Petal-shaped wall surface evaporating pipe for micro combustion chamber

A technology of micro-combustion chambers and evaporation tubes, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as the difficulty of reducing the volume of micro-combustion chambers, and achieve reduced combustion chamber length, thorough atomization, and heat exchange The effect of the enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described now in conjunction with accompanying drawing:

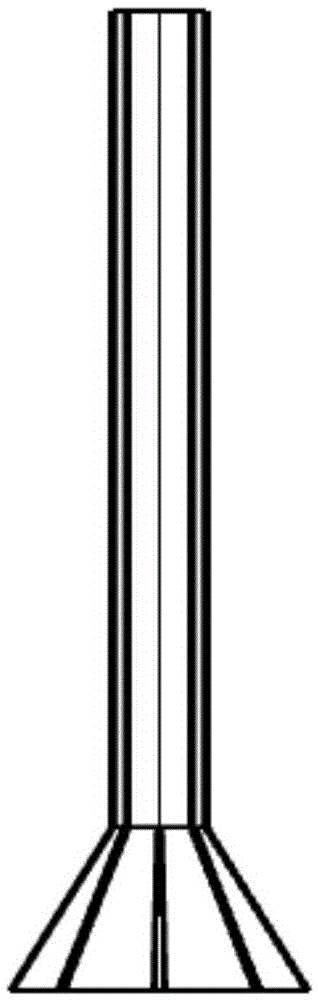

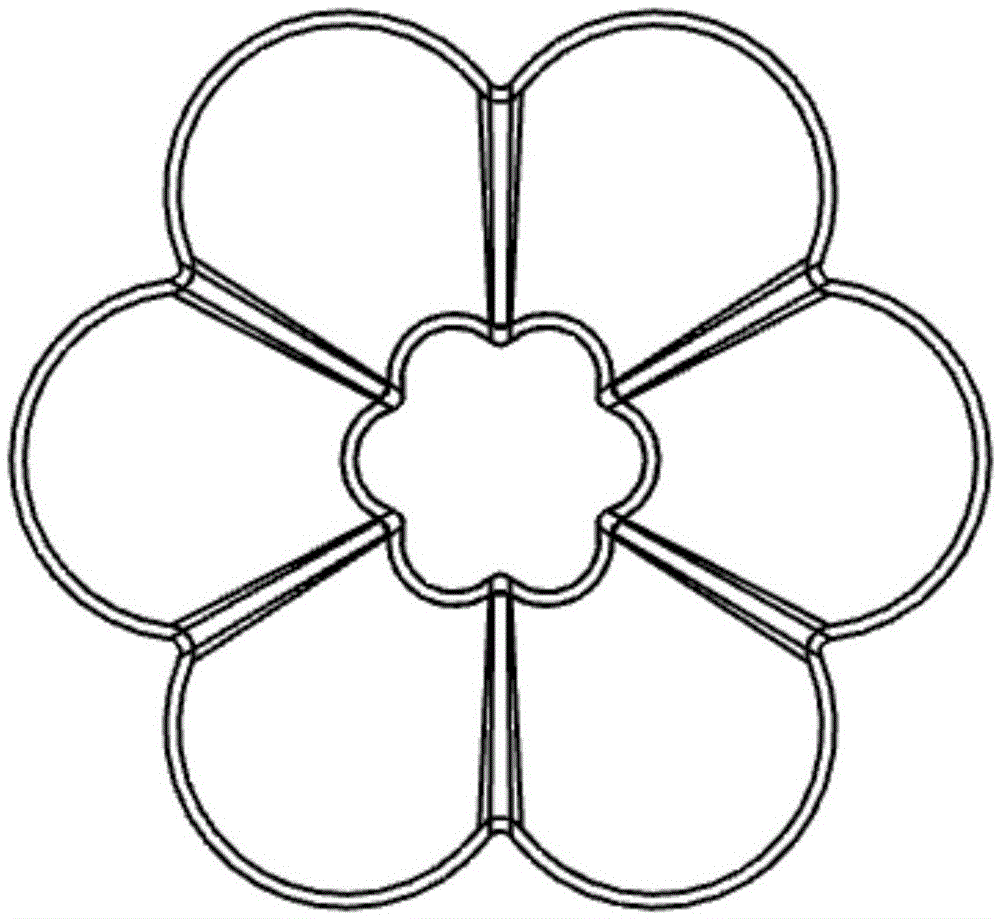

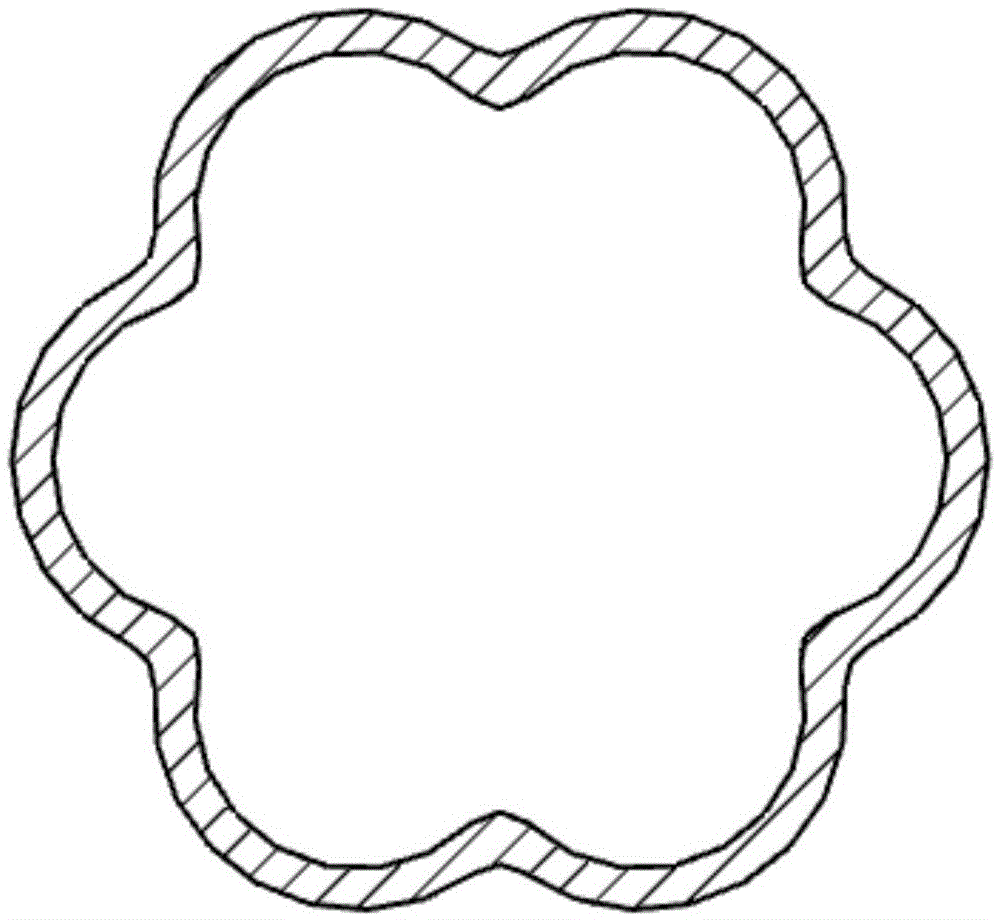

[0023] combine figure 1 , figure 2 , the present invention provides an evaporation tube design structure that can effectively improve fuel atomization efficiency in a micro combustion chamber. figure 1 is a side view of the wall of the evaporation tube, figure 2 It is a cross-sectional view of the evaporation tube seen from the direction of the nozzle, and the petal shape of the nozzle can be clearly seen. image 3 It is a cross-sectional view of the pipe wall. It can be seen that both the inner and outer walls are petal-shaped, and the rounded corners are excessively rounded. Figure 4 A perspective view of an evaporating tube.

[0024] In the micro-combustion chamber, due to the small size, the combustion will face a series of problems, such as high local temperature, insufficient combustion, carbon deposits, etc. The main problem is that the residence time of the fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com