End-in and side-out pusher type heating furnace automatic positioning tapping device

An automatic positioning and steel-pushing technology, which is applied to heat treatment furnaces, lighting and heating equipment, furnaces, etc., to avoid manual high-intensity work and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

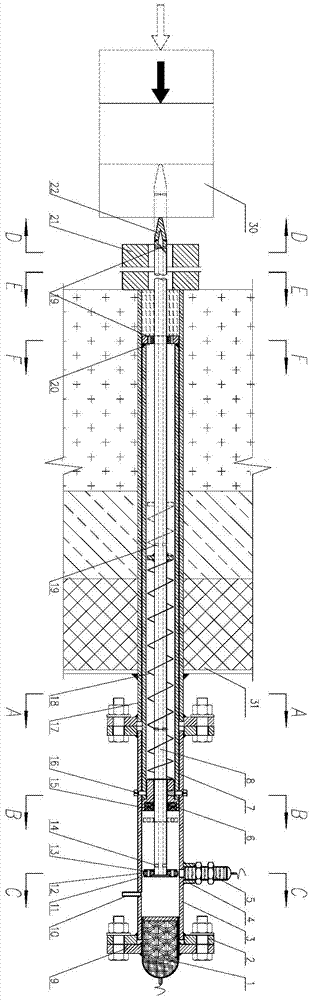

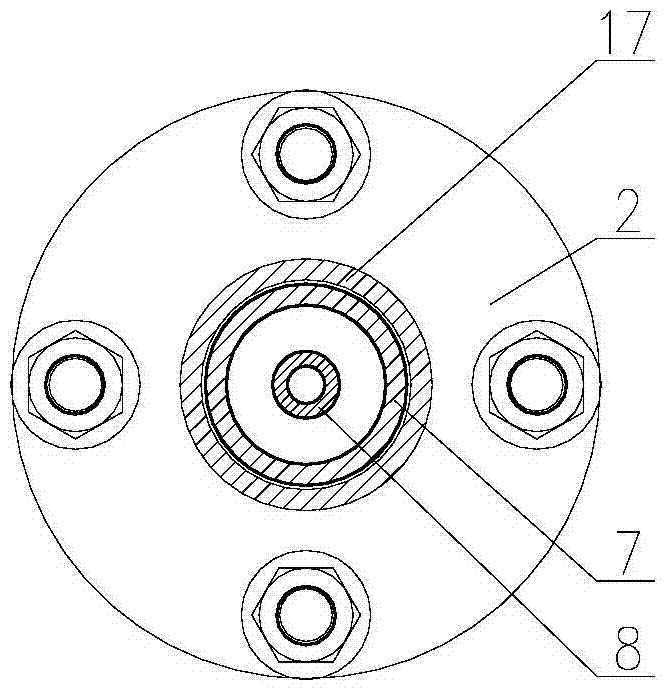

[0024] As shown in the figure, the end-in and side-out pushing type heating furnace automatic tapping positioning device in this embodiment includes a casing and a probe guide rod 8 arranged in the casing. The inside of the right end of the casing is fixed with an electromagnet 1 through a flange 2 and a special-shaped flange 9, and is spaced at a certain distance from the electromagnet 1, and an inductive sensor 5 is fixed on the left side of the casing wall of the electromagnet 1, The inductive sensor 5 is fixed on the top of the casing wall by the threaded sleeve 4 that is sleeved on its outside, and a permanent magnet 6 is arranged at a certain distance on the left side of the inductive sensor 5, and the middle part of the permanent magnet 6 A gap is left, and the probe guide rod 8 passes through the gap in the middle of the permanent magnet 6 .

[0025] A plurality of support seats are provided at the inner distance of the casing, and the probe guide rod 8 is arranged on ...

Embodiment 2

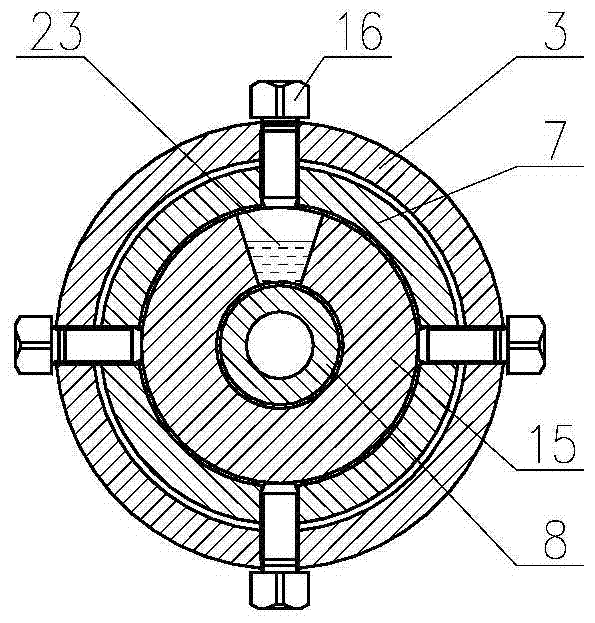

[0037] In this embodiment, the end-in and side-out pusher type heating furnace automatic tapping positioning device is based on Embodiment 1, and discloses a specific structure of a bushing. The bushing includes interconnected first sub-sleeves 7 , the second sub-sleeve 3, the nozzle diameter of the first sub-sleeve 7 is slightly smaller than the nozzle diameter of the second sub-sleeve 3, and one end of the second sub-sleeve 3 is sleeved on the first sub-sleeve On one end of the pipe 7, the two are connected by threads, and are fixed and locked by bolts, thereby fixing the two sleeve pipes together. The length selection of the first sub-sleeve 7 and the second sub-sleeve 3 is preferably when the whole device is installed on the furnace wall, and the installation and connection positions of the two sub-sleeves are located outside the furnace wall.

[0038] In this embodiment, the casing structure of the automatic tapping positioning device for the end-in and side-out pushing t...

Embodiment 3

[0040] In this embodiment, the end-in and side-out pushing type heating furnace automatic tapping positioning device is based on Embodiment 1 or Embodiment 2, and the compressed air pipe is connected to the casing on the right side of the casing, that is, on the outside of the furnace wall. 10. The probe guide rod is preferably a hollow structure, and an air inlet 14 is provided on the probe guide rod, and corresponding air diffuser holes 19 are provided; a communication sleeve is provided on the displacement signal plate 12 of the probe guide rod. Air guide holes 13 inside the tube.

[0041] In this embodiment, the end-in and side-out pusher type heating furnace automatic tapping positioning device allows compressed air to enter the bushing through the compressed air pipe 10, and further compressed air enters the probe guide rod through the air inlet 14, and passes through the corresponding diffusers. The pores are exported. During this process, the compressed air exchanges h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com