Manufacturing method for titanium alloy and nickel-base superalloy laser additive connection

A nickel-based superalloy, laser additive technology, applied in laser welding equipment, manufacturing tools, additive processing, etc., can solve problems such as limiting alloy connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Laser additive bonding test of TA15 titanium alloy and GH4169 superalloy

[0034] 1. Preparation of parts to be connected

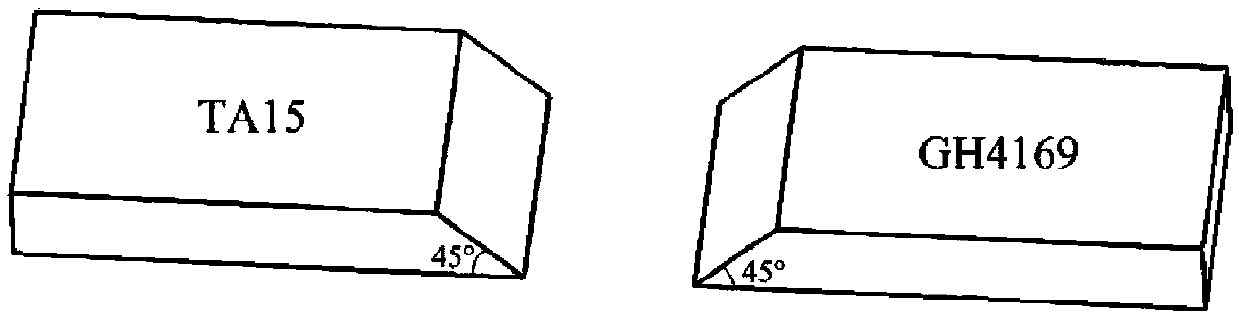

[0035] Make a 45-degree bevel on the workpieces to be connected of titanium alloy and high-temperature alloy by machining, and the size is 60mmx30mmx10mm. Grind the groove and the surrounding area with a rotary file tool, and clean it with alcohol and acetone after grinding.

[0036] 2. Implementation process

[0037] The GH4169, Nb and Cu powders are prepared by vaporized atomization, and the powder meshes are 100-200 meshes.

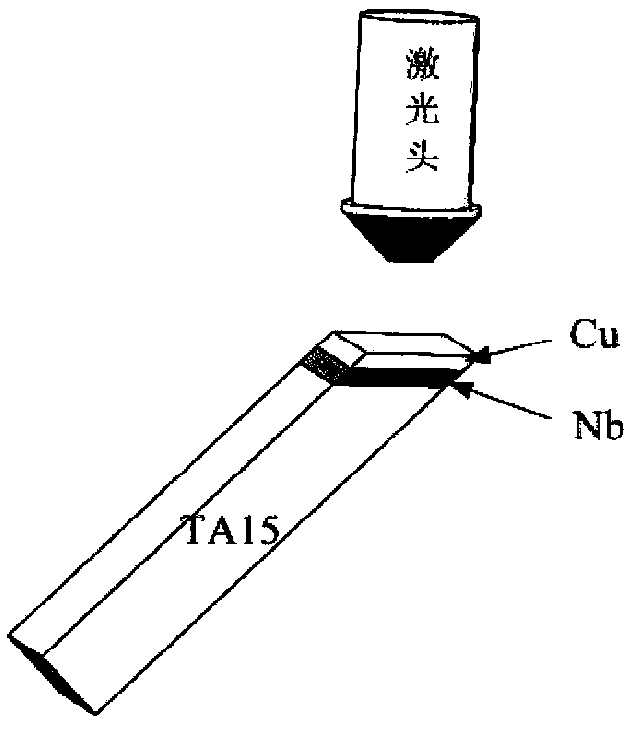

[0038] Form 1mm thick Nb on the groove surface of TA15 titanium alloy by laser additive manufacturing method, the main process parameters of laser forming are laser power 2400W, scanning speed 6mm / s and powder feeding speed 80g / min; then form 1mm thick on Nb Cu, the main process parameters of laser forming are laser power 1600W, scanning speed 8mm / s and powder feeding speed 70g / min.

