A glass plate beveling device

A glass plate and mounting plate technology, applied in the field of glass plate chamfering devices, can solve the problems of easy manual damage, time-consuming and labor-intensive, etc., and achieve the effects of improving efficiency, reducing manual operation, and facilitating manual replacement of glass plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

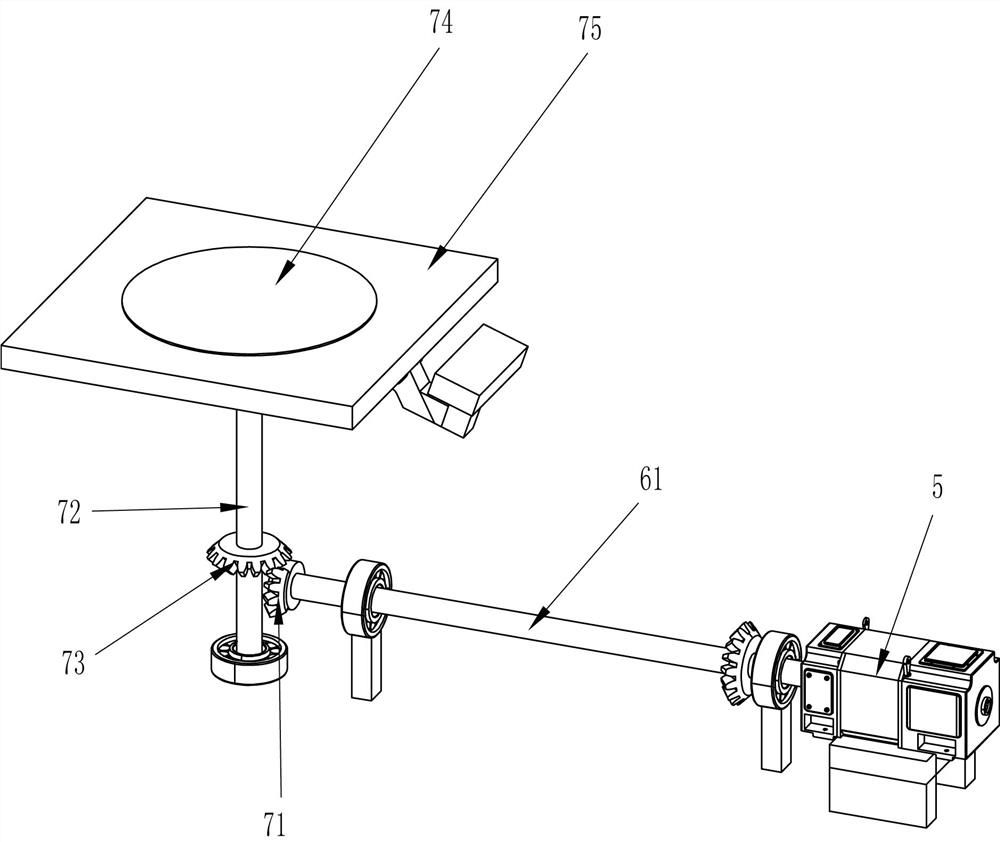

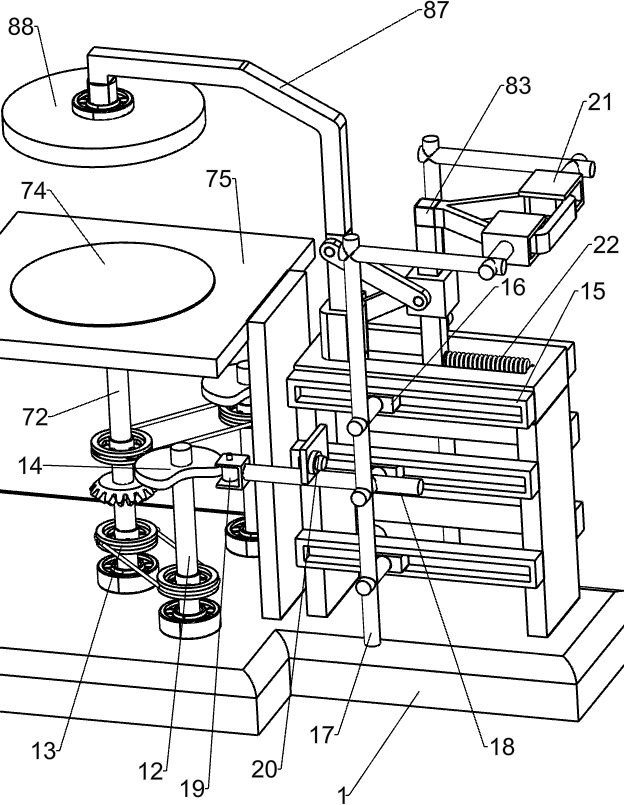

[0055] A glass plate chamfering device, such as figure 1 As shown, it includes a base 1, a support rod 2, a support platform 3, a support frame 4, a motor 5, a beating mechanism 6, an intermittent rotation mechanism 7, a pressing mechanism 8 and a fixed block 11. There are support rods 2, a support platform 3 is provided between the tops of the two support rods 2, a motor 5 is installed on the right side of the base 1, and the motor 5 is located on the right side of the support rod 2, and a beating mechanism 6 is provided on the top of the support platform 3, and the beating mechanism 6 Connected with the motor 5, the left side of the base 1 is equipped with an intermittent rotation mechanism 7, the intermittent rotation mechanism 7 is connected with the beating mechanism 6, the left side of the base 1 is provided with a support frame 4, and the intermittent rotation mechanism 7 is located between the support frame 4 and the support rod 2 , A pressing mechanism 8 is installed ...

