Full-automatic rotary spraying device

A rotary spraying and fully automatic technology, which is applied in safety devices, mining equipment, earth square drilling and mining, etc., can solve the problems of small coverage, large water consumption, inconvenient use, etc., and achieve good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

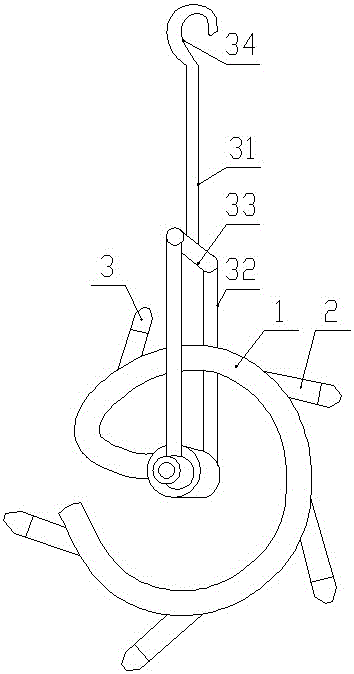

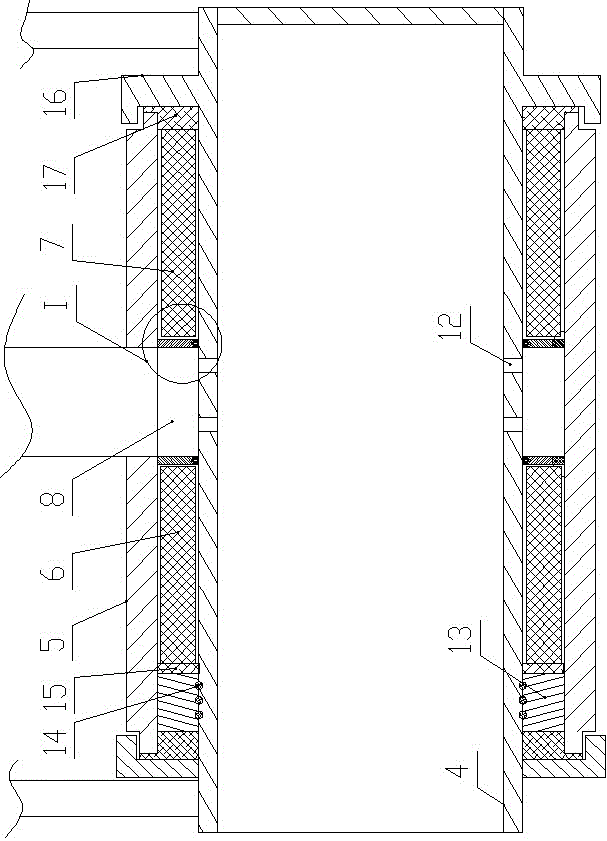

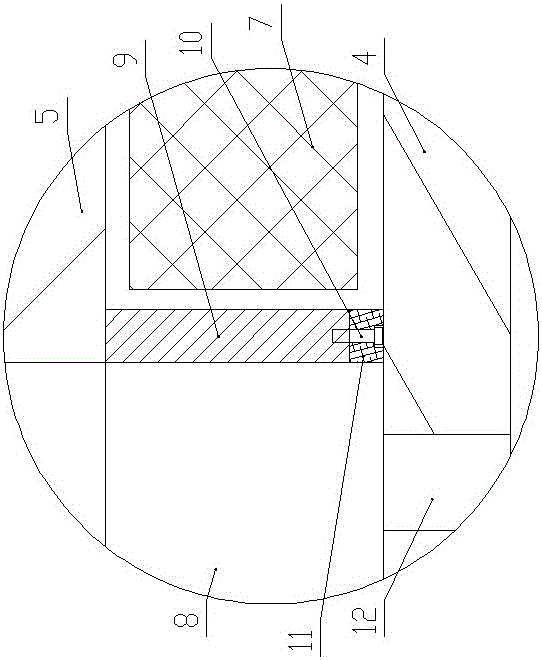

[0023] Such as Figure 1-6 As shown, the fully automatic rotary spraying device of the present invention includes a support frame, a rotating water pipe 1 and a water supply rotating mechanism; the rotating water pipe 1 is connected to the support frame by rotating the water supply rotating mechanism; the rotating water pipe 1 is in the shape of an Archimedes spiral, The inner end of the rotating water pipe 1 is connected with the water supply rotating mechanism, and the outer end of the rotating water pipe 1 is blocked. There are atomizing nozzles 3;

[0024] The water supply rotation mechanism includes a water injection pipe 4 and a casing 5, the water injection pipe 4 is fixedly connected with the support frame, one end of the water injection pipe 4 is open, the open end is a water inlet, and the other end of the water injection pipe 4 is blocked; 5 sets of casings Set on the water injection pipe 4, between one end of the casing 5 and the open end of the water injection pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com