Pre-mixing micro-catalysis combustion chamber with low heat loss

A micro-catalytic combustion chamber and pre-mixing technology, applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of reduced residence time of pre-mixed gas, increased combustion instability, and increased difficulty of complete reaction. The effect of photoelectric conversion efficiency, prolongation of residence time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

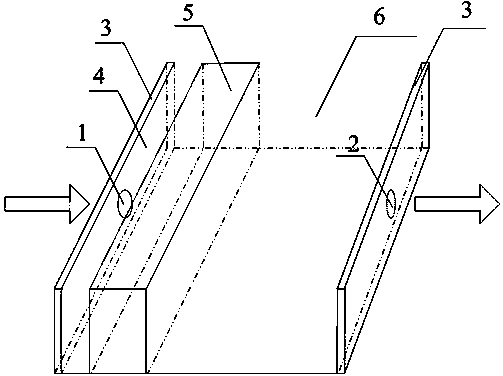

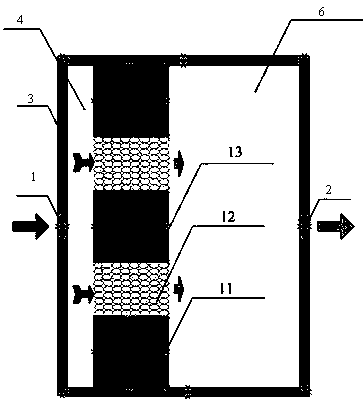

[0012] Such as figure 1 , the internal size of the combustion chamber is 10mm×10mm×1mm, the thickness of the outer wall 3 is 0.2mm, the micro-burner is made of polycrystalline alumina material, the front end of the partition is 1mm away from the air inlet, the partition divides the burner into two, close to the inlet The side of the gas port is the preheating zone 4, the side close to the exhaust port is the combustion zone 6, and the diameters of the exhaust port 1 and the intake port 2 are both 0.5 mm; figure 2 , the separator 5 is made up of three copper sheets 11 of 2.4mm×2mm×1mm, three platinum sheets 13 of 0.1mm×2mm×1mm and two porous copper sheets 12 of 2.5mm×2mm×1mm, wherein the platinum sheets 13 Adhere to the back of the copper sheet 11 (the side of the platinum sheet close to the combustion zone), and then arrange it with the porous copper sheet 12 at intervals, wherein the porous copper sheet 12 is not in contact with the wall of the combustion chamber, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com