Cam based on flexible engine oil injection

An engine and cam technology, used in engine components, machines/engines, mechanical equipment, etc., can solve the requirements that cannot take into account the requirements of injection pressure, injection rate and injection timing, and can not meet the requirements of emission regulations and economy. problems such as low injection pressure in the oil system, to achieve the effect of reducing noise and pollutant emissions, reducing emissions, and increasing fuel injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in more detail below in conjunction with accompanying drawing example:

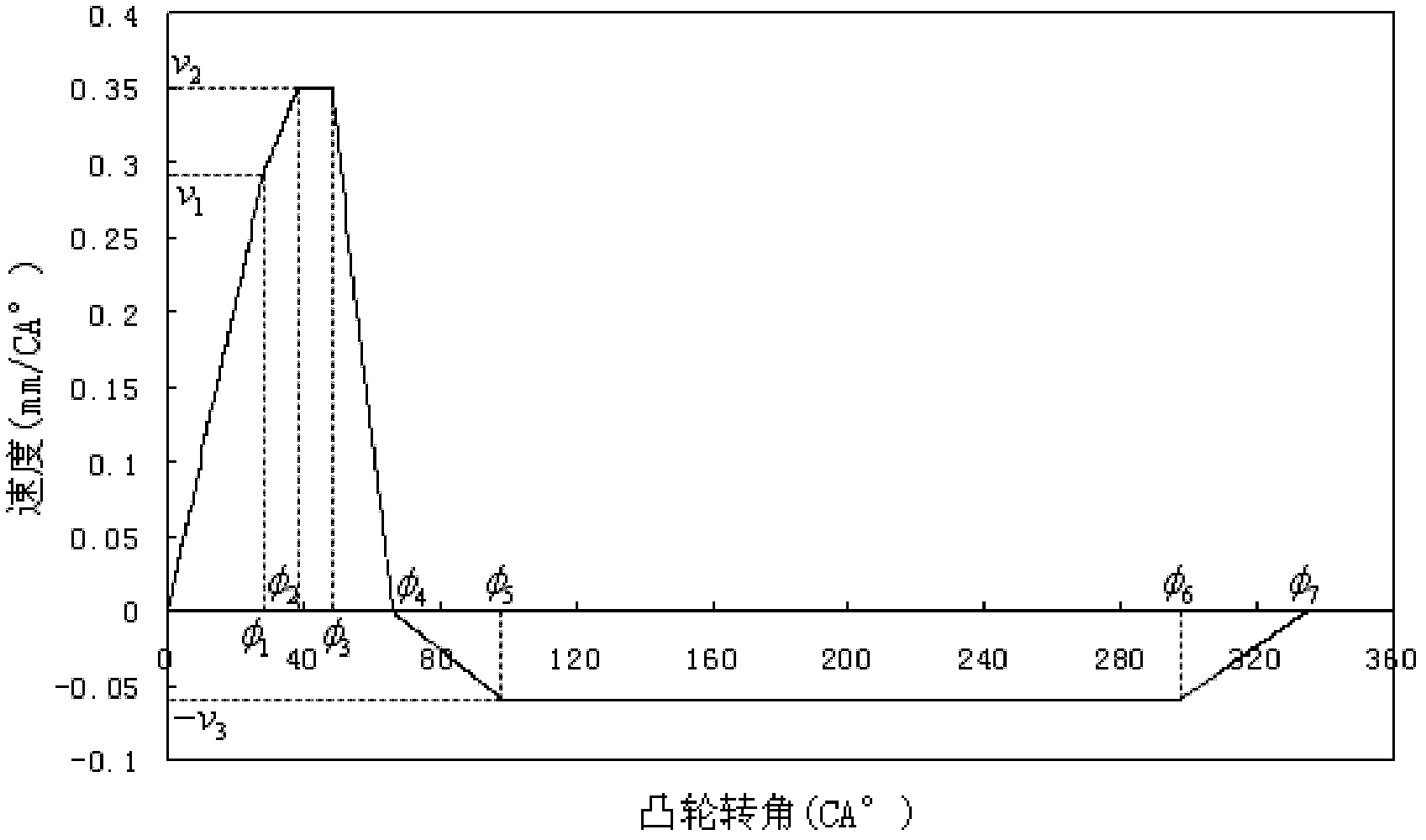

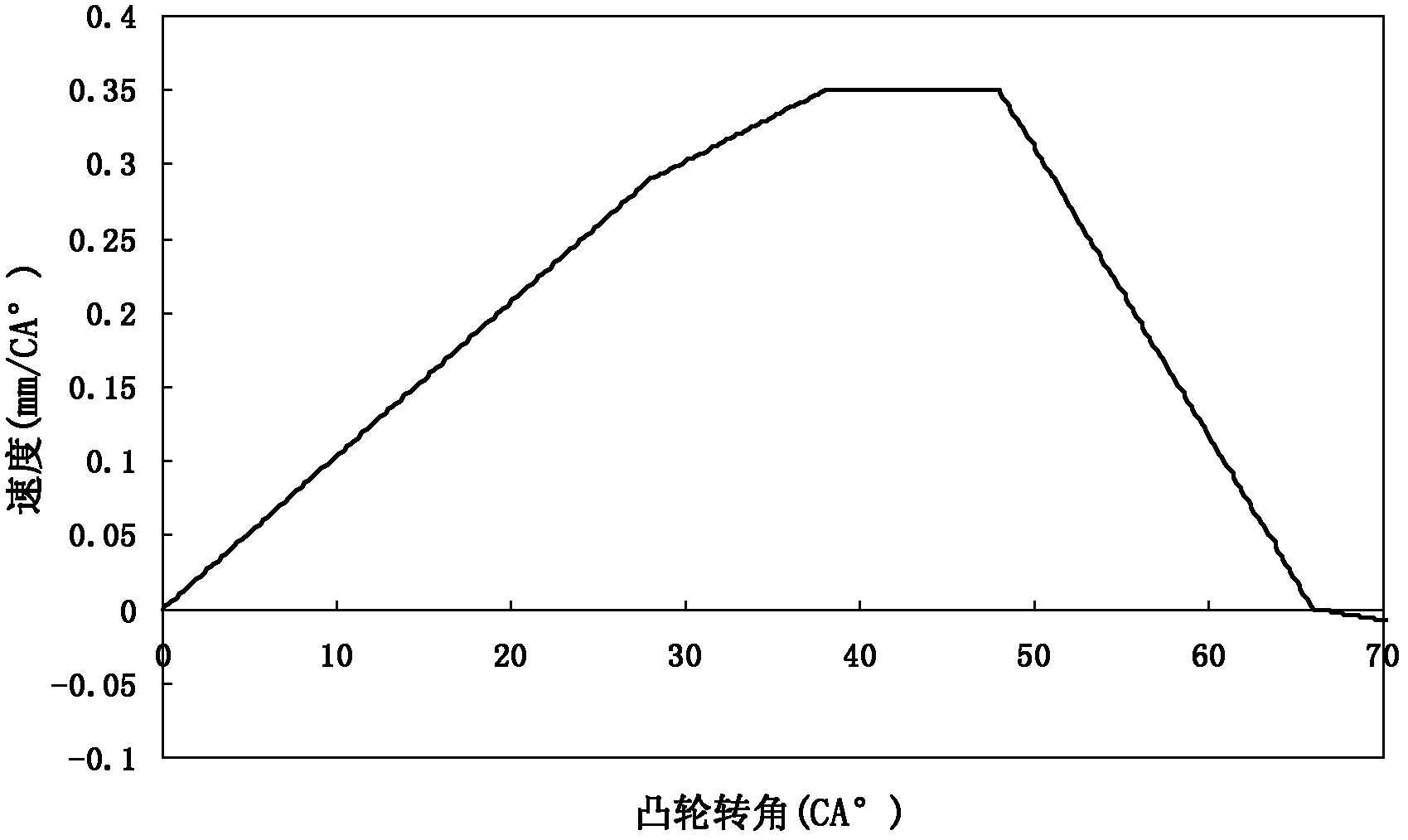

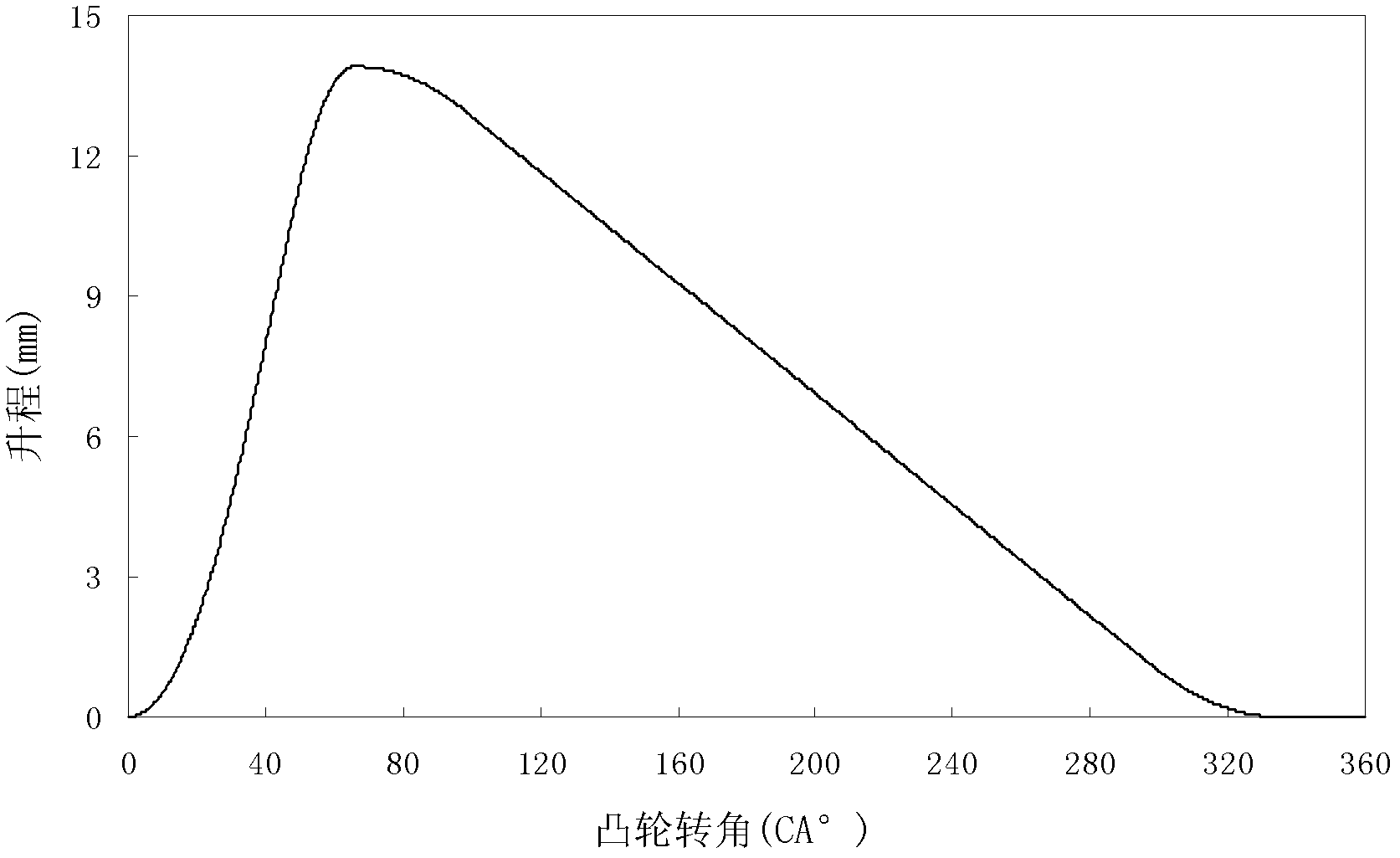

[0039] With reference to Figures 1 to 3, the profile of the flexible fuel injection cam of the present invention has a thrust section corresponding to the forward constant acceleration stage of the movement law of the plunger follower [0°, φ 1 ], working section [φ 1 , φ 3 ] and the forward and other deceleration stages [φ 3 , φ 4 ], the return section of the cam corresponds to the reverse constant acceleration stage of the plunger follower motion law [φ 4 , φ 5 ], reverse constant velocity stage [φ 5 , φ 6 ] (rate size is v 3 ) and deceleration stages such as reverse [φ 6 , φ 7 ]. The cam working section also includes the acceleration stage [φ 1 , φ 2 ] (initial rate is v 1 ) and forward constant velocity stage [φ 2 , φ 3 ] (rate size is v 2 ). The equations of motion for each segment of the plunger follower are:

[0040] 1. Forward constant acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com