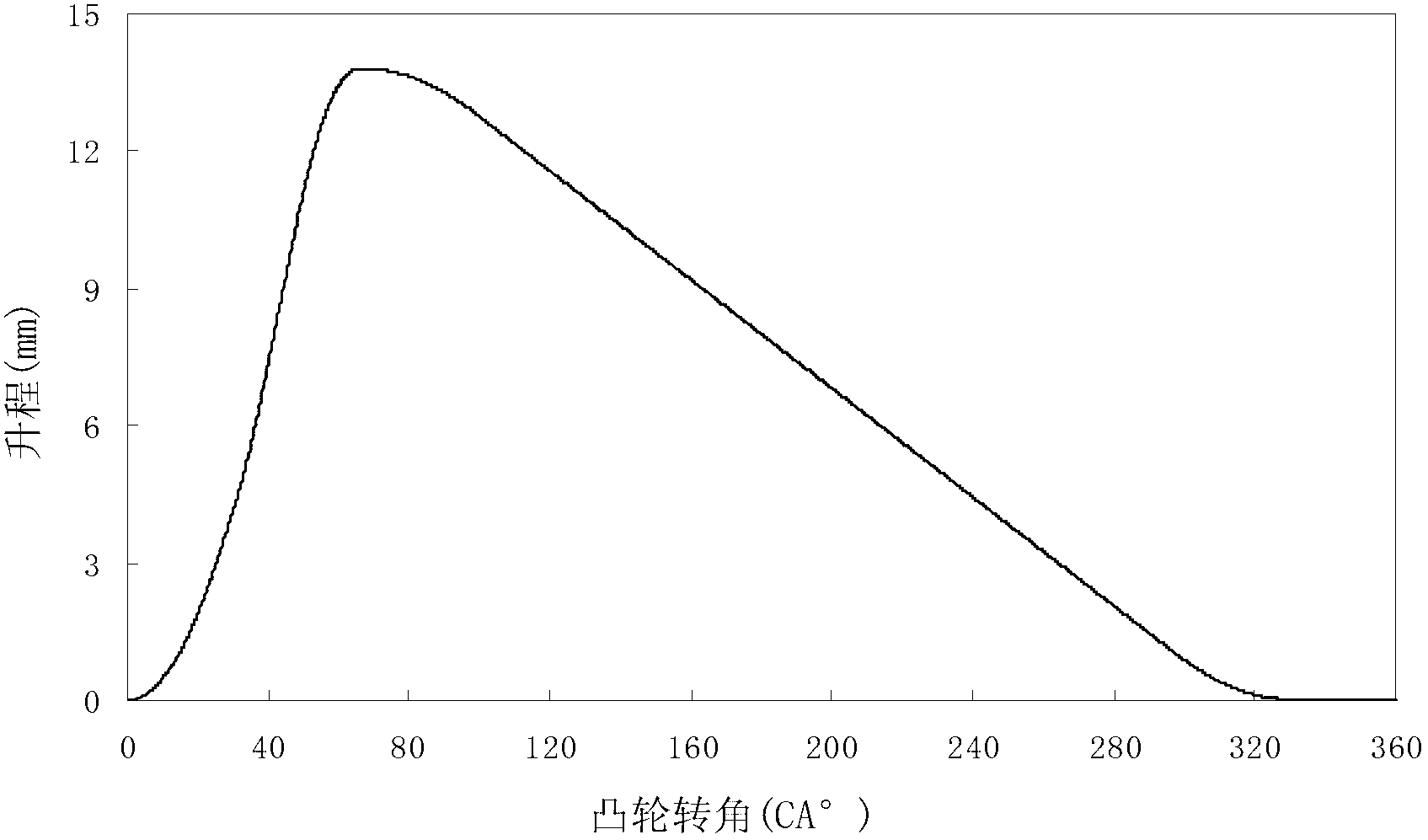

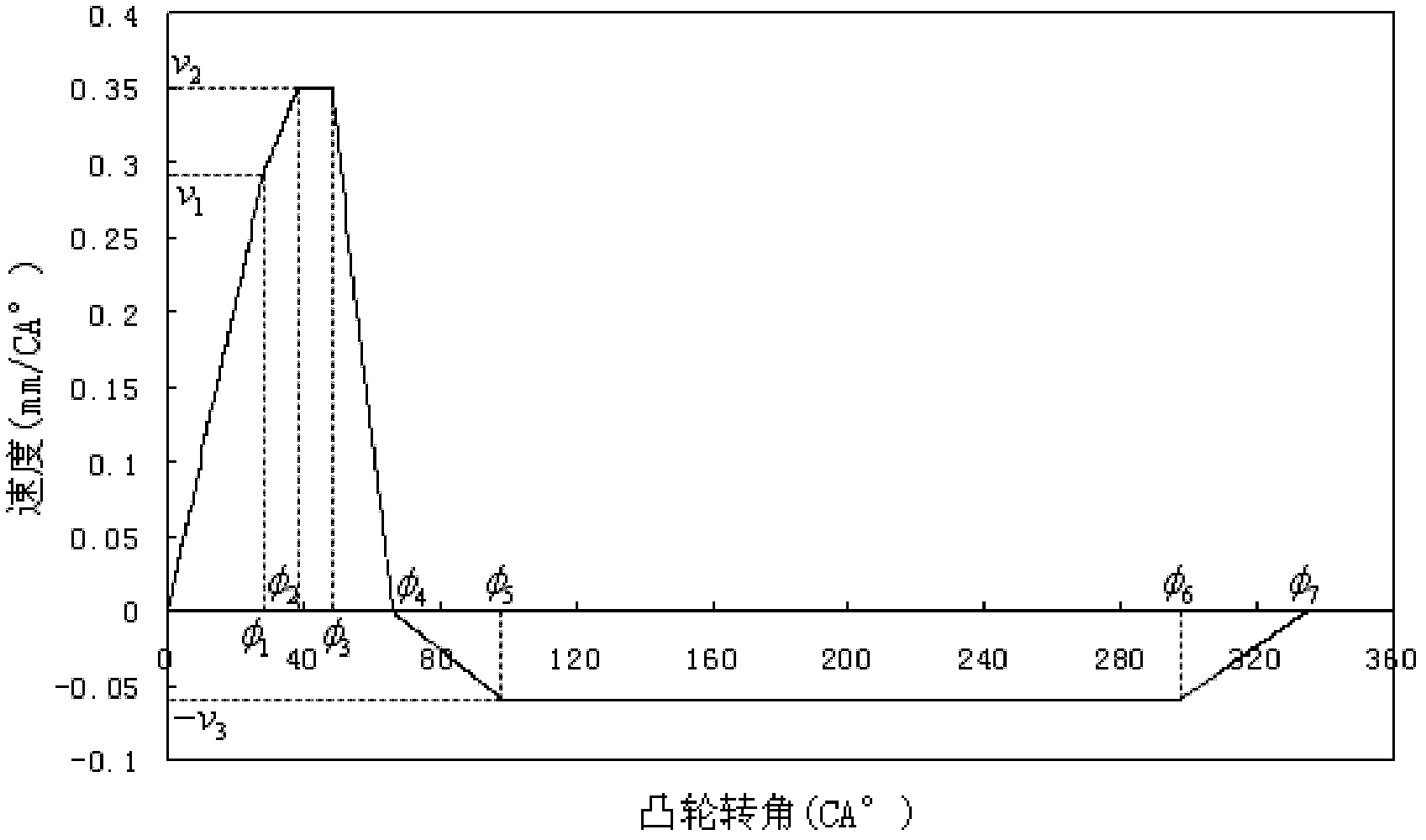

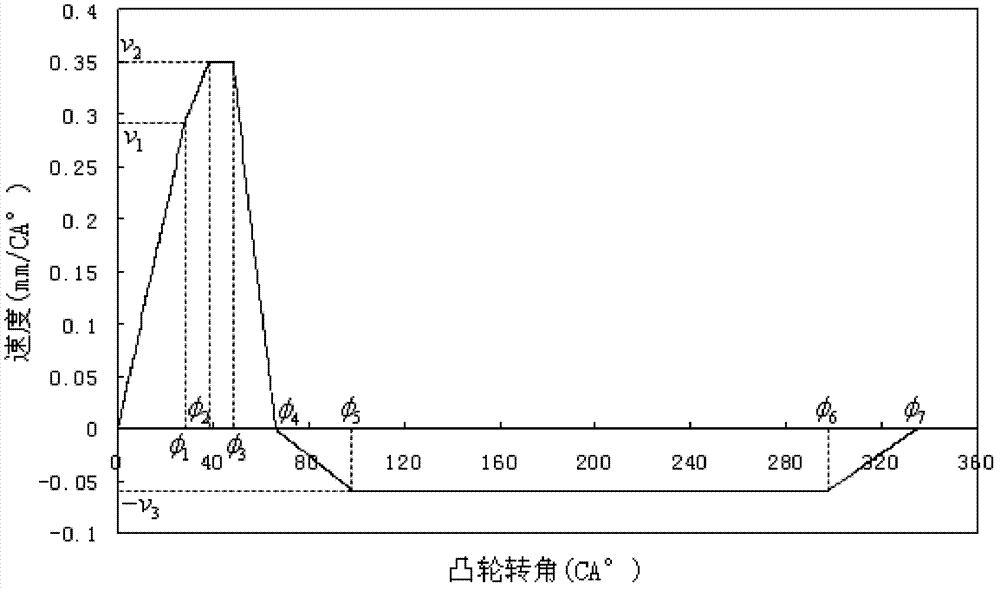

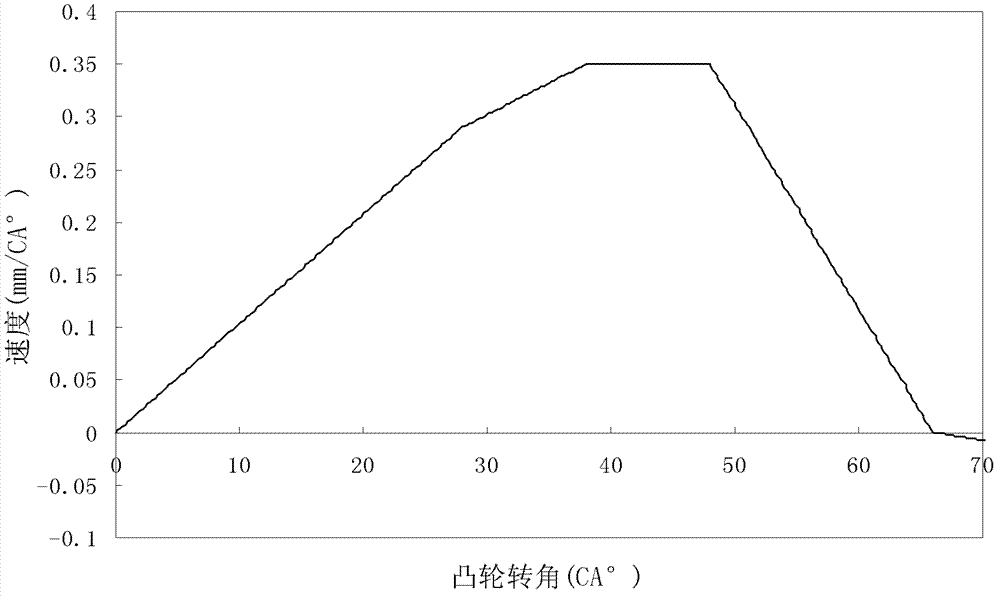

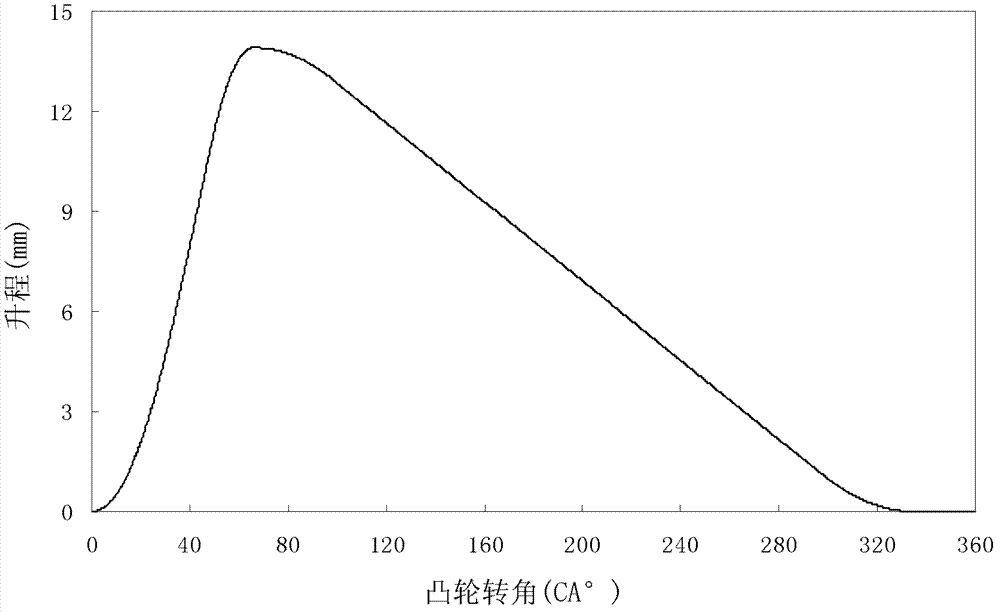

Boot-shaped profile line cam

InactiveCN102661223AStable jobEmission reductionFuel injection apparatusMachines/enginesInjection pressureSingle injection

The invention aims to provide a boot-shaped profile line cam which comprises an extending stroke section and a return stroke section, wherein the extending stroke section corresponds to the forward uniform acceleration phase, the working phase and the forward uniform deceleration phase of the movement rule of a plunger follower; the return stroke section corresponds to the reversal uniform acceleration phase, the reversal uniform speed phase and the reversal uniform deceleration phase of the movement rule of the plunger follower, and the speed in the reversal uniform speed phase is v3; and the working phase also comprises two uniform speed phases and a uniform acceleration phase, and the speeds in the two uniform speed phases are respectively v1 and v2. With the boot-shaped profile line cam, different requirements of main injection and pilot injection on injection pressure and injection speed in the secondary injection of a diesel can be met at the same time, and the boot-shaped injection is realized in single injection.

Owner:HARBIN ENG UNIV

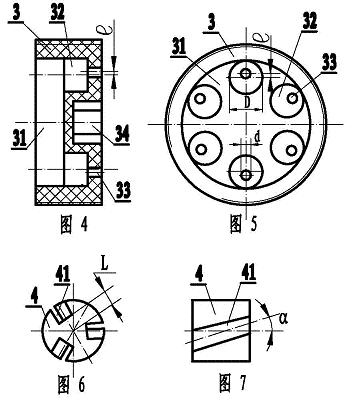

Nozzle of interrupted clear water extinguisher

InactiveCN102166398ATangential thrust safetySufficient tangential thrustFire rescueElectricityCombustion

The invention discloses a nozzle of an interrupted clear water extinguisher, which comprises a nozzle shell, wherein the nozzle shell is internally and fixedly provided with an interrupted flow guide seat, and the flow guide seat is provided with at least one flow guide column installing hole; cup bottoms of the flow guide column installing holes with cup-shaped structures are provided with a plurality of water spraying holes, and the eccentricities e between the flow guide column installing holes and the water spraying holes are equal to 0.1-3mm; and the flow guide column installing holes are internally and movably provided with a plurality of helical type flow guide columns, the surface of the each helical type flow guide column is provided with at least one helical flow guide groove, and the helical angles alpha of the helical flow guide grooves are equal to 30-60 degrees; and the distance from the bottom of each helical flow guide groove to the axial lead of each helical type flowguide column is less than the semidiameter of each water spraying hole. The ratio of the diameter D of each flow guide column installing hole to the diameter d of each water spraying hole D / r is equal to 2-3. The nozzle not only can extinguish a combustion source with electricity by the clean water, but also is reasonable and simple in structure, safe and convenient in use, and widely used for various fire-fighting lances.

