A double-pump axial variable displacement piston pump

A variable plunger, axial technology, used in pumps, multi-cylinder pumps, pump components, etc., can solve the problems of high cost of double pump structure, low control accuracy, large axial size, etc., to reduce complexity and manufacturing costs. , The effect of improving lubricating conditions and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

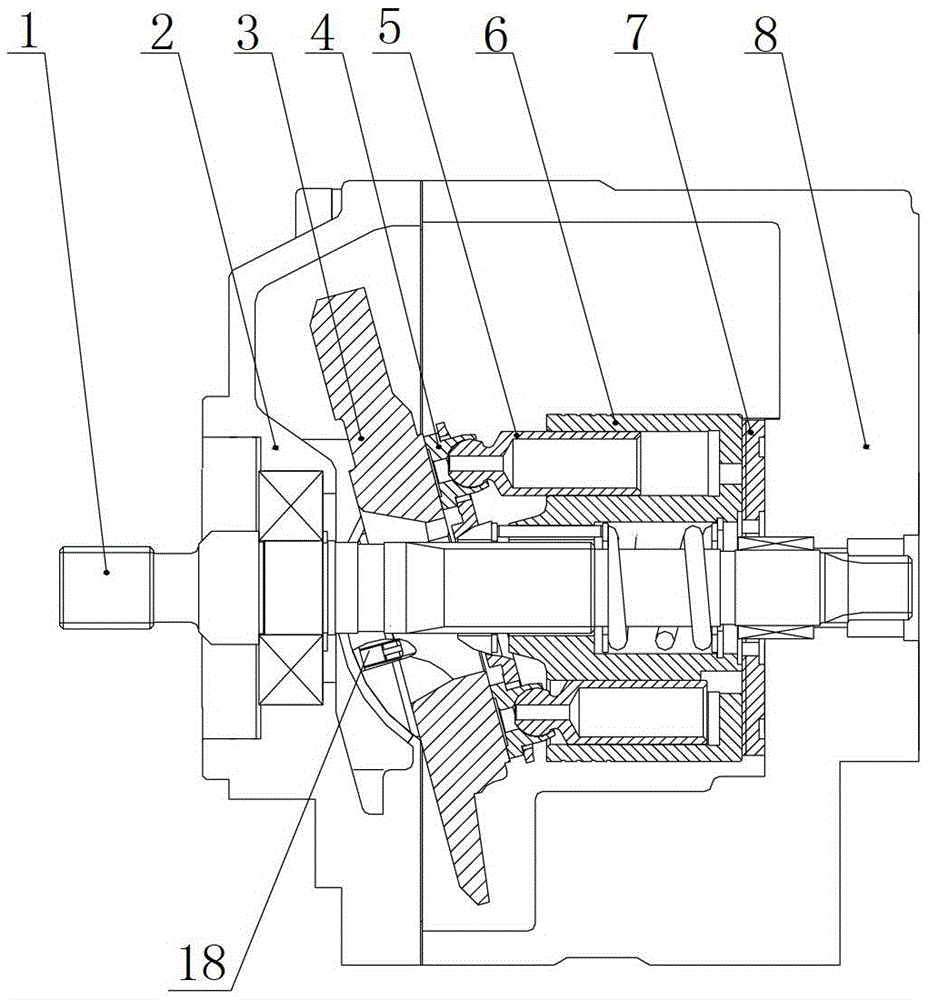

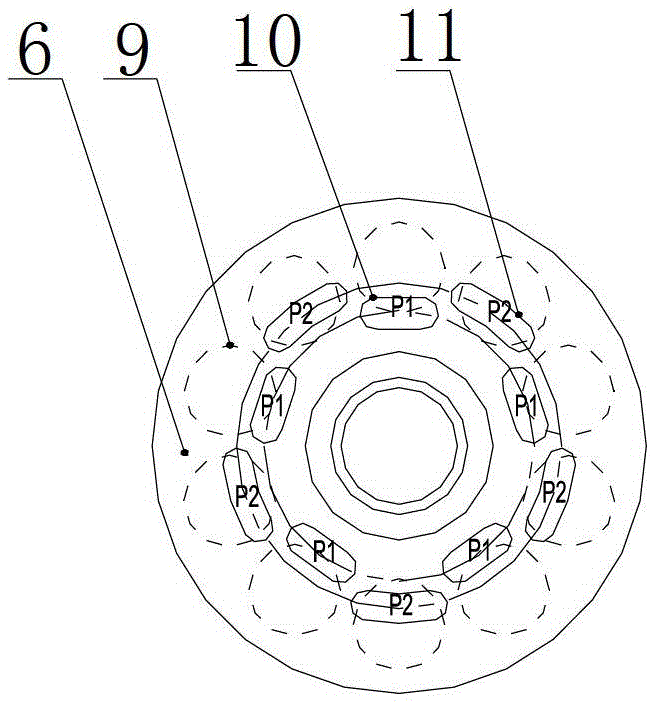

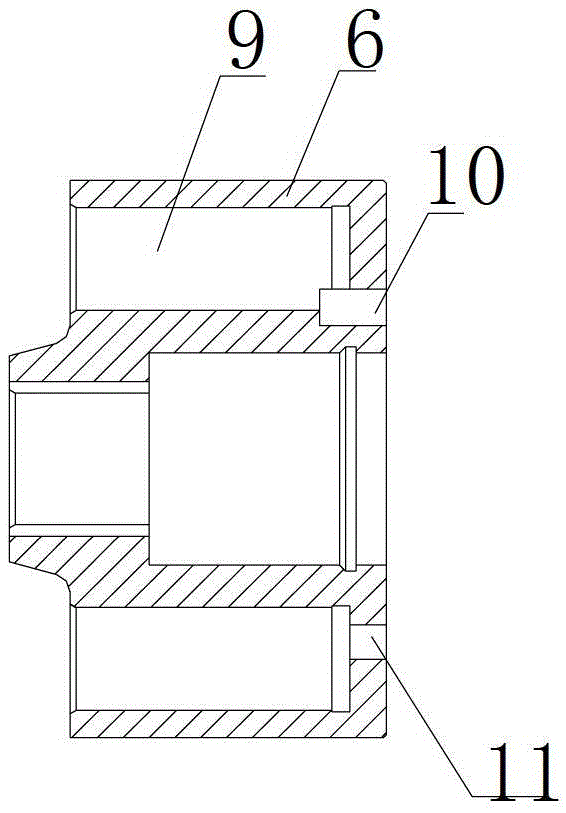

[0033] The assembly structure of the axial piston pump of the present invention is shown in Figure 1-Figure 5 , including pump shaft 1, end cover 2, swash plate 3, sliding shoe 4, plunger 5, cylinder block 6, oil distribution plate 7, and housing 8. One end of the oil distribution plate 7 is connected with the end face of the housing 8, and the other end of the oil distribution plate 7 is connected with the end face of the cylinder block 6. The end face of the cylinder block 6 in contact with the oil distribution plate is provided with a cylinder oil discharge port. The disc 7 is provided with an oil port of the oil distribution plate, the housing 8 is provided with a housing oil port, and the cylinder oil discharge port includes a plurality of first cylinder oil discharge ports P1 and a plurality of second cylinder oil discharge ports P2, A plurality of first cylinder oil discharge ports P1 are evenly distributed on the cylinder body 6, a plurality of second cylinder oil dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com