Contra-rotating outer framework water-air dual-purpose engine

An engine and exoskeleton technology, which is applied in the direction of machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of water-air dual-purpose engines in the test verification stage, etc., to improve structural efficiency, reduce series, and reduce structural weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

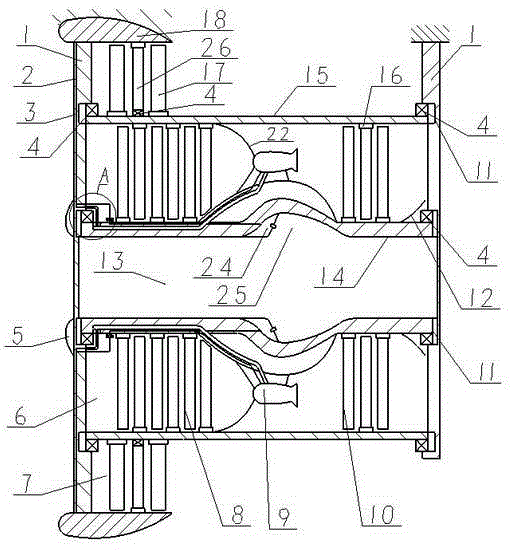

[0034] Below in conjunction with accompanying drawing this design is further described.

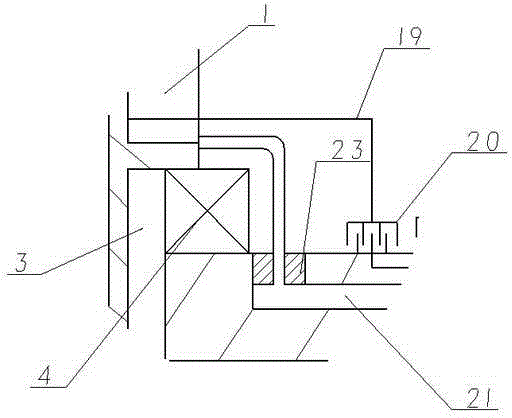

[0035] Such as figure 1 As shown, a counter-rotating exoskeleton water-air dual-purpose engine, the main structure of the engine includes: (1) support frame, (2) oil and electricity pipeline, (3) front thrust bearing, (4) circumferential bearing, (5) Fairing, (6) Inner duct, (7) Outer duct, (8) Compressor, (9) Annular combustor, (10) Turbine, (11), Rear thrust bearing, (12) Convergence Exhaust nozzle, (13) central duct, (14) inner rotor, (15) outer rotor, (16) blade tenon, (17) fan, (18) engine cover, (19) power transmission pipeline, (20 ) conductive slip ring, (21) oil pipeline, (22) convergence channel, (23) rotary joint, (24) metal fuel chamber, (25) metal-water reaction combustion chamber, (26) fan vane; it is characterized in that :

[0036]The engine front support frame (1) is fixedly arranged in the engine cover (18), and the engine cover (18) and the engine rear support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com