High-strength gray cast iron modifier and modification treatment process thereof

A technology of modification treatment and modification agent, which is applied in the field of high-strength gray cast iron modification agent and new modification agent, and achieves significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The modification process of the modification agent of the present invention adopts the pouring method in the cast iron ladle: the modification agent is put into the bottom of the gray cast iron ladle, and when the gray cast iron (C: 2.92~3.48; Si: 1.52~2.46) melted in the cupola or electric furnace ; Mn: 0.22~0.78; P: 0.011~0.048; S: 0.03~0.15; Cr: 0.15~0.5; Cu: 0.3~0.78; Sn: 0.011~0.098) When the temperature of molten iron reaches 1480-1550 degrees, pour the In the cast iron ladle, the high-temperature molten iron melts the modifier, and the elements in the modifier enter the gray cast iron molten iron to obtain high-strength gray cast iron.

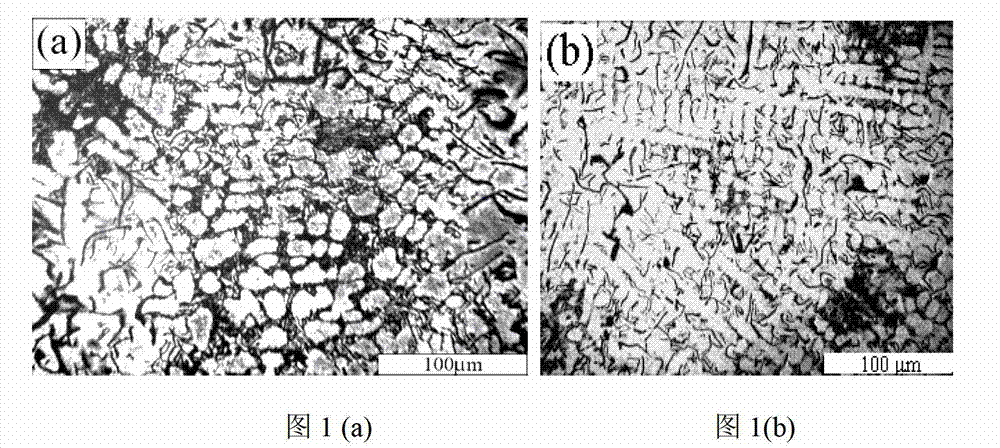

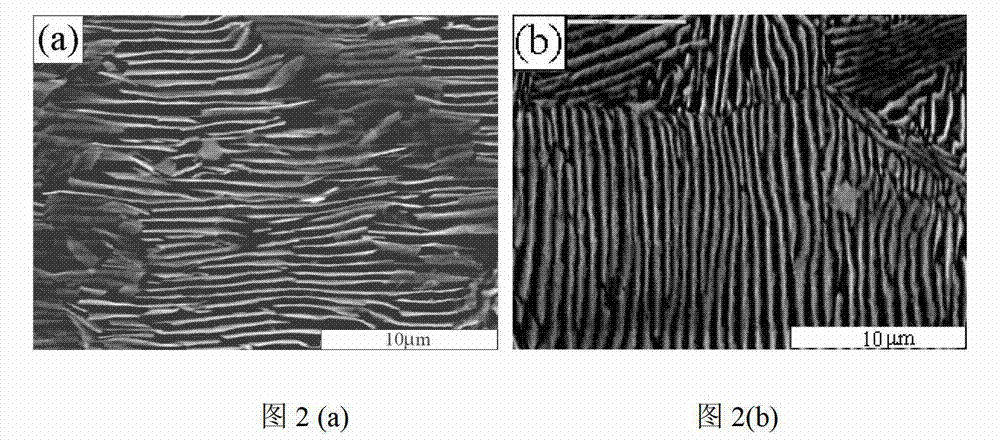

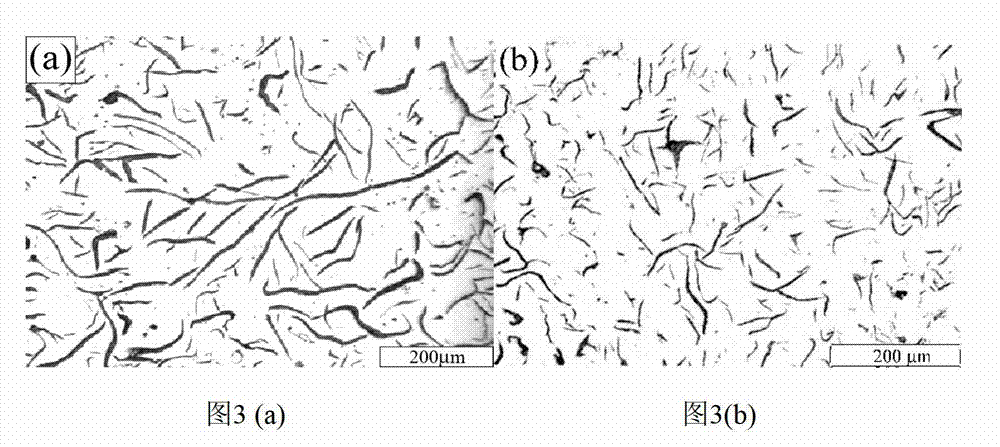

[0024] The positive effect of the present invention's optimized design of the composition of the modificator is to improve the primary austenite dendrite, pearlite, graphite and eutectic group structure of the gray cast iron, thereby improving the tensile strength of the gray cast iron, and the result is an unexpected significant ...

Embodiment 2

[0052] The JMC light-duty vehicle engine independently developed by Jiangling Motors Co., Ltd. has the characteristics of high explosion pressure, low oil consumption, and light engine block weight. Therefore, it is required that the engine block has high strength, and the tensile strength of the top surface of the block body is ≥ 250MPa. Casting JMC light-duty vehicle engine cylinder blocks with Mo alloyed high-strength gray cast iron has major and key problems such as the cylinder body strength not meeting the requirements and casting defects such as shrinkage cracks and concave shrinkage. At the same time, the production cost is high. Using the "a high-strength gray cast iron modifier" of the present invention to modify the micro-alloyed high-strength gray cast iron to cast the JMC light-duty vehicle engine cylinder block successfully solves the problem of using Mo-added alloyed high-strength gray cast iron. The major and key problems of casting defects such as shrinkage c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com