Optimization and Improvement of an Internal Combustion Engine Fuel Injection System Based on Flash Boiling Spray

A technology of fuel injection system and internal combustion engine, which is applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems of unfavorable fuel and air mixing, little improvement of internal combustion engine efficiency, insufficient consideration of external factors, etc., to promote spray atomization. effect, improved spray characteristics, improved combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

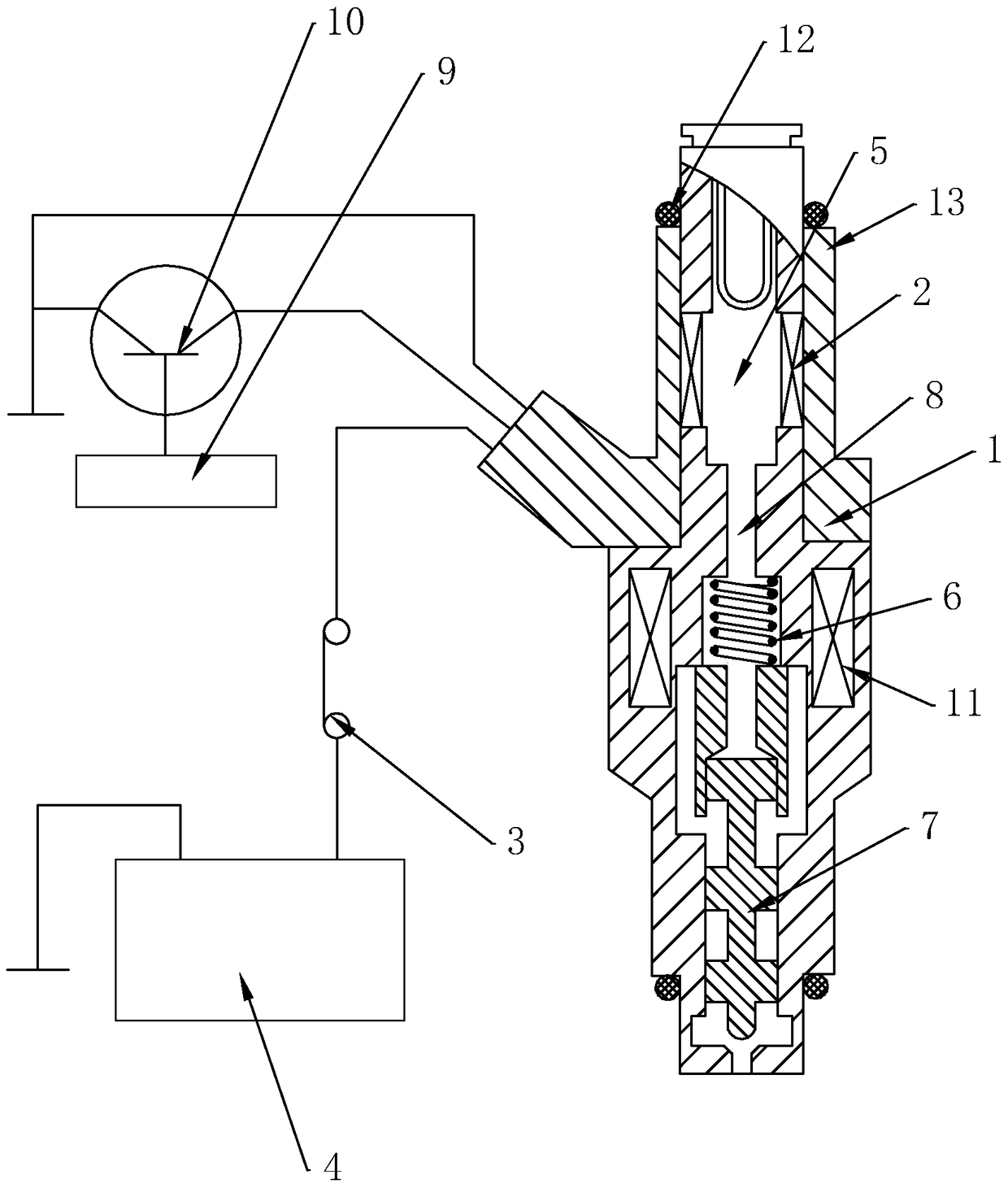

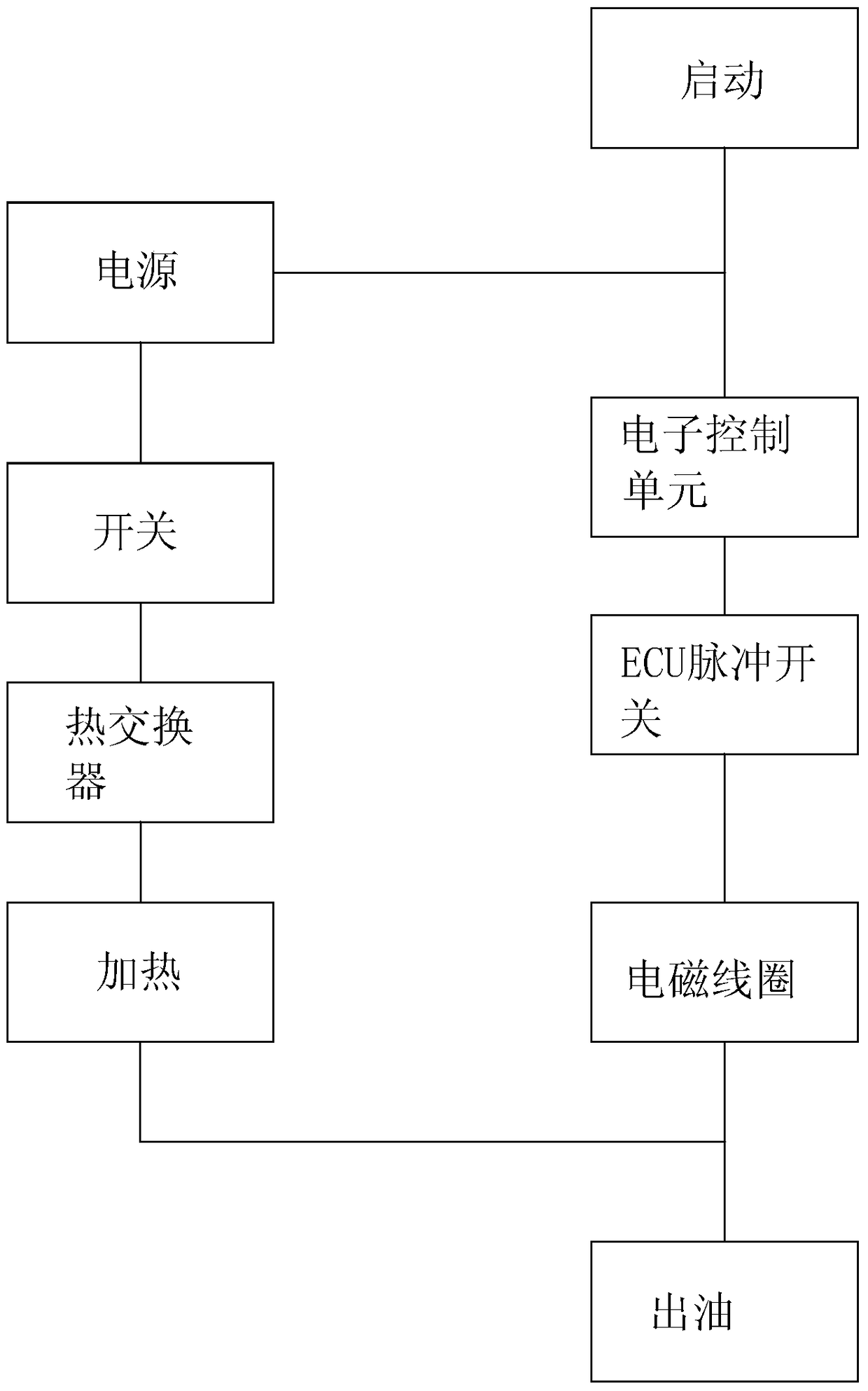

[0020] refer to Figure 1 to Figure 2 As shown, the optimization and improvement of an internal combustion engine fuel injection system based on flash boiling spray implemented in this case includes a fuel injector body, a heat exchanger and a switch are arranged on the fuel injector body, and one end of the switch is connected to There is a power supply, the connecting heat exchanger is connected to the other end of the switch, the grounding end of the heat exchanger is grounded, a cavity is provided in the injector body, a spring and a needle valve are provided in the cavity, There is also a limiting groove inside the fuel injector, the limiting groove communicates with the cavity, one end of the spring is connected to the limiting groove, and the other end is connected to the needle valve, and the diameter of the end of the needle valve is larger than the limiting groove. The aperture of the position groove is smaller than the aperture of the cavity. The injector body is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com