Novel portable gas stove based on Swiss roll structure micro-combustor

A technology of micro-burners and card-type furnaces, which is applied to heating fuels, household furnaces/stoves, gaseous heating fuels, etc., can solve the problems of no preheating process of fuels, temperature differences in combustion chambers, and insufficient combustion, etc., to achieve reduction Effects of heat loss, reduced fuel loss, and long energy supply time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

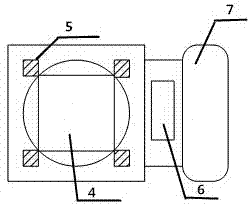

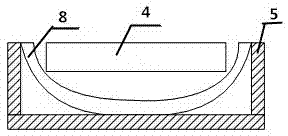

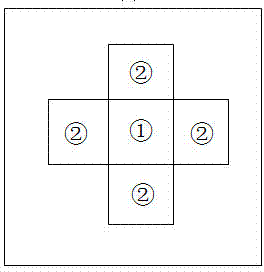

[0028] The novel swiss roll micro-burner cassette furnace of this embodiment is mainly composed of combustion chamber 4, fuel pipeline control electronic valve 6, fuel gas storage cylinder 7, rotating parabolic heat collecting mirror 8 and other main structures. Combustion chamber 4 is placed on support 5, and combustion chamber 4 is made of 5 micro burners, and fuel gas cylinder 7 draws 2 copper pipes and links to each other with fuel pipeline control electronic valve 6, is controlled the opening and closing of pipeline by pipeline control electronic valve. Of the 2 copper pipes drawn out, one is connected to the entrance of the combustion chamber ①, and the other is connected to the entrance of the other combustion chamber ② with 4 branch pipes. The micro-combustor is designed as a swirling channel with a rectangular cross-section, which increases convective heat transfer and preheats the reactants. The difference in the entire combustion room temperature is small, and the co...

Embodiment 2

[0034] In this embodiment, other structures are the same as in Embodiment 1, except that the square rotary micro-burner is changed into a circular rotary micro-burner.

[0035] Figure 7 It is the front view of the circular rotary swiss roll micro burner of the present invention. Its basic structure is similar to that of a square rotary swiss roll structure micro-burner, where A is the combustion chamber inlet of a cylindrical boss with a diameter of 8mm, and place B is the combustion chamber outlet of a cylindrical boss with a diameter of 8mm. The channel section of the circular swirling swiss roll micro burner is a rectangle of 10×3 mm, the inner diameter of the spiral channel is 10 mm, and the outer diameter is 80 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com