Owner:东台市星海船用设备有限公司

A Conical Airflow Field Atomization Injection Device

InactiveCN103362533BLarge water mist coverageEnhanced spray atomization effectDust removalFire preventionEngineeringWater pipe

The invention relates to an atomizing and spraying device of a conical air flow field. The device is characterized in that a dustproof end cap is fixedly arranged on a casing to form a conical annular seam, a generating line of the conical annular seam and an axis form an included angle, the conical annular seam forms a spraying angle of the conical air flow field, the center of the dustproof end cap is provided with a water pipe inlet, the periphery of the center of the dustproof end cap is uniformly provided with eight ventilation holes in the circumferential direction, the connecting part of the dustproof end cap and the casing is provided with a compressed air inlet which is communicated with compressed air, and the pipe diameter of the casing is gradually increased from interior to exterior to form a horn-shaped passage structure. The atomizing and spraying device has the advantages that a mechanical rotary part and a power source are not arranged, so the safe production of coal mines is favorable, the spraying and atomizing effects are good, and the coverage range of water mist is large; the structure is simple, and the convenience in use is realized; and the noise is less, and the working is safe and reliable.

Owner:TAIYUAN UNIV OF TECH

Composite heat carrier medium anti-corrosion coating and preparation method thereof

ActiveCN110241375AAccelerated corrosionImprove heat resistanceMolten spray coatingHeat carrierHigh entropy alloys

The invention provides a composite heat carrier medium anti-corrosion coating and a preparation method thereof. The coating comprises the following elements of, in percentage by weight, 3.0%-7.5% of Al, 20.0%-23.0% of Cr, 23.0%-26.0% of Ni, 23.0%-26.0% of Co, 0.5%-2.0% of Re, 0.5%-1.5% of Si, and 22.0%-25.0% of Fe. The main components of the coating are the five elements of Al, Cr, Ni, Co and Fe, and the five elements can form an AlxCoCrFeNi series high-entropy alloy in the coating, and the excellent mechanical property is achieved; meanwhile, the five elements have the excellent corrosion resistance and high temperature resistance; and the binding force between the coating prepared through the method and an N80 carbon steel base material can reach 145 MPa or higher.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

