Method for making guide vane inner ring by opening process window

A technology of guide vane inner ring and process window, which is applied in the field of precision casting, can solve the problems of difficult coating process, surface swelling, and impervious drying, etc., and achieve the effects of saving metal raw materials, shortening the processing cycle, and increasing the thrust-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in detail, but protection scope of the present invention is not limited to following embodiment:

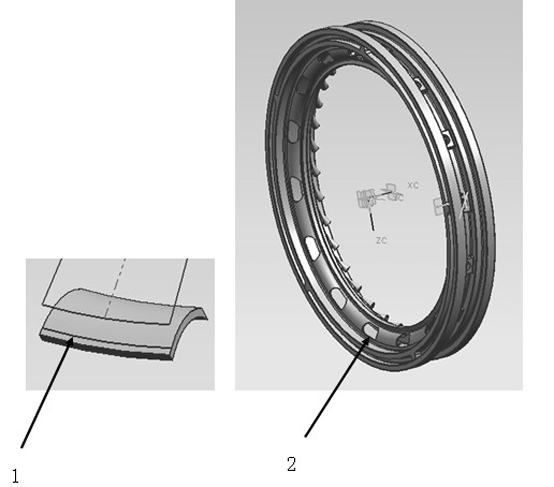

[0018] The profile size of the inner ring of the guide vane prepared in this embodiment is ф620×85, the wall thickness of the main body is 2 mm, the outer ring has 15 through holes, and the inner ring has 35 small nozzle holes with an inner diameter of 8 mm;

[0019] Concrete preparation process steps are:

[0020] (1) Wax mold preparation

[0021] Using the UG solid modeling method, the computer model of the inner ring of the guide vane is designed, and then the computer model of the inner ring of the guide vane is divided into 4 pieces on average in the circumferential direction, which are respectively fired with a laser rapid prototyping machine, and the joint surface of each wax piece Make a fixed tenon on the jig, then use the fixed tenon to combine paste and wax welding on the fixture, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com