Thermal barrier coating with two bonding layers and preparation method of thermal barrier coating

A thermal barrier coating and bonding layer technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problem of not improving the bonding layer's ability to alleviate thermal expansion mismatch, The ability of matching has not improved, so as to achieve the effect of improving lifespan, alleviating thermal expansion mismatch, and reducing weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

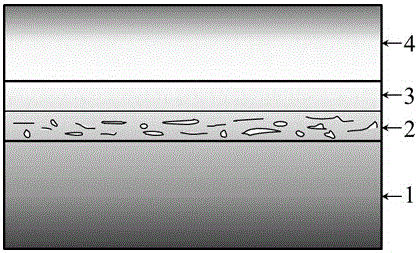

[0026] Such as figure 1 As shown, in this embodiment, two bonding layers with different structures are deposited on the superalloy substrate 1: the first layer of bonding layer (porous layer) and the second layer of bonding layer (dense layer), and in the dense layer A ceramic layer is deposited on the surface.

[0027] In the present embodiment, the composition of the two bonding layers is NiCoCrAlTaY, and the composition of the surface ceramic layer 4 is 8wt%Y 2 o 3 Stable ZrO 2 (8YSZ).

[0028] In this embodiment, the material of the superalloy substrate 1 is nickel-based superalloy IN738.

[0029] In this embodiment, the thickness of the first bonding layer 2 (porous layer) is 75 μm, the thickness of the second bonding layer 3 (dense layer) is 75 μm, and the thickness of the ceramic layer is 250 μm.

[0030] to combine figure 1 , a method for preparing a thermal barrier coating with a double-layer bonding layer, comprising the steps of:

[0031] Step 1, use coarse s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com