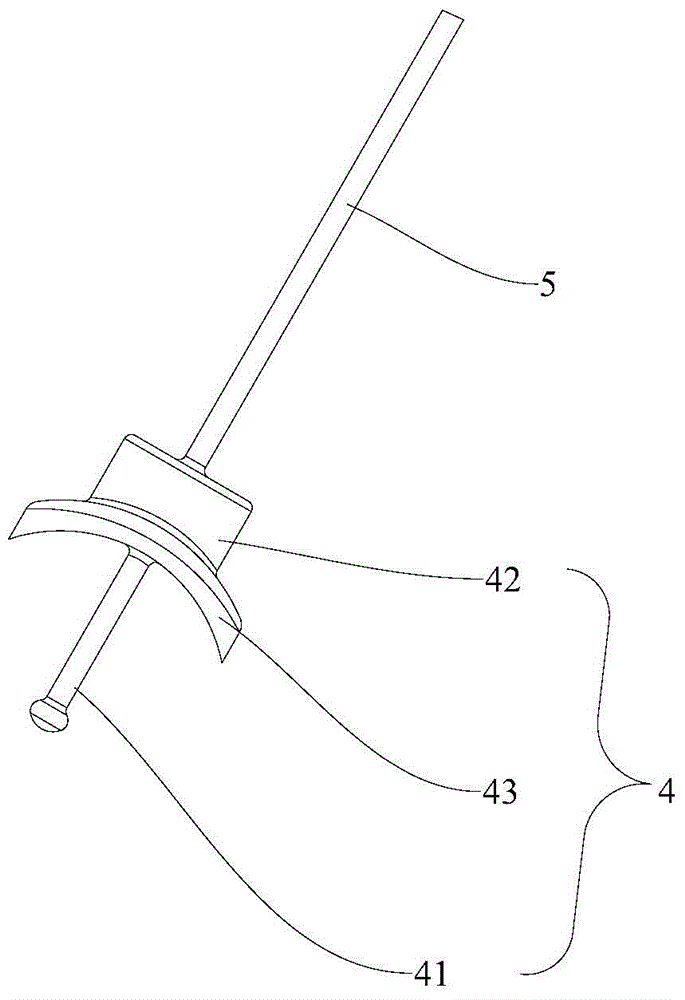

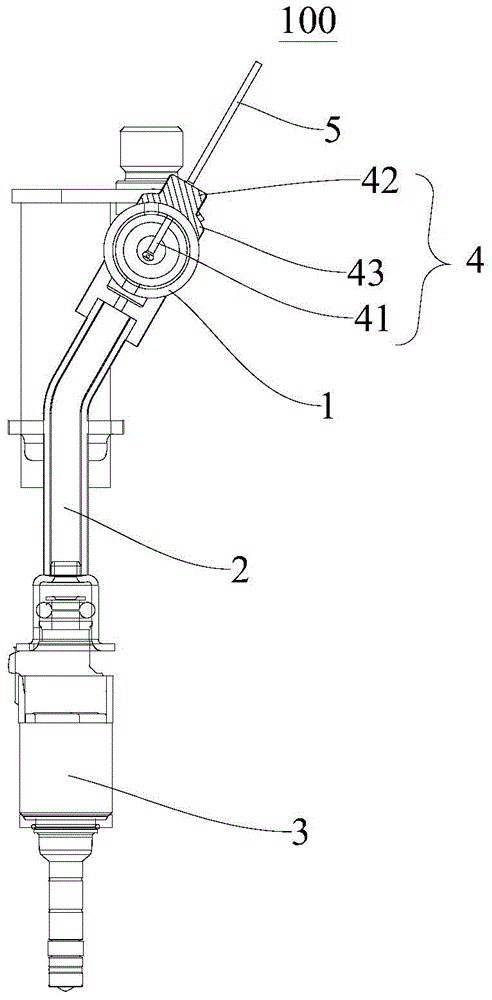

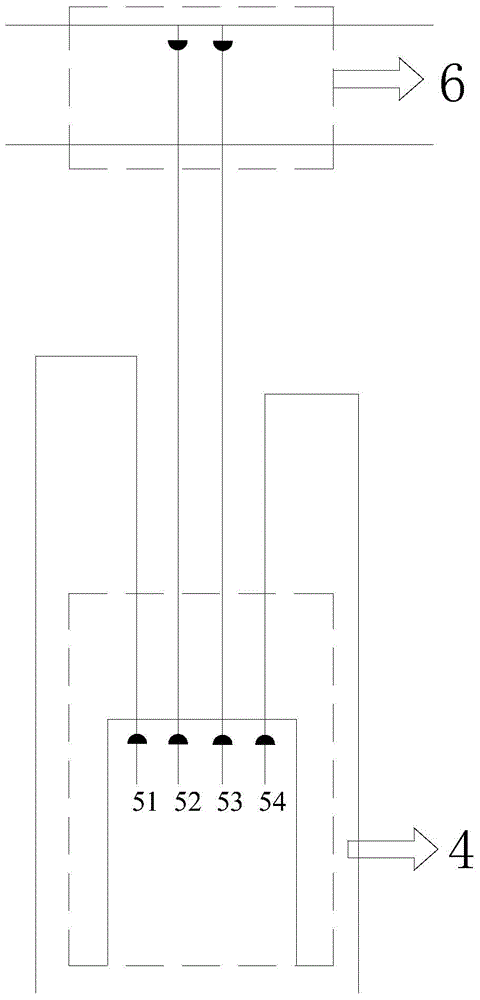

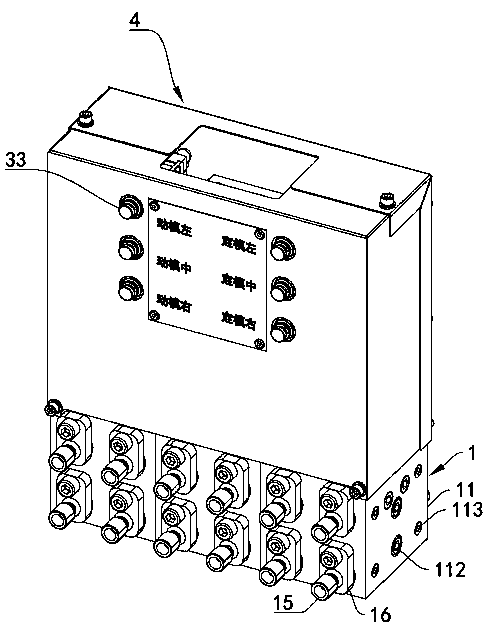

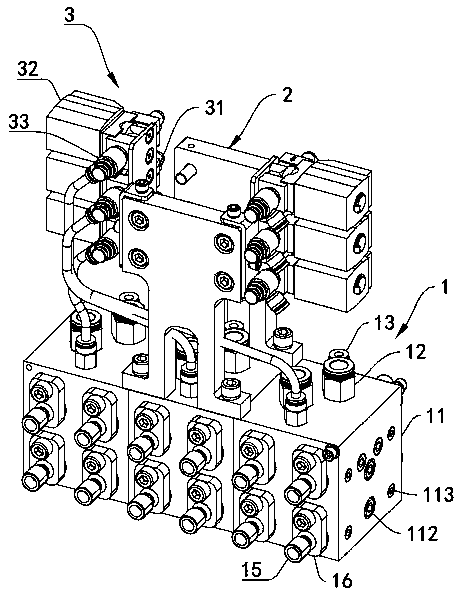

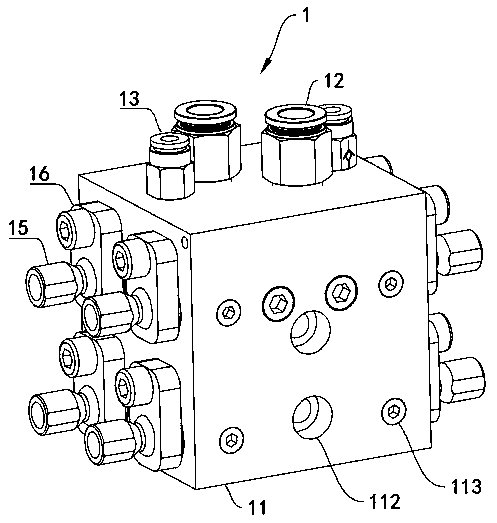

Atomizing mechanism and spraying device for die-casting production

The invention discloses an atomizing mechanism. The atomizing mechanism comprises a valve body, one or more gas connectors, one or more fluid connectors, one or more mixing valves and one or more nozzles, wherein the valve body is provided with a valve cavity and a plurality of communicating holes; the communicating holes communicate with the valve cavity; the gas connectors are arranged in the valve body, and are connected with one of the communicating holes; the fluid connectors are arranged in the valve body, and are connected with one of the communicating holes; the mixing valves are arranged in one of the communicating holes, and each mixing valve communicates with the corresponding gas connector and the corresponding fluid connector; and the nozzles are arranged in the valve body, and each nozzle is connected with the corresponding mixing valve. The invention also provides a spraying device for die-casting production. The spraying device for die-casting production is simple in structure; low-distance spraying of a die-casting mold can be realized through the driving of the mechanical arm; the spraying and atomizing effect is good; and besides, the expansibility of the atomizing mechanism is high, so that through the assembling of different shapes, the atomizing mechanism is suitable for various complicated die-casting molds.

Owner:佛山市文杰智能机械有限公司

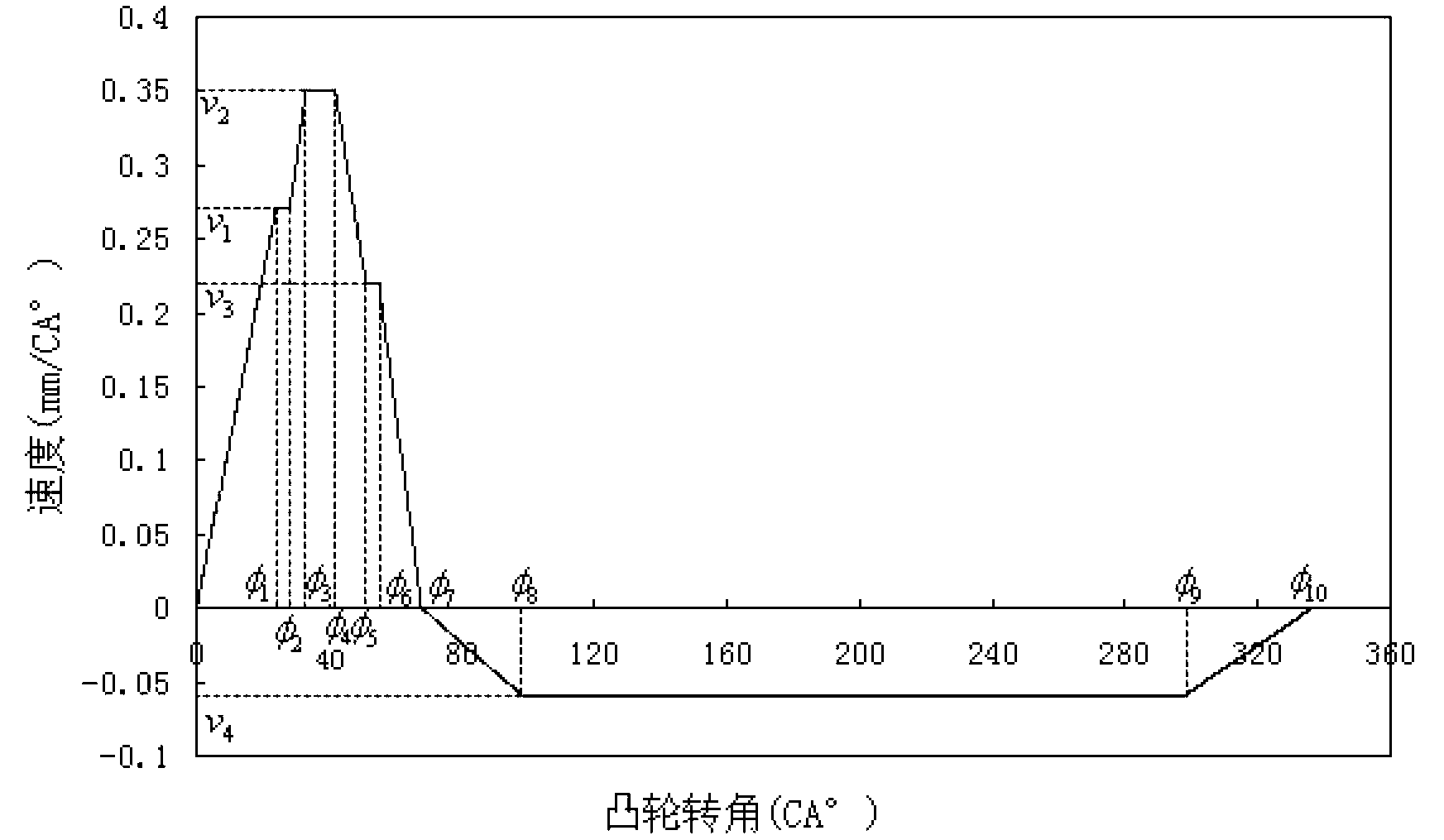

Multi-section molded line cam

InactiveCN102705124AReduce working noiseEmission reductionMachines/enginesFuel injecting pumpsInjection pressureMultiple injection

The invention aims to provide a multi-section molded line cam, which comprises an actuating travel section and a return travel section. The actuating travel section corresponds to two forward uniform acceleration stages, three forward constant speed stages and two forward uniform deceleration stages of movement rules of a plunger driven part, and the return travel section corresponds to a backward uniform acceleration stage, a backward constant speed stage and a backward deceleration stage of the movement rules of the plunger driven part. A working section comprises the three constant speed stages, the second uniform acceleration stage and the first uniform deceleration stage of the actuating travel section. The speed of the first constant speed stage of the working section is v1, the speed of the second constant speed stage of the working section is v2, the speed of the third constant speed stage of the working section is v3, and the speed of the backward constant speed stage is v4. The oil injection pressure and oil injection speed of main injection are increased, different requirements of oil injection of each stage for the oil injection pressure and the oil injection speed during multiple injection are combined, and the aims of lowering the working noise of an engine, reducing the emissions of pollutants and improving an oil injection atomization effect are fulfilled.

Owner:HARBIN ENG UNIV

A kind of composite heat carrier medium anticorrosion coating and preparation method thereof

ActiveCN110241375BAccelerated corrosionImprove heat resistanceMolten spray coatingHeat carrierHigh entropy alloys

