Ceramic matrix composite and preparation method and application thereof

A composite material and ceramic-based technology, which is applied in the field of ultra-high temperature ceramic-based composite materials, can solve the problems of silicon carbide fiber or carbon fiber decomposition and damage, high preparation cost, and large grain size, so as to improve the sintering density and speed up the compaction speed , Improve the effect of packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) According to the proportion of 85% zirconium diboride, 10% zirconium disilicide, and 5% multi-walled carbon nanotubes in parts by mass, take 20.0000g zirconium diboride powder on an analytical balance with an accuracy of 0.0001mg ( Purity 99.5%, average particle size 2μm), 2.3529g zirconium disilicide powder (purity 99.5%, average particle size 1μm), 1.1765g multi-walled carbon nanotubes (purity 97.5%, outer diameter 20-40nm, length 5-15μm ).

[0038] 2) Put the above weighed zirconium diboride and zirconium disilicide powder together into a beaker for ultrasonic vibration dispersion for 30 minutes, and add absolute ethanol solution as a dispersion medium.

[0039] 3) Put the weighed multi-walled carbon nanotubes into a beaker for ultrasonic vibration dispersion for 30 minutes, and add absolute ethanol solution as a dispersion medium.

[0040] 4) Put the zirconium diboride and zirconium disilicide powder and the multi-walled carbon nanotube slurry that have been dis...

Embodiment 2

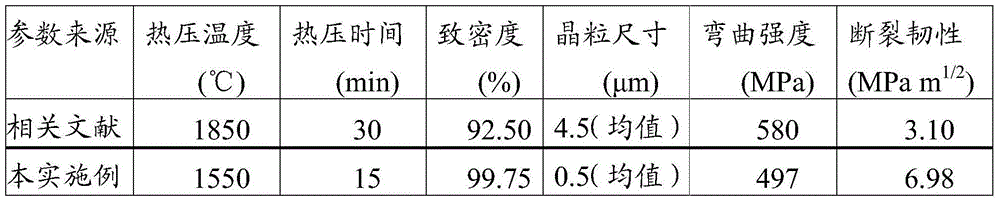

[0046] The sintering parameters in this embodiment are different from those in Embodiment 1. The second-step sintering temperature is set to 1550° C., and the others are the same as in Embodiment 1.

Embodiment 3

[0048] The sintering parameters of this embodiment are different from those of Embodiment 1. The second-step sintering temperature is set to 1650° C., and the others are the same as those of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com