A kind of sodium alginate/n-succinyl chitosan composite airgel and its preparation method and application

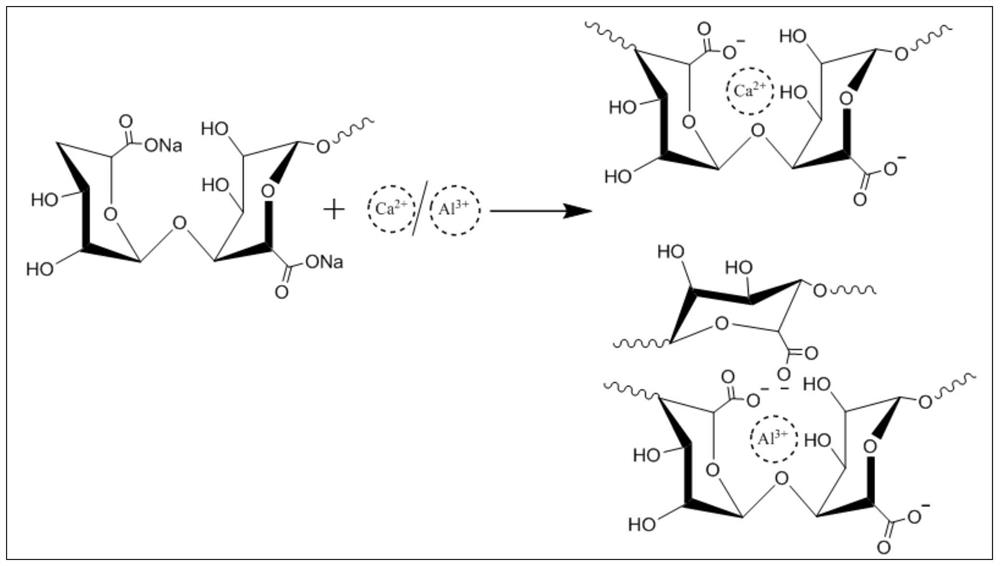

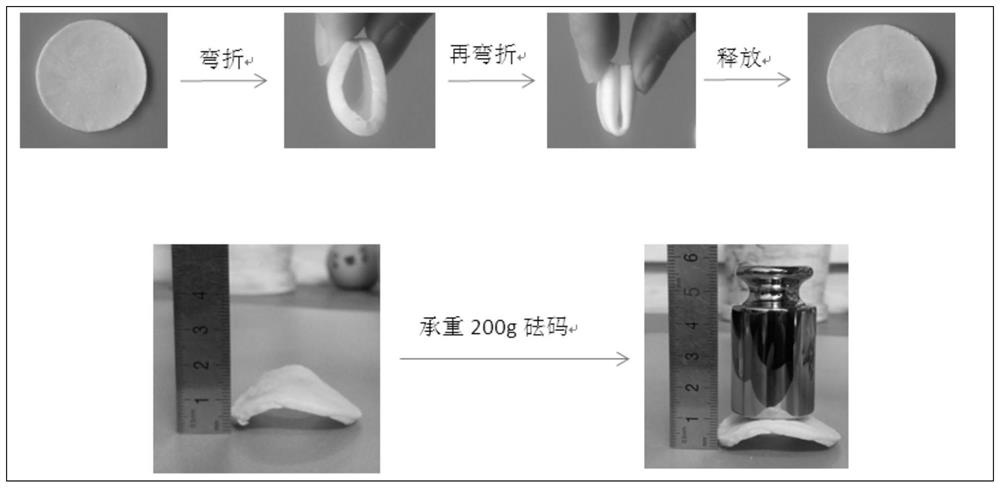

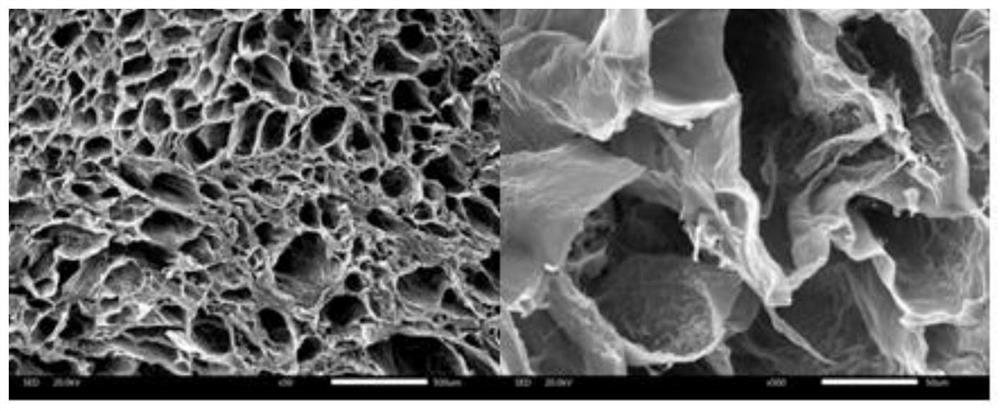

A technology of succinyl chitosan and succinyl chitosan water, which is applied in the field of sodium alginate/N-succinyl chitosan composite airgel and its preparation, can solve the problems of poor fractionation efficiency, low recyclability, Secondary pollution and other problems, to achieve excellent mechanical properties, excellent surface affinity, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A preparation method of sodium alginate / N-succinyl chitosan composite aerogel, the specific steps are as follows:

[0032](1) Preparation of sodium alginate / N-succinyl chitosan mixed solution;

[0033]A. Add 0.2g of N-succinyl chitosan to 10 mL of water, stir thoroughly to dissolve and obtain a 2wt% N-succinyl chitosan solution;

[0034]B. Add 0.8g of sodium alginate to 10mL of water, fully stir to dissolve it to obtain a 7.4wt% sodium alginate solution;

[0035]C. Add the above N-succinyl chitosan solution to the alginic acid solution, magnetically stir for 2 hours and then ultrasonically disperse for 15 minutes to obtain a sodium alginate / N-succinyl chitosan mixed solution;

[0036](2) Preparation of uncrosslinked sodium alginate / N-succinyl chitosan composite aerogel: pour the sodium alginate / N-succinyl chitosan uniform solution obtained in step (1) into a height of 2 cm 、In a cylindrical mold with a diameter of 6 cm, and put it in the freezer at -40℃ for 4h to freeze the solution into sha...

Embodiment 2

[0046]A preparation method of sodium alginate / N-succinyl chitosan composite aerogel, the specific steps are as follows:

[0047](1) Preparation of sodium alginate / N-succinyl chitosan mixed solution;

