Building construction site dust suppression device

A construction and on-site technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separating agents, can solve the problems of not being able to adapt well to site needs, inconvenient installation and disassembly, and large manual labor. Reduce the amount of manual labor, improve construction efficiency, and achieve high dust reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

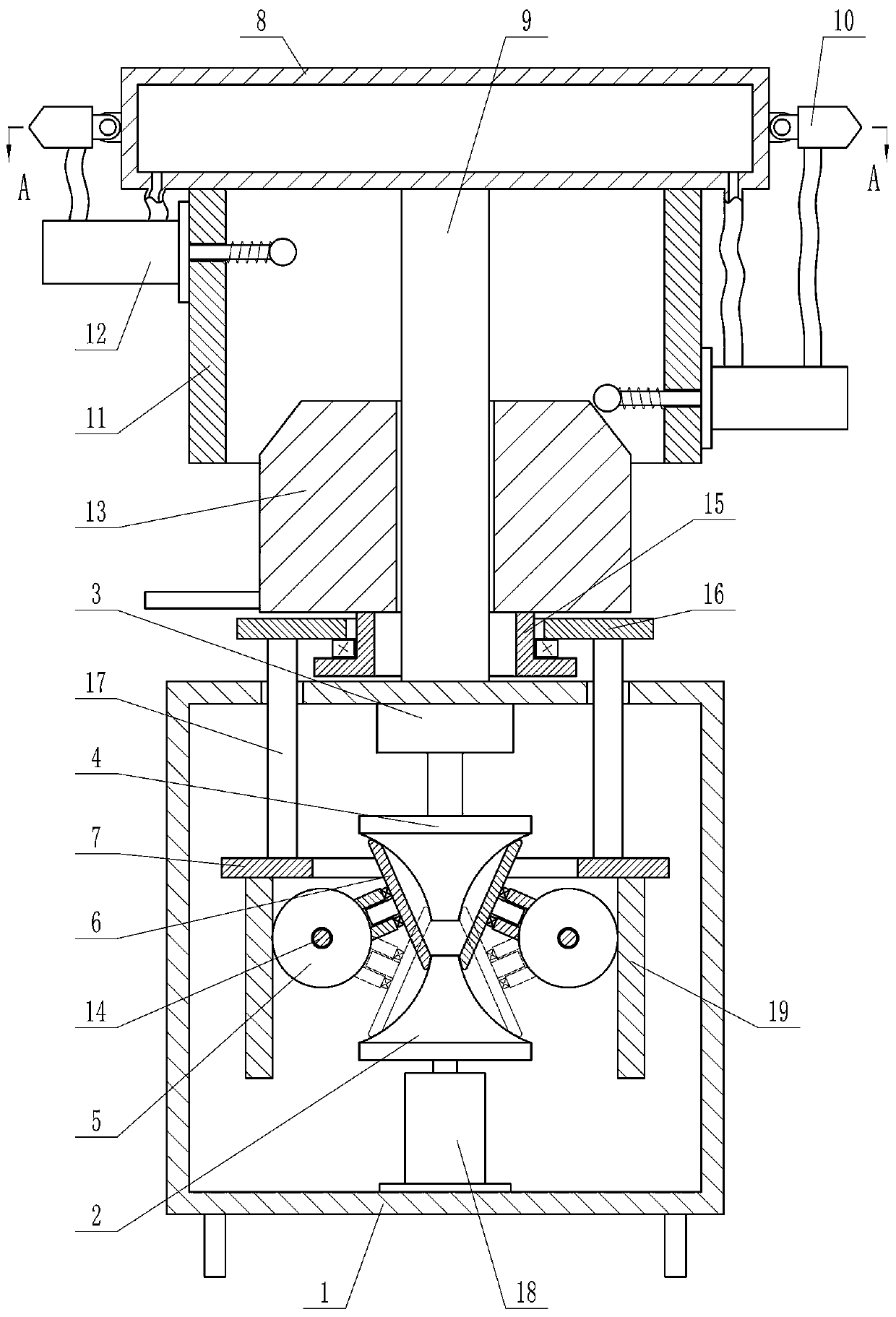

