A self-excited oscillation high-efficiency atomization device driven by ultrasonic airflow

An atomization device and self-excited oscillation technology, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems that the atomization cannot meet the fine requirements, the acceleration of water flow is not sufficient, the effect of turbulent water flow is not strong, etc., and achieve water mist coverage The effect of large range, low noise and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

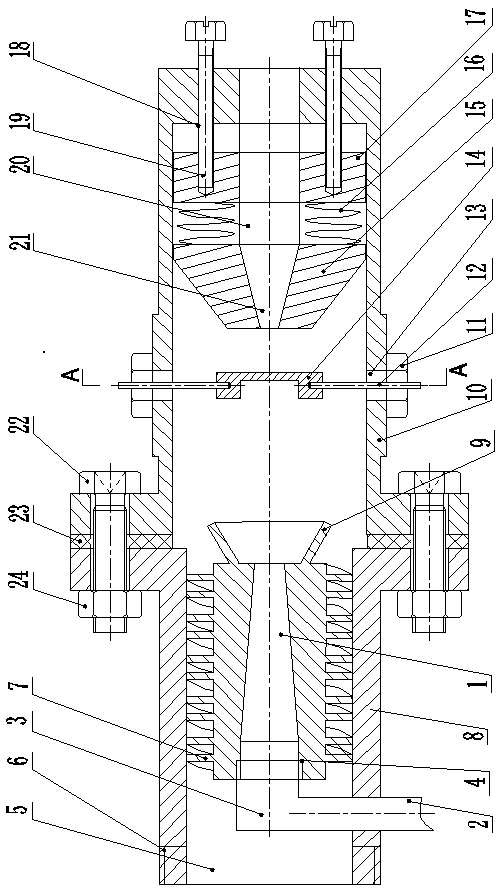

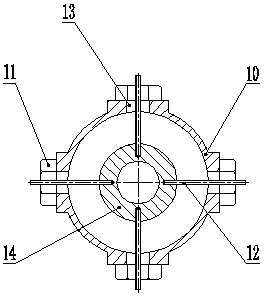

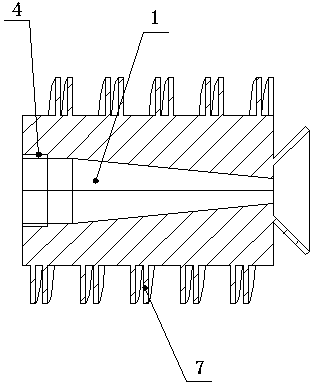

[0022] like Figure 1~3 As shown, a self-excited oscillation high-efficiency atomization device driven by ultrasonic airflow, including a liquid-gas introduction shell (8) and a liquid-gas oscillation shell (10), a liquid-gas introduction shell (8) and a liquid-gas oscillation shell The body (10) is connected; the interior of the liquid gas introduction shell (8) is provided with a spiral water flow introduction valve (7), and the center of the spiral water flow introduction valve (7) is provided with an air flow tapering channel (1), and the spiral water flow introduction valve (7) ) is provided with a spiral groove on the outer wall, and the spiral water flow inlet valve (7) cooperates with the liquid-gas inlet shell (8) in a gap; the side of the liquid-gas inlet shell (8) is provided with an airflow conduit (3), and the airflow tapered channel ( 1) It is connected with the airflow conduit (3) through threads, and the other side of the airflow conduit (3) is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com