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

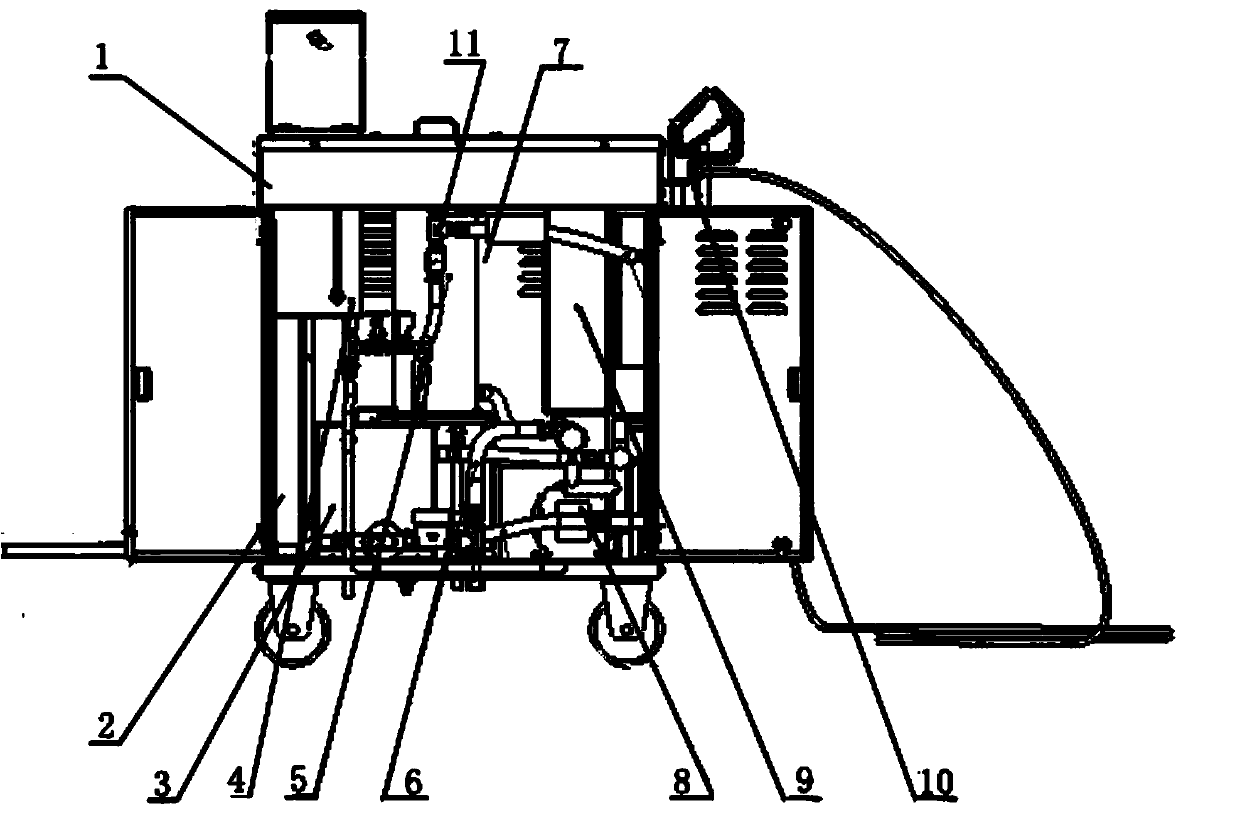

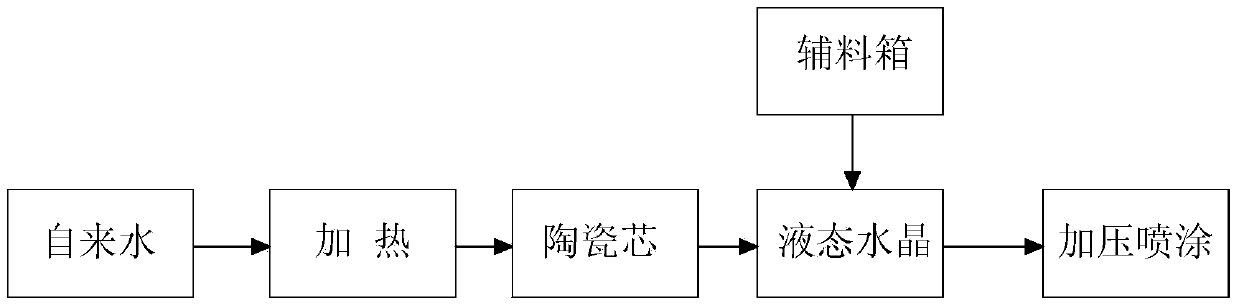

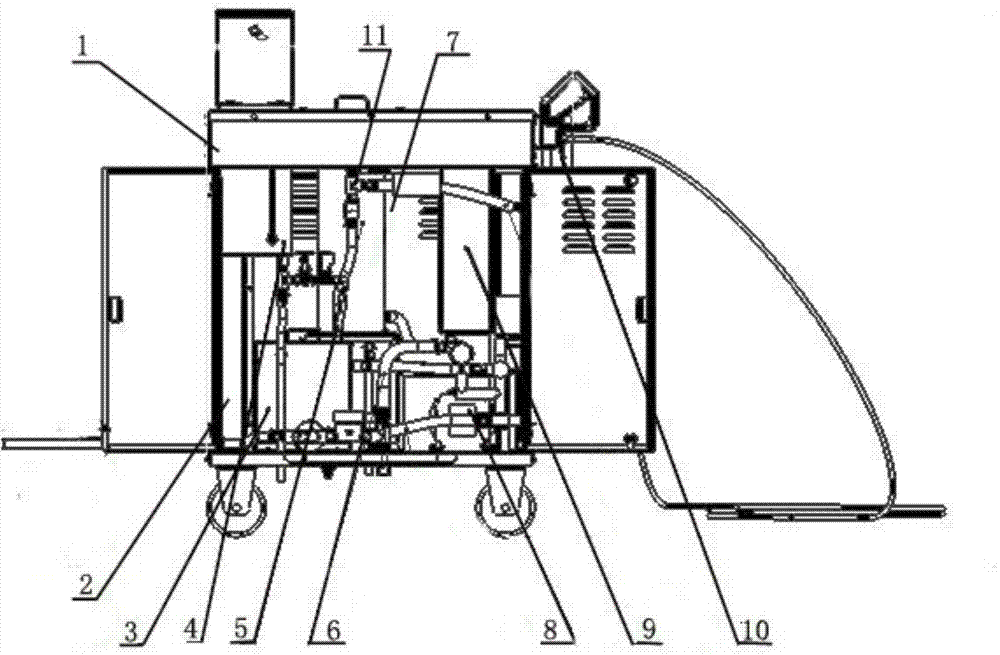

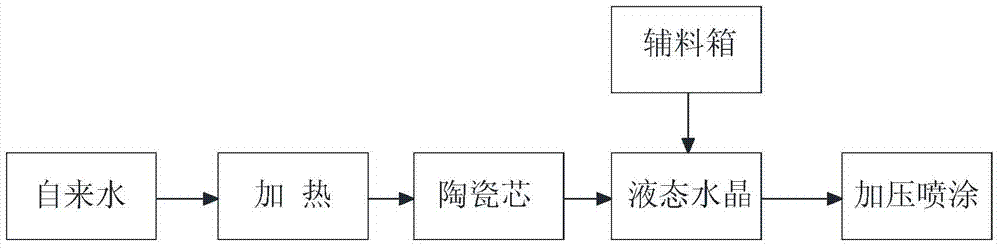

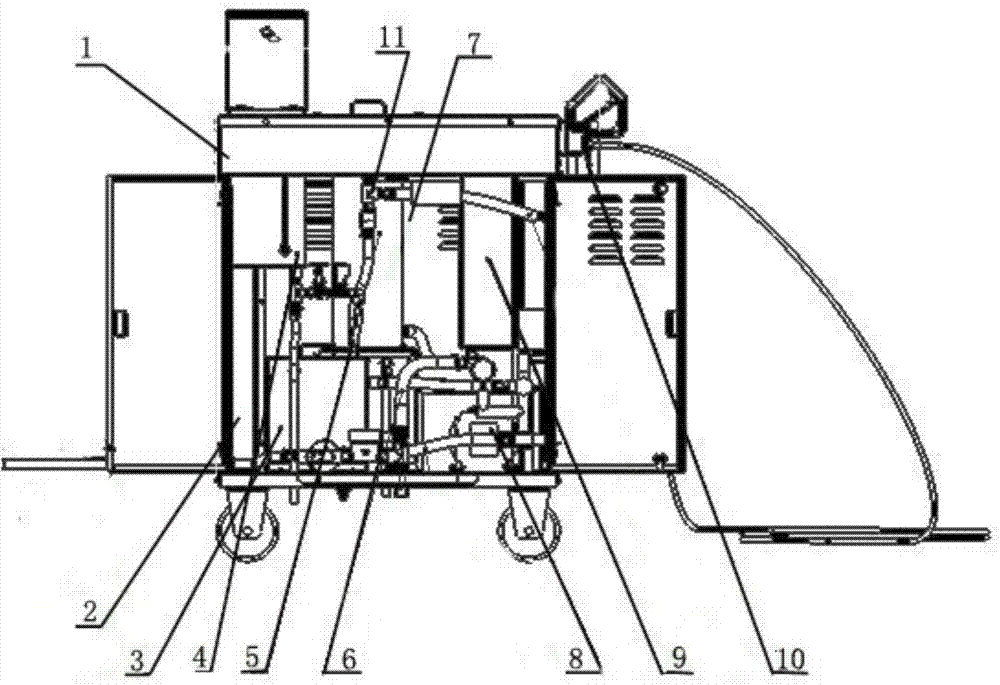

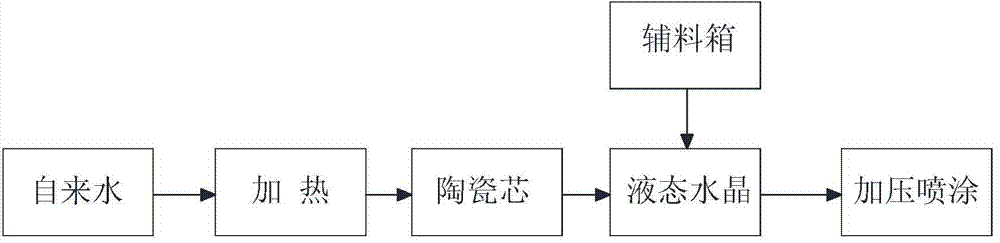

Liquid crystal film spaying machine and film spaying process

ActiveCN103464320AImprove efficiencyHigh degree of automationLiquid spraying apparatusAutomatic controlElectrolysis

The invention discloses a liquid crystal film spaying machine and a film spaying process. The liquid crystal film spaying machine comprises a machine case, a feed water pipe sleeve, a heating system, a ceramic core, a water storage tank, a fuel tank, an auxiliary material tank, a flow control device, a high-pressure airless spraying system and a programmable logic controller (PLC) automatic control system. The liquid crystal film spaying machine utilizes warm water and the specific high-performance ceramic core to perform water electrolysis so as to improve activity, meanwhile vitreous components produced by the ceramic in the ionization process dissolve in the water to form low-temperature glass, then the low-temperature glass is mixed with a raw material in the auxiliary material tank in a proportioning mode to form crystal functional liquid, and impulse current occurs on the contacted and cleaned coating surface through pressurized spraying, is combined with the vitreous components in the anodic crystal functional liquid and simultaneously reacts with carbon dioxide in the air to form a crystal film. The liquid crystal film spaying machine and the film spaying process are high in automation degree, and the problems of high technical cost, high energy consumption and large difference caused by manual waxing or glazing in the prior art can be effectively solved.

Owner:JIANGSU ZHONGOU FERTILIZER

A liquid crystal film-shooting machine and film-shooting process

ActiveCN103464320BImprove efficiencyHigh degree of automationLiquid spraying apparatusElectrolysisAutomatic control

The invention discloses a liquid crystal film spaying machine and a film spaying process. The liquid crystal film spaying machine comprises a machine case, a feed water pipe sleeve, a heating system, a ceramic core, a water storage tank, a fuel tank, an auxiliary material tank, a flow control device, a high-pressure airless spraying system and a programmable logic controller (PLC) automatic control system. The liquid crystal film spaying machine utilizes warm water and the specific high-performance ceramic core to perform water electrolysis so as to improve activity, meanwhile vitreous components produced by the ceramic in the ionization process dissolve in the water to form low-temperature glass, then the low-temperature glass is mixed with a raw material in the auxiliary material tank in a proportioning mode to form crystal functional liquid, and impulse current occurs on the contacted and cleaned coating surface through pressurized spraying, is combined with the vitreous components in the anodic crystal functional liquid and simultaneously reacts with carbon dioxide in the air to form a crystal film. The liquid crystal film spaying machine and the film spaying process are high in automation degree, and the problems of high technical cost, high energy consumption and large difference caused by manual waxing or glazing in the prior art can be effectively solved.

