High molecular spraying dust suppressant prepared based on graft copolymerization method and preparation method

A dust suppressant and polymer technology, applied in the field of mine dust-proof dust collector, can solve the problems of single chemical dust suppression technology, high material cost, secondary environmental pollution, etc., and achieve the effect of reducing dust diffusion and improving dust reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

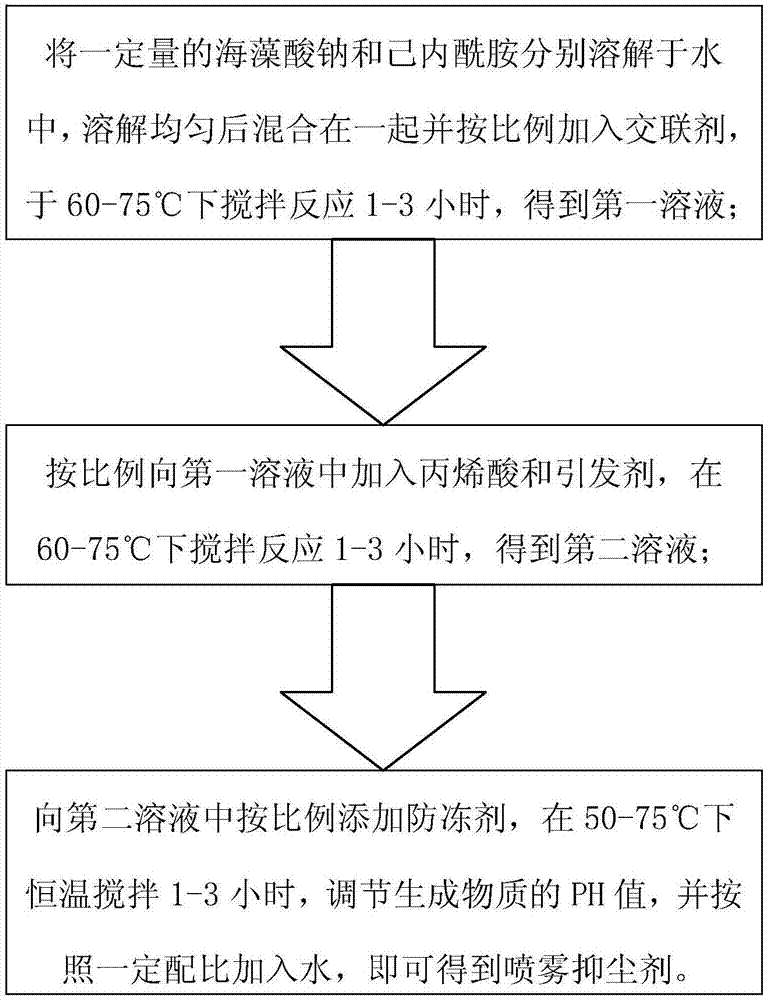

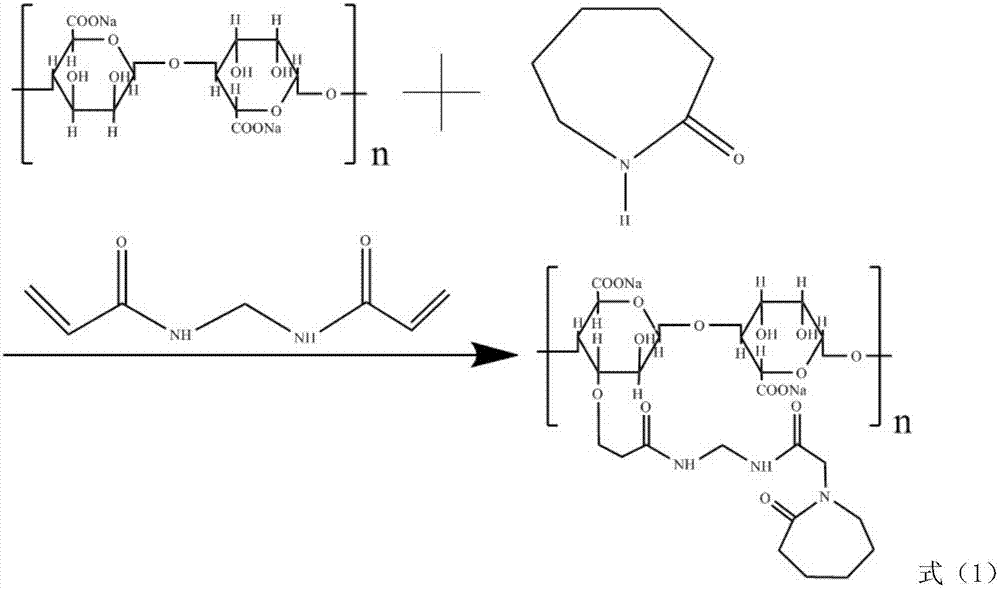

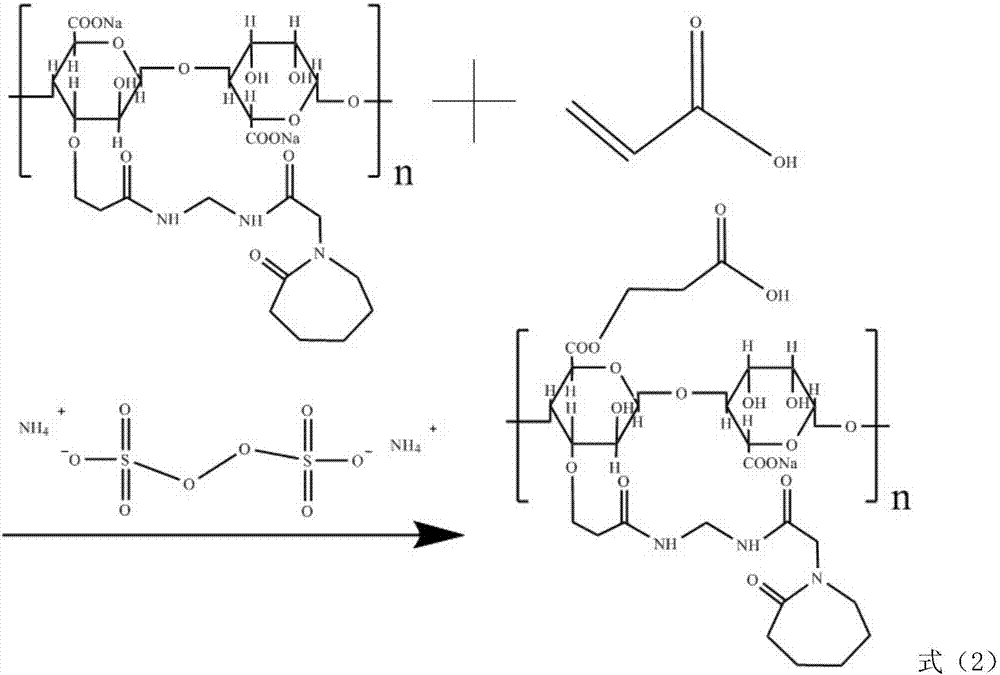

[0033] Weigh 1.5g of sodium alginate and dissolve it in 200ml of water. Dissolve another 6g of caprolactam in 50ml of water and add 0.04g of N,N'-methylenebisacrylamide, mix with sodium alginate, and stir at 60°C for reaction 1 Hour. 1ml of acrylic acid and 0.08g of ammonium persulfate were added thereto, and the temperature was kept at 60° C. and stirred for 1 hour to react. Add 0.024g of potassium monododecyl phosphate to it, add water to 300ml, stir and react at a constant temperature of 50°C for 1h, adjust the pH value to 7, and add water to dilute. Final test related performance.

Embodiment 2

[0035] Weigh 1.5g of sodium alginate and dissolve it in 200ml of water. Dissolve another 6g of caprolactam in 50ml of water and add 0.04g of N,N'-methylenebisacrylamide, mix with sodium alginate, and stir at 60°C for reaction 1 Hour. 2ml of acrylic acid and 0.08g of ammonium persulfate were added thereto, and the temperature was kept at 60° C. and stirred for 1 hour. Add 0.024g of potassium monododecyl phosphate to it, add water to 300ml, stir and react at a constant temperature of 50°C for 1 hour, adjust the pH value to 7, and add water to dilute. Final test related performance.

Embodiment 3

[0037] Weigh 1.5g of sodium alginate and dissolve it in 200ml of water, and another 6g of caprolactam is dissolved in 50ml of water and add 0.04g of N,N'-methylenebisacrylamide, mix with sodium alginate, stir and react at 60°C for 1 hour . 3ml of acrylic acid and 0.08g of ammonium persulfate were added thereto, and the mixture was kept at 60° C. and stirred for 1 hour. Add 0.024g of potassium monododecyl phosphate to it, add water to 300ml, stir and react at a constant temperature of 50°C for 1 hour, adjust the pH value to 7, and add water to dilute. Final test related performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com