A Piezoelectric-Magnetoelectric Composite Microgenerator

A magnetoelectric composite and generator technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, asynchronous induction motors, etc., can solve low conversion efficiency, long activation time and complex structure and other issues, to achieve the effect of improving the axial impact resistance, improving the impact resistance, and improving the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

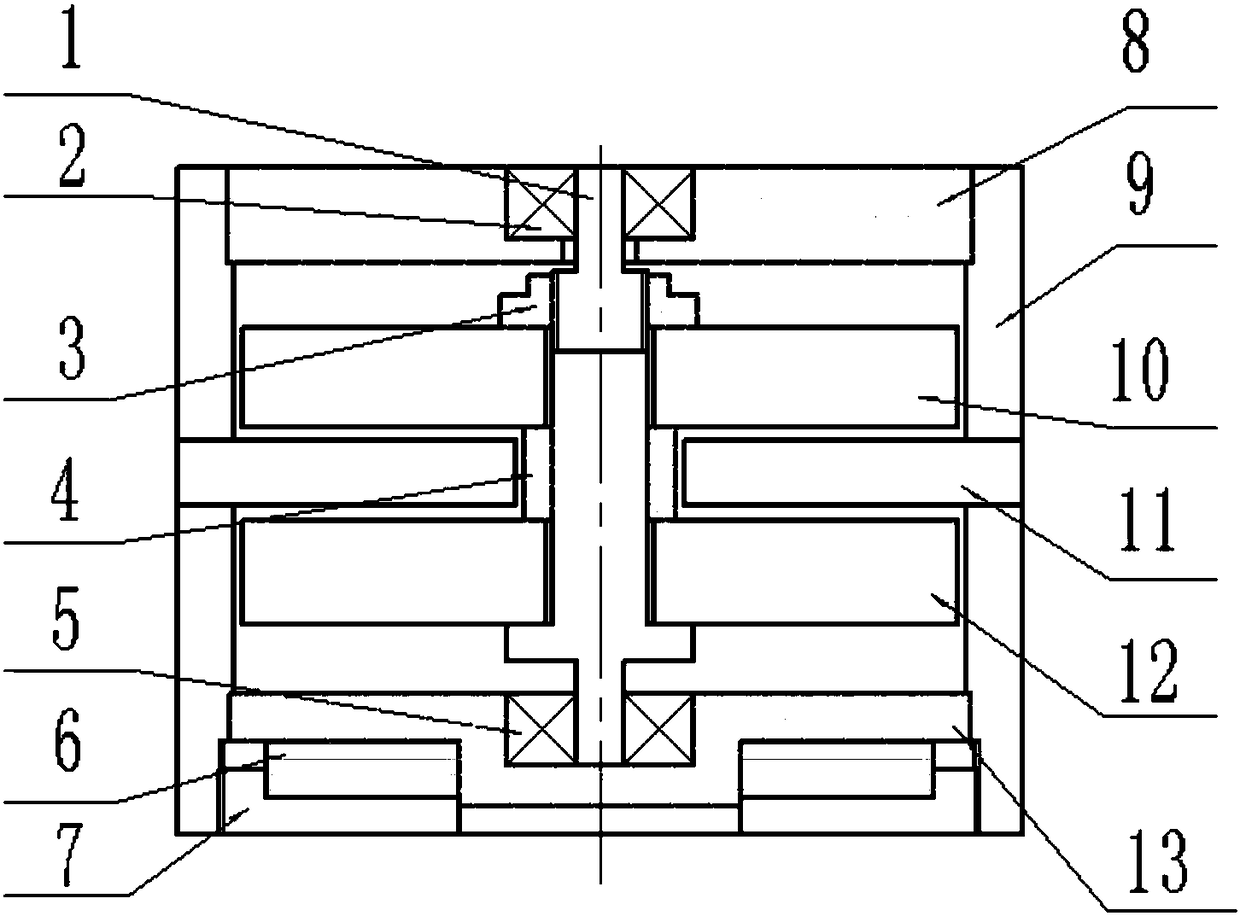

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

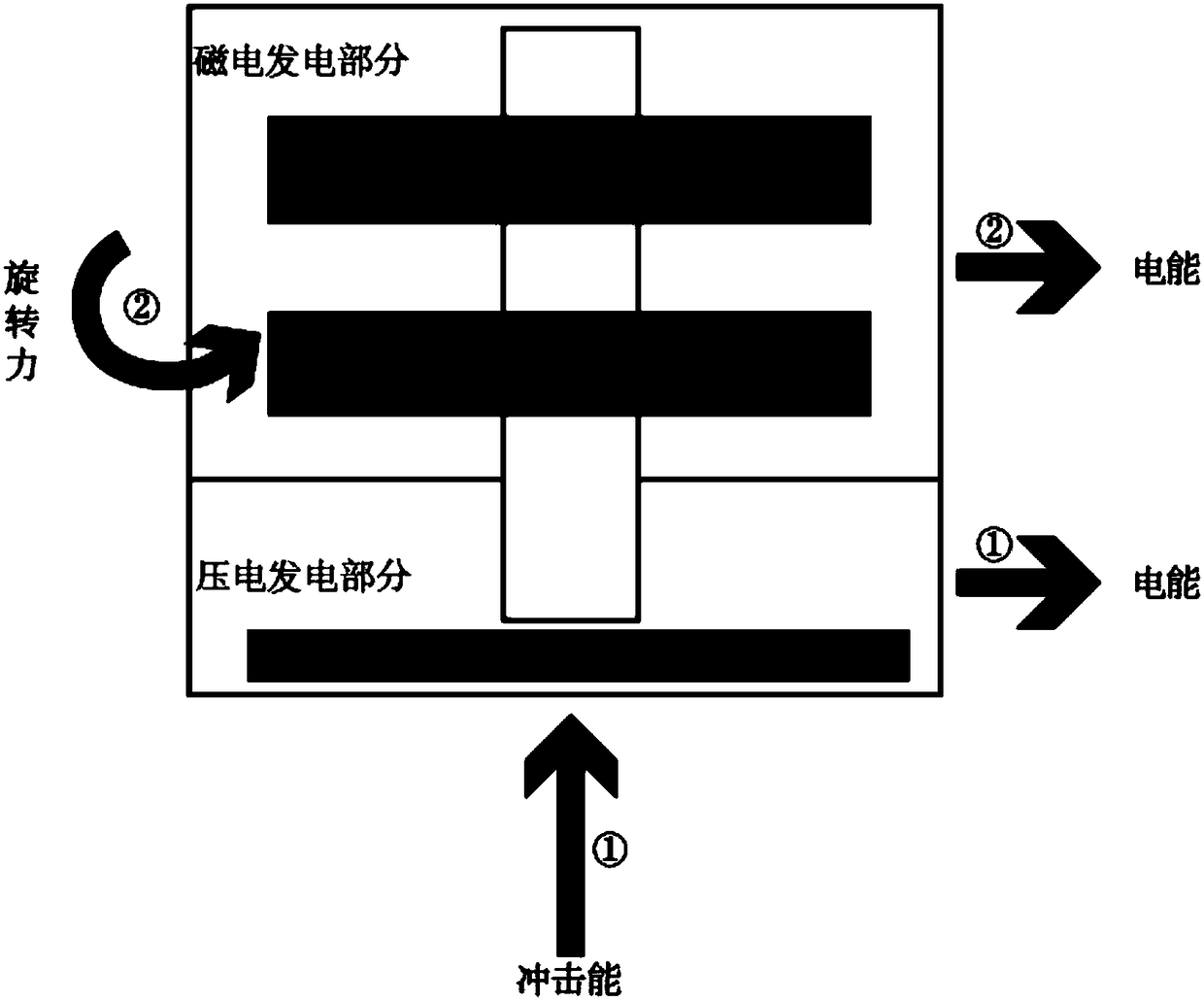

[0032] This embodiment provides a piezoelectric-magnetoelectric composite micro-generator, the micro-generator is composed of a piezoelectric part and a magnetoelectric part, and its working principle is as follows figure 1 shown.

[0033] Among them, the piezoelectric micro-generator part adopts a piezoelectric stack structure composed of multi-layer piezoelectric materials. Piezoelectric generators have fast activation properties and thus have the advantage of short activation times. The power source is the external axial impact force, which is converted into electrical energy through the piezoelectric effect of the piezoelectric stack.

[0034] The magnetoelectric generator part adopts the structure of the disc permanent magnet micro generator. Compared with other micro-generators, the disc-type permanent magnet micro-generator has the advantages of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com