Air heating type fuel economizer

A technology of air heating and fuel economizer, which is applied in the direction of combustion air/combustion-air treatment, machine/engine, fuel heat treatment device, etc. It can solve the problems of incomplete combustion of gasoline, increased fuel consumption, and power drop, etc., and achieves inhibition of diffusion and loss, improve combustion efficiency, and intensify the effect of thermal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

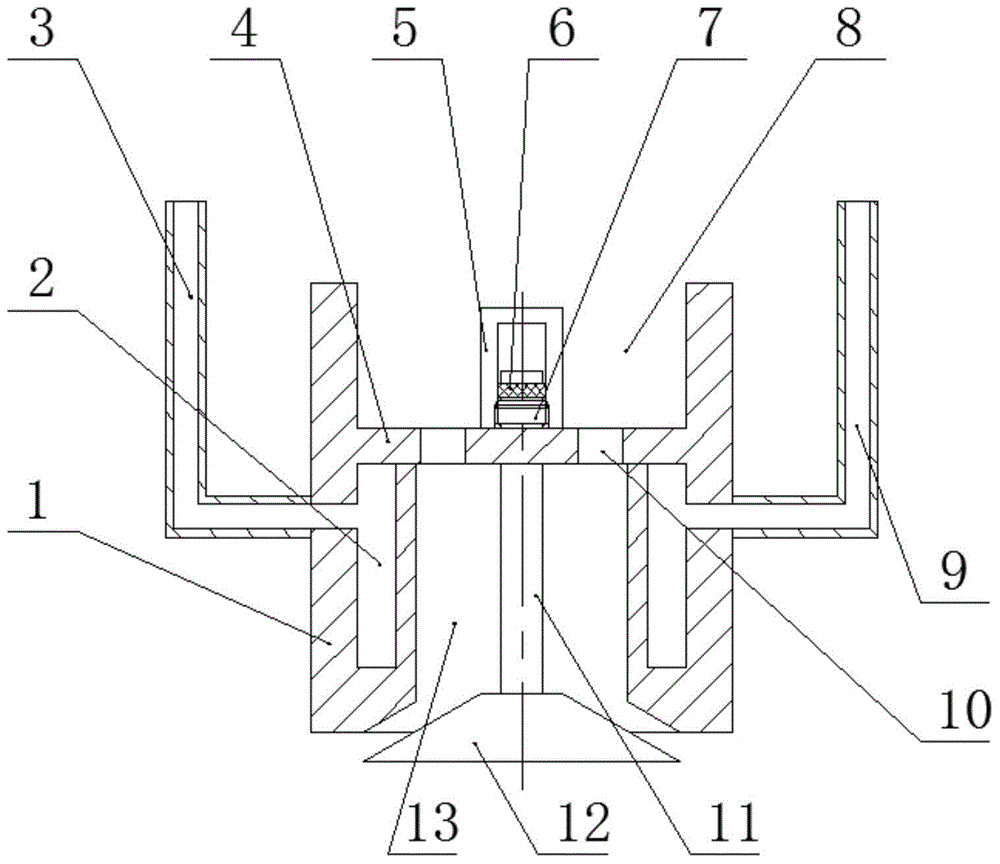

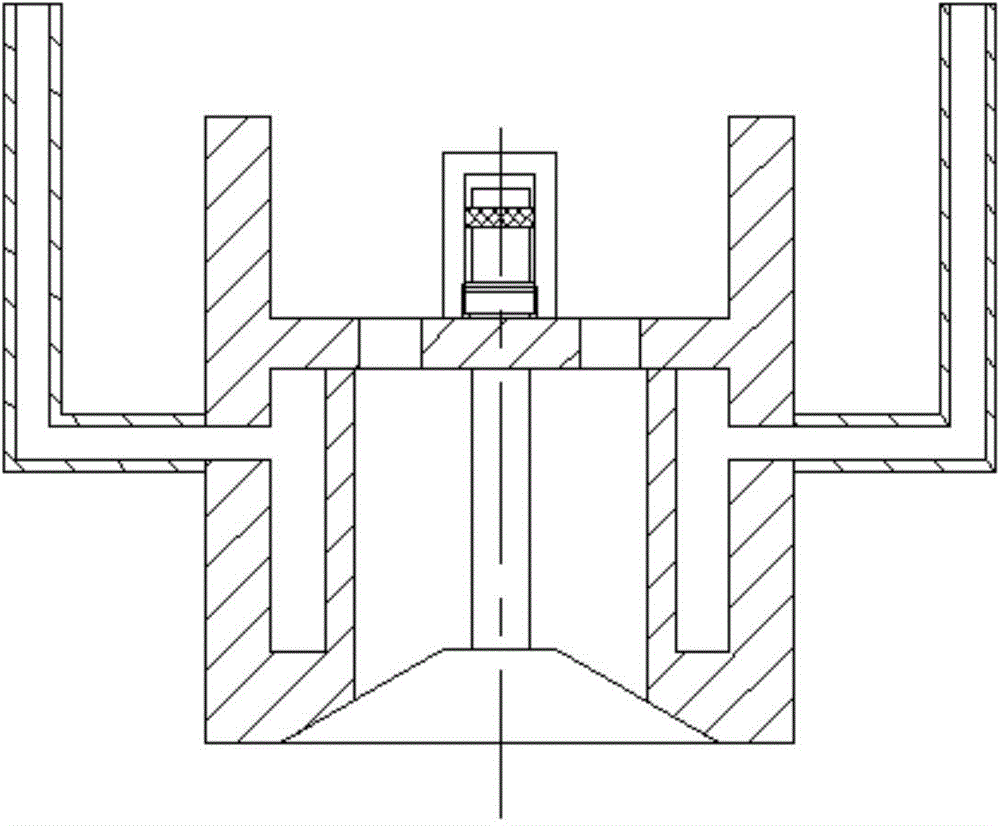

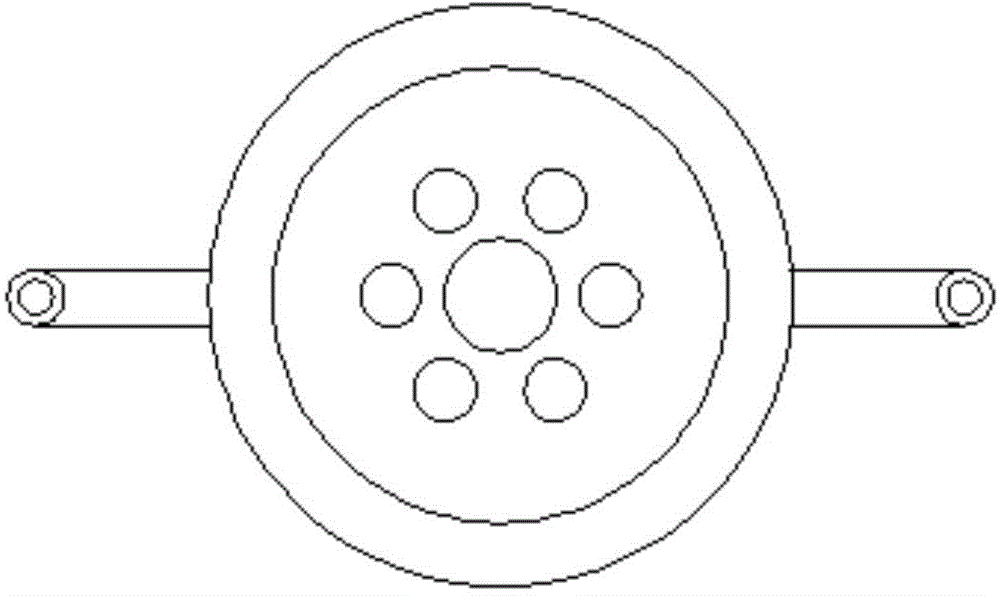

[0038] An air-heated fuel economizer, comprising: a casing 1, which is a hollow tube with two ends open, and a partition 4 is fixedly arranged in the inner cavity of the casing 1, and the partition 4 divides the inner cavity of the casing along the axis It is divided into an air inlet chamber 8 and an air outlet chamber 13 in the direction. The housing 1 is provided with a water chamber 2 in the wall around the air outlet chamber 13, and the separator 4 is provided with 6 uniformly distributed circular air holes 10 on the same circumference. , and the partition plate 2 is provided with a mounting seat 7 at the center of one side of the air intake chamber 8, the vacuum chamber 5 is fixedly connected with the mounting seat 7 by threads, and the center of the mounting seat 7 and the partition plate 4 is provided with a through hole to sleeve The ejector rod 11, the ejector rod 11 can slide along the through hole, one end of the ejector rod 11 extends into the inner cavity of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com