A negative pressure suction air-water mixed jet ultrasonic oscillation high-efficiency atomization device

An ultrasonic oscillation and atomization device technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of inability to meet high-efficiency atomization requirements, weak water turbulence effect, and insufficiently uniform atomization, etc., to achieve water mist coverage Large size, good spray atomization effect, and the effect of improving dust reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

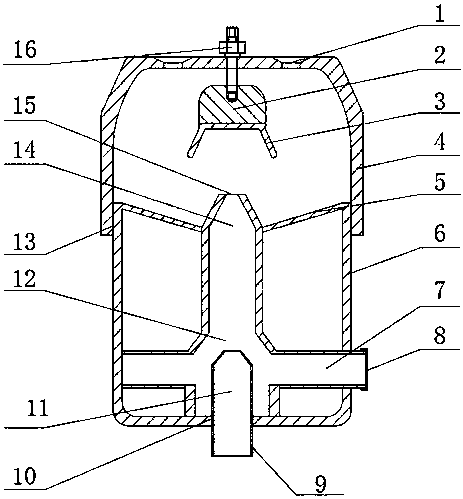

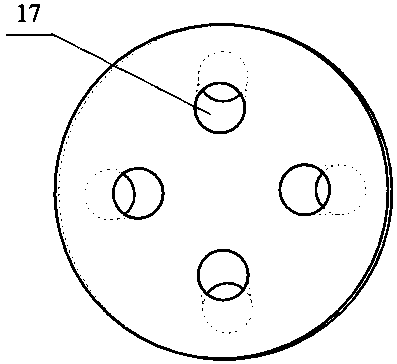

[0021] Such as figure 1 , 2 As shown, a negative pressure suction type air-water mixed jet ultrasonic oscillation high-efficiency atomization device includes an atomization generating shell (4) and a water-gas mixed entering shell (6), an atomizing generating shell (4) and water The air mixed into the shell (6) is connected through the shell adjusting thread (13); the water air mixed into the shell (6) is provided with a water inlet (9) below, and an air inlet screen (8) is provided on the side; The water flow passes through the water inlet (9) and the water inlet channel (11) and enters the water-air mixture tapering channel (12). The lower part of the water inlet channel is cylindrical and the upper part is an inverted cone; Divided into three sections, the lower section is an inverted conical structure, the bottom of the lower section is connected to the air intake chamber, the middle section is cylindrical, and the upper section is an inverted conical water-air mixture th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com