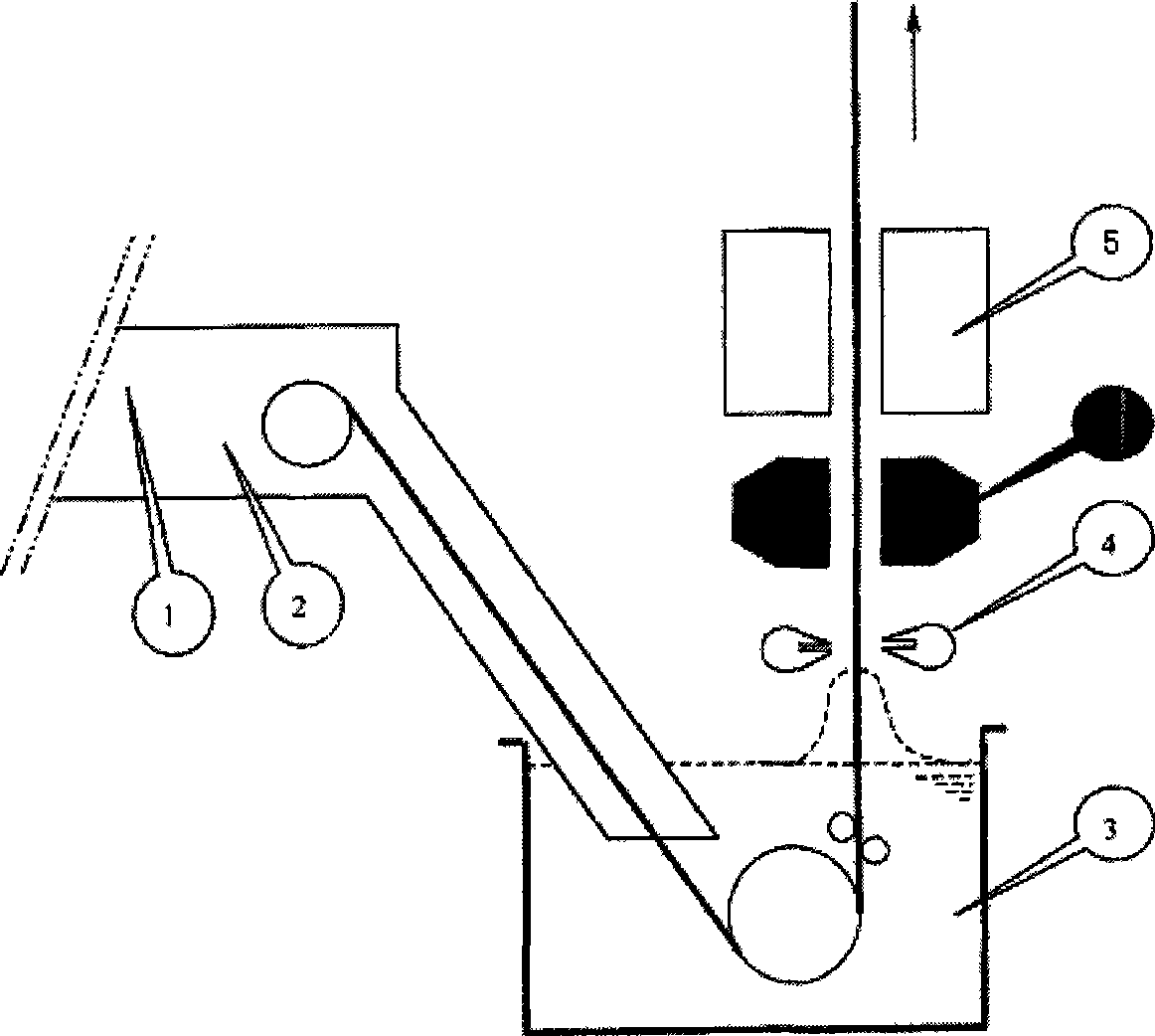

Steel plate minimum spangle galvanizing spray art

A spangle, steel plate technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of uneven spangle, dripping, waste of paint and coating, etc., to save paint consumption, water droplet size Reduced size and improved fogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be described in detail below in conjunction with specific embodiments, so as to better understand the content of the invention.

[0017] First, the galvanized steel sheet or steel strip is heated and reduced by a heating furnace and then galvanized in a zinc pot. The galvanizing temperature is 450-495°C, and the galvanizing amount is controlled at 60-220g / m 2 In between, the galvanized steel plate or steel strip scrapes off the excess zinc liquid on the steel plate (steel strip) through the air knife set above the zinc pot; and then sprays and cools it through the spray nozzle of the small spangle machine set above the air knife , to form small spangles on the surface of the steel plate. The selection of the spangle nozzle is very important. In the present invention, its diameter is required to be 2 mm, the water pressure is 2 bar, and the compressed air pressure is 4 bar. In addition, the distance between the spangle nozzle and the air knife is adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com