Silicon carbide fiber reinforced ceramic based structure wave absorption composite material and preparation method thereof

A silicon carbide fiber and composite material technology, applied in the field of wave absorbing materials, can solve the problems of high complex dielectric constant, serious impedance mismatch, poor controllability and uniformity of the dielectric properties of wave absorbing composite materials, etc. Good absorbing properties and mechanical properties, high flexural strength, good absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 9

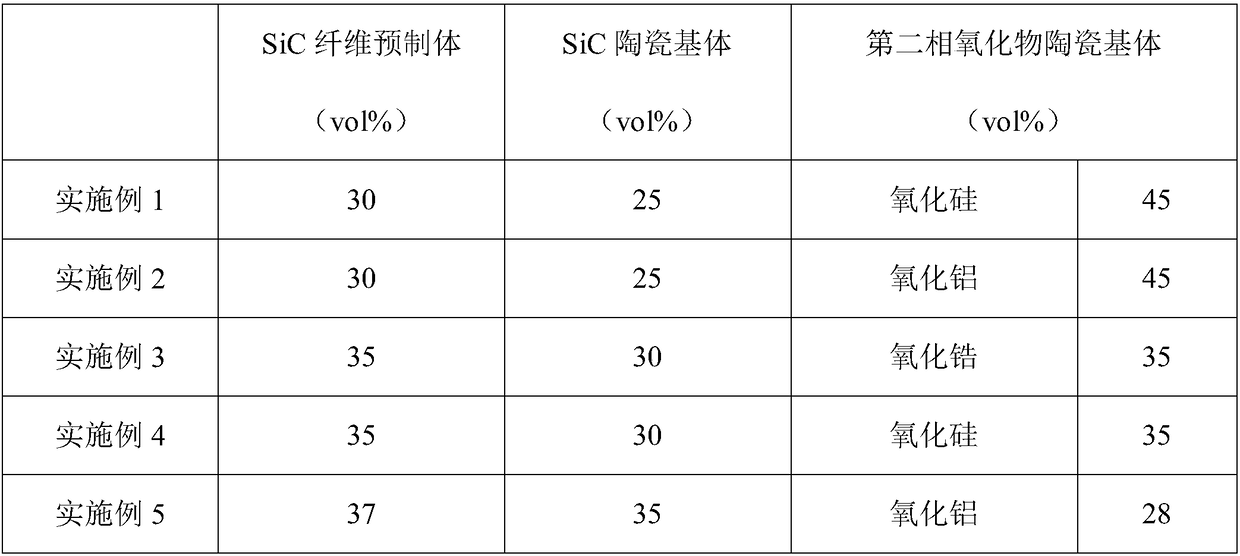

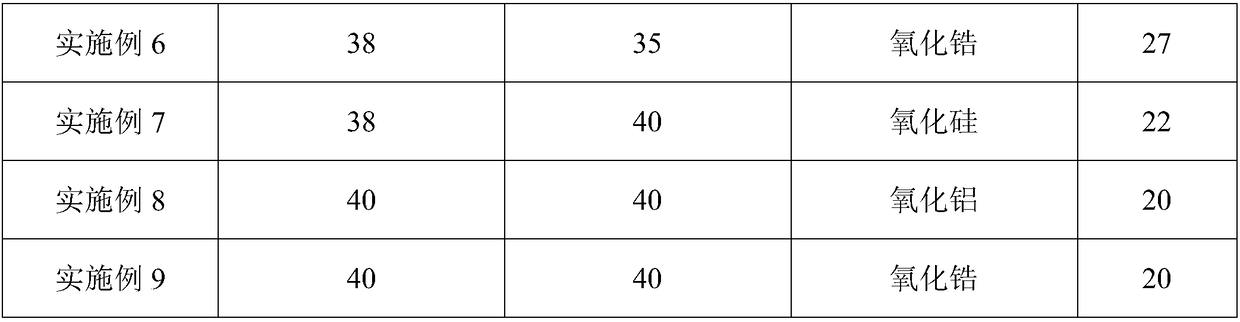

[0025] The invention is a SiC with adjustable dielectric properties f The microwave-absorbing composite material with ceramic matrix structure will be described in detail below through 9 examples with different components. SiC with adjustable dielectric properties of the present invention f The microwave-absorbing composite material with a ceramic matrix structure is composed of a SiC fiber prefabricated body, a SiC ceramic matrix and a second-phase oxide ceramic matrix.

[0026] The concrete component of table 1 embodiment 1 to embodiment 9

[0027]

[0028]

[0029] The preparation specific process of above-mentioned embodiment 1-9 is:

[0030] Step 1. Degumming of the SiC fiber preform. Ultrasonic cleaning with acetone was used to remove the glue. Soak the 2.5DSiC fiber preform in acetone for 10 minutes and ultrasonically oscillate for 5 minutes. Take out the SiC fiber preform and clean it with absolute ethanol. After cleaning, put it in an oven at 100°C for 30 min...

Embodiment 10

[0042] In the SiC fiber-reinforced ceramic matrix structure wave-absorbing composite material of this embodiment, the SiC fiber preform is 35 vol%, the SiC ceramic matrix is 30 vol%, and the silicon oxide ceramic matrix is 35 vol%.

[0043] Step 1. Degumming of the SiC fiber preform. Ultrasonic cleaning with acetone was used to remove the glue. Soak the 2.5DSiC fiber preform in acetone for 10 minutes and ultrasonically oscillate for 5 minutes. Take out the SiC fiber preform and clean it with absolute ethanol. After cleaning, put it in an oven at 100°C for 30 minutes. Glued SiC fiber preform.

[0044] Step 2. Put the SiC fiber prefabricated body after degumming in step 1 into a conventional chemical vapor deposition furnace, and prepare the SiC ceramic matrix by chemical vapor infiltration; The methyl silane precursor is passed into the chemical vapor deposition furnace, and argon is input as the diluent gas and carbon dioxide as the reaction gas at the same time. The pre...

Embodiment 11

[0048] In the SiC fiber-reinforced ceramic matrix structure wave-absorbing composite material of this embodiment, the SiC fiber preform is 35 vol%, the SiC ceramic matrix is 30 vol%, and the silicon oxide ceramic matrix is 35 vol%.

[0049] Step 1. Degumming of the SiC fiber preform. Ultrasonic cleaning with acetone was used to remove the glue. Soak the 2.5DSiC fiber preform in acetone for 10 minutes and ultrasonically oscillate for 5 minutes. Take out the SiC fiber preform and clean it with absolute ethanol. After cleaning, put it in an oven at 100°C for 30 minutes. Glued SiC fiber preform.

[0050] Step 2. Put the SiC fiber prefabricated body after degumming in step 1 into a conventional chemical vapor deposition furnace, and prepare the SiC ceramic matrix by chemical vapor infiltration; The methyl silane precursor is passed into the chemical vapor deposition furnace, and argon is input as the diluent gas and carbon dioxide as the reaction gas at the same time. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com