Comprehensive treatment method of dust produced during coal cutting against wind by coal cutter in fully-mechanized coal mining working face

A technology of fully mechanized mining face and comprehensive treatment, applied in the fields of dust prevention, mining equipment, earthwork drilling, etc., can solve the problem of low dust reduction efficiency and achieve the effect of improving dust reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

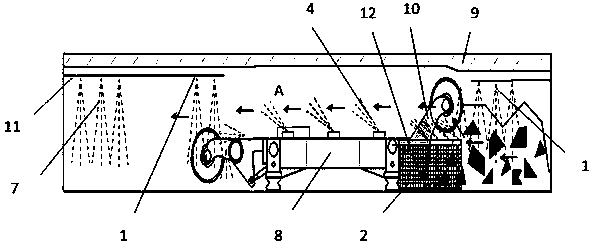

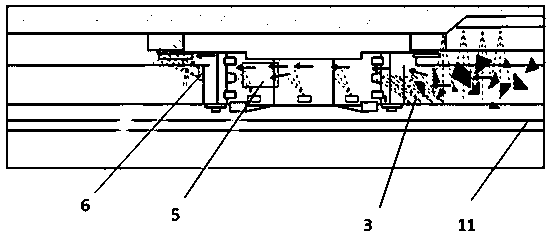

[0022] Such as figure 1 , figure 2 as shown, figure 1 It is the front view when the coal shearer 8 mines the coal body 9, figure 2 For top view. The first spraying device 1 is arranged on the top of the shearer support 11, the second spraying device 3 is evenly arranged on the rigid cantilever beam 12, the dust curtain 2 is hung under the rigid cantilever beam 12, and the third spraying device 4 is evenly arranged On the side of the walking part of the coal mining machine that is close to the sidewalk. The dust curtain 2 and the rocker arm 10 of the windward side shearer can form a semi-closed space at the end of the shearer, which can accumulate the dust generated by the collapse impact. The fourth spraying device 5 is arranged on the side of the shearer face close to the coal wall, the fifth spraying device 6 is installed at the root of the rocker arm of the drum on the downwind side of the shearer, and the sixth spraying device 7 is arranged on the top of the shearer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com