Porous corundum ceramics used for heating atomizer and production method of porous corundum ceramics used for heating atomizer

An atomizer and heating technology, applied in the field of ceramics, can solve the problems of porous ceramics such as low compressive strength, insufficient atomization effect, easy damage and slag loss, etc., to ensure rapid replenishment and adsorption, improve capillary effect, and increase porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

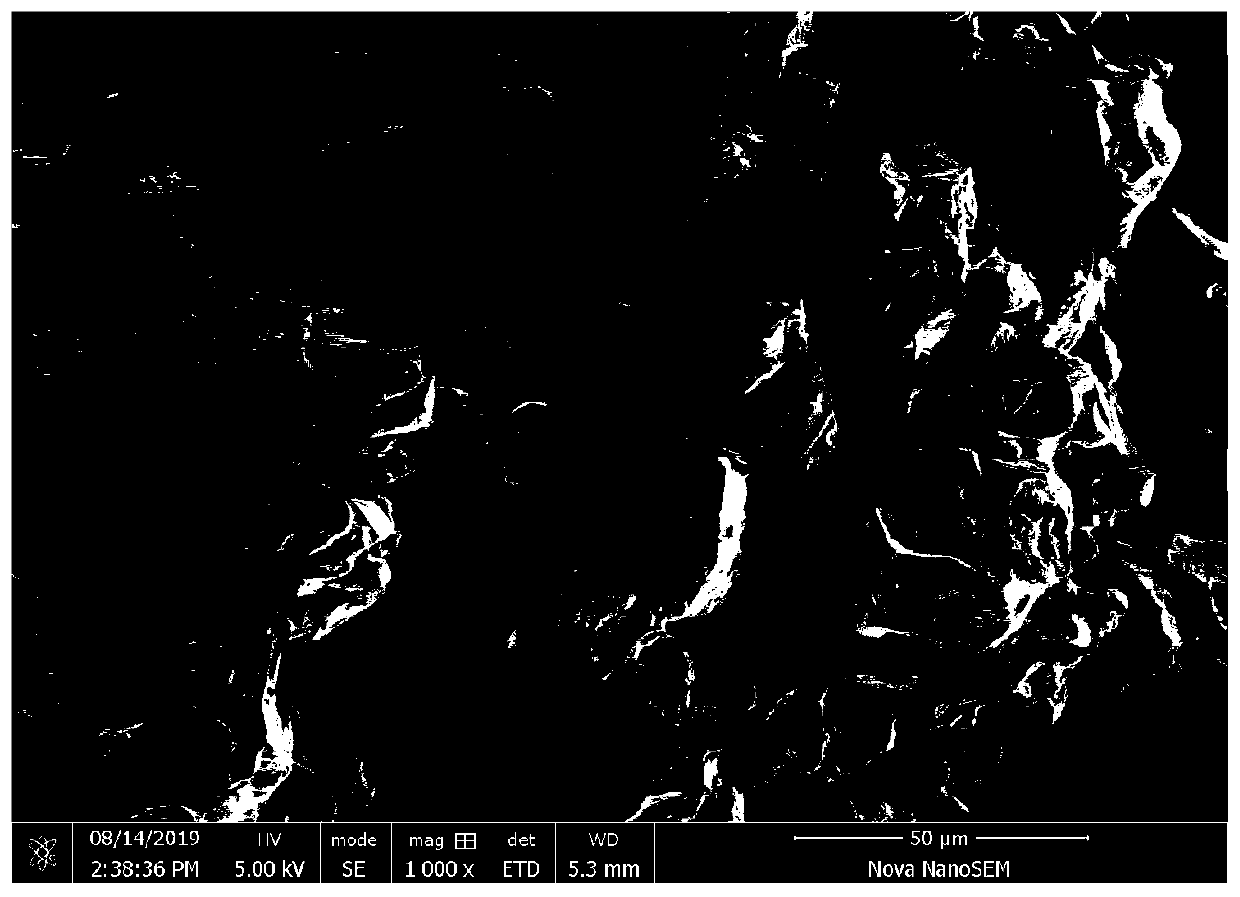

Image

Examples

Embodiment 1

[0037] A method for preparing porous corundum ceramics for heating atomizers of the present invention comprises the following steps:

[0038] (1) Proportioning of raw materials: 40wt% of corundum, 15wt% of cellulose, 10wt% of montmorillonite, 20% of magnesium oxide, 15wt% of coke; the sum of the above components is 100%;

[0039] (2) Mixing and pulping: put the above-mentioned raw materials into the mixing equipment, add 200% deionized water, and mix and mill for 10 hours to obtain the slurry;

[0040] (3) Spray granulation: the resulting slurry is spray-dried and granulated;

[0041] (4) Compression molding: put the ceramic granulation material into a steel mold, and dry press molding to obtain a green body;

[0042] (5) Sintering: put the green body into a muffle furnace for sintering, the sintering temperature is 1350 degrees, and keep warm for 2 hours. Cool to obtain porous corundum ceramics.

[0043] (6) Put the porous corundum ceramics into a 30% malic acid solution a...

Embodiment 2

[0045] A method for preparing porous corundum ceramics for heating atomizers of the present invention comprises the following steps:

[0046] (1) Raw material ratio: corundum 60wt%, starch 10wt%, silicon dioxide 10wt%, activated carbon 10wt%, ammonium carbonate 10%; the sum of the above components is 100%;

[0047] (2) Mixing and pulping: put the above-mentioned raw materials into the mixing equipment, add 250% deionized water, and stir at a high speed for 5 hours to obtain a slurry;

[0048] (3) Spray granulation: the resulting slurry is spray-dried and granulated;

[0049] (4) Compression molding: put the ceramic granulation material into a steel mold, and dry press molding to obtain a green body;

[0050] (5) Sintering: put the green body into an air atmosphere tunnel furnace for sintering at a sintering temperature of 1400 degrees, and keep it warm for 2 hours. Cool to obtain porous corundum ceramics.

[0051] (6) Put the porous corundum ceramics into 20% gluconic acid ...

Embodiment 3

[0053] A method for preparing porous corundum ceramics for heating atomizers of the present invention comprises the following steps:

[0054] (1) Raw material ratio: 70wt% of corundum, 2wt% of PVA, 8wt% of sepiolite, 10wt% of titanium dioxide, 10wt% of coal powder; the sum of the above components is 100%;

[0055](2) Mixing and pulping: put the above-mentioned raw materials into the mixing equipment, add deionized water, mix and mill for 6 hours to obtain the slurry;

[0056] (3) Spray granulation: the resulting slurry is spray-dried and granulated;

[0057] (4) Compression molding: put the ceramic granulation material into a steel mold, and dry press molding to obtain a green body;

[0058] (5) Sintering: put the green body into an air atmosphere bell furnace for sintering, the sintering temperature is 1450 degrees, and keep warm for 1 hour. Cool to obtain porous corundum ceramics.

[0059] (6) Put the porous corundum ceramic into 40% tartaric acid solution, and soak at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com