Owner:JIANGSU ZHONGOU FERTILIZER

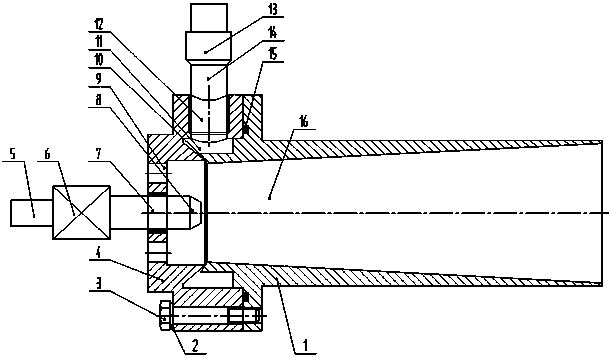

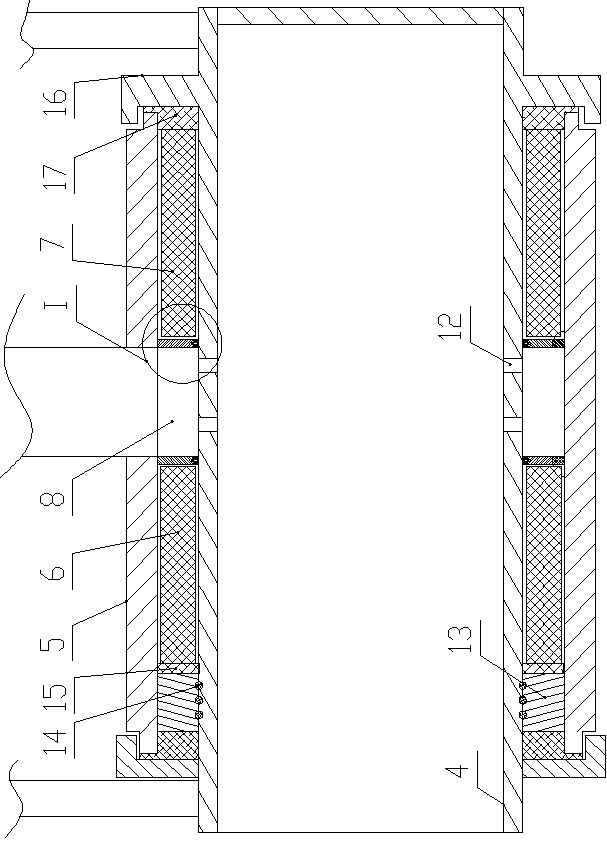

A self-excited oscillation high-efficiency atomization device driven by ultrasonic airflow

ActiveCN105921338BEnhanced spray atomization effectLarge coverage area of water mistLiquid spraying apparatusSelf-oscillationWater flow

The invention discloses a water flow self-oscillation efficient atomization device under push of ultrasonic air flow, which comprises a liquid and gas leading-in shell and a liquid and gas oscillation shell, wherein a spiral water flow leading-in valve is arranged in the liquid and gas leading-in shell, an air flow decreasing channel is arranged at the center of the spiral water flow leading-in valve, and a spiral groove is arranged on the outer wall of the spiral water flow leading-in valve; an air flow guide tube is arranged at one side of the liquid and gas leading-in shell, and the air flow decreasing channel is connected with the air flow guide tube; an air flow ultrasonic oscillation cavity is formed in the liquid and gas oscillation shell; and a water mist leading-out channel is arranged on a tail bottom plate of the liquid and gas oscillation shell, an oscillation baffle plate is connected with a water flow oscillation generating block through a spring, and a water mist increasing channel is arranged in the water flow oscillation generating block. The device has no need of being provided with power machinery parts and external power sources thereof and has the advantages of being good in spray atomization effect, large in water mist coverage area, easy to control and adjust, convenient to use, relatively small in noise and safe and reliable in working.

Owner:TAIYUAN UNIV OF TECH

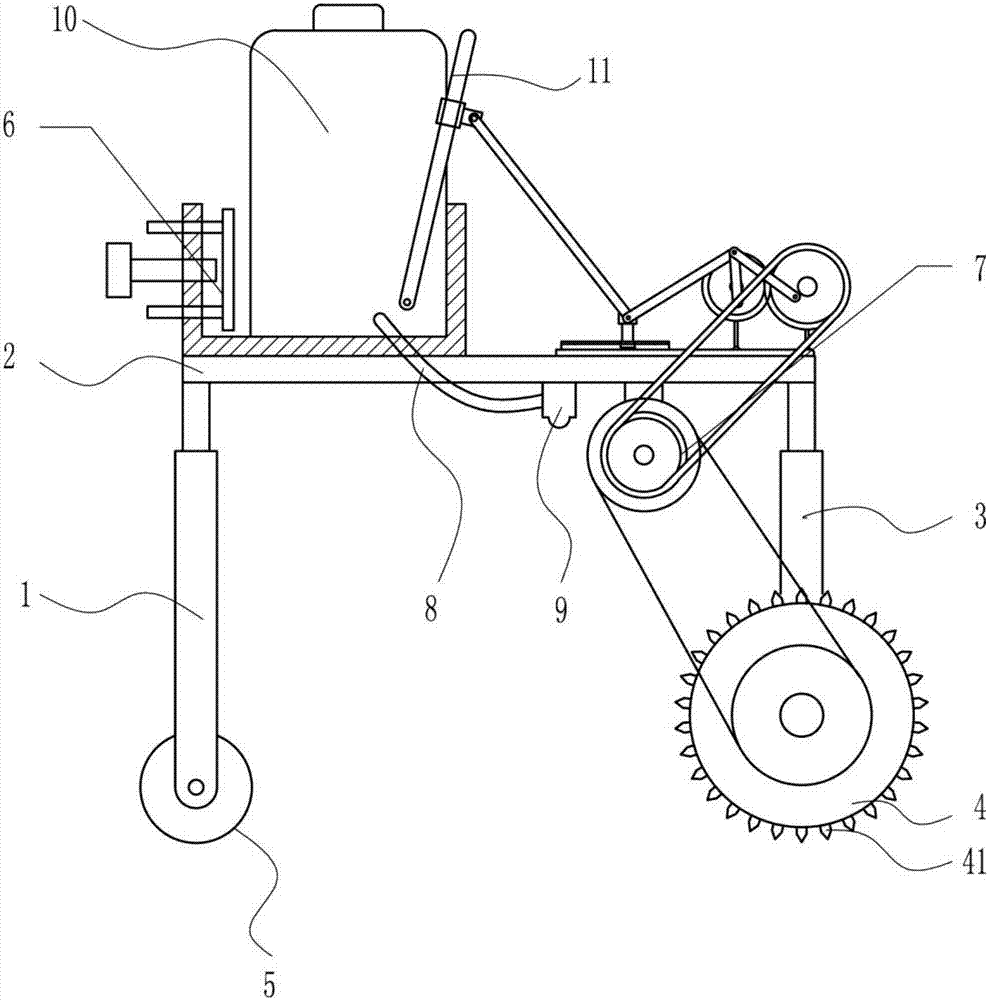

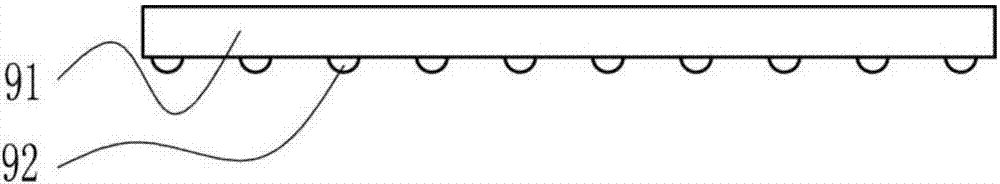

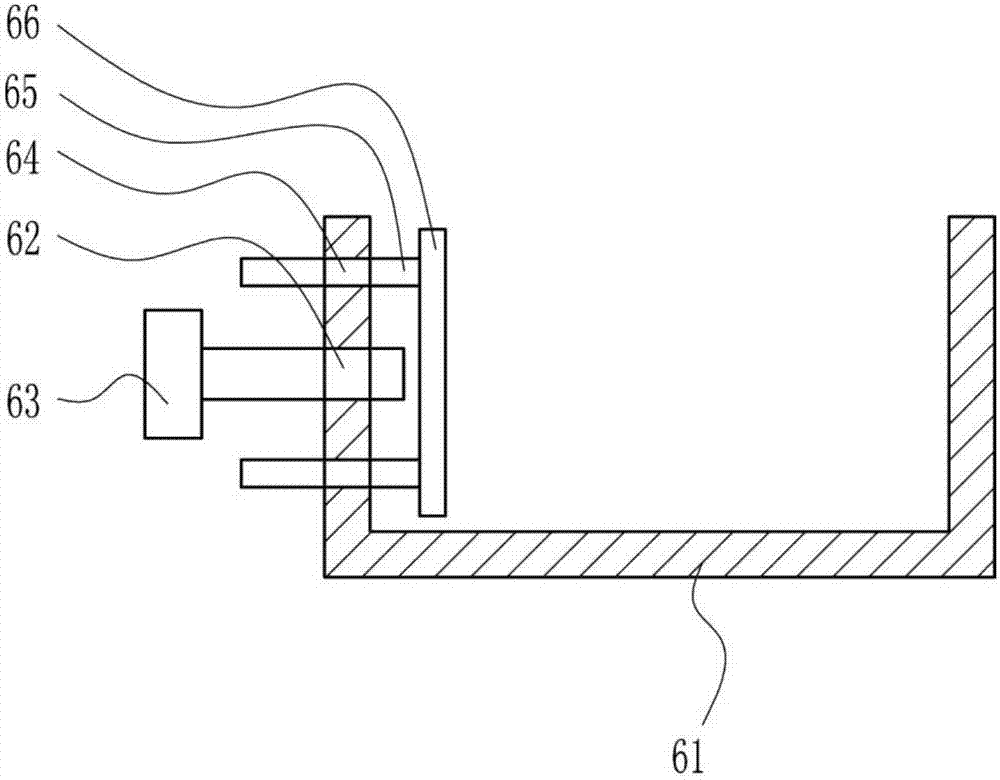

Spraying cart dedicated for garden lawn

InactiveCN107873683AReduce riskEnhanced spray atomization effectInsect catchers and killersAgricultural engineeringGarden lawn

The present invention relates to a spraying cart, and especially relates to a spraying cart dedicated for a garden lawn. The technical problem to be solved is to provide a spraying cart dedicated fora garden lawn. To solve the technical problem, the present invention provides the spraying cart dedicated for the garden lawn, comprising a first telescopic rod, a second telescopic rod, a transversesupport, a first wheel, a second wheel and teeth; the first telescopic rod and the second telescopic rod are symmetrically disposed at left and right sides of the transverse support, the first wheel is connected below the first telescopic rod, the second wheel is connected below the second telescopic rod, the diameter of the second wheel is greater than that of the first wheel, and the periphery of the second wheel is provided with a loop of teeth. The spraying cart is manually pulled for spraying, the atomization effect is good, both time and labor are saved, the risk of manually spraying soup is largely reduced, working efficiency is effectively improved, and the spraying cart is low in cost, simple in manufacture and convenient to use and is firm and stable.