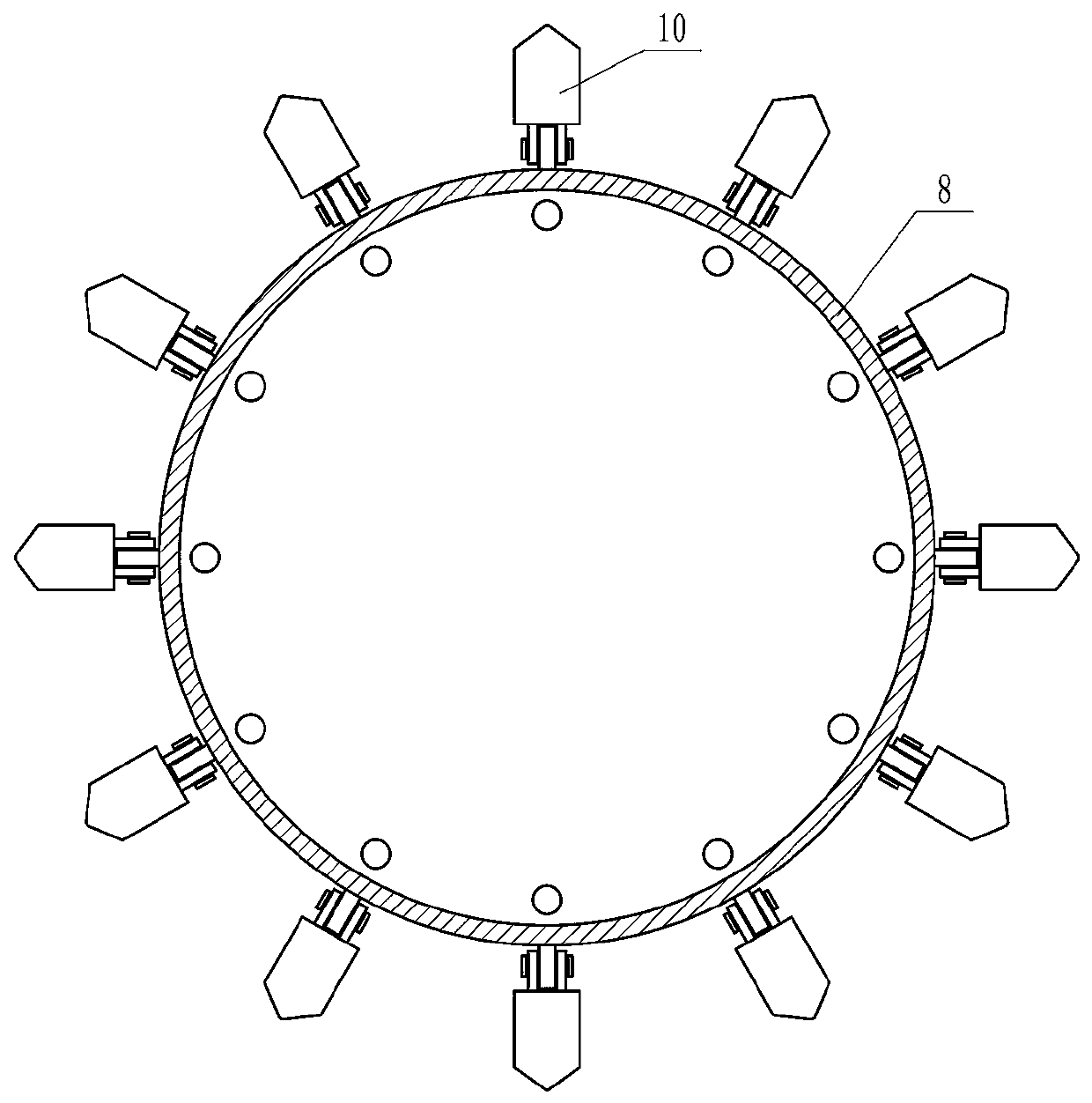

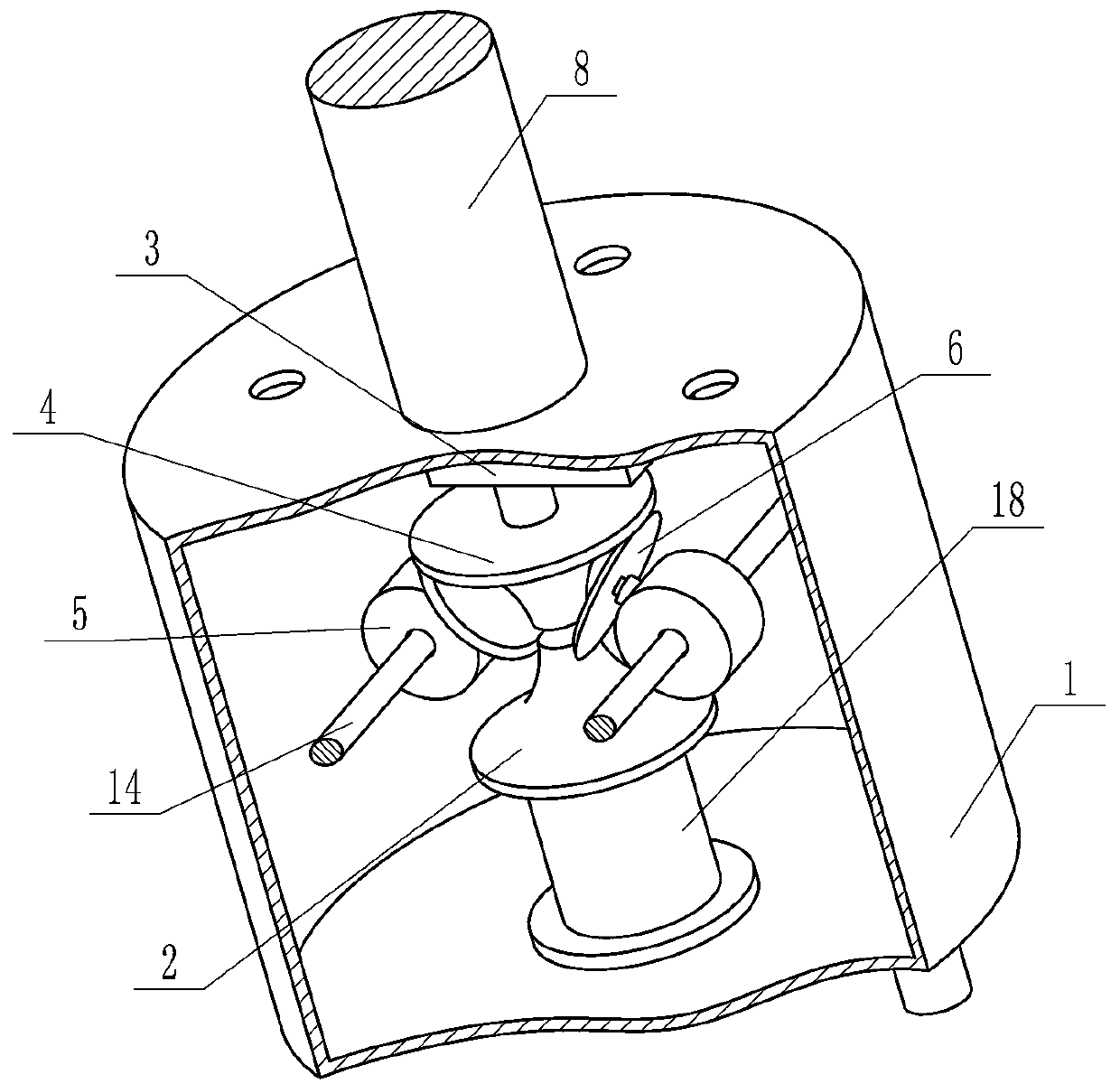

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Depend on Figure 1 to Figure 6 Given, the present invention includes a housing 1 placed horizontally. There is a horizontal and actively rotating first friction wheel 2 inside the housing 1. The diameter of the first friction wheel 2 gradually decreases from bottom to top. The upper side of the housing 1 A water pump 3 is fixed on the plate, and a second friction wheel 4 is fixed on the lower side of the water pump 3. The diameter of the first friction wheel 2 gradually decreases from bottom to top, and the second friction wheel 4 is symmetrical to the first friction wheel 2 up and down. The left and right sides of friction wheel 2 all have the gear 5 that end faces forward and can rotate, and the side of gear 5 near the first friction wheel 2 has the friction disc 6 that can rotate, and the rotation of gear 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com