High toughness yttrium oxide stabilized tetragonal zirconia material unaffected by sintering and preparation method thereof

A technology of tetragonal zirconia and yttrium oxide, applied in zirconia and other directions, can solve the problems of narrow sintering process parameter range, reduced fracture toughness of 3Y-TZP material, reduced metal ion distribution uniformity, etc., and achieves simple sintering process and sintering temperature. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

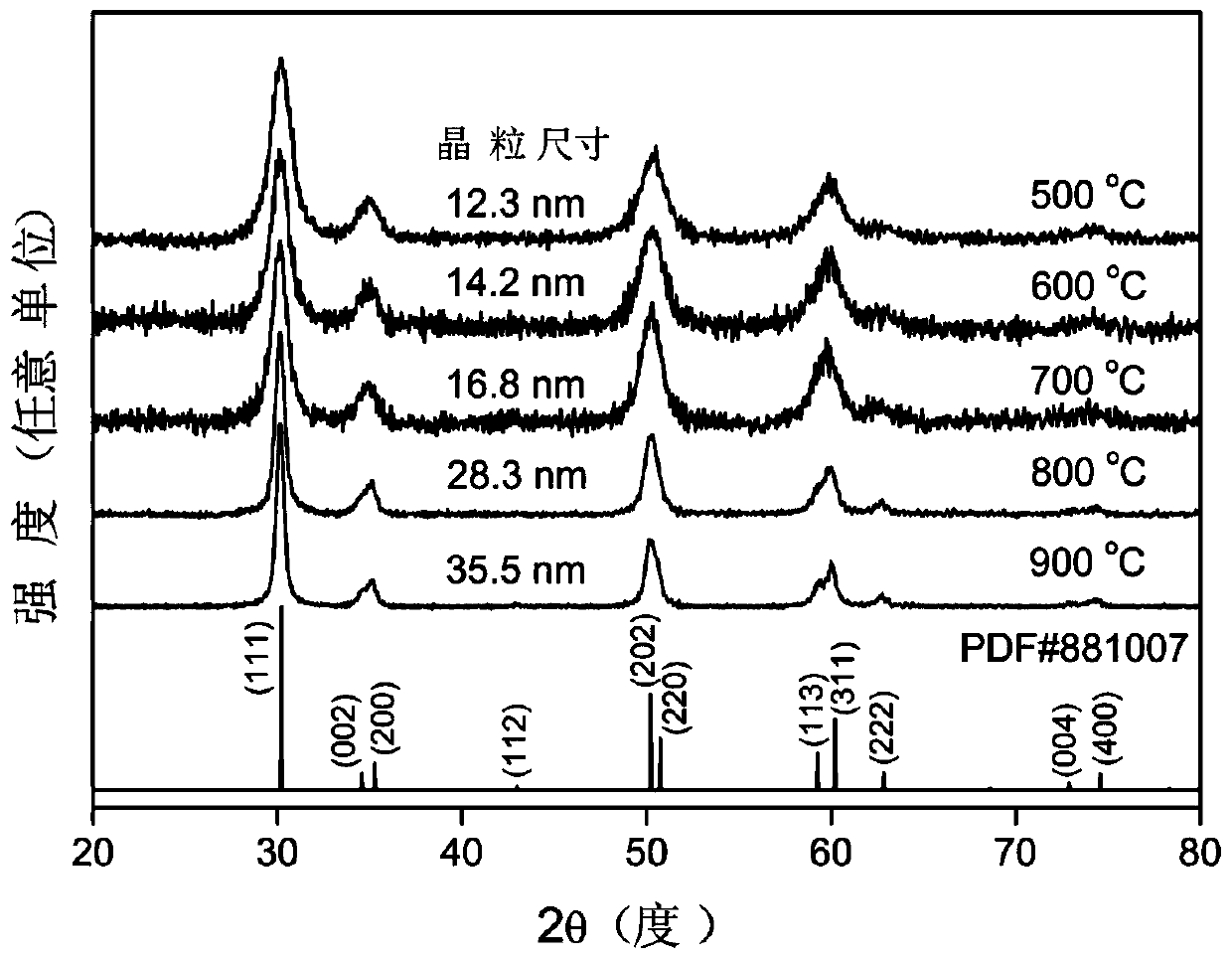

[0042] With a purity of 99.99% Zr(NO 3 ) 4 ·3H 2 O and Y (NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O=0.94:0.06 ingredients, use deionized water as solvent, prepare an aqueous solution with a total concentration of metal ions of 0.2mol / L, stir magnetically for 1-3h until it is clear and transparent, then add additives such as citric acid hexahydrate and molecular weight of 20000 Polyethylene glycol, wherein the amount of citric acid added 160g / L, polyethylene glycol 20g / L, and then magnetically stirred until clear and transparent, thereby preparing the sol.

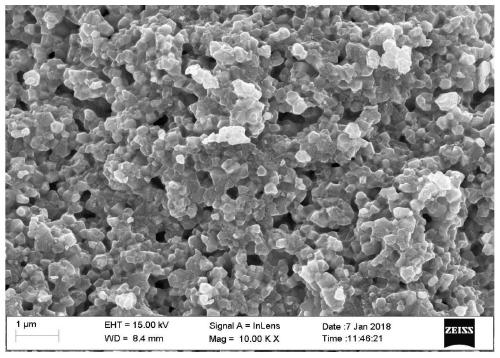

[0043] The above-prepared sol was atomized into a corundum crucible by a pressure atomization method, the atomization pressure was 0.3 MPa, and the temperature of the corundum crucible was 500°C. After the atomization of the sol was completed, the temperature of the corundum crucible was raised to 900° C. for 1 hour, and then cooled to room temperature to obtain 3...

