Pipeline flexible connecting device and using method thereof

A flexible connection and pipeline technology, applied in the direction of pipe joints, adjustable connections, heating devices, etc., can solve the problems of not being able to control the heat energy loss of the system well, inconvenient production and installation, and affecting the safety of operation, so as to avoid sudden Effects of large-scale leakage, low cost, and low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0028]

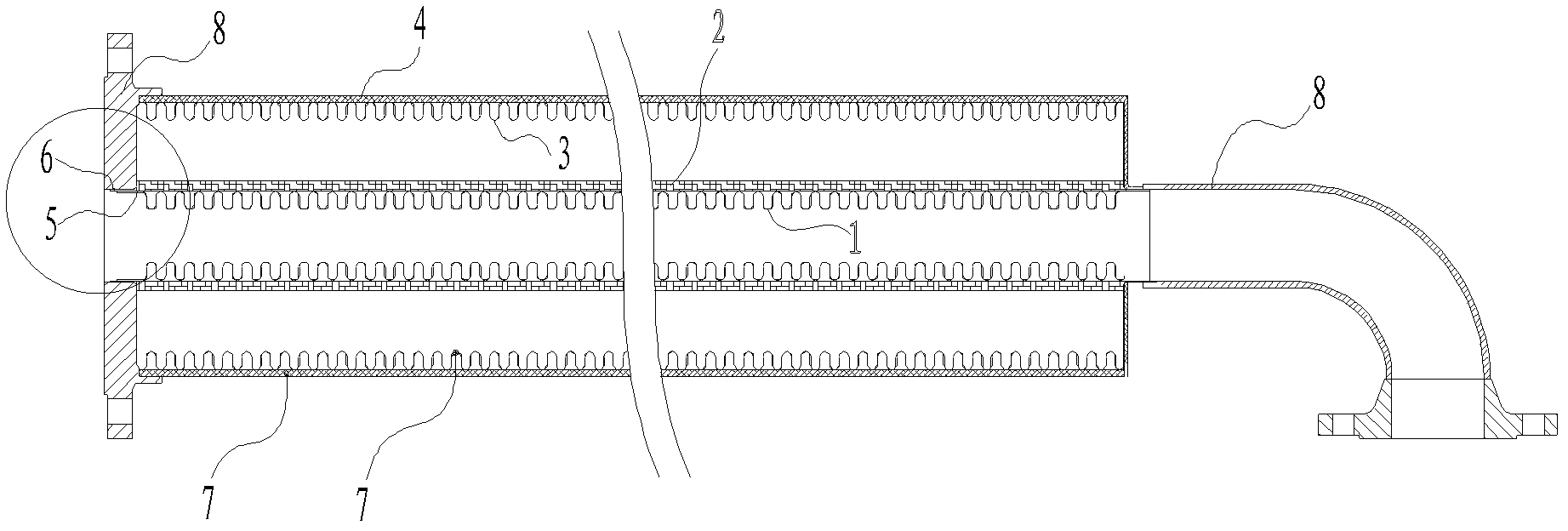

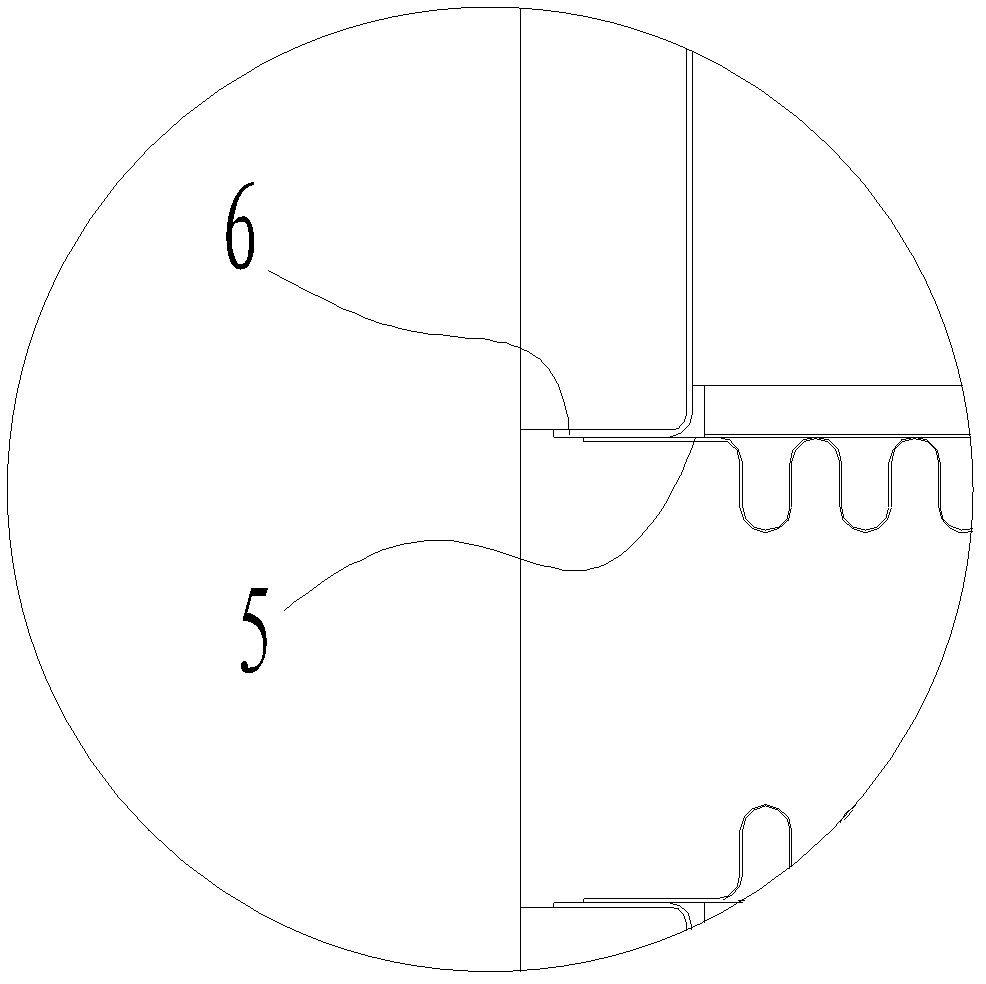

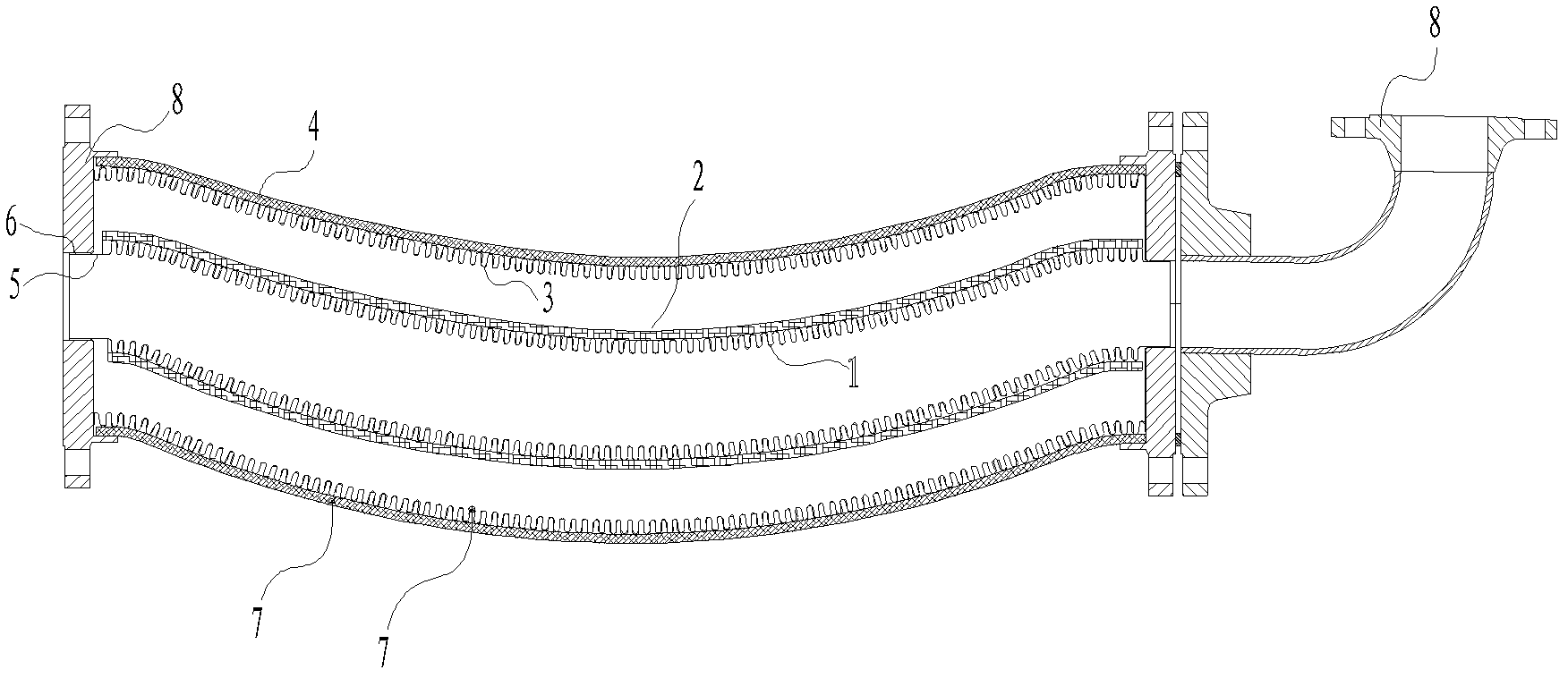

[0029] figure 1 It is a structural schematic diagram of the first implementation of the pipeline flexible connection device of the present invention; the pipeline flexible connection device is composed of at least one group of pipeline flexible connection device units, and each group of device units is composed of no less than two layers of metal bellows and two At least one closed space is formed between the metal bellows that are nested in each other. The metal bellows includes a bellows structure and a straight metal pipe with a certain length at the end; Among them, at least one layer of metal bellows is provided with a reinforcing layer on the outside.

[0030] Such as figure 1 As shown, a single device unit of the pipeline flexible connection device specifically includes a first metal bellows 1, a first reinforcement layer 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com