Liquid crystal film shooting machine

A technology of liquid crystal and film injection machine, which is applied in the direction of liquid spraying device, spraying device, etc., which can solve the problems of high cost, large difference, and high energy consumption of manual waxing or sealing glaze technology, and achieve good spraying atomization effect, There is no spraying dead angle and the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical content of the present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

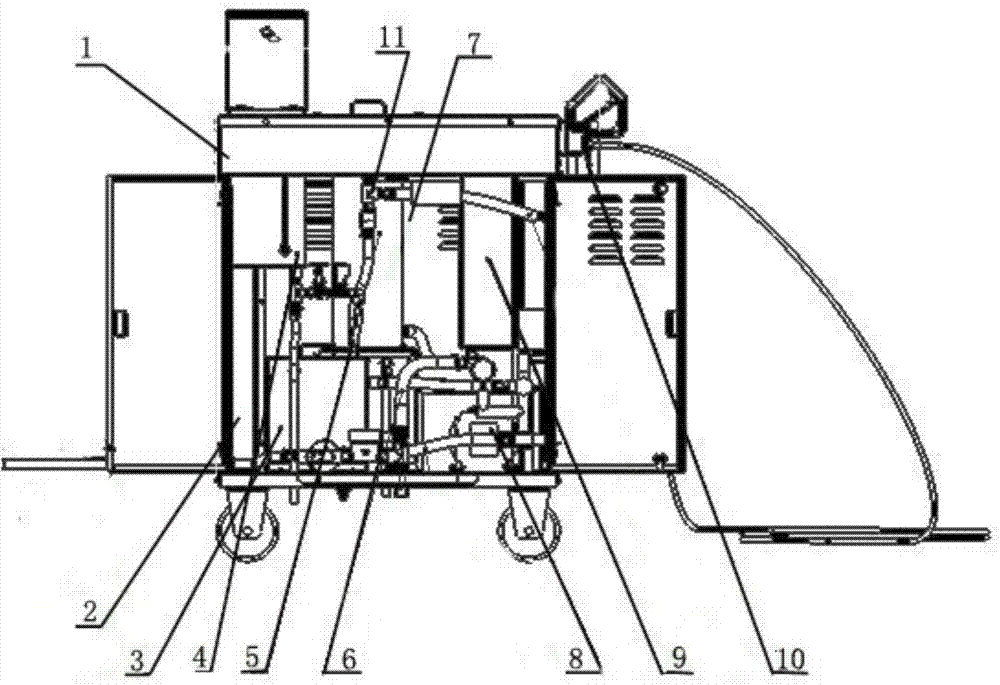

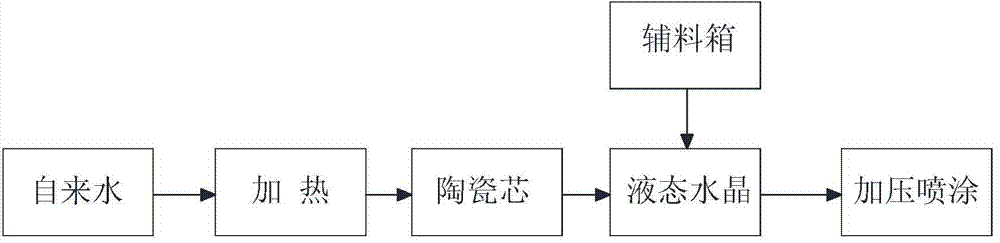

[0015] combine figure 1 , figure 2 As shown, a liquid crystal film shooting machine includes a chassis 1, a water supply pipeline cover 6, a heating system 9, a ceramic core 7, a water storage tank 3, a fuel tank 2, an auxiliary material box 4, a flow control device 5, and a high-pressure airless Spraying system 8 and PLC automatic control system. The high-pressure airless spraying system has high efficiency, no spraying dead angle, and good spraying atomization effect. The high-pressure airless spraying system 8 is equipped with a high-pressure airless spraying gun 10, and the PLC automatic control system automatically detects, alarms and protects the liquid crystal spray film various devices of the machine.

[0016] The water supply pipeline part set 6 includes a water body filter 11, a pressure reducing shut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com