Device for improving titanium tetrachloride refining heat exchange efficiency and method thereof

A heat exchange efficiency, titanium tetrachloride technology, applied in titanium tetrachloride, titanium halide, chemical industry, etc., can solve the problem of shortening the service life of heat exchangers, cracking of heat exchanger tube welds, and fluctuations in oxygen content of sponge titanium And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

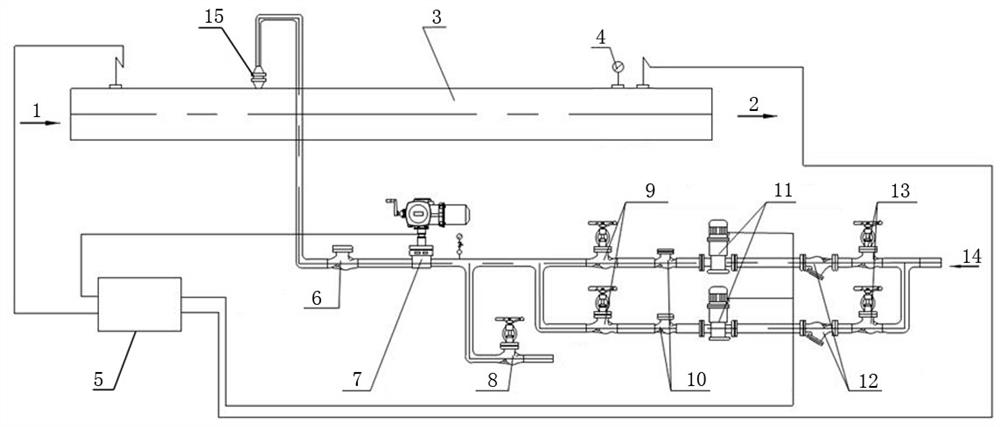

[0024] Referring to the accompanying drawings, a device for improving the heat exchange efficiency of titanium tetrachloride refining includes a water atomization device and a vaporization unit installed on the steam line 3 at the inlet end of the heat exchanger, wherein the water atomization device includes The water pipeline and the nozzle 15 at the end of the water pipeline, the water pipeline is used to deliver pressure water to the nozzle 15, the nozzle 15 is used to spray the pressure water into the steam pipeline, and the nozzle 15 is installed on the steam pipeline 3 above; the vaporization unit is a venturi tube, and the venturi tube is arranged in the steam pipeline 3 downstream of the spray head 15, and is used to vaporize the water mist and mix it with superheated steam to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com