Micro-thermal photovoltaic system for cooling based on heat pipe principle

A technology based on the principle of micro-thermal photoelectricity and heat pipe, which is used in photovoltaic power generation, optical radiation generators, photovoltaic modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

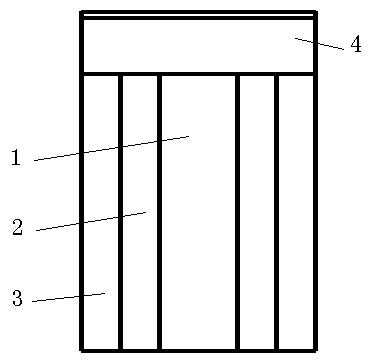

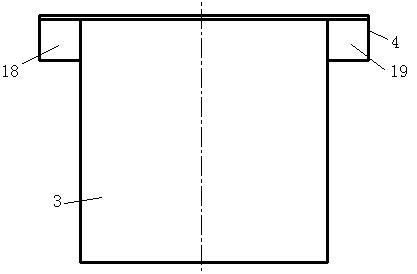

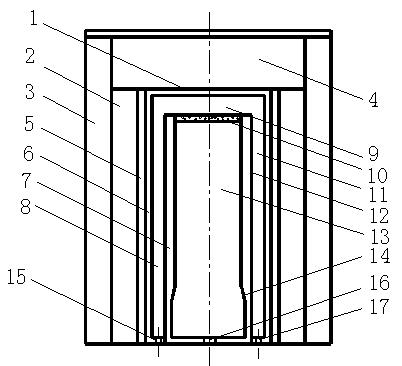

[0019] Such as figure 1 with figure 2 As shown, the present invention is made up of four parts: micro burner 1, photovoltaic cell 2, flat heat pipe 3 and gas cooling system 4, and the uppermost part is gas cooling system 4, and micro burner 1 is positioned at just below gas cooling system 4 and is connected with gas The cooling system 4 is connected.

[0020] Such as Figure 1-3 Shown, micro-combustor 1 comprises glass cover 6 and micro-combustion chamber 13, and glass cover 6 adopts organic quartz glass, and micro-combustion chamber 13 is set in the inner chamber of glass cover 6, and glass cover 6 and micro-combustion chamber The bottom surface of 13 is flush, and all leaves space between the both sides of glass cover 6 and micro-combustion chamber 13 and the top. The micro-combustion chamber 13 is made up of the micro-combustion chamber shell 7 and the porous medium panel 10, and the micro-combustion chamber shell 7 adopts SiC ceramics with strong high temperature resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com