Large off-line ash removal bag-type dust collector

A bag-type dust collector and dust collector technology are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., which can solve problems such as shortened service life, damage, and blockage of filter bags, so as to improve dust reduction efficiency and prolong service life. , The effect of flue gas flow load balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

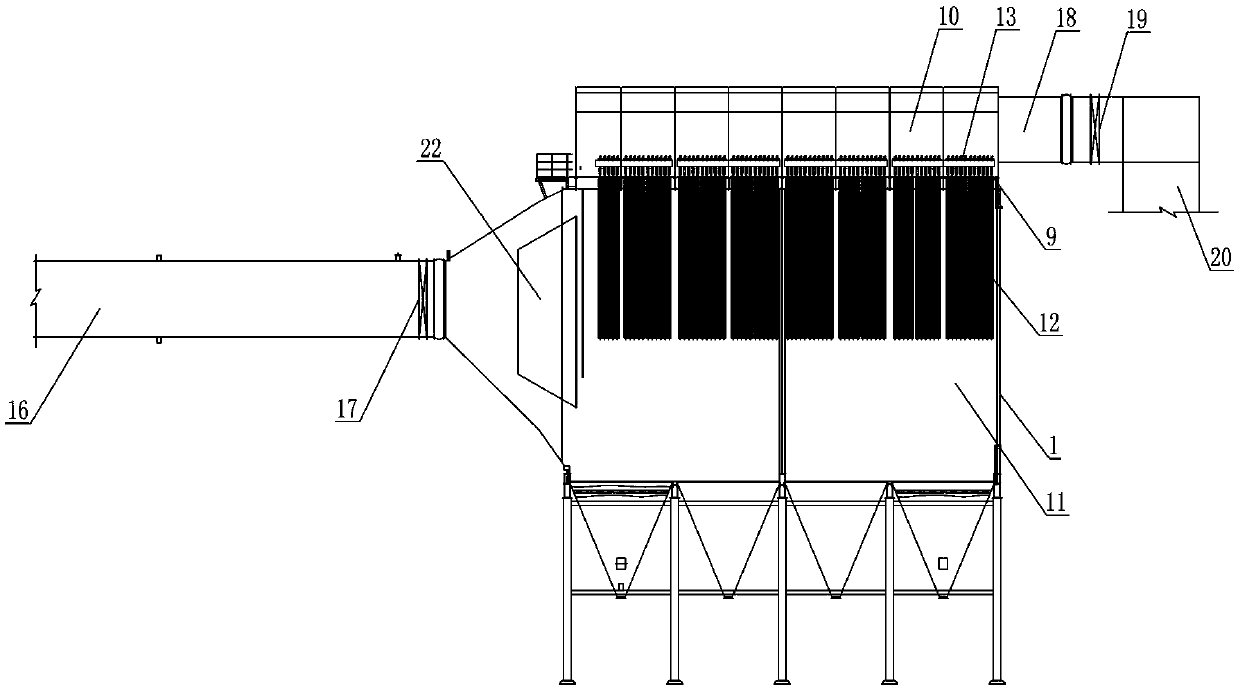

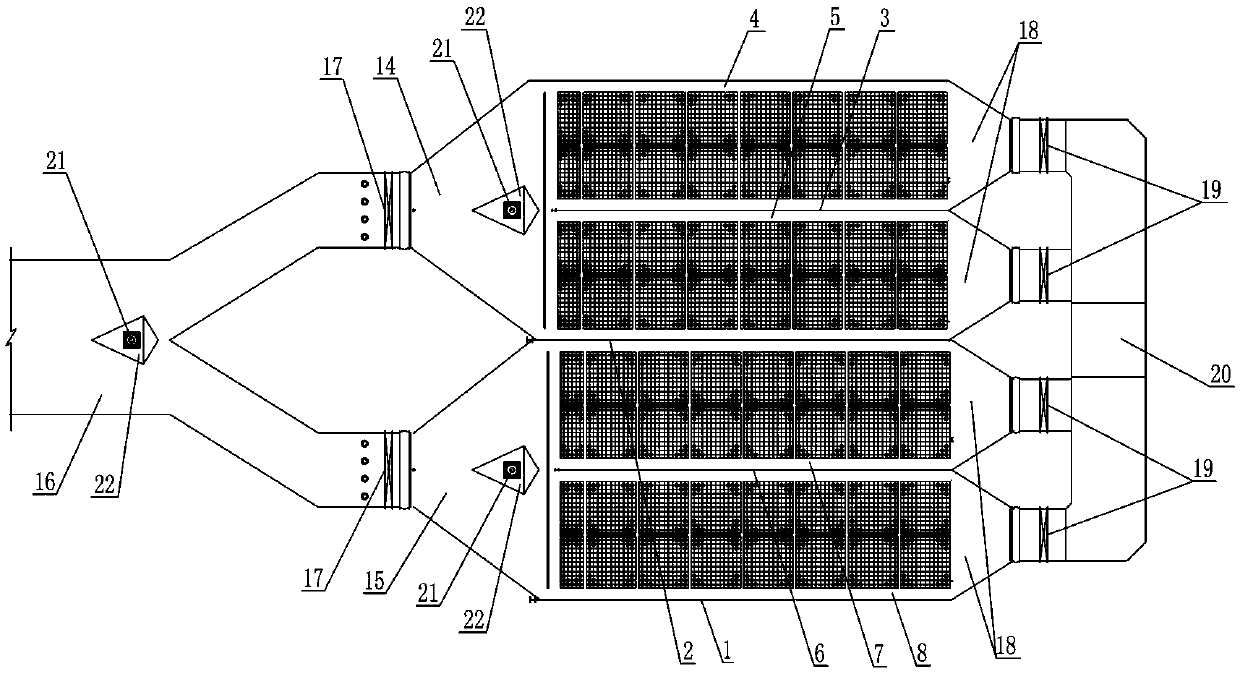

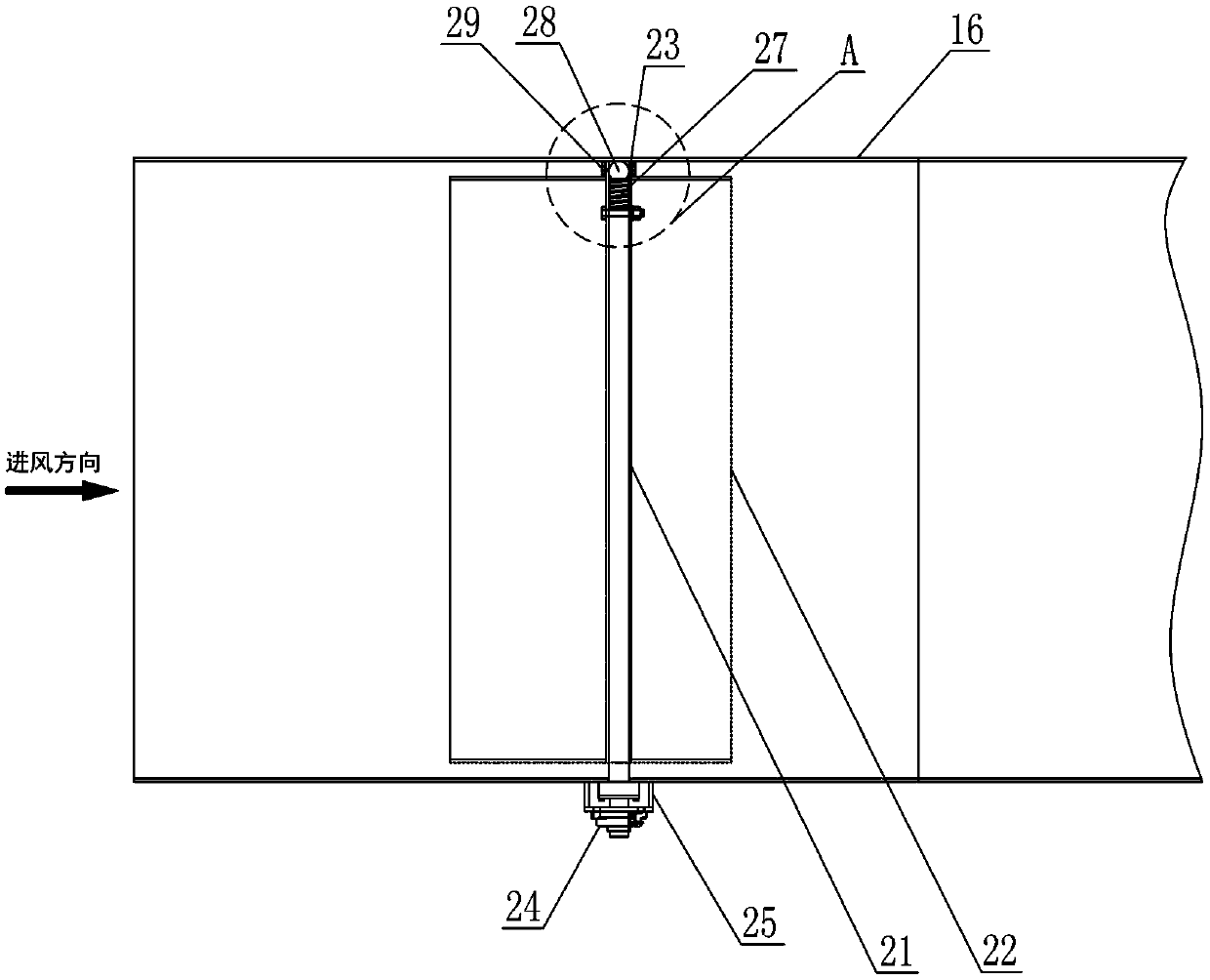

[0017] Such as figure 1 , figure 2 As shown, the above-mentioned large-scale off-line dust-cleaning bag-type dust collector includes a dust collector box 1, and the interior of the dust collector box 1 is divided into two rows of independently sealed left and right passages by the first partition 2, The inside of the left channel is divided into two rows of independently sealed first left chamber 4 and first right chamber 5 by the second left partition 3, and the inside of the right passage is divided into two rows of independently sealed by the second right partition 6. The second left chamber 7 and the second right chamber 8, each chamber is divided into an upper clean air chamber 10 and a lower smoke chamber 11 by a flower board 9, and vertically hung on the flower board 9 of each chamber A number of filter bags 12, in the upper clean air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com