[0048]A. Add 0.4g of N-succinyl chitosan to 10 mL of water, stir thoroughly to dissolve it to obtain a 4wt% N-succinyl chitosan solution;

[0049]B. Add 0.6g of sodium alginate to 10mL of water, fully stir to dissolve it to obtain a 5.7% by weight sodium alginate solution;

[0050]C. Add the above-mentioned N-succinyl chitosan solution to the alginic acid solution, magnetically stir for 2 hours and then ultrasonically disperse for 15 minutes to obtain a sodium alginate / N-succinyl chitosan mixed solution;

[0051](2) Preparation of uncrosslinked sodium alginate / N-succinyl chitosan composite aerogel: pour the uniform sodium alginate / N-succinyl chitosan solution obtained in step (1) into a cylindrical mold And put it in the freezer at -40℃ for more than 4h to freeze the solution, and then freeze-dry it ...

Embodiment 3

[0054]A preparation method of sodium alginate / N-succinyl chitosan composite aerogel, the specific steps are as follows:

[0055](1) Preparation of sodium alginate / N-succinyl chitosan mixed solution;

[0056]A. Add 0.1g of N-succinyl chitosan into 10 mL of water, stir thoroughly to dissolve it to obtain a 1wt% N-succinyl chitosan solution;

[0057]B. Add 0.9g of sodium alginate to 10mL of water, fully stir to dissolve it to obtain an 8.3wt% sodium alginate solution;

[0058]C. Add the above-mentioned N-succinyl chitosan solution to the alginic acid solution, magnetically stir for 2 hours and then ultrasonically disperse for 15 minutes to obtain a sodium alginate / N-succinyl chitosan mixed solution;

[0059](2) Preparation of uncrosslinked sodium alginate / N-succinyl chitosan composite aerogel: pour the uniform sodium alginate / N-succinyl chitosan solution obtained in step (1) into a cylindrical mold And put it in the freezer at -40℃ for more than 4h to freeze the solution into shape, then freeze-dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com