Electric fuel oil jet propeller

A technology of a propeller and a fuel nozzle is applied in the field of electric fuel jet propulsion, which can solve the problems of low working efficiency, high production cost and high technical difficulty of an electric ducted fan engine, and achieves reduction of processing difficulty, light weight, and economical improvement. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

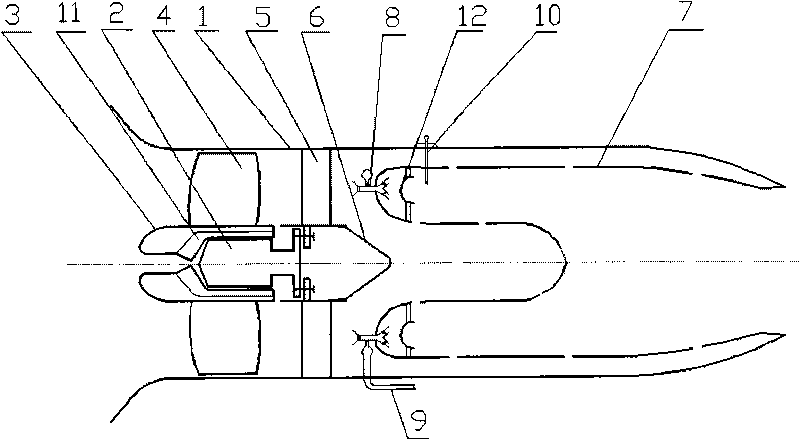

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

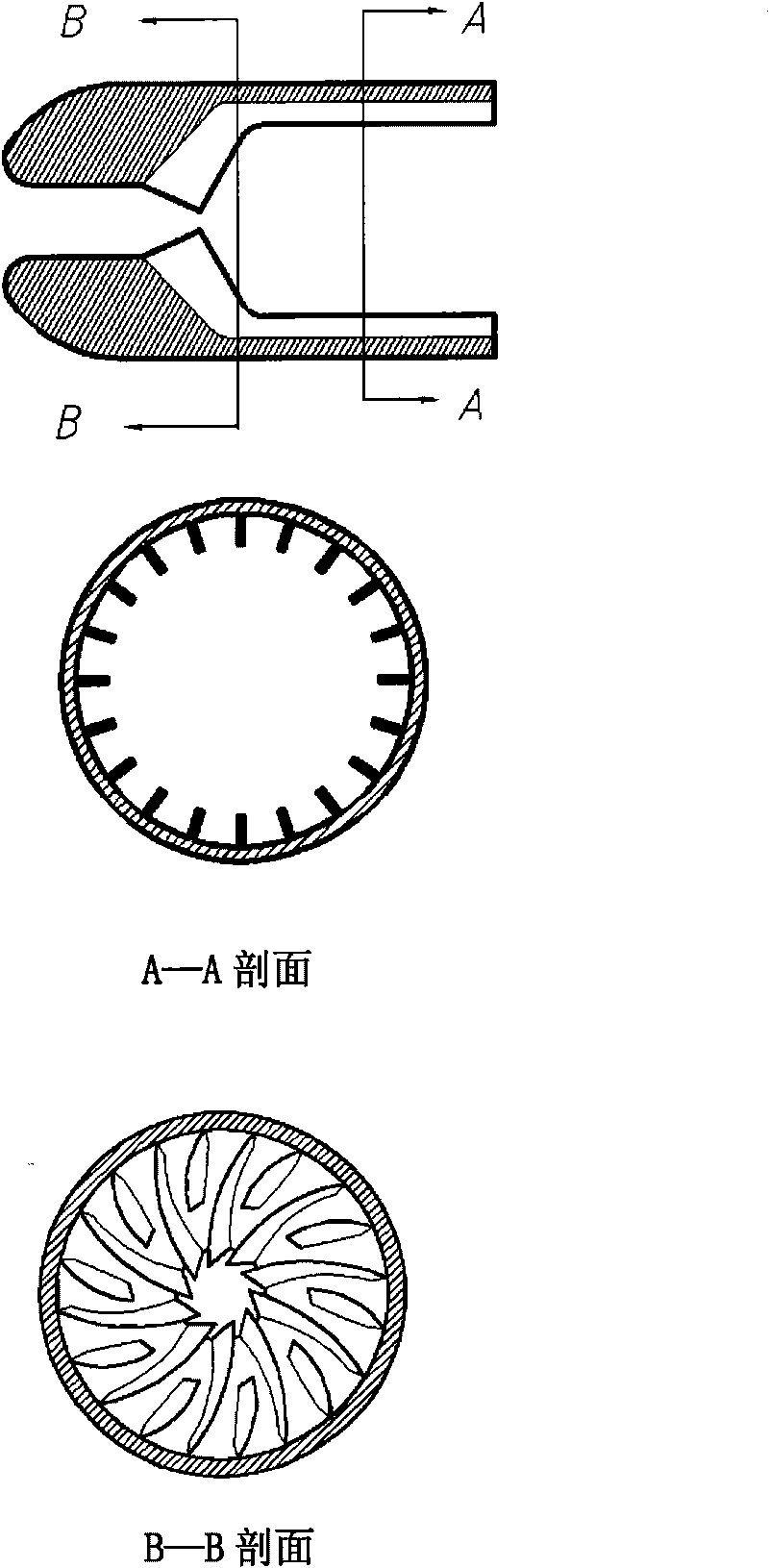

[0020] Please refer to the accompanying drawings, in the figure, the fan blade 4 is fixed on the fan hub 3, and the fan hub 3 is installed on the outer rotor of the outer rotor DC motor 2, and is fastened uniformly in the circumferential direction with three screws. The front end of the fan hub 3 has a similar funnel-shaped hole and the inner cavity adopts spiral cooling fins 11, and the fins are arranged at intervals between long and short blades (as attached figure 2 As shown), the spiral heat dissipation fins 11 can not only absorb the heat of the outer rotor DC motor, but also form a simple centrifugal fan. When the outer rotor DC motor 2 rotates at high speed, the airflow is sucked from the opening at the front end of the fan hub 3 and flows through the ribs. The heat is taken away during the chip, and then flows out from the heat shield 6 and finally enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com