Preparation method for heat-conducting anti-flaming PET/PBT composite material and application thereof

A composite material and mixed material technology, applied in the field of functional material preparation, can solve problems such as hidden dangers of electrical conductivity and uneven dispersion of graphene, and achieve the effects of good dispersibility, improved dispersion performance, and safe technical problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

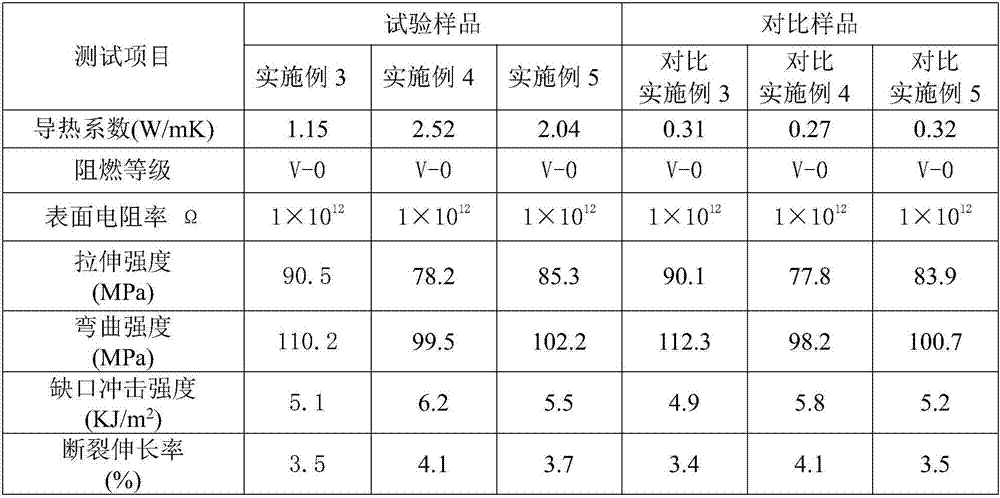

Examples

Embodiment 1

[0085] This embodiment provides a preparation method for conducting shell core-type activated carbon intercalation graphene, including the following procedures and steps:

[0086] Process 1: The process of preparing activated carbon intercalated graphene

[0087] Step 1: Acidify pretreatment of activated carbon with dilute nitric acid.

[0088] Step 2: adding a dispersant to the solvent and stirring evenly, then adding graphene, and ultrasonically dispersing for 2-24 hours to obtain a graphene suspension. In this step, the solvent is deionized water or ethanol.

[0089] Step 3: Add 200-300 mesh activated carbon to the graphene suspension in step 2, and continue ultrasonic dispersion for 30min-3h to obtain a suspension mixture, which is washed and centrifugally filtered to obtain a prefabricated activated carbon intercalated graphene body.

[0090] Step 4: heat-treating the activated carbon intercalated graphene preform in step 3 by microwave to obtain activated carbon inter...

Embodiment 2

[0097] On the basis of Example 1, this example further provides a method for preparing a thermally conductive and flame-retardant PET / PBT composite material, including the following procedures and steps:

[0098] Step 1: batching, accurately preparing the components required for the composite material, drying PET and PBT at a temperature of 105-140° C. for 1-4 hours, and storing them for later use.

[0099] Step 2: Add heat conducting agent, flame retardant, and flame retardant synergist into a high-speed mixer, then add coupling agent for surface coupling treatment, and obtain a mixture after mixing evenly. In this step, the coupling agent is one of aluminate coupling agent, titanate coupling agent, and silane coupling agent, or two or more coupling agents are used in combination.

[0100] Step 3: Continue to add core-shell type activated carbon intercalated graphene, PET, and PBT to the mixture in step 2 and add them to the high-speed mixer, then add lubricant and toughening...

Embodiment 3

[0104] In order to further improve the mechanical properties, heat resistance and processing properties of PET / PBT, flame retardants, lubricants, etc. are added to the PET / PBT system to obtain a multi-functional, high-performance and high-practicability modified polymer.

[0105] The thermally conductive and flame-retardant PET / PBT composite material of this embodiment includes the following components and parts by weight: 30% for PET; 10% for PBT; 0.5% for shell-core activated carbon intercalation graphene; 23.9% for alkali-free glass fiber 23% for MgO; 0.3% for E wax; 3% for POE-g-GMA; 2% for sodium antimonate; 7% for decabromodiphenylethane; 0.3% for aluminate coupling agent. in:

[0106] The core-shell type activated carbon intercalation graphene uses activated carbon intercalation graphene as the core layer, and the cross-linked structure polymer covering and connecting the core layer is the shell layer. In the core-shell type activated carbon intercalation graphene, each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com