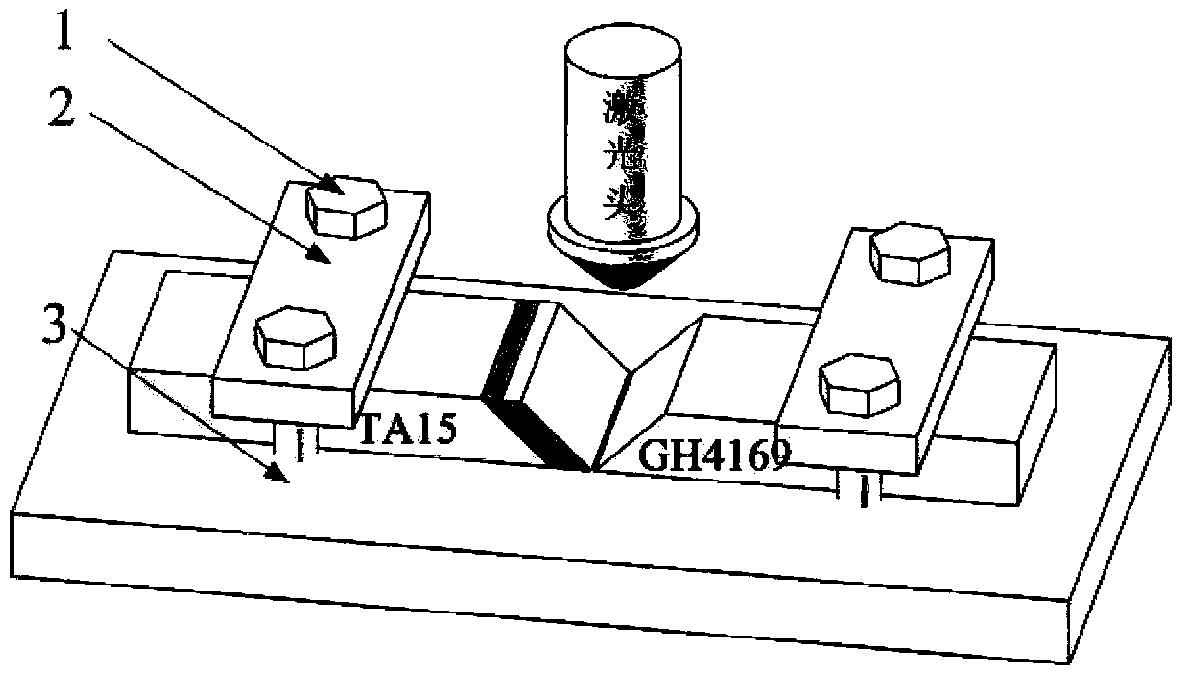

[0039] Install the TA15 titanium al...

Embodiment 2

[0043] (1) Prepare a 45-degree groove on the workpieces to be connected of titanium alloy and high-temperature alloy by machining, and grind the groove and the surrounding 7mm area with a rotary file tool. After grinding, first clean it with absolute ethanol, and then Clean with anhydrous acetone to make the groove surface free of oil and other impurities;

[0044](2), forming 0.5mm thick Nb on the surface of the titanium alloy groove by laser additive manufacturing, and then forming 0.5mm thick Cu on the Nb, using Nb / Cu as a connecting transition layer; both the Nb layer and the Cu layer Nb and Cu powders are used and prepared by argon atomization, and the particle size of Nb and Cu powders is 100 mesh.

[0045] (3) Install the workpieces to be connected of titanium alloy and nickel-based superalloy on the laser additive connection fixture, and use nickel-based superalloy powder for laser additive connection; install the workpieces to be connected of titanium alloy and nickel...

Embodiment 3

[0050] (1) Prepare a 45-degree groove on the workpieces to be connected of titanium alloy and high-temperature alloy by machining, and grind the groove and the surrounding 15mm area with a rotary file tool. After grinding, clean it with absolute ethanol, and then Clean with anhydrous acetone to make the groove surface free of oil and other impurities;

[0051] (2) Form 0.7mm thick Nb on the surface of titanium alloy groove by laser additive manufacturing method, then form 0.7mm thick Cu on Nb, and use Nb / Cu as the connecting transition layer; Nb layer and Cu layer are both Nb and Cu powders are used and prepared by argon atomization, and the particle size of Nb and Cu powders is 200 mesh.

[0052] (3) Install the workpieces to be connected of titanium alloy and nickel-based superalloy on the laser additive connection fixture, and use nickel-based superalloy powder for laser additive connection; install the workpieces to be connected of titanium alloy and nickel-based superallo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com