Embodiment 2

[0049] With a purity of 99.99% Zr(NO 3 ) 4 ·3H 2 O and Y (NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O=0.94:0.06 ingredients, use deionized water as solvent, prepare an aqueous solution with a total concentration of metal ions of 0.2mol / L, stir magnetically for 1-3h until it is clear and transparent, then add additives such as citric acid hexahydrate and molecular weight of 20000 Polyethylene glycol, wherein the amount of citric acid added 160g / L, polyethylene glycol 20g / L, and then magnetically stirred until clear and transparent, thereby preparing the sol.

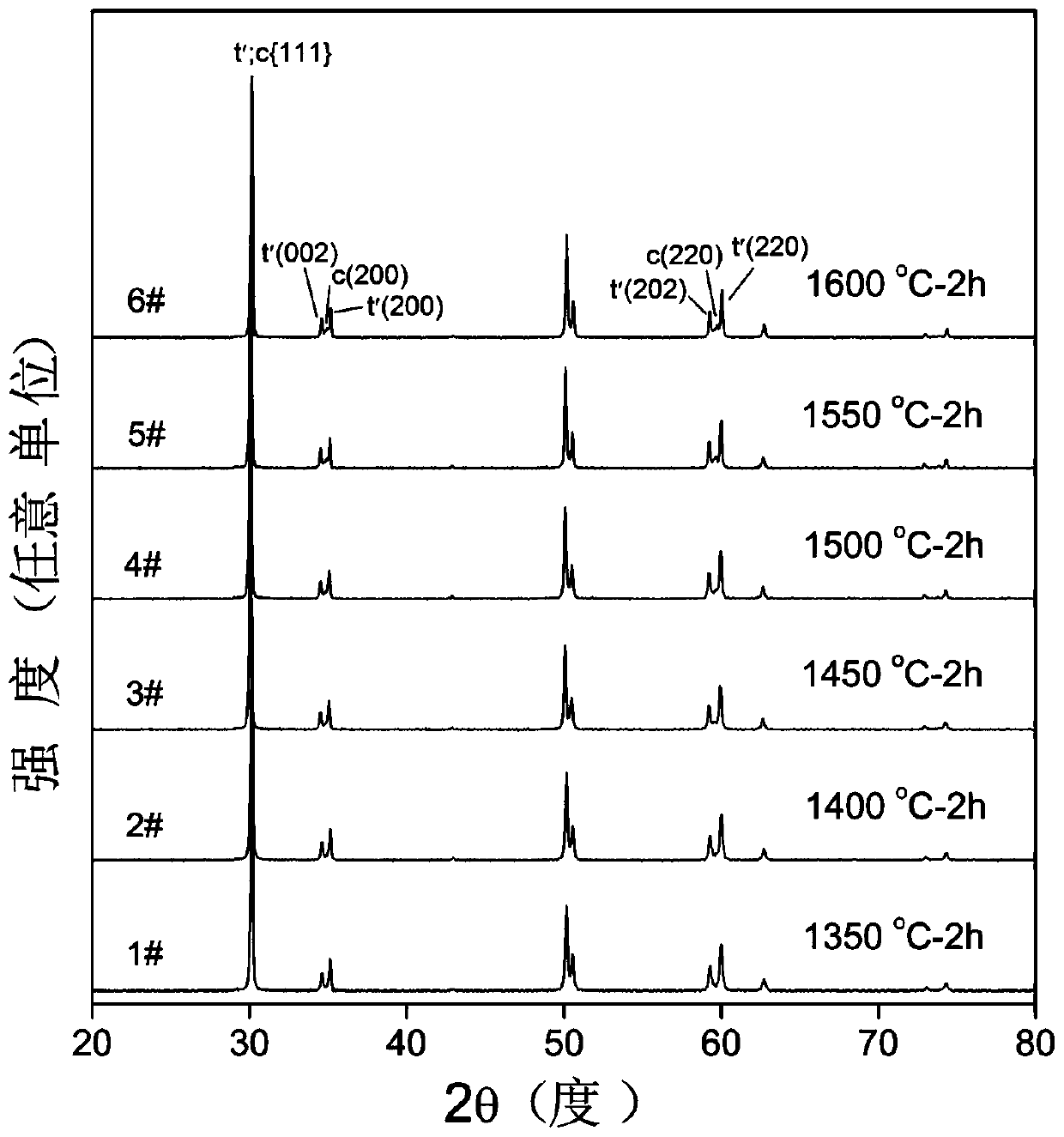

[0050] The above-prepared sol was atomized into a corundum crucible by a pressure atomization method, the atomization pressure was 0.3 MPa, and the temperature of the corundum crucible was 500°C. After the atomization of the sol was completed, the temperature of the corundum crucible was raised to 900° C. for 1 hour, and then cooled to room temperature to obtain 3...

Embodiment 3

[0057] With a purity of 99.99% Zr(NO 3 ) 4 ·3H 2 O and Y (NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O=0.94:0.06 ingredients, use deionized water as solvent, prepare an aqueous solution with a total concentration of metal ions of 0.2mol / L, stir magnetically for 1-3h until it is clear and transparent, then add additives such as citric acid hexahydrate and molecular weight of 20000 Polyethylene glycol, wherein the amount of citric acid added 160g / L, polyethylene glycol 20g / L, and then magnetically stirred until clear and transparent, thereby preparing the sol.

[0058] The above-prepared sol was atomized into a corundum crucible by a pressure atomization method, the atomization pressure was 0.3 MPa, and the temperature of the corundum crucible was 500°C. After the atomization of the sol was completed, the temperature of the corundum crucible was raised to 900° C. for 1 hour, and then cooled to room temperature to obtain 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com