Gas-water mixing bubbler

A bubbler and diverter technology, which is applied in water supply installations, water resource protection, indoor sanitary pipe installations, etc., can solve the problems of insufficient water particles and poor water saving effect, and achieve full water particles and increase jet flow. Multiple collision chances, the effect of increasing the chance of jet collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

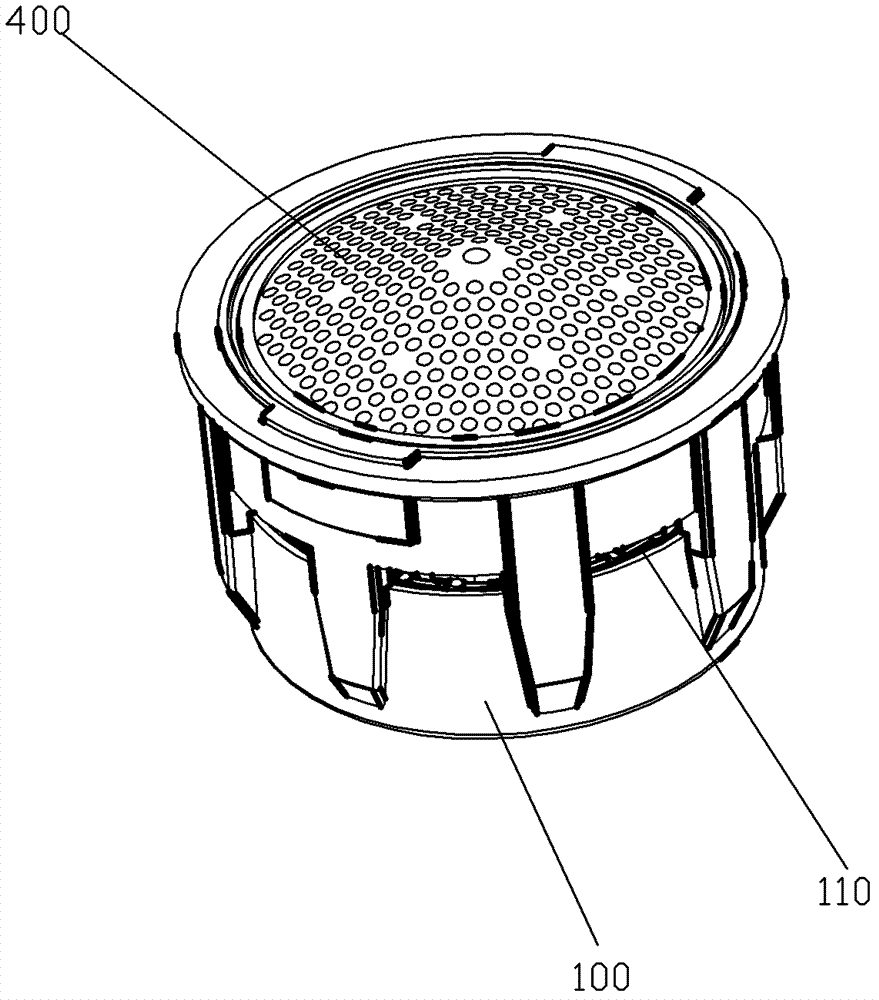

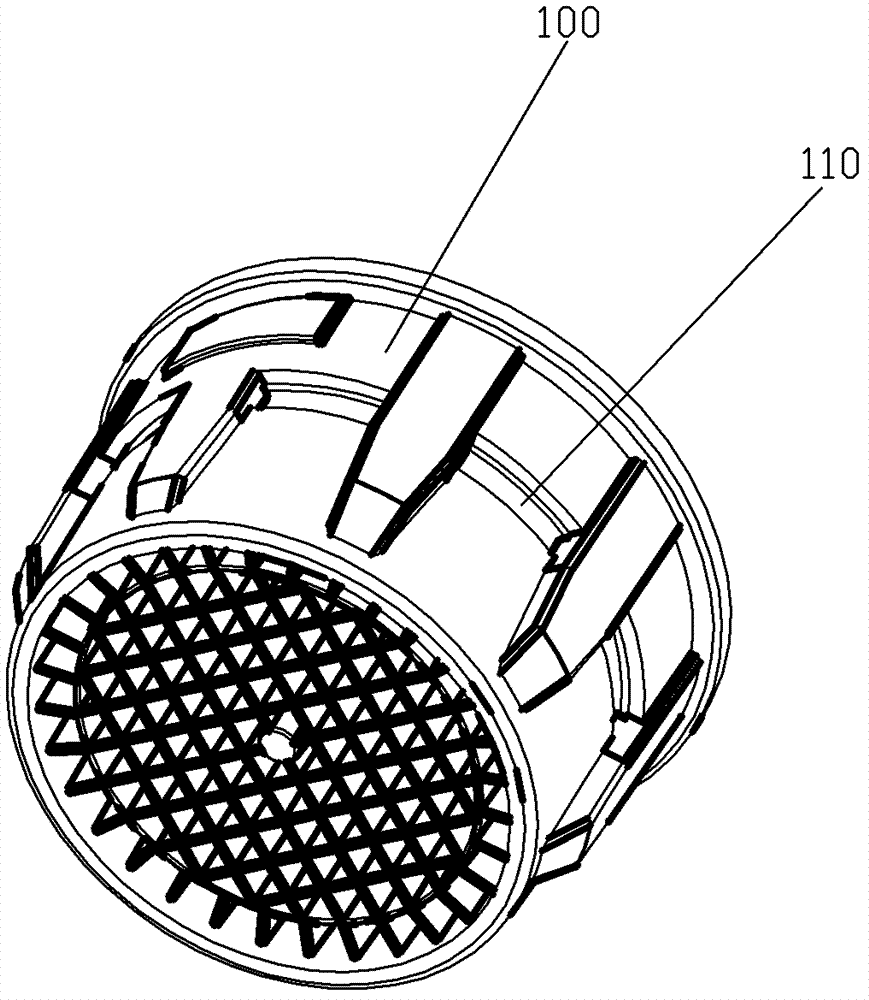

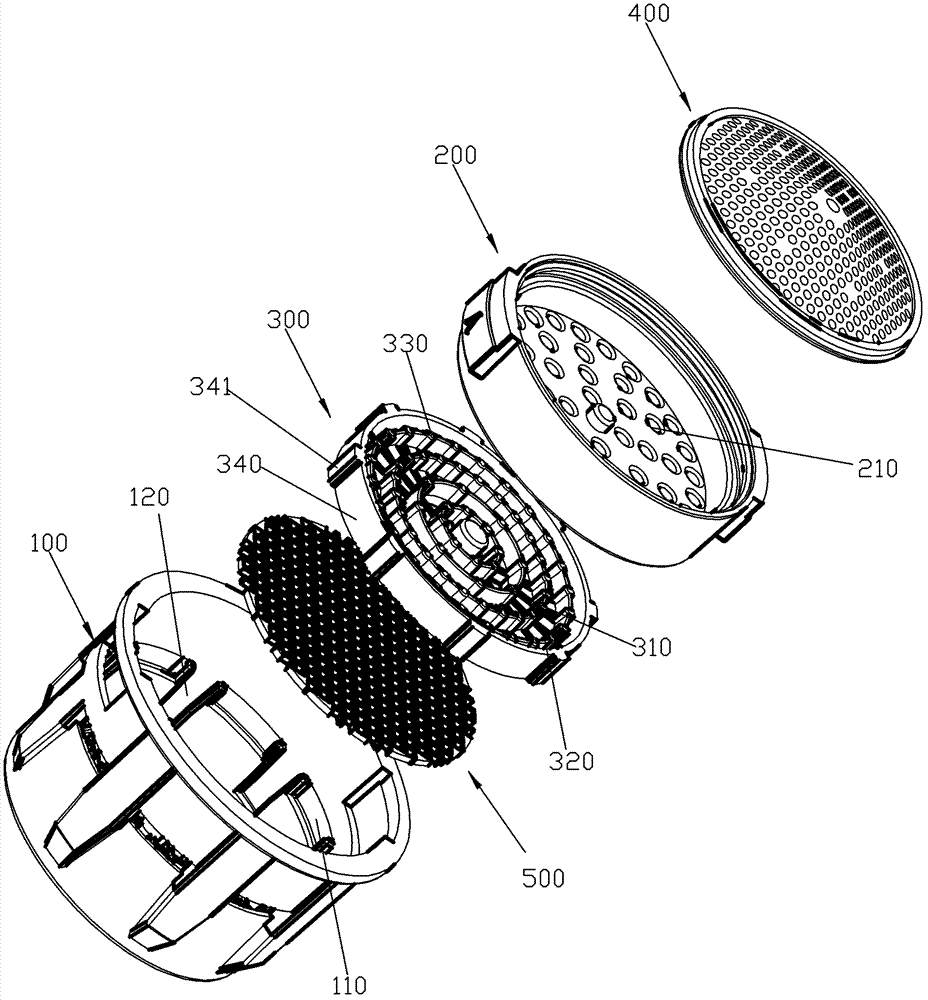

[0023] look up Figure 1 to Figure 5 , a gas-water mixing bubbler, which includes a body 100, a diverter 200, an insert 300, a filter element 400 and a metal mesh 500.

[0024] The body 100 has an air suction hole 110 and a gap that run through the inside and outside of the body. The outer port of the air suction hole 110 is located on the outer surface of the body, and the inner port is located on the inner surface of the body. 200). The shunt 200 has protrusions on its periphery, and the shunt 200 is fitted into the assembly hole of the body 100 and the protrusions are engaged with the notches of the body 100 to fix the shunt 200 and the body 100 .

[0025] The insert 300 is fitted into the assembly hole of the body 100. In order to limit the rotation of the insert 300 relative to the body, preferably, a plurality of positioning bosses 341 are provided outside the insert 300, and an opening is provided in the body facing inward. The positioning groove 120 on the top, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com