Owner:胡经宇

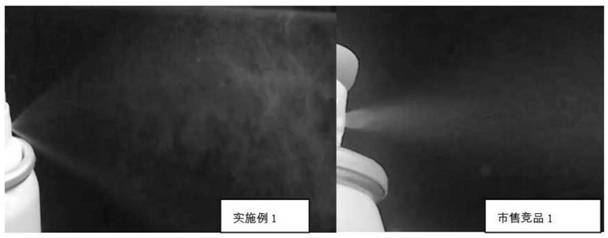

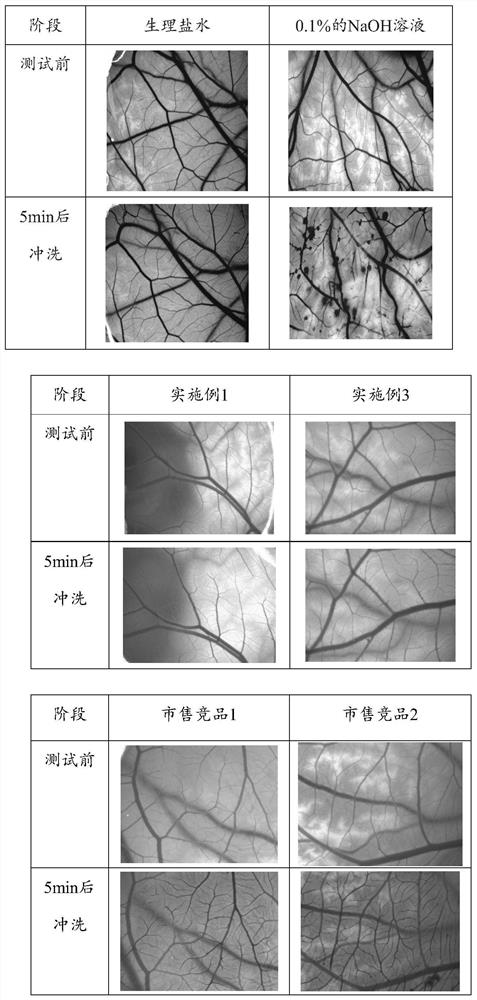

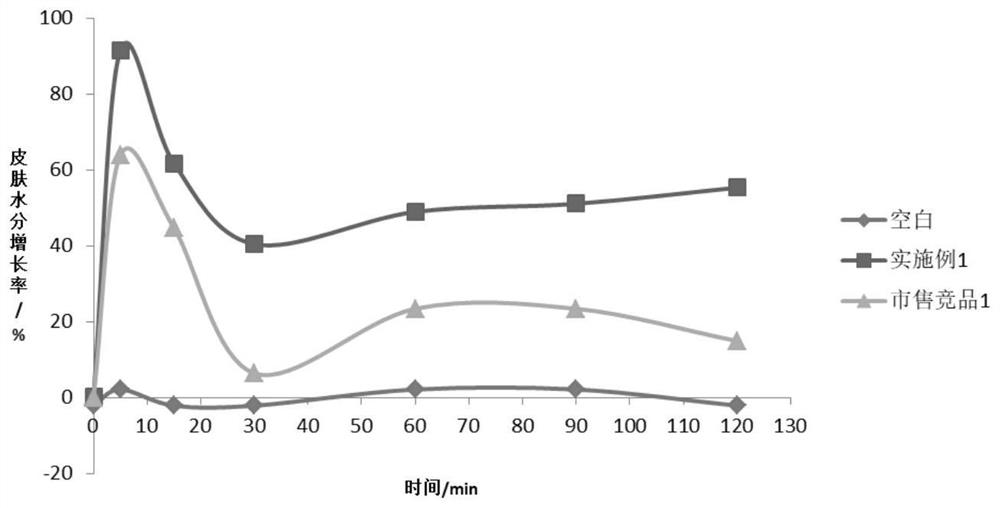

A kind of spray preparation for improving atomization effect and preparation method thereof

The invention discloses a spray preparation for improving the atomization effect, which comprises the following components in parts by weight: 0.15-1.2 parts of an atomized composition, 0.5-5 parts of a moisturizing agent, 0.2-5 parts of active components, antiseptic 0.1-1 parts of components, water balance, the sum of the parts by weight of the above-mentioned components is 100 parts; the atomized composition is composed of surfactant and grease, and the parts by weight of the surfactant are the same as The ratio of parts by weight of oil is 2:1. The spray formulation of the present invention is matched with the spray composition and the moisturizing agent, so that the atomized particles are uniform and fine, and the spray effect is soft, and at the same time, the spray formulation has good safety and moisturizing effect. The invention also discloses a preparation method of the spray preparation for improving the atomization effect.

Owner:YUNNAN BOTANEE BIO TECH GRP CO LTD +1

Nozzle of interrupted clear water extinguisher

InactiveCN102166398BTangential thrust safetySufficient tangential thrustFire rescueElectricityCombustion

The invention discloses a nozzle of an interrupted clear water extinguisher, which comprises a nozzle shell, wherein the nozzle shell is internally and fixedly provided with an interrupted flow guide seat, and the flow guide seat is provided with at least one flow guide column installing hole; cup bottoms of the flow guide column installing holes with cup-shaped structures are provided with a plurality of water spraying holes, and the eccentricities e between the flow guide column installing holes and the water spraying holes are equal to 0.1-3mm; and the flow guide column installing holes are internally and movably provided with a plurality of helical type flow guide columns, the surface of the each helical type flow guide column is provided with at least one helical flow guide groove, and the helical angles alpha of the helical flow guide grooves are equal to 30-60 degrees; and the distance from the bottom of each helical flow guide groove to the axial lead of each helical type flowguide column is less than the semidiameter of each water spraying hole. The ratio of the diameter D of each flow guide column installing hole to the diameter d of each water spraying hole D / r is equal to 2-3. The nozzle not only can extinguish a combustion source with electricity by the clean water, but also is reasonable and simple in structure, safe and convenient in use, and widely used for various fire-fighting lances.

Owner:东台市星海船用设备有限公司

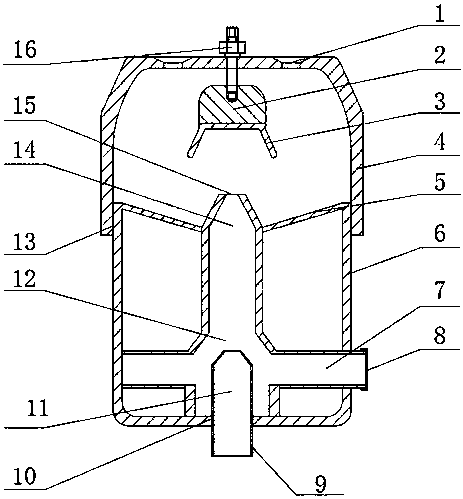

engine

ActiveCN104405549BHeating temperature is easy to controlEnhanced spray atomization effectFuel injection apparatusMachines/enginesFuel oilThermal efficiency

The invention discloses an engine, which comprises: a fuel rail; a plurality of connecting pipes; a plurality of fuel injectors, which are respectively connected to the fuel rail through a plurality of connecting pipes; used for detecting a plurality of fuel injectors A plurality of fuel injection detection devices for the working state of the fuel tank; a plurality of fuel heating devices, and a plurality of fuel heating devices respectively corresponding to a plurality of connecting pipes. Each fuel heating device includes: a heater assembly, the heater assembly includes a temperature detection module and A heater; a driver; a controller, the controller is respectively connected with a plurality of fuel injection detection devices and a plurality of engine fuel heating devices. According to the engine of the embodiment of the present invention, the engine can reduce the phenomenon of fuel wet wall and engine oil dilution, make the engine combustion process more complete, and produce less carbon deposits and hydrocarbon emissions, improve the thermal efficiency of the engine, and reduce fuel consumption.

Owner:GREAT WALL MOTOR CO LTD

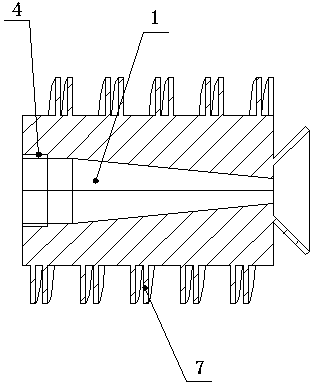

Liquid crystal film shooting machine

InactiveCN104722421AHigh degree of automationHigh technology costLiquid spraying apparatusIonizationHeating system

The invention discloses a liquid crystal film shooting machine which comprises a case, a feedwater pipeline portion sleeve, a heating system, a ceramic core, a water storage tank, a fuel tank, a supplementary material box, a flow-control device, a high-pressure airless spraying system and an automatic PLC (programmable logic controller) control system. Water is electrolyzed and increased in activity through the high-performance ceramic core by the aid of warm water, glassy components generated during ionization process of ceramics are dissolved in the water to form low-temperature glass and then blended and matched with raw materials in the supplementary material box to form functional crystal liquid, and the functional crystal liquid generates surge current via pressurized spraying and contacting the spraying surface which is cleaned, so that the functional crystal liquid can be combined together with glass components in the functional crystal liquid and react with carbon dioxide in the air to form a crystallized film. The liquid crystal film shooting machine is high in automation level, and can effectively solve problems about high cost, high energy consumption and bigger difference existing in existing manual waxing or glaze sealing technologies in the prior art.

