Method for preparing single crystal high temperature alloy block material through laser 3D printing

A high-temperature alloy and 3D printing technology, which is applied in the growth of polycrystalline materials, single crystal growth, crystal growth, etc., can solve the problems of high cost and complicated single crystal blade forming process, and achieve the effect of improving the thrust-to-weight ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

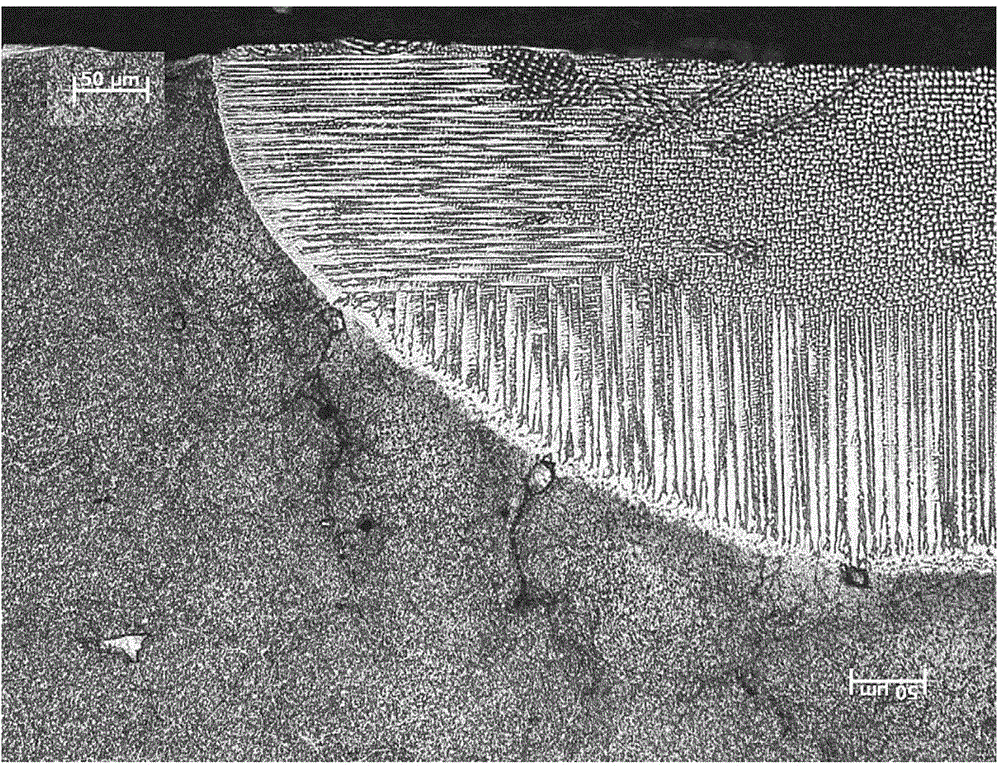

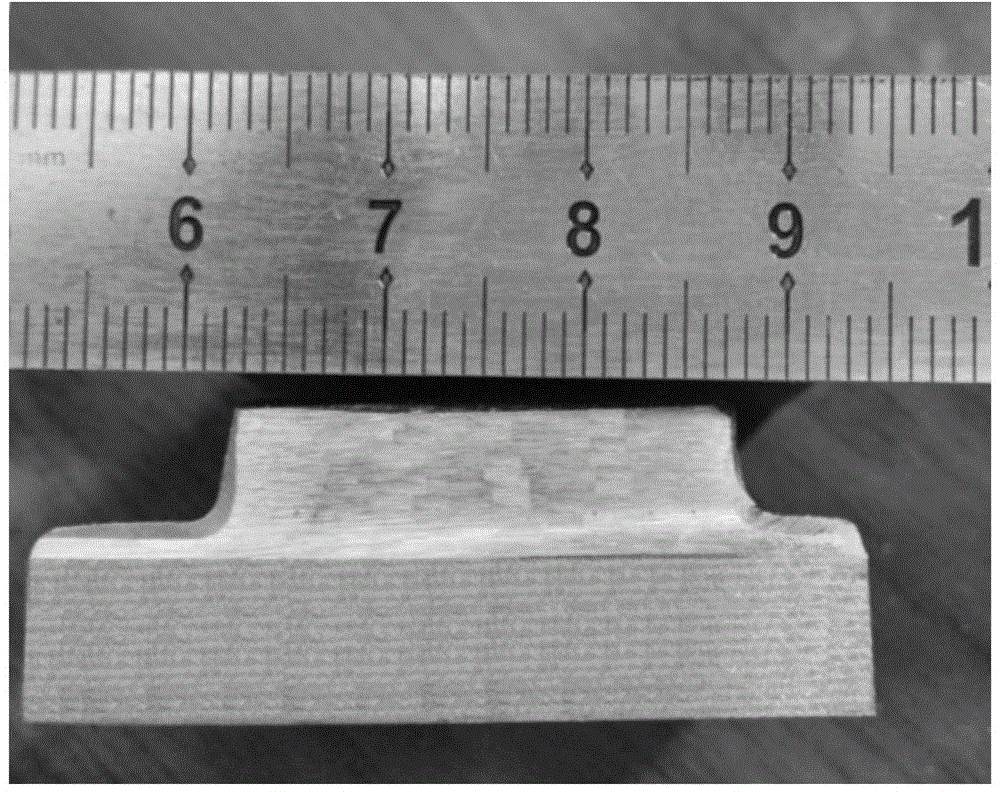

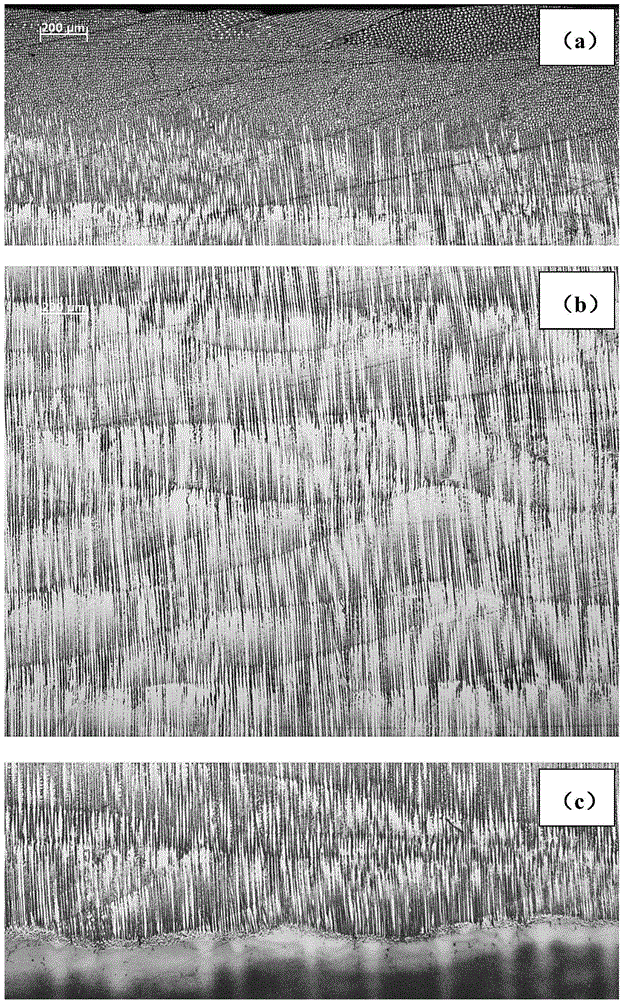

[0028] Firstly, a wax mold is prepared, and then ceramic refractory slurry is coated on the outside of the wax mold, and a ceramic mold shell with seed crystals is obtained through dewaxing and roasting. The nickel-based superalloy master alloy (brand SRR99) was melted and refined in the crucible of the vacuum single crystal furnace, and then poured into the ceramic mold shell. pull. After the mold shell is cooled to room temperature, the shell can be cleaned to obtain a nickel-based single crystal superalloy. The substrate is cut by wire cutting on the single crystal matrix, and the angle between the normal direction of the substrate surface and the direction is about 3°. In the second step, the base material is at room temperature, and the surface of the single crystal superalloy base material is remelted by laser with a laser power of 700w and a scanning speed of 300mm / min, and a metallographic microscope is used to observe the remelted structure. remelted microstructure...

Embodiment 2