Embodiment 2

[0058] Specifically, such as Figure 1-3 and Figure 5 As shown, the knocking mechanism 6 includes a first rotating shaft 61, a first bevel gear 62, a cylindrical block 63, a guide block 65, a slide bar 66, a hammer 67, a first spring 68, a second rotating shaft 69 and a second bevel gear 610, the right side of the base 1 is rotatably provided with a first rotating shaft 61, the right end of the first rotating shaft 61 is connected with the output shaft of the motor 5, the first bevel gear 62 is installed on the right side of the first rotating shaft 61, and the top of the supporting platform 3 rotates The formula is provided with a cylindrical block 63, and the side of the cylindrical block 63 is provided with a chute 64, and three-quarters of the chute 64 is wave-shaped, and one-quarter of the chute 64 is arranged in parallel, supporting A guide block 65 is installed on the left side of the top of the table 3, and the inside of the guide block 65 is slidably provided with a...

Embodiment 3

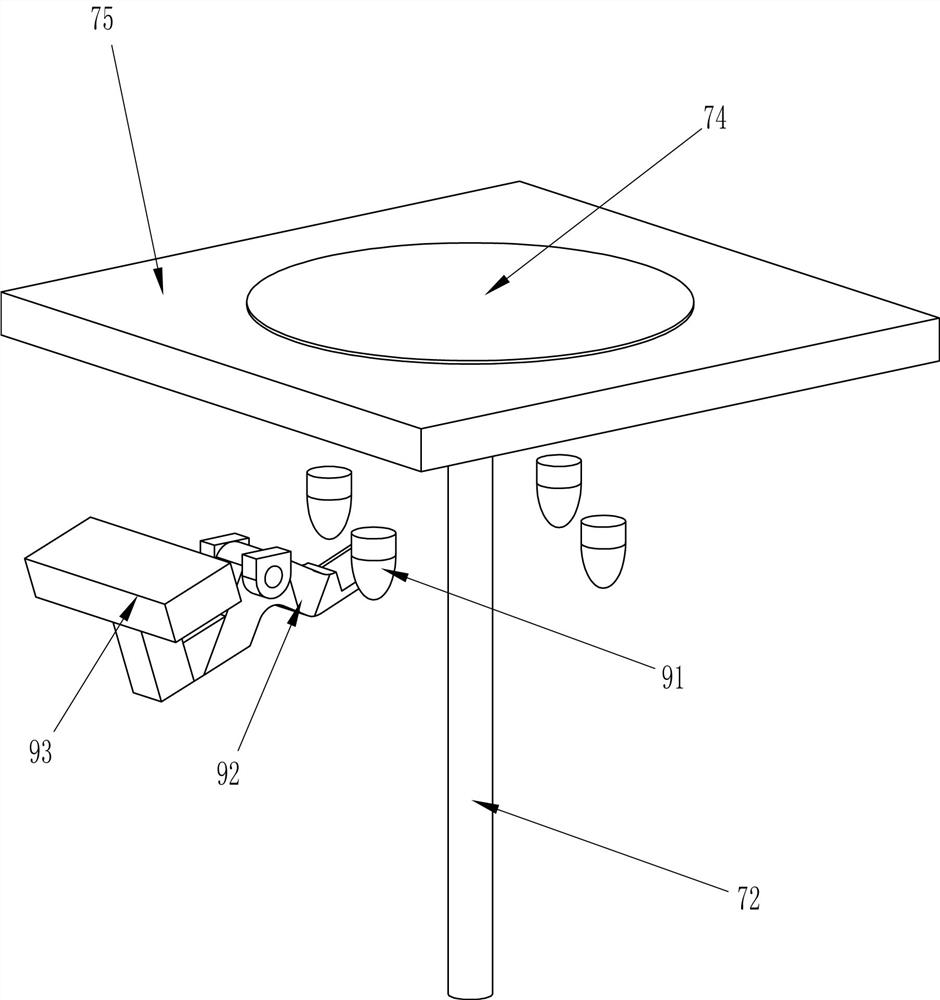

[0065] according to figure 1 , Figure 3-4 and Figure 6-7 As can be seen from the diagram, it also includes a pusher mechanism 9, which includes a bump 91, an L-shaped connecting rod 92 and a push block 93, and bumps 91 are installed on the front, rear, left, and right sides of the bottom of the turntable 74, and the workbench 75 right The bottom of the side is rotatably equipped with an L-shaped connecting rod 92, which cooperates with the protrusion 91, and the end of the L-shaped connecting rod 92 is connected with a push block 93.

[0066] When the hammer 67 knocks the corner of the glass plate away and the turntable 74 starts to rotate, the turntable 74 rotates to drive the bump 91 to contact the L-shaped connecting rod 92, the L-shaped connecting rod 92 swings counterclockwise, and the push block 93 swings upwards, thereby jacking up At the bottom of the corner of the glass plate knocked off, when the bump 91 is out of contact with the L-shaped connecting rod 92, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com