Atomizing and spraying device of conical air flow field

A spray device and airflow field technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve the problems of high water supply pressure and low droplet atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

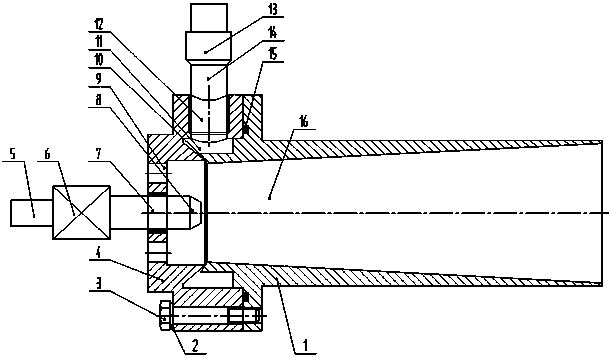

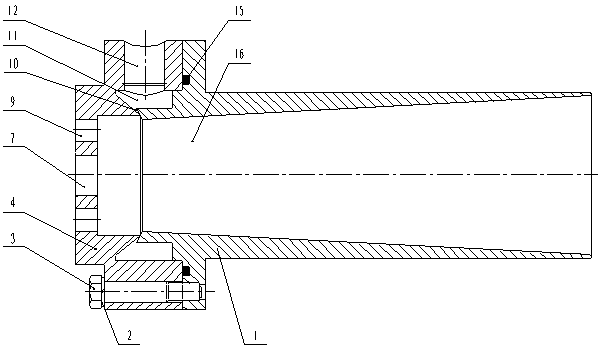

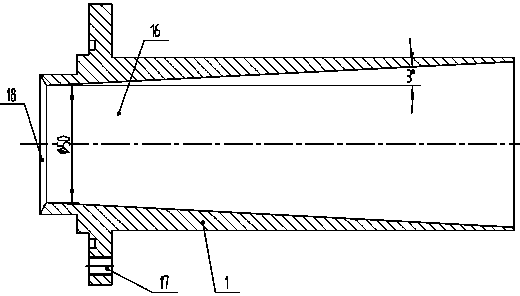

[0027] Such as figure 1 As described above, implementing a conical airflow field atomization injection device is composed of a dust removal end cover 4 and a housing 1. The diameter of the end face of the connection between the dust removal end cover 4 and the housing 1 is Φ120mm, and the length of the dust removal end cover 4 is 48mm, the length of the housing 1 is 202mm, the outer diameter of the housing throat 18 is Φ60mm, the inner diameter of the housing throat 18 is Φ50mm, and the diameter of the end of the channel 16 is Φ74mm. The dust removal end cover 4 and the shell 1 are connected by three bolts 3, and the gaskets selected for connection should be thin copper sheets, which can ensure that the tapered ring gap formed by the dust removal end cover 4 and the shell 1 remains unchanged and It is convenient to disassemble the dust removal end cover and the shell, and its performance is stable; the dust removal end cover 4 is provided with a water pipe inlet 7, a vent hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com