[0032] Firstly, a wax mold is prepared, and then ceramic refractory slurry is coated on the outside of the wax mold, and a ceramic mold shell with seed crystals is obtained through dewaxing and roasting. The nickel-based superalloy master alloy (brand SRR99) was melted and refined in the crucible of the vacuum single crystal furnace, and then poured into the ceramic mold shell. pull. After the mold shell is cooled to room temperature, the shell can be cleaned to obtain a nickel-based single crystal superalloy. The substrate is cut by wire cutting on the single crystal matrix, and the angle between the normal direction of the substrate surface and the direction is about 15°. In the second step, the substrate is preheated to 200°C, and the surface of the single crystal superalloy substrate is remelted by laser. The laser power is 1500w, the scanning speed is 900mm / min, and the remelted structure is observed with a metallographic microscope. remelted microstructure such as F...

Embodiment 3

[0036] Firstly, a wax mold is prepared, and then ceramic refractory slurry is coated on the outside of the wax mold, and a ceramic mold shell with seed crystals is obtained through dewaxing and roasting. The nickel-based superalloy master alloy (brand DD99) was melted and refined in the crucible of the vacuum single crystal furnace, and then poured into the ceramic mold shell. pull. After the mold shell is cooled to room temperature, the shell can be cleaned to obtain a nickel-based single crystal superalloy. The substrate is cut by wire cutting on the single crystal matrix, and the angle between the normal direction of the substrate surface and the direction is about 2°. In the second step, the substrate is preheated to 400°C, and the surface of the single crystal superalloy substrate is remelted with a laser, the laser power is 2500w, and the scanning speed is 2000mm / min, and the remelted structure is observed with a metallographic microscope. remelted microstructure such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com