Owner:SHANDONG URBAN MINING ENVIRONMENTAL PROTECTION GRP

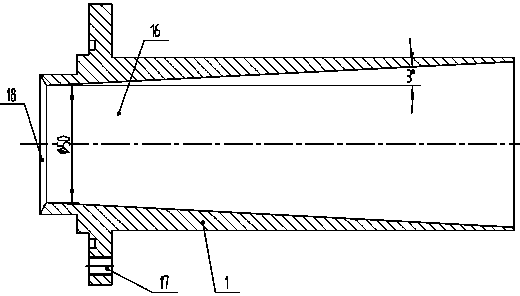

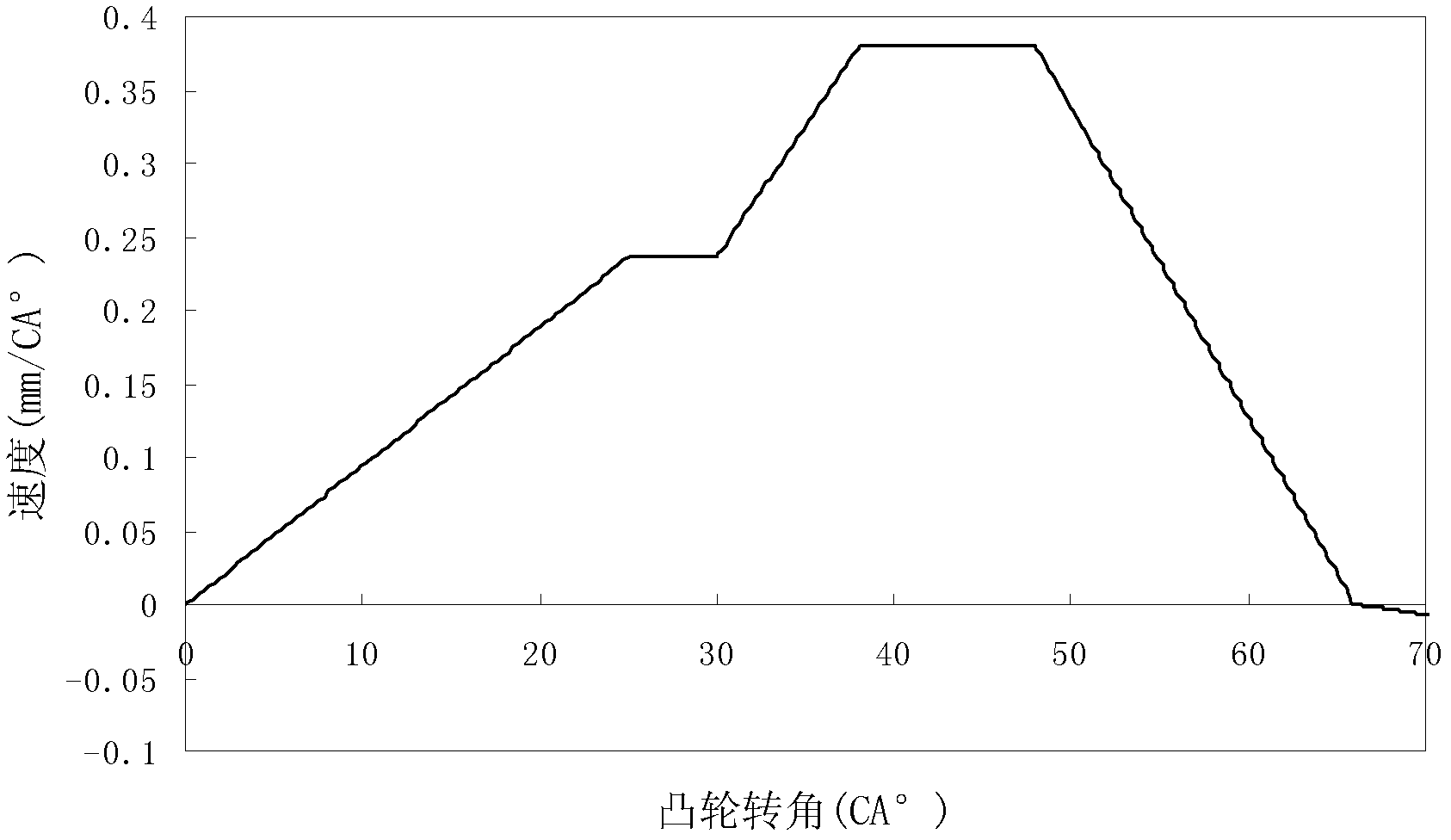

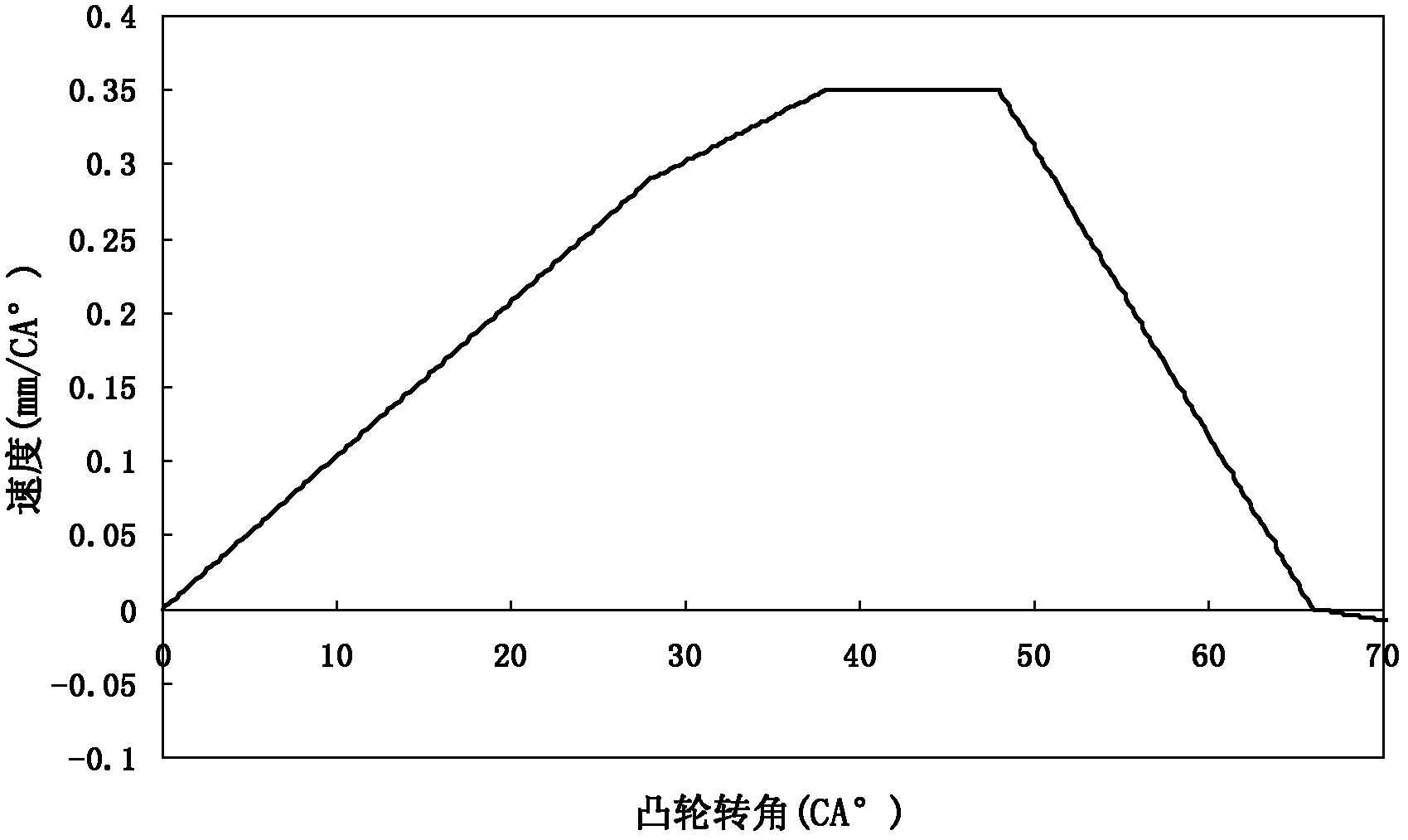

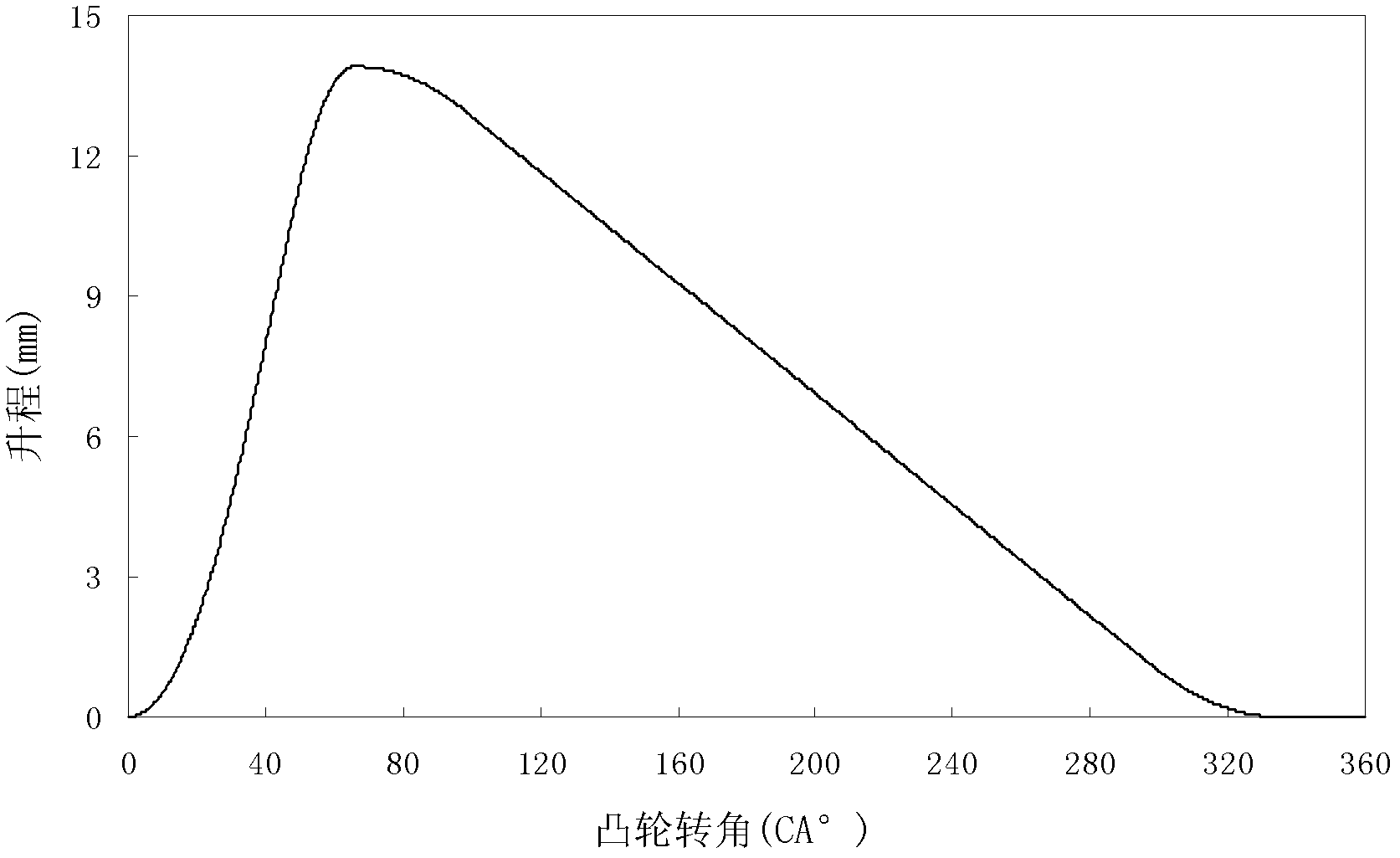

Cam based on flexible engine oil injection

InactiveCN102678410AStable jobEmission reductionFuel injection apparatusMachines/enginesInjection pressureInitial rate

The invention aims to provide a cam based on flexible engine oil injection. The cam comprises a rise travel section and a return section, wherein the rise travel section corresponds to a positive equally accelerating stage, a working section and a positive equally decelerating stage of a motion rule of an engine plunger driven piece; the return section corresponds to a reverse equally accelerating stage, a reverse constant speed stage and a reverse equally decelerating stage of the motion rule of the engine plunger driven piece; the reverse constant speed stage has the rate of v3; and the working section comprises an accelerating stage and a positive constant speed stage, wherein the accelerating stage has the initial rate of v1, and the positive constant speed stage has the rate of v2. The cam has the advantages that the requirements of oil injection pressure, oil injection speed and oil injection timing of a diesel engine at high / low rotary speed can be met, the oil injection flexibility under high-rotary speed working conditions can be improved, and the oil injection pressure under low-rotary speed working conditions is increased.

