Liquid fuel burning micro-combustor applied to micro-thermal photoelectric system

A technology of liquid fuel and micro-combustor, which is applied to the combustion of liquid fuel and gaseous fuel, the combustion of catalytic material, and the combustion method. It can solve the problems of single gas fuel, insufficient combustion, and instability, and achieve complete Combustion, improved combustion efficiency, less pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

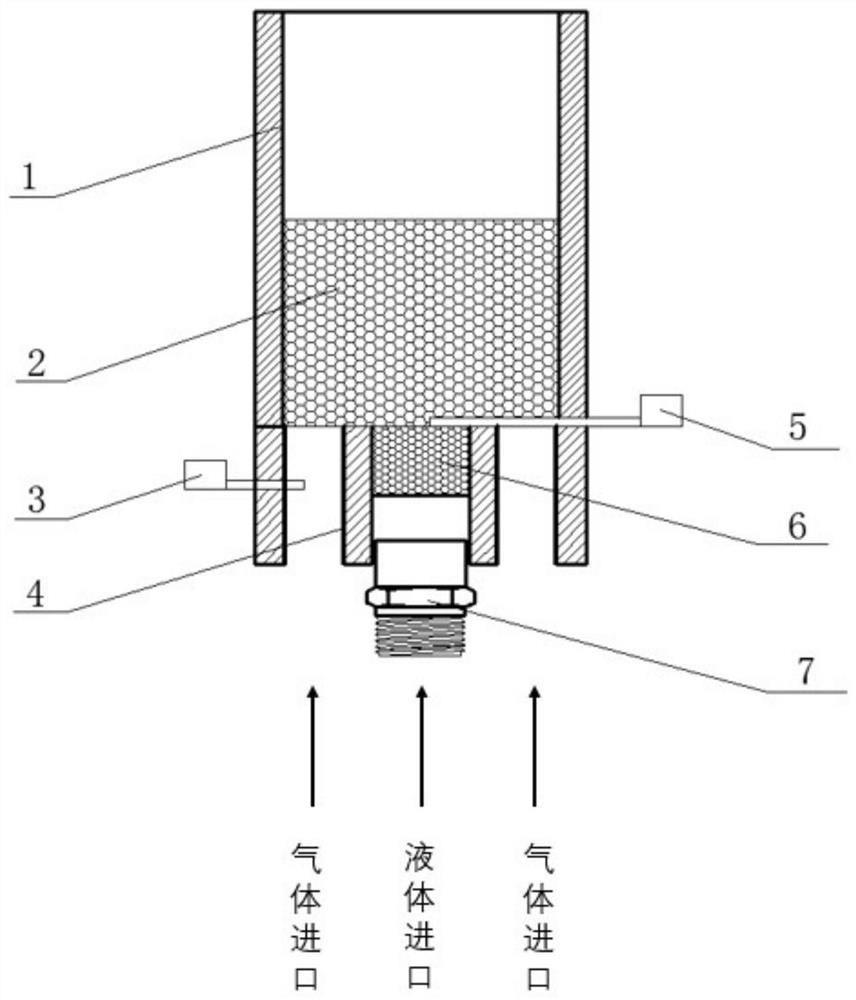

[0023] Such as figure 1 As shown, the micro-combustor of the present invention, which is applied to the micro-thermal photoelectric system for burning liquid fuel, includes a feed channel and a combustion chamber 1, and the feed channel is located at the entrance of the combustion chamber 1, and the feed channel It includes a gaseous fuel channel 4 and a liquid fuel channel, the gaseous fuel channel 4 surrounds the liquid fuel channel, the middle part of the gaseous fuel channel 4 is provided with a first igniter 3, and the junction of the liquid fuel channel and the combustion chamber 1 is provided with The second igniter 5 first ignites the gaseous fuel channel through the first igniter 3, and is used for preheating the liquid fuel channel. The first igniter 3 is an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com