Device for cleaning a combing segment in a combing machine

A cleaning and combing technology, which is applied in combing machines, fiber processing, textiles and papermaking, etc. It can solve the problems of changing the speed of the brush roller and affecting the cleaning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

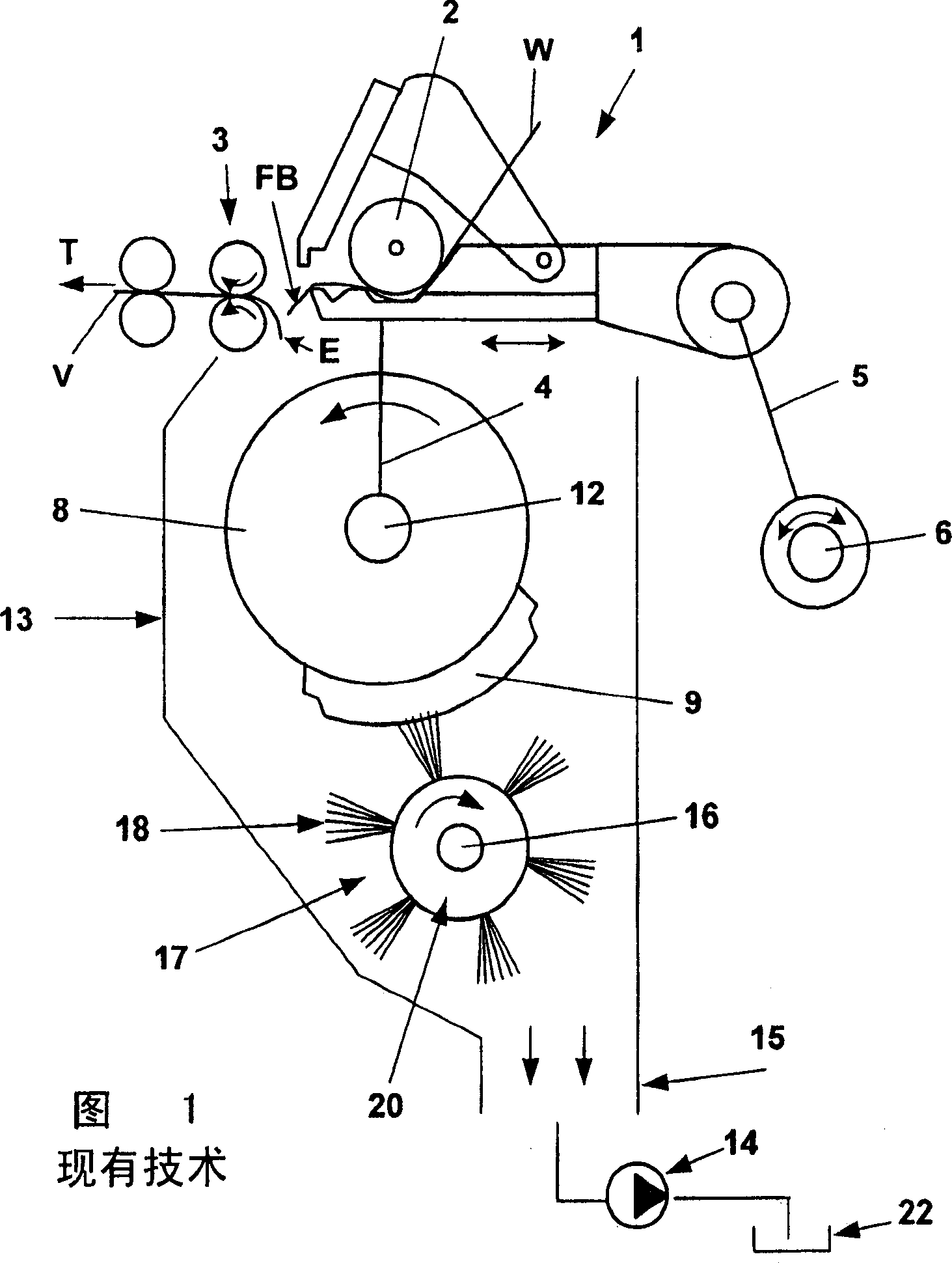

[0036] Fig. 1 is a schematic side view of a combing device of a combing machine. There are actually 8 such combs arranged next to each other. The combing unit contains a nipper unit (called upper nipper for short fibers) which is reciprocated by means of rocker arms 4,5. Rocker arms 4 (only one shown) are rotatably mounted on the circular comb axis 12 and the nipper 1 . A rocker arm 5 , which is rotatably mounted on the rod 1 , is connected in a rotatably fixed manner to a driven nipper shaft 6 . The lap W is fed to a feed drum 2 rotatably mounted inside the nipper 1 . The lap W is unwound by lap rollers, not shown, and is also fixed on lap rollers of the unwinding process, also not shown.

[0037] In the position shown in FIG. 1, the nipper device 1 is open and is in the front position in which the ends FB protruding from the nipper device (referred to as fiber bundles) are laid on the finished On the end E of the nonwoven fabric V, and welded on the end E. The nonwoven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com