Owner:HARBIN ENG UNIV

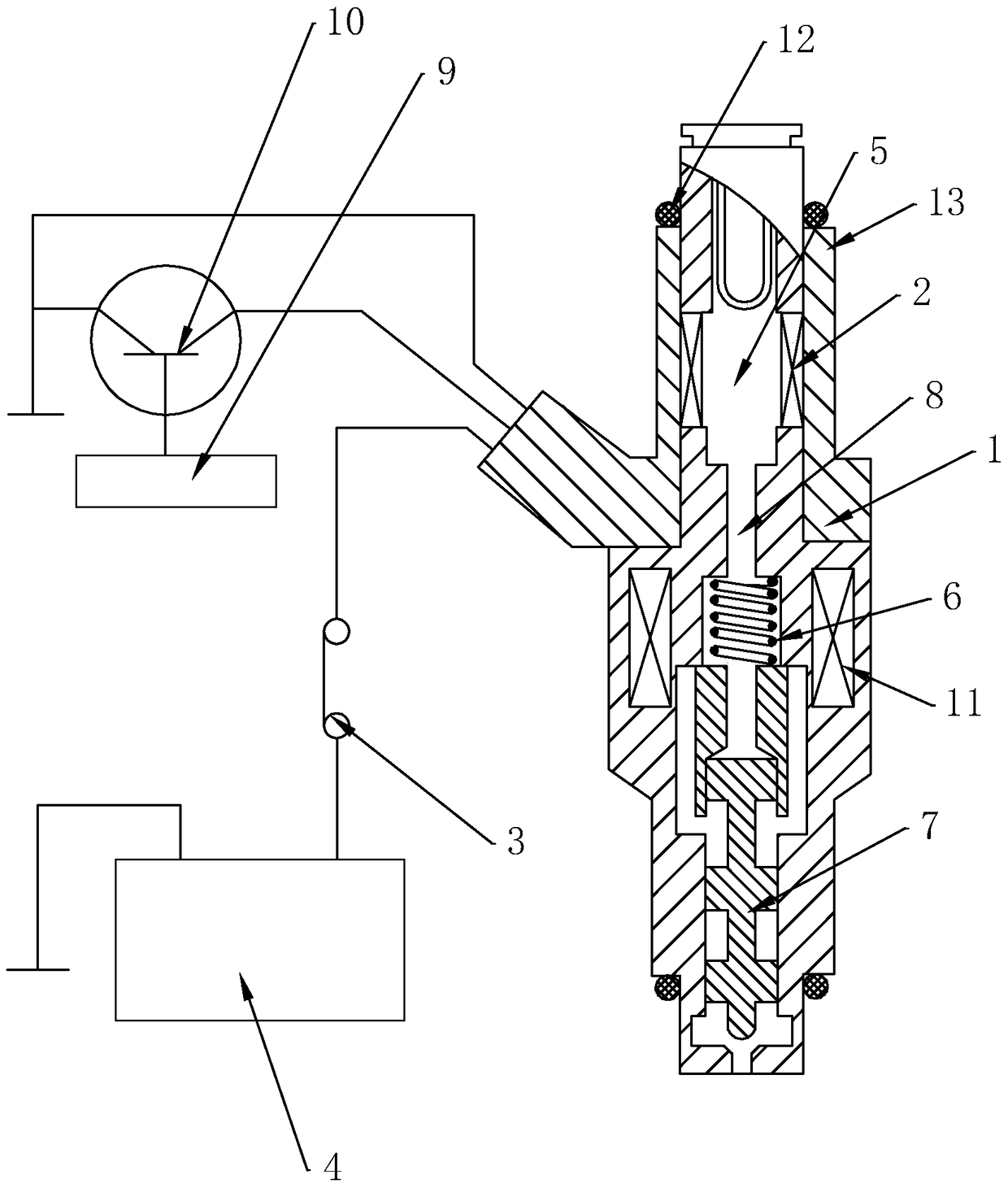

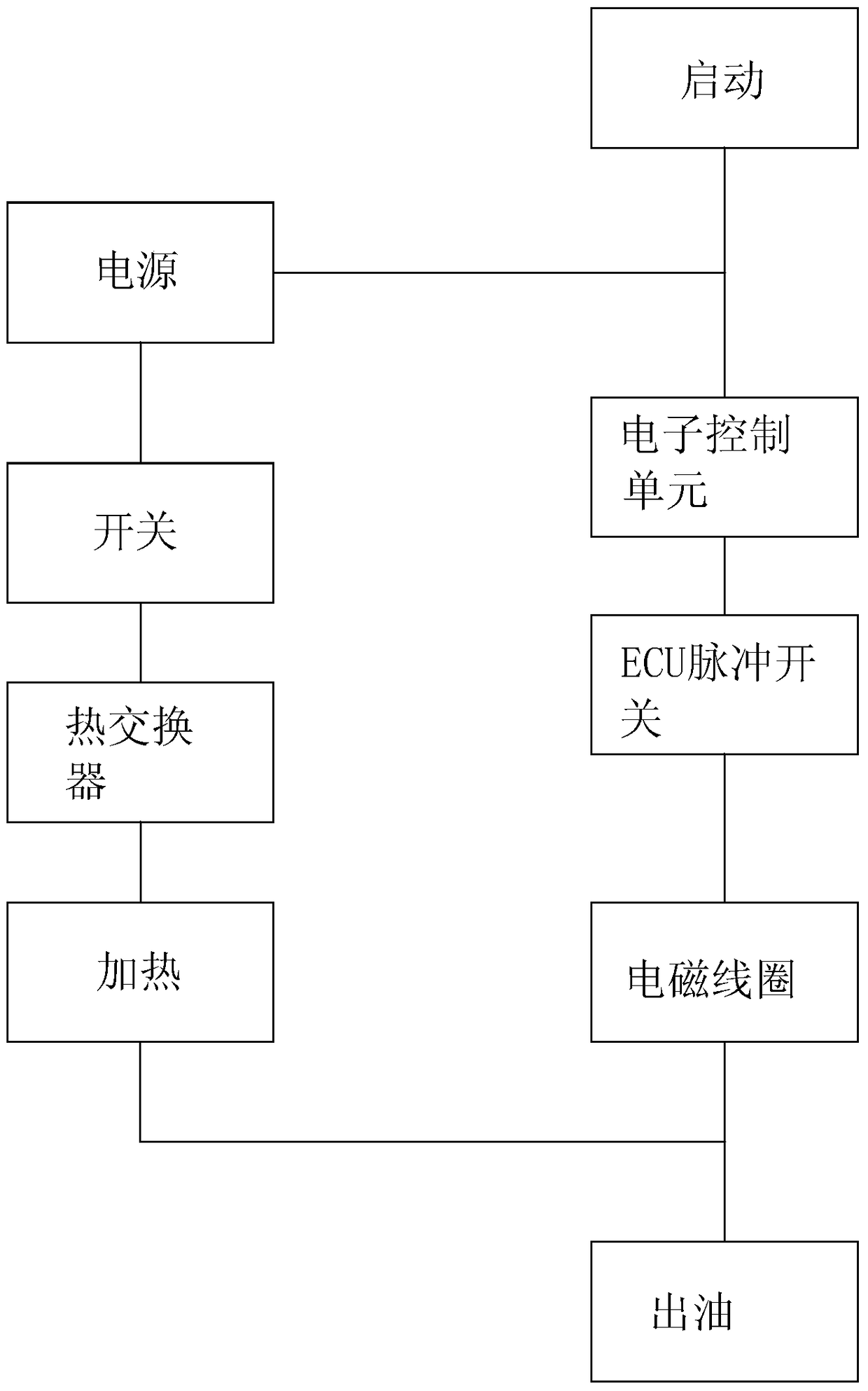

Optimization and Improvement of an Internal Combustion Engine Fuel Injection System Based on Flash Boiling Spray

ActiveCN104879254BHeating fastImprove heating efficiencyFuel injection apparatusMachines/enginesExternal combustion engineLiquid fuel

The invention discloses optimization and improvement of a fuel injection system of an internal combustion engine based on flash boiling spray. The key technical point of the optimization and improvement is that the fuel injection system includes an oil nozzle body; a heat exchanger and a switch are arranged on the oil nozzle body; one end of the switch is connected with a power source, and the heat exchanger is connected to the other end of the switch; an earthing end of the heat exchanger is earthed. Through improving fuel temperature in the nozzle, the optimization and improvement of the fuel injection system of the internal combustion engine based on flash boiling spray can increase the bubble concentration of fluid fuel in the nozzle; and thereby, the goal of flash boiling spray is realized.

Owner:ZHEJIANG UNIV OF TECH

A spiral atomization jet dust suppression device

InactiveCN105863719BIncrease the lateral areaImprove atomization efficiencyDust removalFire preventionEngineeringScrew thread

The invention discloses a screw type atomization-spraying dust precipitating device applicable to atomization of water or water-air and other media with relatively low viscosity. An upper end cover of the device adopts a cylindrical structure, an external thread is arranged at the upper end part, an air inlet is horizontally formed in the middle of the upper end cover and adopts a bolt hole structure, a screw valve is arranged in the center of the upper end cover, and the screw valve and the center of the upper end cover are located on the same axis; a taper hole is formed in the center inside the screw valve and connected with the air inlet, through holes are formed in positions equally spaced from the periphery of the taper hole and are water inlets, a plurality of screw grooves are arranged on the outer edge of the screw valve and have rectangular sections, and the length-width ratio of the rectangles is gradually increased; the upper end cover and an oscillation cavity at the lower end are connected through bolts; the lower end of the oscillation cavity is connected with a connecting piece through threads, the connecting piece adopts a U-shaped groove structure, a bulge is arranged in the middle of the U-shaped groove, and a horn-shaped spray head is arranged in the center of the bulge. The device is simple in structure, easy to control and adjust, good in atomization effect, high in practicability, safe and reliable.

Owner:TAIYUAN UNIV OF TECH

Cam based on flexible engine oil injection

InactiveCN102678410BStable jobEmission reductionFuel injection apparatusMachines/enginesInjection pressureInitial rate

The invention aims to provide a cam based on flexible engine oil injection. The cam comprises a rise travel section and a return section, wherein the rise travel section corresponds to a positive equally accelerating stage, a working section and a positive equally decelerating stage of a motion rule of an engine plunger driven piece; the return section corresponds to a reverse equally accelerating stage, a reverse constant speed stage and a reverse equally decelerating stage of the motion rule of the engine plunger driven piece; the reverse constant speed stage has the rate of v3; and the working section comprises an accelerating stage and a positive constant speed stage, wherein the accelerating stage has the initial rate of v1, and the positive constant speed stage has the rate of v2. The cam has the advantages that the requirements of oil injection pressure, oil injection speed and oil injection timing of a diesel engine at high / low rotary speed can be met, the oil injection flexibility under high-rotary speed working conditions can be improved, and the oil injection pressure under low-rotary speed working conditions is increased.

Owner:HARBIN ENG UNIV

Fully automatic rotary spray device

InactiveCN105971659BAchieve the purpose of automatic rotationEnhanced spray atomization effectDust removalFire preventionWater flowEngineering

A full-automatic rotary spraying device comprises a supporting frame, a rotary water pipe and a water feeding rotating mechanism. The rotary water pipe is rotatably connected to the supporting frame through the water feeding rotating mechanism. The rotary water pipe is in the shape of the Achimedean spiral, the inner end of the rotary water pipe is connected with the water feeding rotating mechanism, and the outer end of the rotary water pipe is sealed. At least two water outlet pipe heads are evenly arranged on the rotary water pipe in the tangential direction of the water flowing direction, and atomizing sprayers are arranged at the outer ends of the water outlet pipe heads. The full-automatic rotary spraying device is reasonable in structure design, good in sealing effect, uniform in water spraying, good in atomizing effect and capable of reducing dust in a coal mining roadway .

Owner:焦作煤业(集团)新乡能源有限公司

A negative pressure suction air-water mixed jet ultrasonic oscillation high-efficiency atomization device

InactiveCN106040510BImprove dust suppression efficiencyGood spray atomization effectLiquid spraying apparatusUltrasonic oscillationAirflow

The invention discloses a negative pressure suction type air-water mixed jet ultrasonic vibration efficient atomization device. The negative pressure suction type air-water mixed jet ultrasonic oscillation efficient atomization device comprises an atomization generating shell and a water-air mixed inlet shell, wherein a water inlet is formed in the lower part of the water-air mixed inlet shell; an air inlet screen is arranged on the side of the water-air mixed inlet shell; after passing through the water inlet and a water inlet channel, water flow is jetted into a water-air mixture convergent channel; negative pressure formed through jetted water draws air flow to enter the water-air mixture convergent channel; mixed water-air flow passes through a water-air mixture throat pipe and is jetted from a water-air mixture jet outlet; a self-exciting oscillation generating baffle plate is mounted on the water-air mixture throat pipe; the water-air mixture jet outlet right faces an ultrasonic oscillation seat; an ultrasonic oscillation annular cavity is arranged below the ultrasonic oscillation seat; through holes are formed in the top of the atomization generating shell; and nozzles which are uniformly and rotatably arranged are placed on the through holes. The device does not need an external air source, and has the advantages that the jet atomization effect is good, the water mist covering range is wide, the concentration of a mist field can be adjusted, the structure is simple, the processing is convenient, and the cost is low.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com