Pulse detonation engine (PDE) magnetic valve high frequency oil supply and ignition system

A pulse detonation and ignition system technology, applied in the field of aerospace power propulsion systems, can solve the problems that the solenoid valve cannot meet the high-frequency work requirements of PDE, the delay time of solenoid valve opening and closing is long, and the solenoid valve oil supply time is short. , to improve fuel atomization, evaporation and blending performance, shorten DDT distance and time, and avoid adaptive control of fuel supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

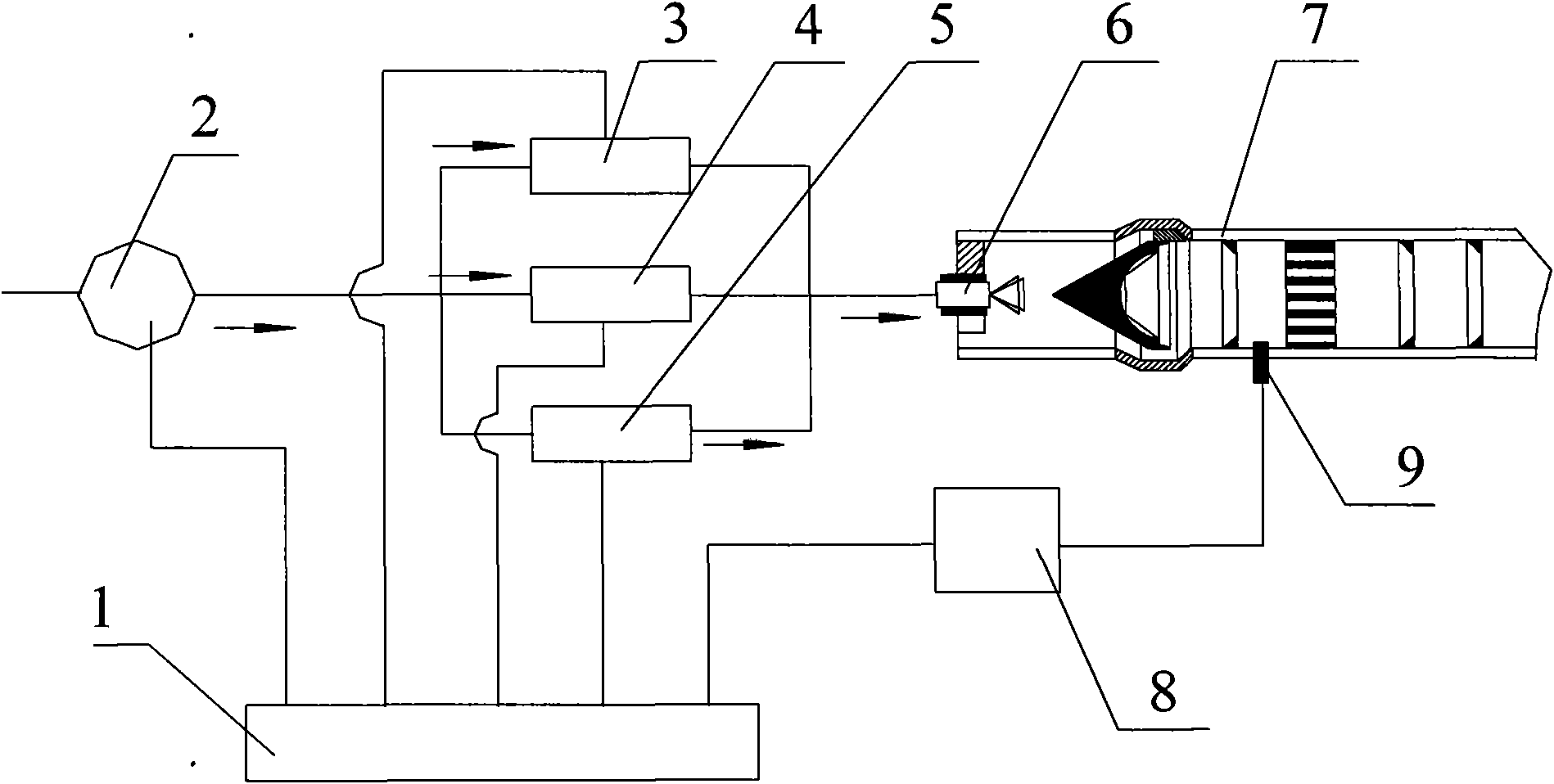

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

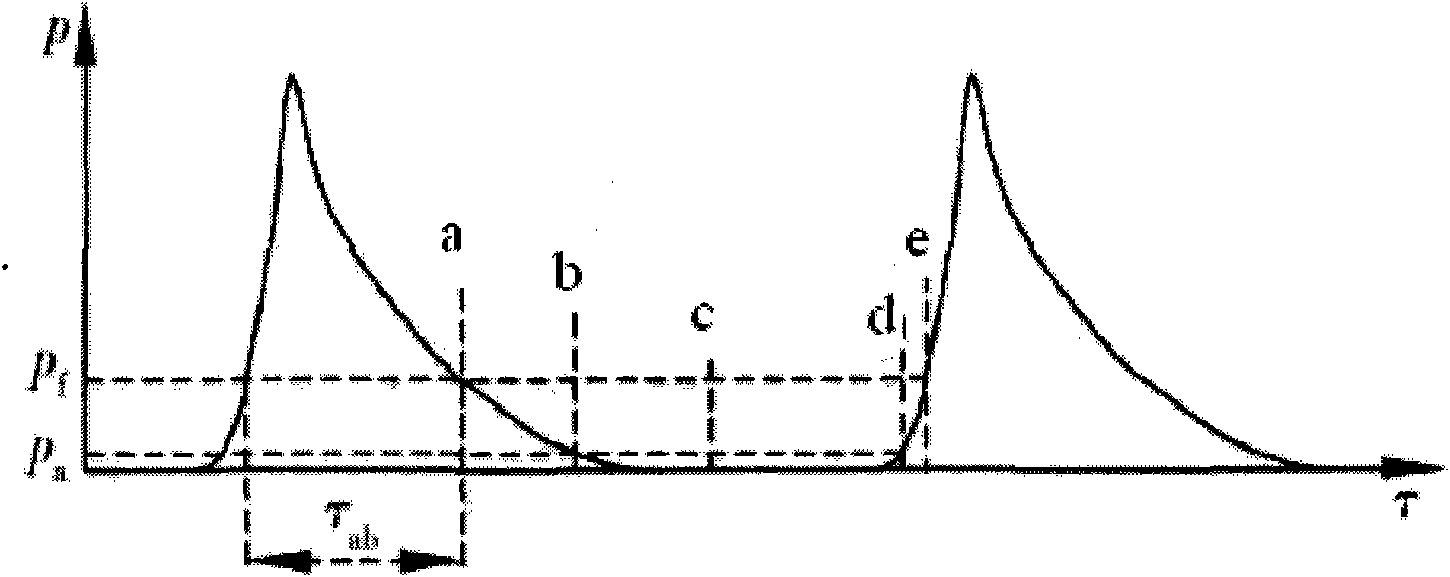

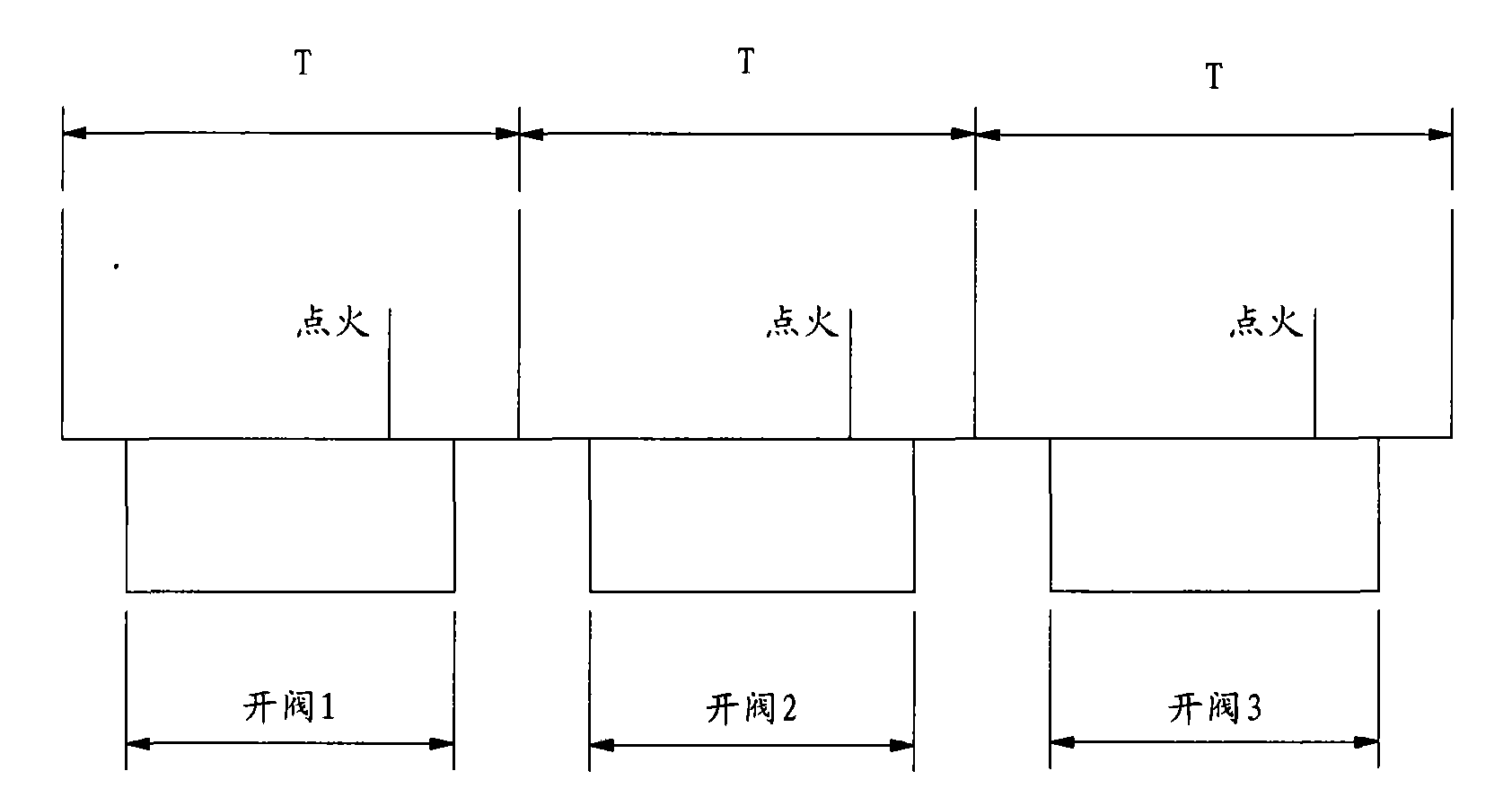

[0024] In order to develop a PDE that uses a solenoid valve to control oil supply, it is necessary to further improve the frequency response characteristics of the solenoid valve and shorten the delay time of the solenoid valve opening and closing, but there are certain technical limits that have not been resolved. If we change our thinking to study the problem of high-frequency intermittent oil supply controlled by PDE solenoid valve, the problem becomes simple. The key to the solution is to place part of the delay time for the opening and closing of the solenoid valve outside of one working cycle of the PDE, so that the normal fuel filling time of one working cycle can be guaranteed, and the switching frequency of the solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com